HTTP://WWW.HOMBI.RU

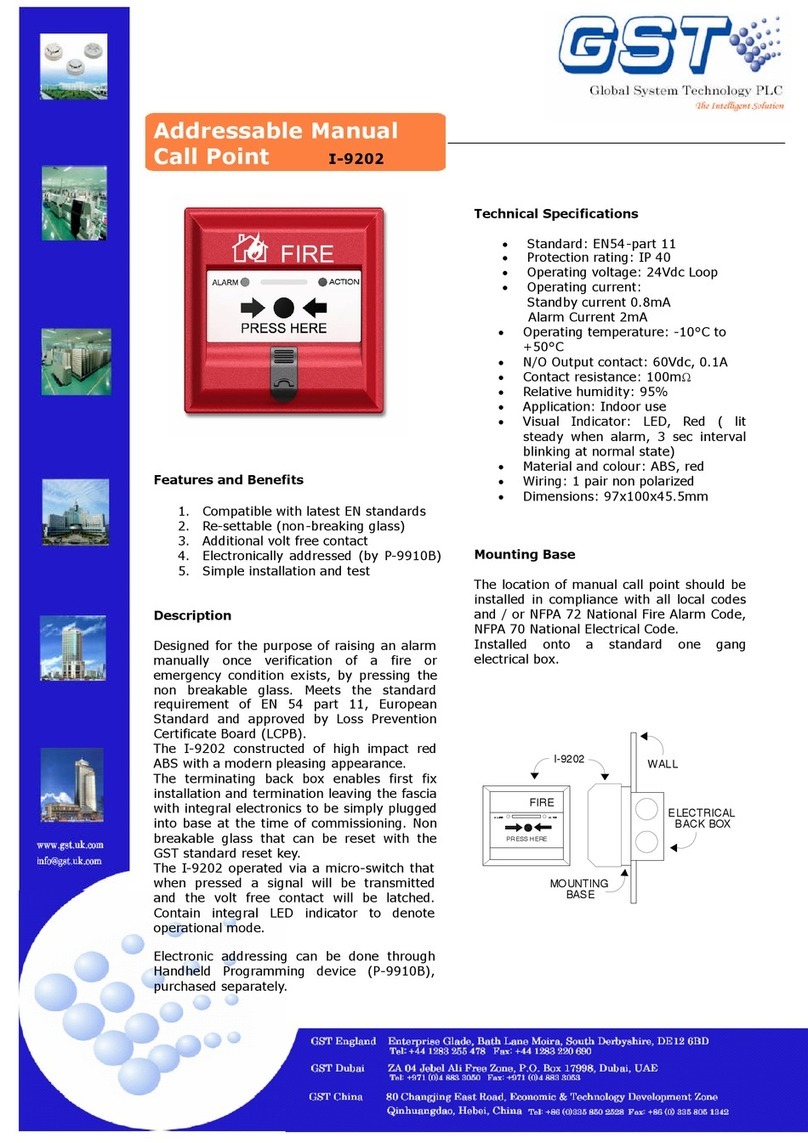

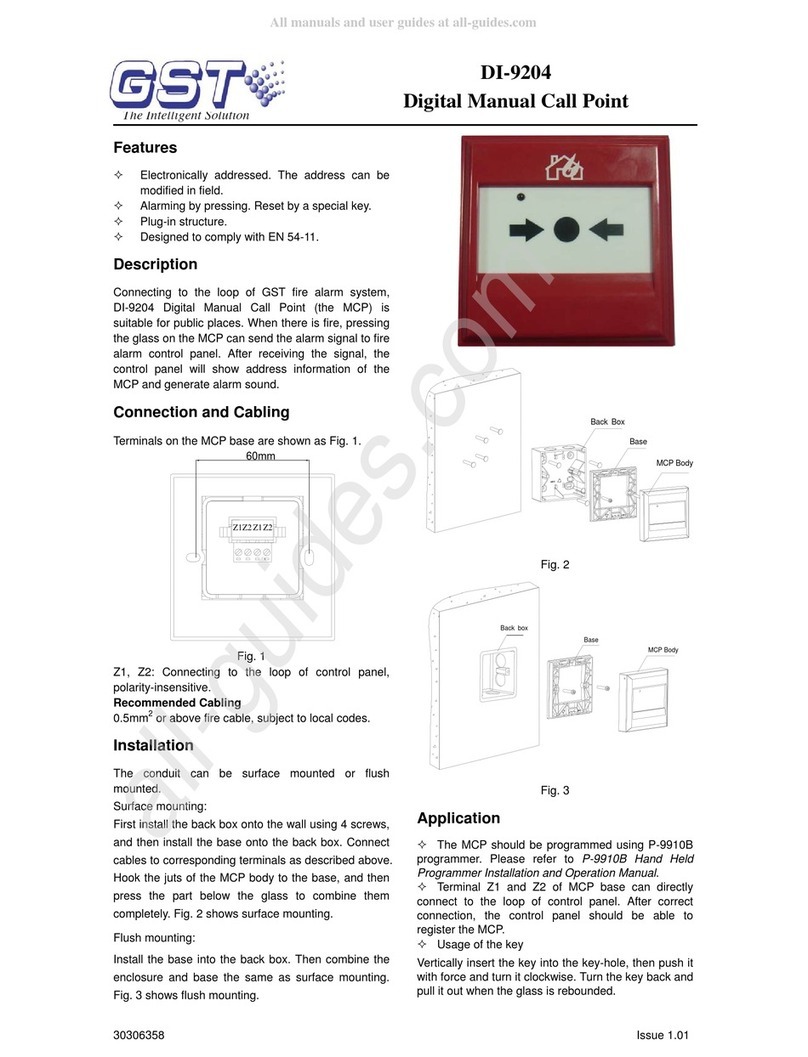

DI-9204Exd Digital Flame-proof Manual Call Point

Installation and Operation Manual The Intelligent Solution

Page 1

1 General

DI-9204Exd Digital Flame-proof Manual Call Point (MCP) is installed in vessels and

industrial explosion-proof areas. When there is fire, pressing the glass on this MCP,

alarm signal can be sent to fire alarm control panel (FACP).

The MCP can work at addressable mode to connect with GST’s series FACP that can

control fire suppression devices and transmit signal through loop. It can also work at

non-addressable mode to connect with 24VDC power and output fire alarm signal

through key switch.

The MCP is applicable to vessels, Zone 1 and 2 of explosive gas atmosphere and Zone

20, 21, and 22 of explosive dust atmosphere. It is also suitable for outdoor application.

2 Features

Using built-in microprocessor for alarm detection and output control. It features

stable operation and good protection against electromagnetic interference.

Electronically addressed. The address can be modified in field.

An independent output contact is provided to control periphery devices.

The MCP is reusable. You can press it to alarm, and reset it by a special key.

With wide temperature range, high ingress protection rating, the MCP can apply

to vessels, outdoors and explosivehazardous environment.

3 Technical Specifications

Operating Voltage:

Addressable Mode: Loop 24V, ranged 16V~28V

Non-addressable Mode: 24VDC, ranged 20VDC~28VDC

Operating Current: Standby Current≤0.8mA

Alarm Current≤2.5mA

Output Capacity: normally open volt-free output, contact capacity is 1A24VDC

Type of Initiating Part: Reusable.

Initiating Mode: Pressing the glass manually.

Resuming Mode: Manually resuming the MCP by a special key.

Fire Indicator: Red. It flashes normally and lights after alarming.

Address Programming Method: Electronic programming ( Address is within

1~242)

Operating Environment: Temperature:-40℃~+70℃

Relative Humidity ≤95%

Dimensions: 211mm×129mm×95mm (without accessories)

Ingress Protection Rating: IP65

Material and Color of the Enclosure: ZL102 aluminum alloy, red

Weight: 2kg

Mounting Hole Distance: 163mm

Explosion-proof marking:Exd BT6/DIPA20 TA,T6Ⅱ; Exd CT6/DIPA20 TA,T6Ⅱ