Table of Contents

GateOperatorClassCategories ......................................................................................InsideCover

MetricConversionChart..........................................................................................................................InsideCover

SafetyInstructionsfortheGP-SL100SlideGateOperators .......................................................1

ImportantSafetyInstructionsfortheSystemDesigner.....................................................................................1

ImportantSafetyInstructionsfortheInstaller ......................................................................................................2

ImportantSafetyInstructionsSpecictoSecondaryMeansofProtectionAgainstEntrapment.......3

ImportantSafetyInstructionsfortheConsumer/EndUser..............................................................................4

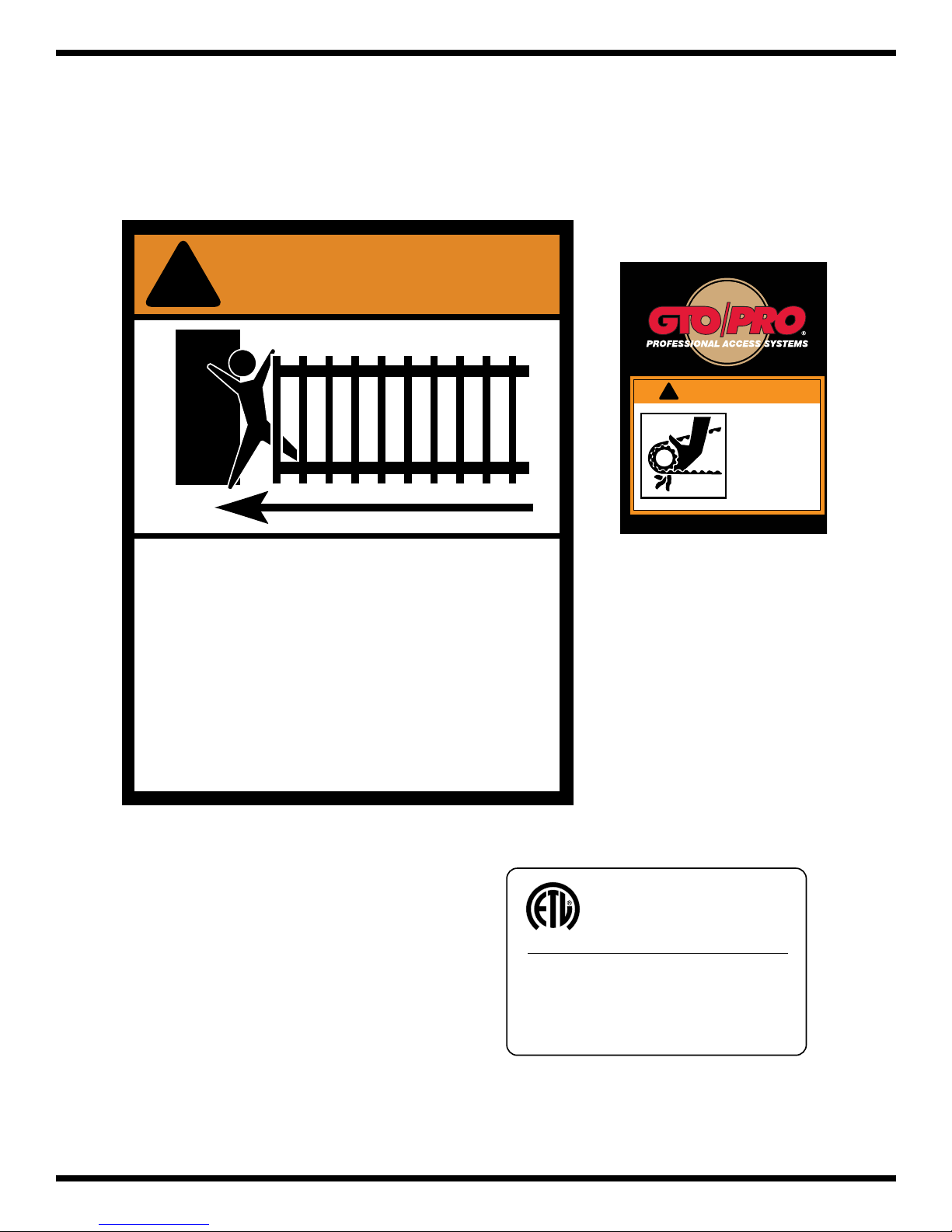

RequiredSafetyPrecautionsforGates.....................................................................................................................5

Warning Labels ................................................................................................................................................................6

Technical Specications ..........................................................................................................................7

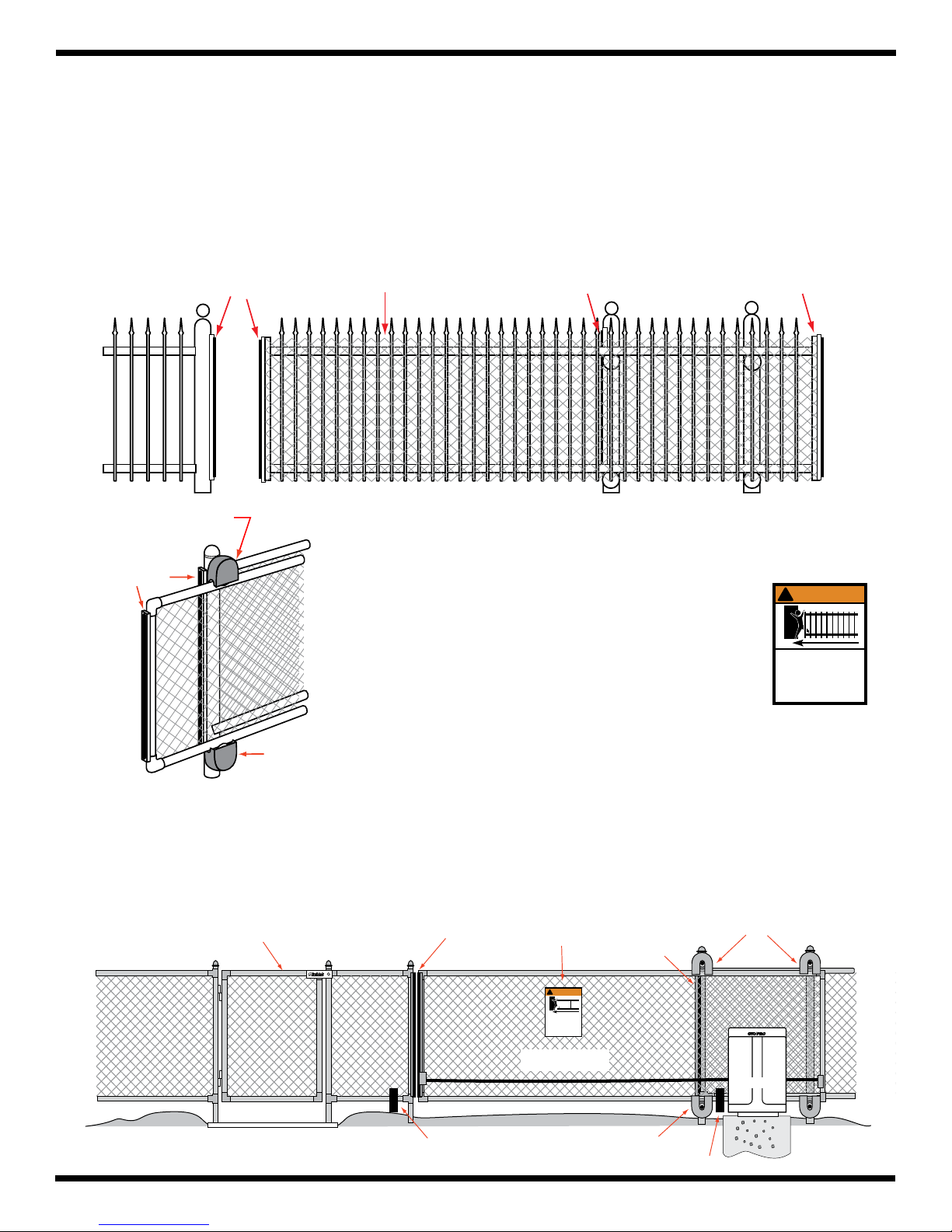

PartsIdentication.....................................................................................................................................8

InstallingtheGateOperator...................................................................................................................9

Preparation of the Gate..................................................................................................................................................9

OperatorInstallationOverview ..................................................................................................................................9

UsingtheMountingTemplate ............................................................................................................................... 10

MountingTemplate(nottoscale)......................................................................................................................... 11

RemovingtheOperatorHousing.......................................................................................................................... 12

MountingtheOperator ............................................................................................................................................ 12

ConnectingPowertotheOperator...................................................................................................................... 12

InstallingtheChain .................................................................................................................................................... 14

ControlBoardDescription ......................................................................................................................................... 15

Setting The Limits ......................................................................................................................................................... 16

Stall Force and Auto-Close Adjustments.............................................................................................................. 17

DIPSwitchSettings ...................................................................................................................................................... 18

InputConnections........................................................................................................................................................ 19

Accessory Terminal Connections............................................................................................................................. 20

OutputConnections .................................................................................................................................................... 21

Accessory Power Supply............................................................................................................................................. 22

PrisonModeOperationandWiringA3-ButtonStation.................................................................................. 23

ReinstallingtheOperatorHousing......................................................................................................................... 24

InstallingaDualSystem.........................................................................................................................25

DualGateLinkConnection........................................................................................................................................ 25

SettingDualGateSequence ................................................................................................................26

OverviewofaDualGateOperatorInstallation .............................................................................27

Maintenance ..............................................................................................................................................28

Troubleshooting Guide..........................................................................................................................29

WarrantyandRepairService...............................................................................................................32

InstallationChecklist............................................................................................................. Back Cover