7

IMPORTANT SAFETY INSTRUCTIONS

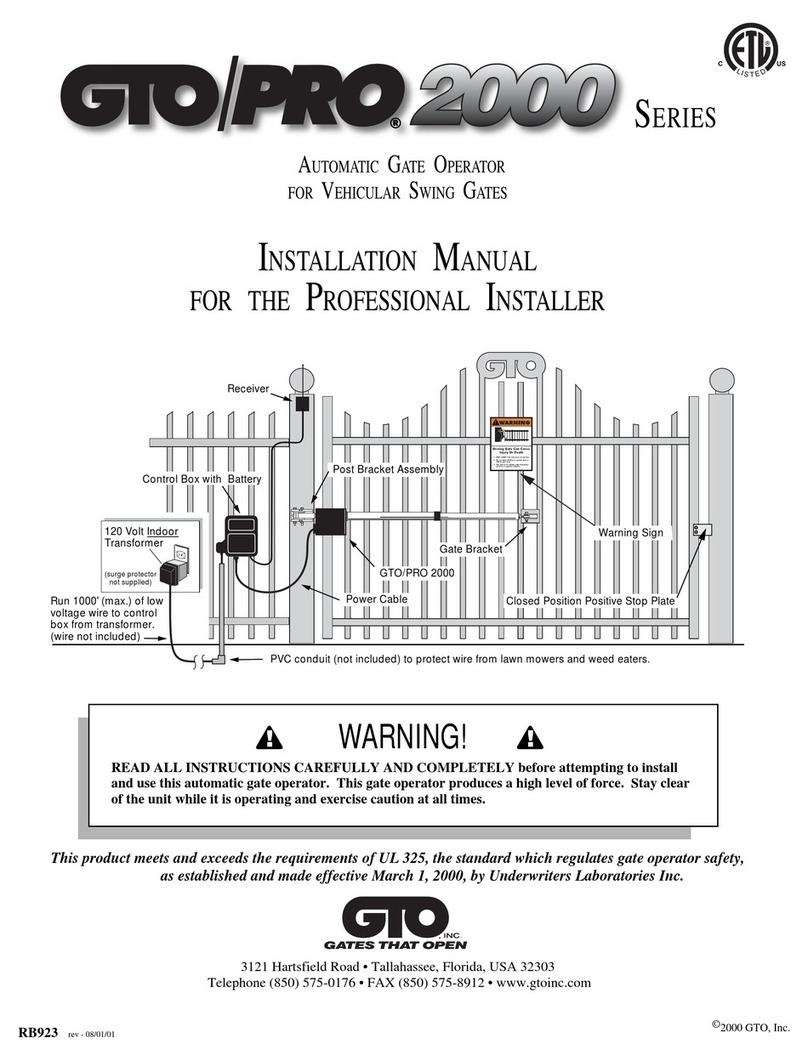

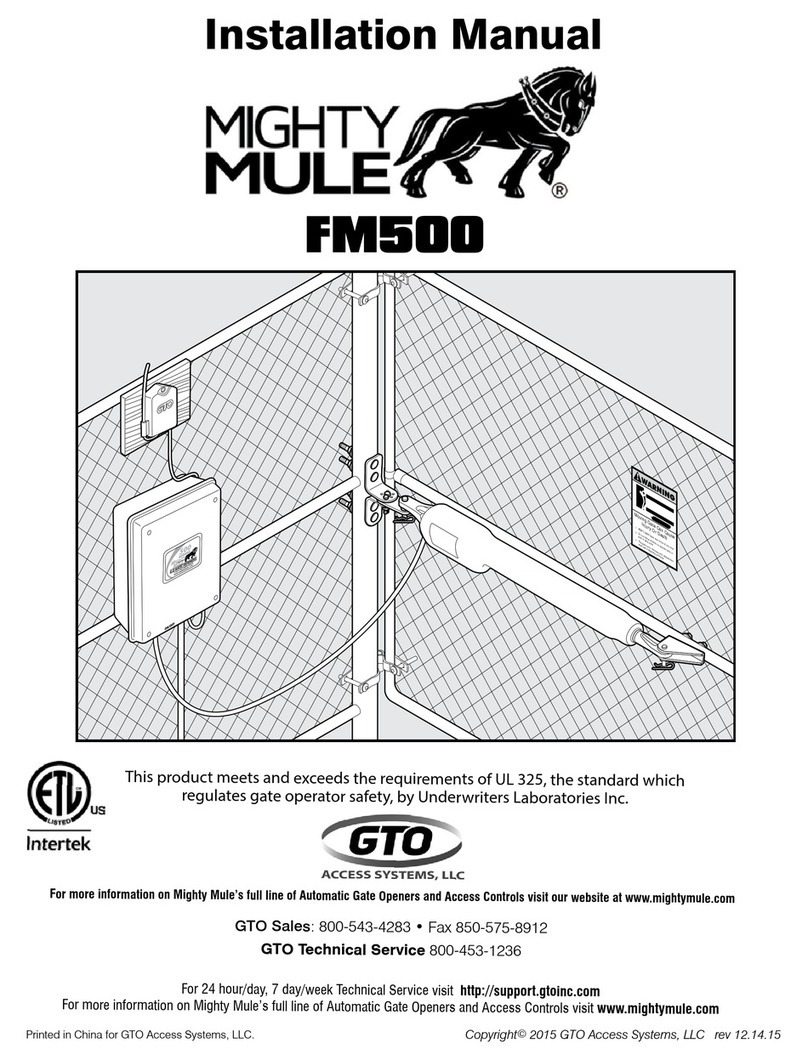

These warning labels should be found at the locations specified below. If any of them are missing, immediately

contact your installer for replacements.

WARNING

!

• Fingers, hands, and

loose clothing may be

dragged into chain

sprockets.

• Fingers and hands can

be injured by rotating

sprockets.

• Keep hands, fingers,

and loose clothing

away from chain and

chain opening in

operator housing.

•Fingers, hands, and loose clothing

may be dragged into chain sprockets.

•Fingers and hands can be injured by

rotating sprockets.

•

Keep hands, fingers, and loose clothing

away from chain and sprockets.

WARNING

!

warning labels (3) located on sides and back

of operator housing

warning label located on top

of control box

•Moving parts inside are capable of

causing injury to fingers and hands.

•DO NOT remove operator housing.

•Consult your safety manual before

making adjustments.

•

For service, call an experienced technician.

AUTOMATIC GATE OPENERS 1-800-543-GATE

WARNING

!

warning label located on front of operator housing

product identification and manual operation instruction

label installed on control box cover

RB2002

Maximum Gate: 1000 lb. (453.4 kg); 30 ft. (9.1 m)

Voltage: 12 Vdc; Frequency: 0 Hz; Power: 93.2 W

Class I, II and III Vehicular Slide Gate Operator

Serial Number: SL2000-xxxxxxx

''%&

Conforms to UL 325 STANDARDS

Certified to CAN/CSA-C22.2 No.247-92

Disconnect operator ONLY when the gate is NOT moving.

TO MANUALLY OPEN AND CLOSE THE GATE:

1. Lift quick release pins UP, then pull them OUT of chain brackets.

2. Lay chain down and manually slide gate to desired position.

Series

GTO, Inc. Tallahassee, Florida USA

L

I

S

T

E

D

75+

RB2001

Maximum Gate: 500 lb. (226.7 kg); 30 ft. (9.1 m)

Voltage: 12 Vdc; Frequency: 0 Hz; Power: 93.2 W

Class I, II and III Vehicular Slide Gate Operator

Serial Number: SL1000-xxxxxxx

''%&

Disconnect operator ONLY when the gate is NOT moving.

TO MANUALLY OPEN AND CLOSE THE GATE:

1. Lift quick release pins UP, then pull them OUT of chain brackets.

2. Lay chain down and manually slide gate to desired position.

Series

GTO, Inc. Tallahassee, Florida USA

SL

L

I

S

T

E

D

75+

Conforms to UL 325 STANDARDS

Certified to CAN/CSA-C22.2 No.247-92