Table of Contents

Class Rating ......................................................................................................................inside cover

Please Read This First..........................................................................................................................ii

Important Safety Instructions........................................................................................................ iii

Technical Specications.................................................................................................................... 1

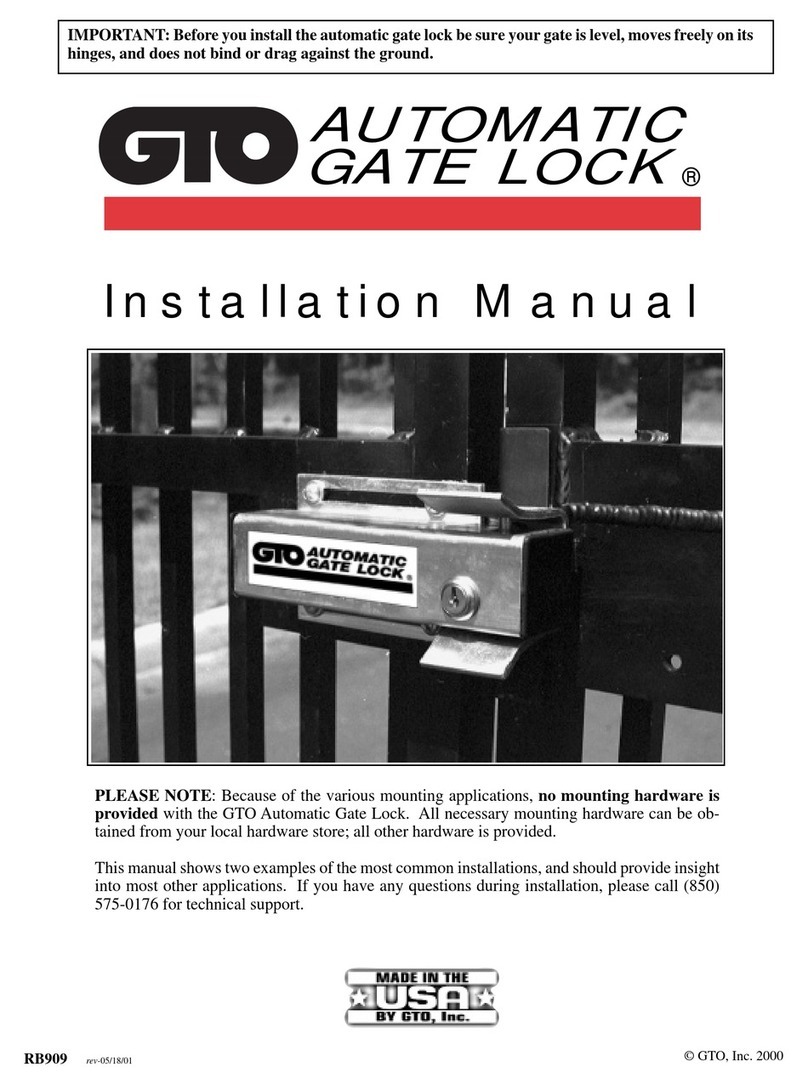

Before You Begin... .............................................................................................................................. 2

Determine Charging Option for Battery: Transformer OR Solar ................................. 2

Solar Panel and Gate Activity Chart ....................................................................................... 2

Check Direction of Gate Swing ................................................................................................ 3

Prepare the Gate ........................................................................................................................... 3

2000XL Parts List ........................................................................................................................... 4

Tools Needed.................................................................................................................................. 5

Materials You may Need for the Installation: ..................................................................... 5

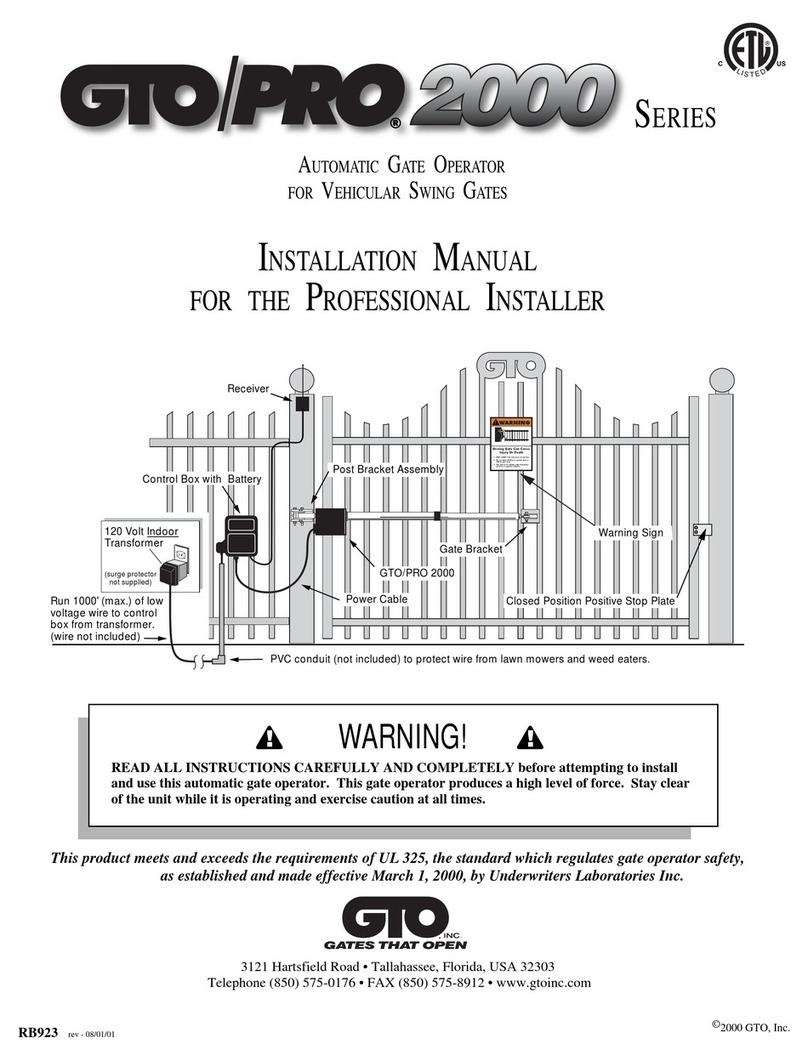

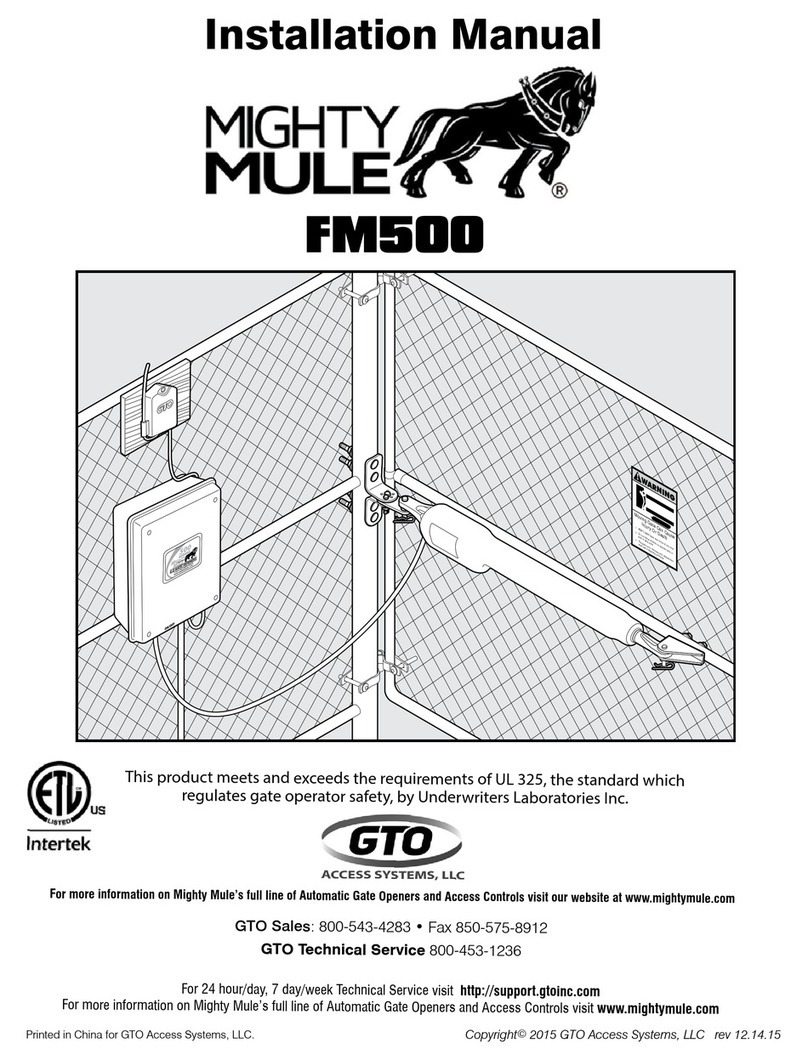

Installation Overview .................................................................................................................. 6

Install the Operator ............................................................................................................................ 8

Install the Post Bracket Assembly ........................................................................................... 8

Check Clearance............................................................................................................................ 9

Install Gate Bracket.....................................................................................................................10

Attach Operator Arm ................................................................................................................10

Installation of the Closed Position Stop Plate ..................................................................11

Mount the Control Box and Receiver...................................................................................12

Connect Operator Power Cable.............................................................................................13

Connect the Transformer .........................................................................................................14

Connect Battery...........................................................................................................................15

Program Control Board ...................................................................................................................16

Set the Closed Position Limit (for Pull-To-Open Applications) ...................................16

Adjust the Stall Force Setting .................................................................................................17

Set Auto Close Time ...................................................................................................................18

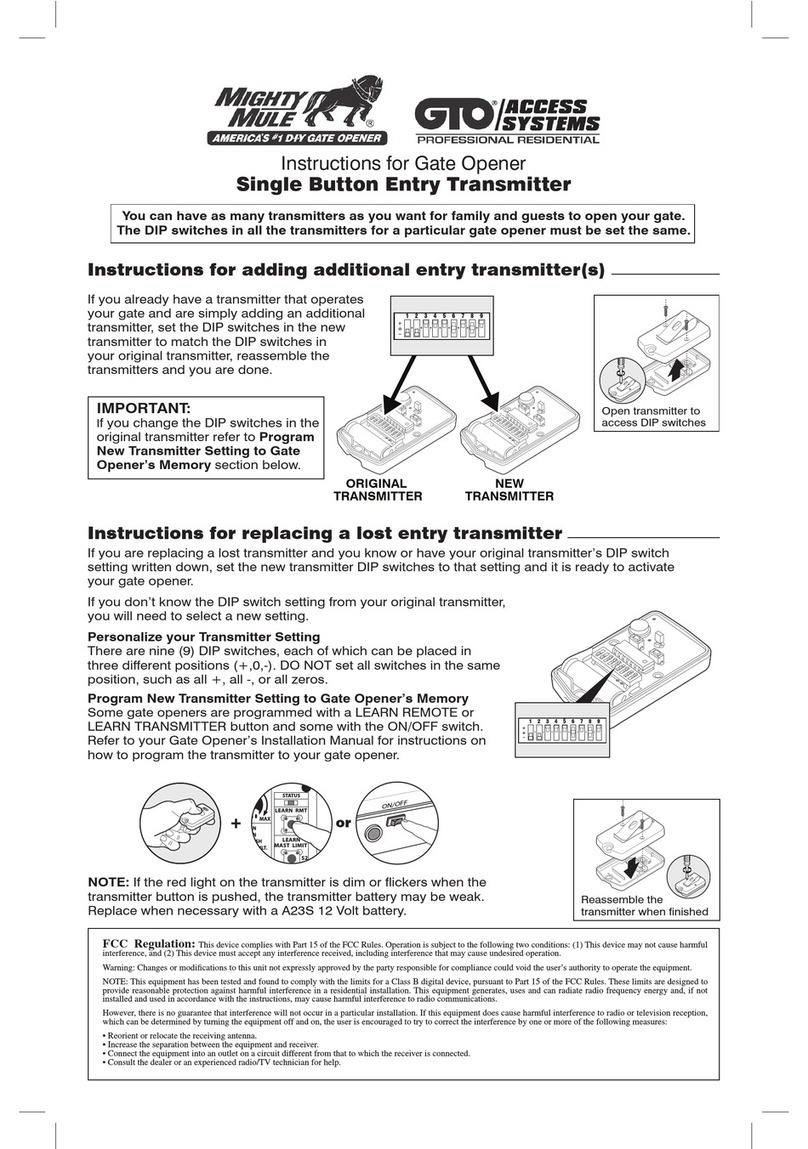

Program Your Personal Transmitter Setting ......................................................................18

Control Board Settings..............................................................................................................19

Connnecting Accessories...............................................................................................................20

Wiring Accessories......................................................................................................................21

Connecting Other Auxiliary Devices (Sirens, Lights, etc.).............................................21

Push-To-Open Installation Information.....................................................................................22

Setting the Open Position Limit (Push-To-Open Installations)...................................23

Column Installation..........................................................................................................................24

Troubleshooting Guide...................................................................................................................25

Voltage Ratings............................................................................................................................26

Repair Service...............................................................................................................................27

Accessories ..........................................................................................................................................28