Installation

Preparing the mounting

location

Before

beginning

this

installation

-

•

Open

engine hatches

and operate

bilge

blowers

for

10

minutes

to

remove

dangerous

fumes

and

hydrogen

gas.

•

Disconnect

all

AC

power

sources.

•

Disconnect

negative

battery

cables from

all

batteries.

•

Wear

safety

goggles,

gloves and

long

sleeved

shirt

when

drilling

or

while

handling

batteries.

Choosing a

mounting

location

1.

Mount this

charger

in

an

upright

position

only,

with

the

aluminum

cooling

fins

running

vertically.

It

is

important

that

the

charger

have

at

least

6

inches

of

unrestricted

airflow

on all sides

for

effective

cooling.

Do

not install

onto

a

carpeted,

upholstered,

or

varnished

surface.

2.

Although

this

charger

is

ruggedly designed,

avoid

mounting

it

in

an

area

that

is

open

to

rain,

snow

or

spray.

3.

Avoid mounting

this charger

within

3

feet

of

a

compass,

TV

or

FM

radio.

4.

Select

a

mounting

location

which

will

allow

the

shortest

DC

wires

between

the

charger

and

the

batteries.

5. Do

not

mount

this unit

directly

over your

batteries

because

their

corrosive

fumes

can

damage

the

circuitry

inside

this

charger.

6.

Be

sure

that

the

mounting

location

will

allow

access

to

the

connections

on

the

charger

after

it

is

mounted.

-5-

Hold

the battery

charger

against the surface wh~re you

are

planning

to

mount

it.

(Be

sure

that

you

will

bc

able

to

drill

holes

through

this

surface

later

without damage

to

wiring,

tanks

or

other

equipment.) Using

a

penc:

1,

mark

the

locations

of

the

battery

charger’s

four

mounting

holes

onto the mounting surface

Drill four

1/4”

holes

through

the mounting

surface

at

the

locations

you

marked

with

pencil.

Note:

Donot

mount

the

charger

until

~~you

made the

following

electricalconnections

have

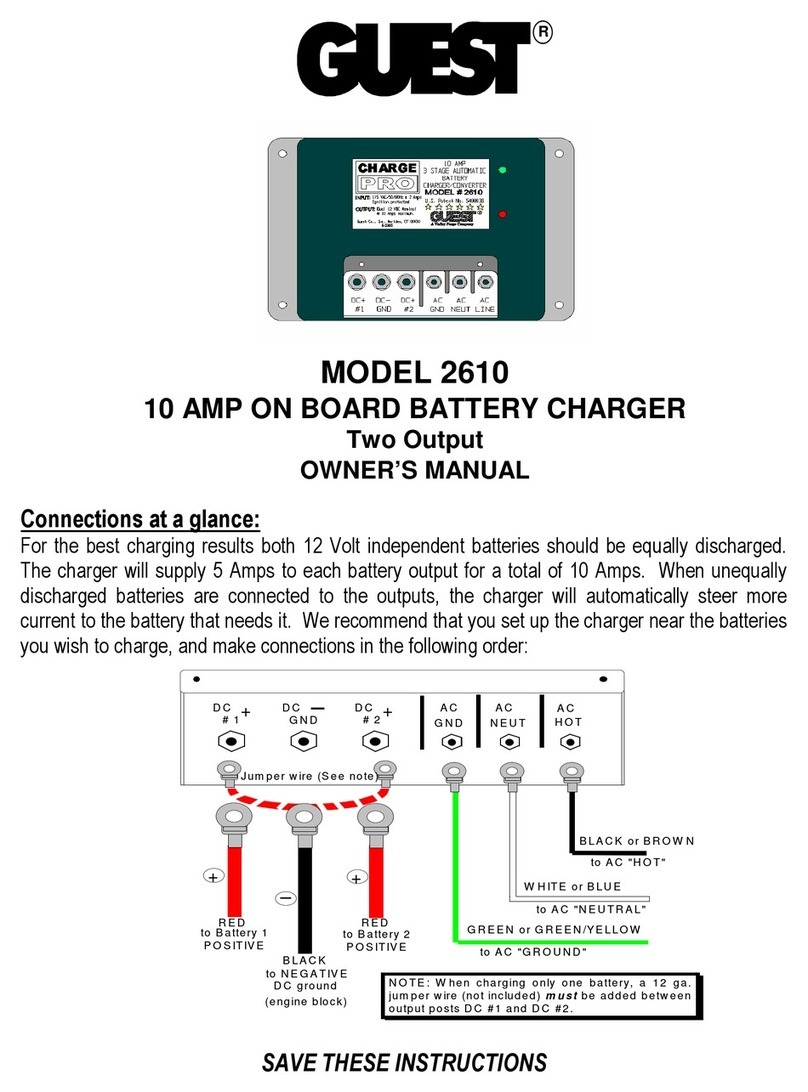

Electrical

connections

Installing

the Guest

2815M1115

or

2815M/230

making two

different

types

of

electrical connections:

(12 volt battery system)

and

the

AC

(dockside power)

Planning

the

DC connections

You

can configure the Guest

281

SM

charger

to

main:ain

one

or two separate

12

volt

batteries. There are

several

ways to

connect

this

charger

into your

present

12

volt

system.

The

simplest

and

most

widely

used connection metho

i

is:

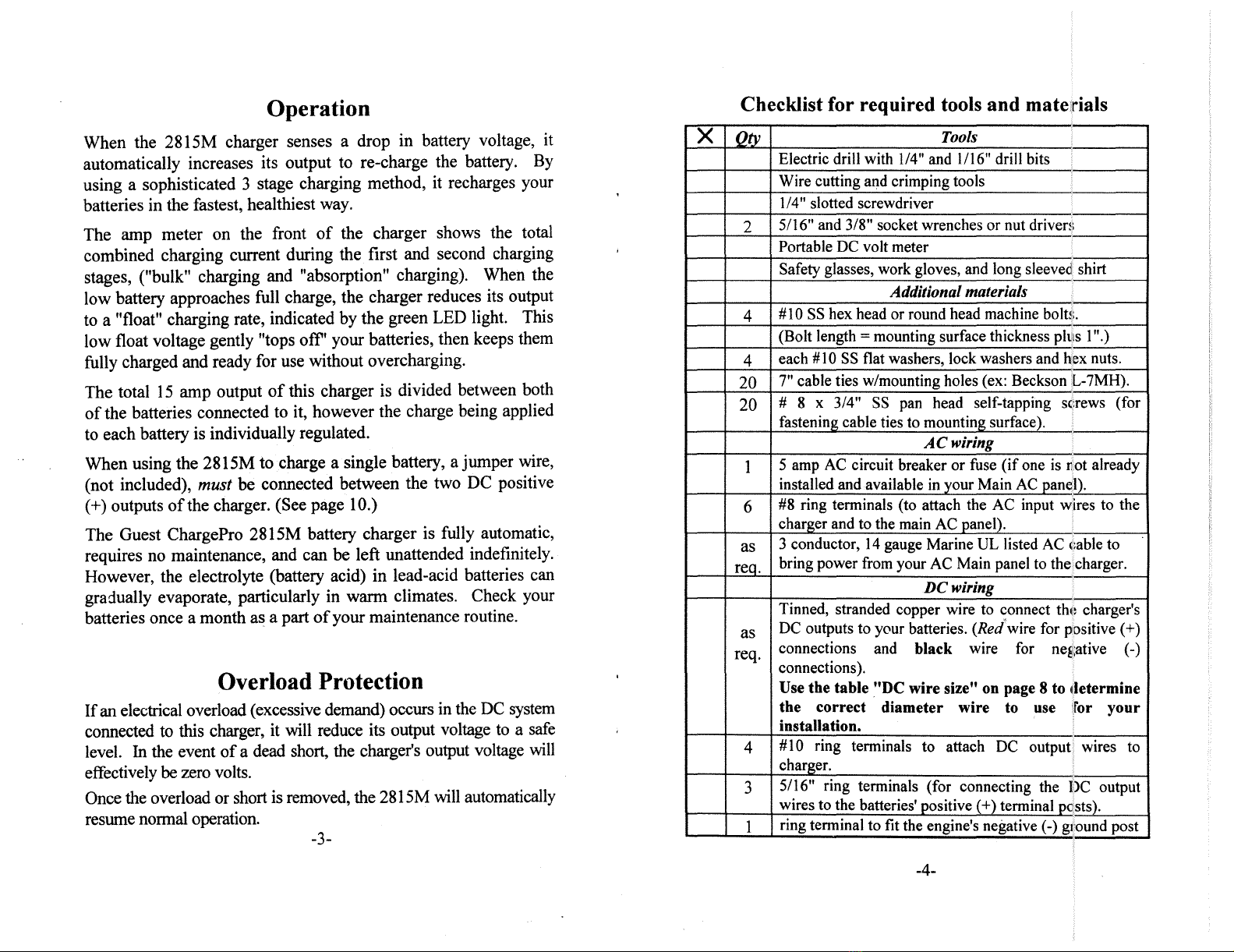

1.

Run one red DC

wire

from each

of

the

charger’s

:wo

DC

positive

(+)

outputs

to

the

positive posts

of

each

battery.

When

charging

a

single

battery,

you

must

conncct

both

charging

outputs

to

the

battery.

2.

Connect

a

black

DC

wire

from

the

charger’s

ommon

negative

(-)

terminal

to

the

engine

block’s

ommon

negative ground terminal.

This

method

is

illustrated

in

diagram

2 on

page

7.

-6-

1.

2.

~equires

the

DC