6

Customer Helpline +44 333 320 1989

NOTE: Before using the tool, read the instruction book carefully,please always

wear overheating protection gloves.

Before using the tool

Before starting the job it is advisable to test the workpiece for the ideal temperature to

use. The description below gives an indication of the likely heat settings required but

always start with the low heat setting.

The distance between the nozzle and the workpiece will vary according to the material

being worked on but this should always be at least 50mm (2inch) or more on either heat

setting.

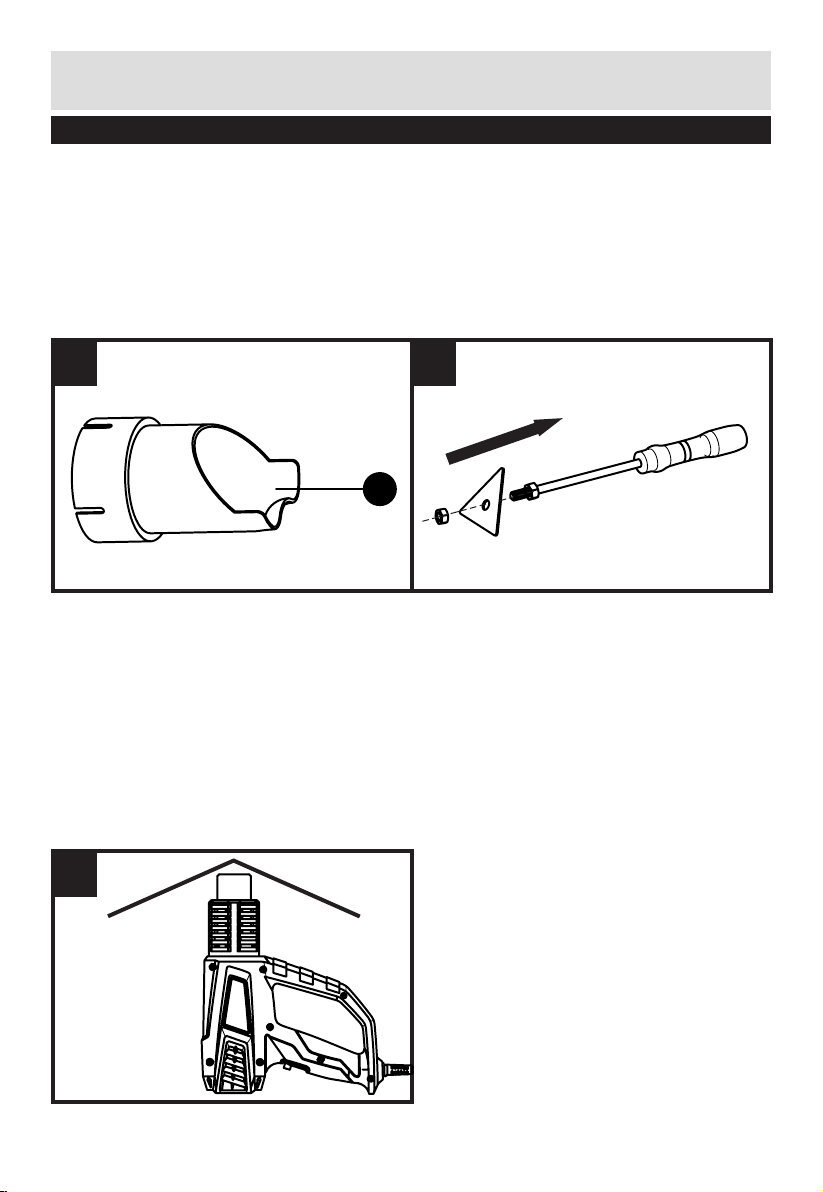

All applications, with the exception of removing paint from the window frames, can be

performed without using a nozzle; however for best results nozzles are recommended.

PUTTING INTO OPERATION

1.SWITCHING ON/OFF

Switching on:

To put into operation, slide the switch (5) to position 1, 2 or 3.

Switching off:

To switch off, slide the on/off switch (5) to the stop at position 0.

After working for a longer time with high temperature, allow the unit to cool by running

in the cold air setting 1 before switching off.

2. THERMO-PROTECTION SWITCH-OFF

When the heater is overloaded (e.g. as a result of restricted air flow), the unit switches

it off automatically, however, the blower continues to run. When the unit has cooled to

operating temperature, the heater is switched on again.

3.SETTING THE AIR FLOW AND TEMPERATURE

The switch (5) can be set to three blower steps. Suitable air flow and temperature

combinations can be selected according to the applications.

1 = 50°C , 500L/min

2 = 400 °C , 250L/min

3= 600°C , 500L/min

The cold air setting 1 is suitable for cooling a warmed work piece or for the drying of

paint. It is also suitable for cooling the unit before placing down or the changing of

nozzles.

The air setting 2 is suitable for Bending Plastic and heating shrinking plastic.

The air setting 3 is suitable for stripping paint and defrosting pipes.

Operating Instructions