i

Contents

1 Preparing for installation·············································································1

Safety sign conventions·····································································································································1

Safety recommendations ···································································································································1

Safety symbols···········································································································································1

General safety recommendations··············································································································2

Electricity safety·········································································································································2

Laser safety················································································································································3

Examining the installation site····························································································································3

Temperature and humidity·························································································································3

Cleanliness·················································································································································4

Cooling·······················································································································································4

Rack···························································································································································5

Altitude·······················································································································································6

ESD prevention··········································································································································6

EMI·····························································································································································6

Lightning protection····································································································································6

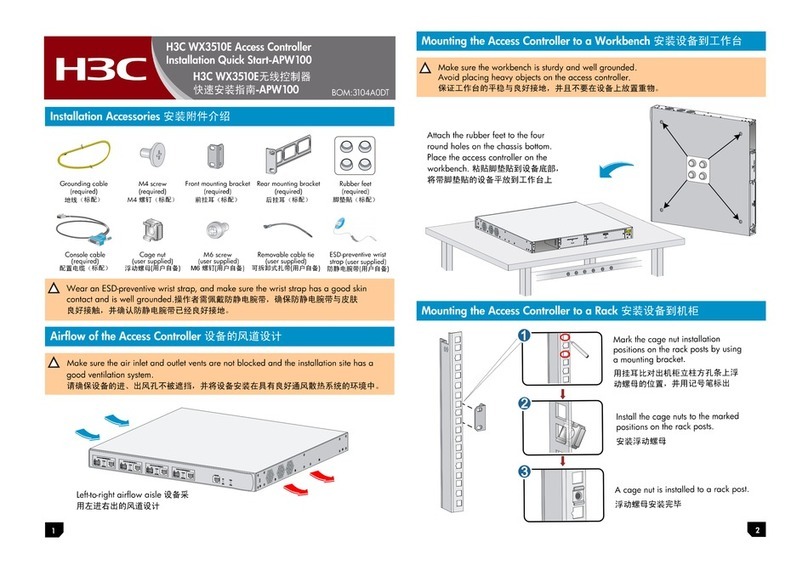

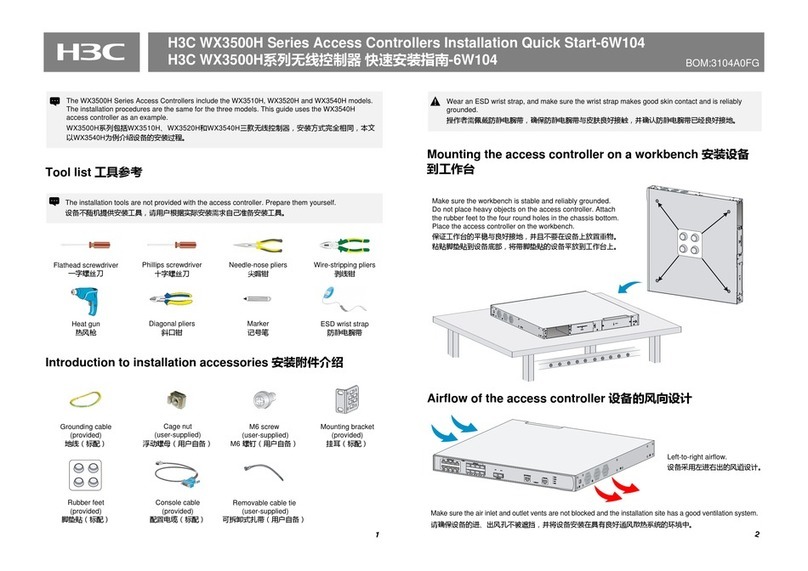

Installation accessories······························································································································7

Installation tools ·········································································································································7

Pre-installation checklist·····································································································································7

2 Installing and removing the device······························································1

Prerequisites······················································································································································1

Installation and removal flowchart······················································································································1

Installing the device············································································································································1

About the SL-2U-FR-S short rail kit············································································································1

Attaching inner rails to the device··············································································································3

Attaching outer rails to the rack··················································································································4

Installing the device in the rack··················································································································6

Installing a power supply····································································································································8

Connecting external cables································································································································8

Cabling guidelines······································································································································8

Connecting a mouse, keyboard, and monitor ····························································································9

Connecting an Ethernet cable····················································································································9

Connecting a fiber port·····························································································································10

Connecting a USB device························································································································11

Connecting the power cord······················································································································12

Removing the device from a rack ····················································································································12

Removing a power supply································································································································13

3 Powering on and powering off the device ···················································1

Important information·········································································································································1

Powering on the device······································································································································1

Powering off the device······································································································································1

Guidelines··················································································································································1

Procedure···················································································································································2

4 Logging in to the device··············································································1

Restrictions and guidelines································································································································1

Flowchart for logging in to the device ················································································································1

Logging in to the device from HDM····················································································································2

Logging in to HDM from the Web interface································································································2

Logging in to the remote console···············································································································3

Logging in to the WBC Monitoring Platform·······························································································9

Logging in to the device from the WBC Monitoring Platform ···········································································13

Logging in to the device from a local PC ·········································································································15

Logging in to the Oasis platform from the local PC··················································································15

Logging in to the AC·································································································································15