4

Powering on the access controller······························································································· 31

Check before power-on ········································································································ 31

Power-on the access controller······························································································· 31

Software maintenance··············································································································· 33

5Support and other resources ······························································································34

Related documentation ············································································································· 34

Contacting H3C························································································································· 34

Obtaining documentation ····································································································· 34

Technical support ·················································································································· 35

Documentation feedback ····································································································· 35

Document conventions and symbols ··························································································· 35

Conventions·························································································································· 35

Symbols ································································································································ 36

AInstallation of lightning arrester for network interfaces ···························································37

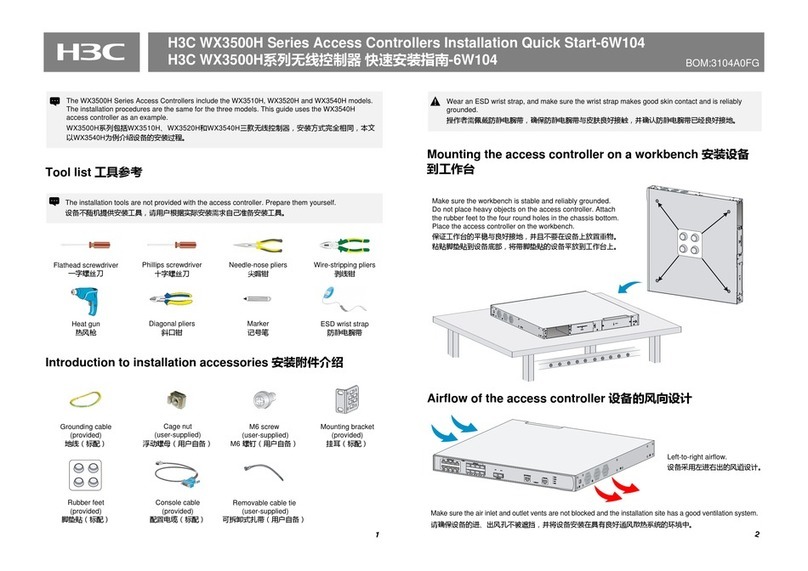

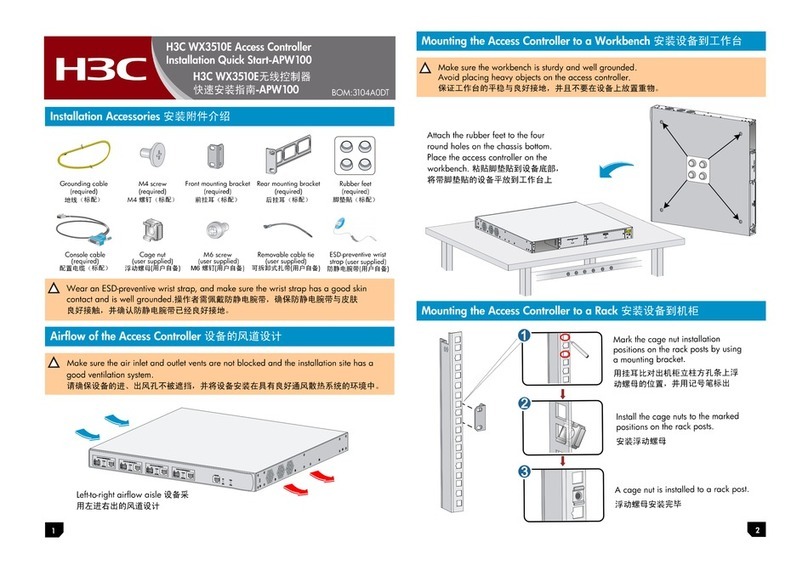

Tools·········································································································································· 37

Installation procedure················································································································· 37

Precautions································································································································ 38

BInstallation of lightning arrester for AC power ·······································································40

CTechnical specifications·····································································································42

Processor and storage ················································································································ 42

Dimensions and weight··············································································································· 42

Fixed interfaces and slots ············································································································ 42

Power input ······························································································································· 43

Components······························································································································ 43

LEDs······································································································································ 43

Fixed interfaces·························································································································· 45

Console port ························································································································· 45

Ethernet interfaces················································································································· 45

Fans······································································································································ 49

Interface numbering··················································································································· 50