H3C S7500 Series User manual

Other H3C Network Hardware manuals

H3C

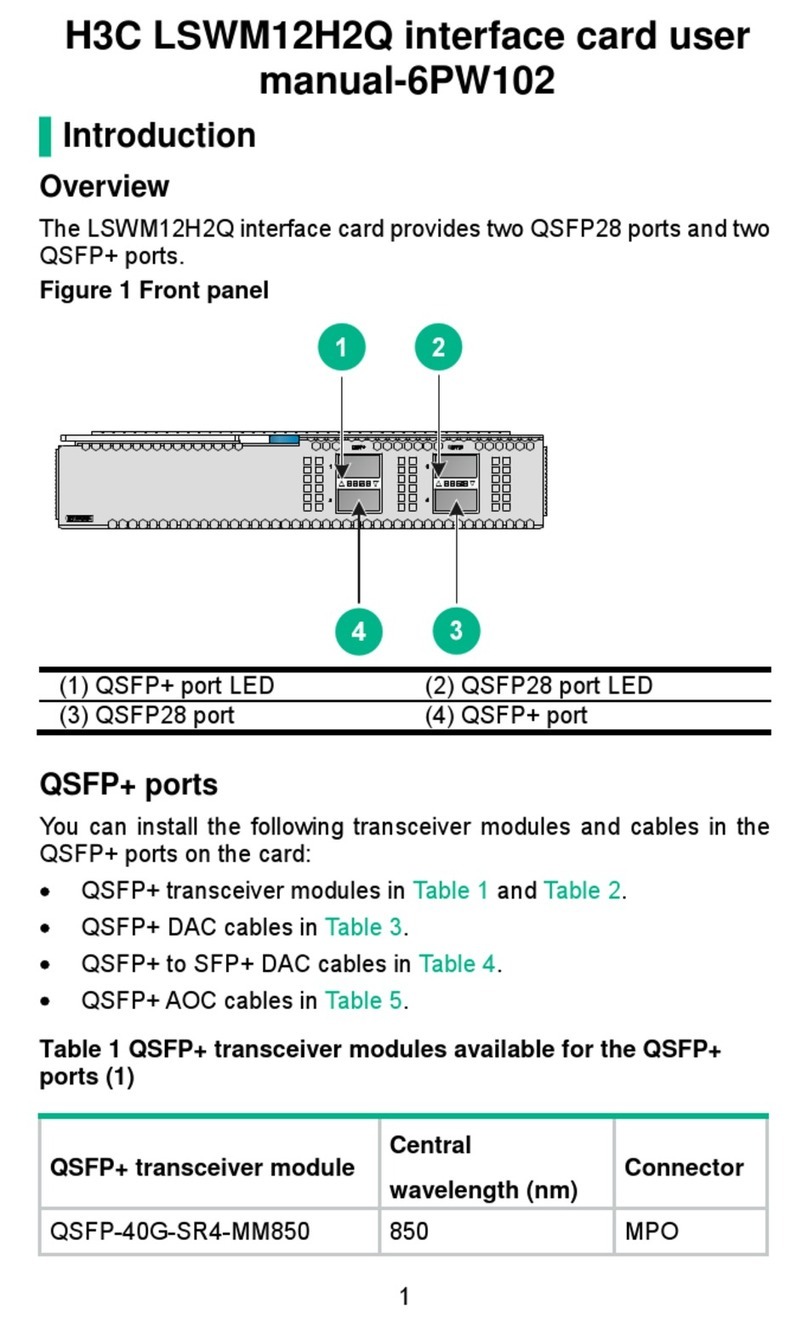

H3C LSWM12H2Q User manual

H3C

H3C SecPath L5030 User manual

H3C

H3C SecPath F5000-AI-20 User manual

H3C

H3C SecPathT5030 User manual

H3C

H3C ETH682i User manual

H3C

H3C NSQ1GT48EA0 User manual

H3C

H3C XE 200 User manual

H3C

H3C H3C S7500E-X Quick guide

H3C

H3C MSR Series Installation manual

H3C

H3C 1000BASE-X-SFP User manual

H3C

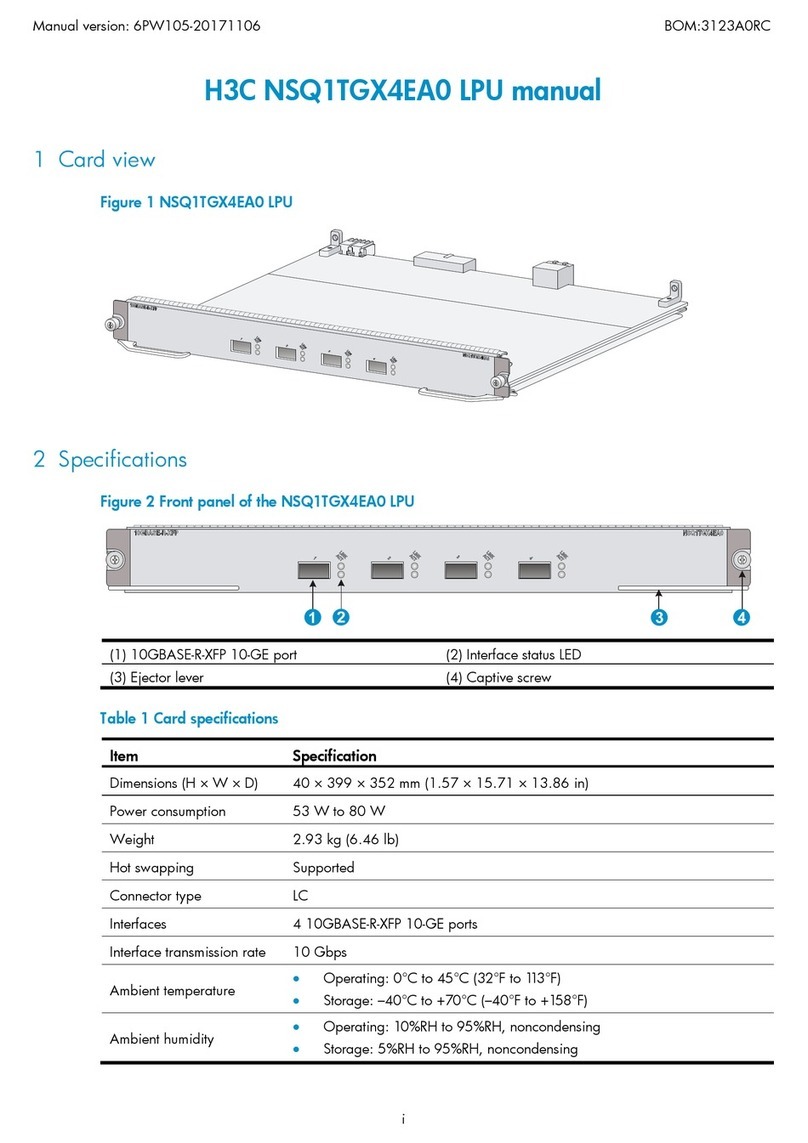

H3C NSQ1TGX4EA0 LPU User manual

H3C

H3C LSWM2ZSP2P User manual

H3C

H3C SecPath U200 Series User manual

H3C

H3C SecPath M9000 NSQ1SUPB0 MPU User manual

H3C

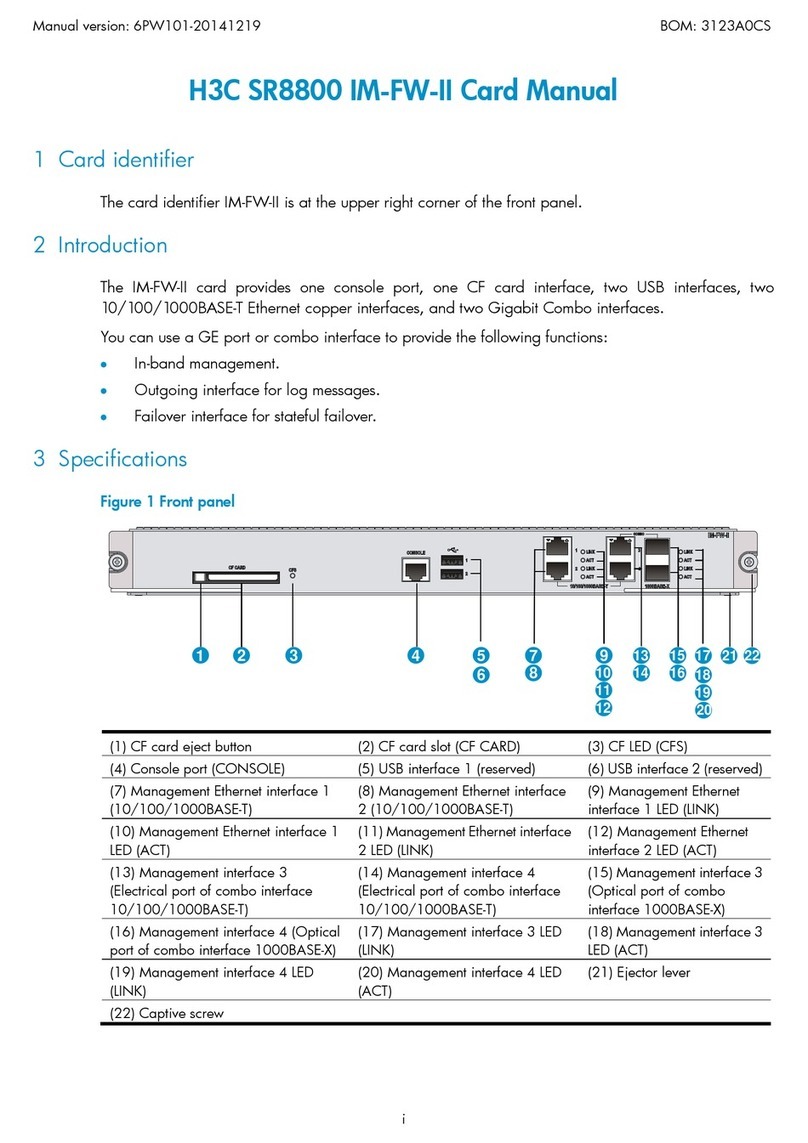

H3C SR8800 IM-FW-II User manual

H3C

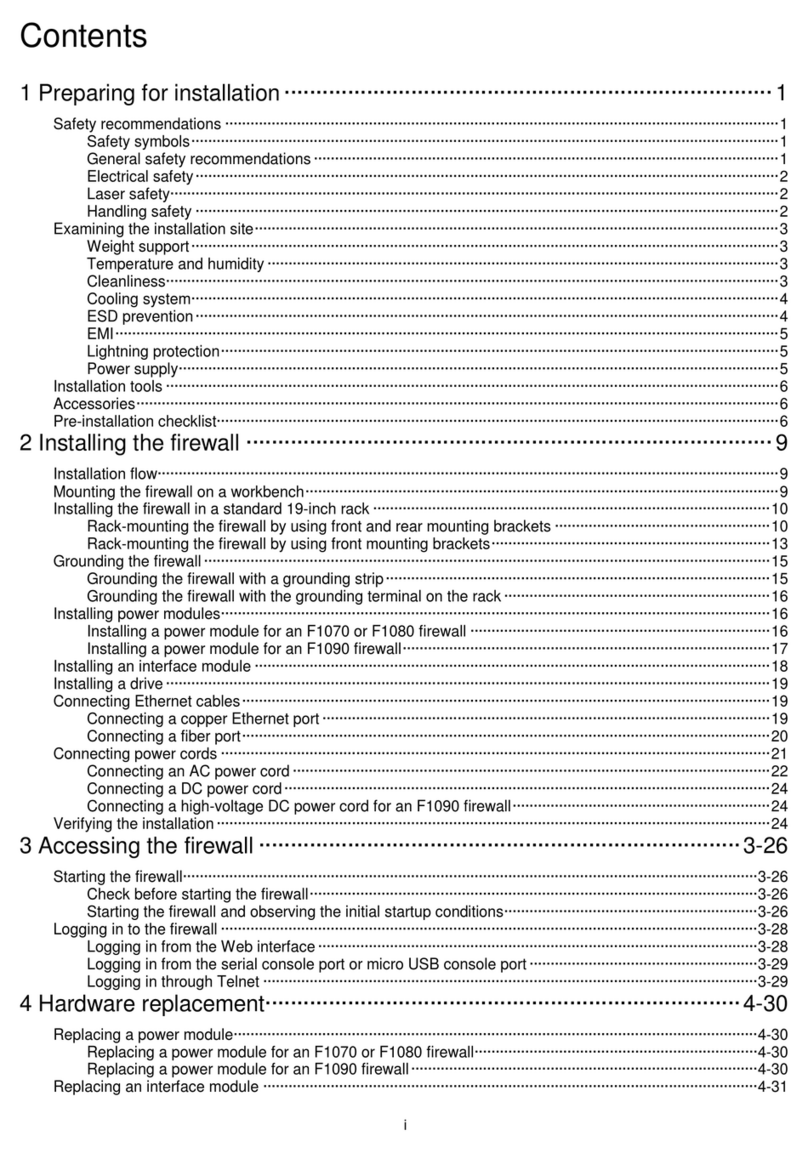

H3C SecPath F1070 User manual

H3C

H3C S5120V3-EI Series User manual

H3C

H3C SecPath L1000-A User manual

H3C

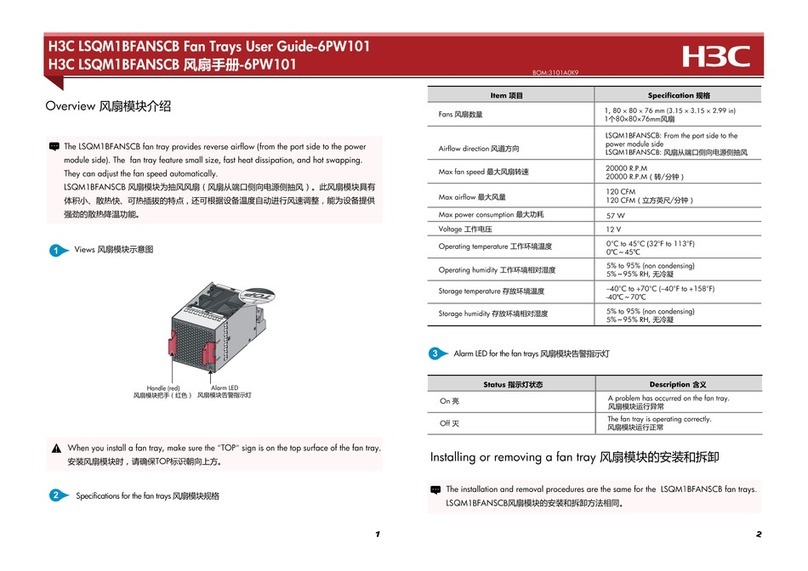

H3C LSQM1BFANSCB User manual

H3C

H3C WA2620X-AGNP User manual

Popular Network Hardware manuals by other brands

Matrix Switch Corporation

Matrix Switch Corporation MSC-HD161DEL product manual

B&B Electronics

B&B Electronics ZXT9-IO-222R2 product manual

Yudor

Yudor YDS-16 user manual

D-Link

D-Link ShareCenter DNS-320L datasheet

Samsung

Samsung ES1642dc Hardware user manual

Honeywell Home

Honeywell Home LTEM-PV Installation and setup guide