i

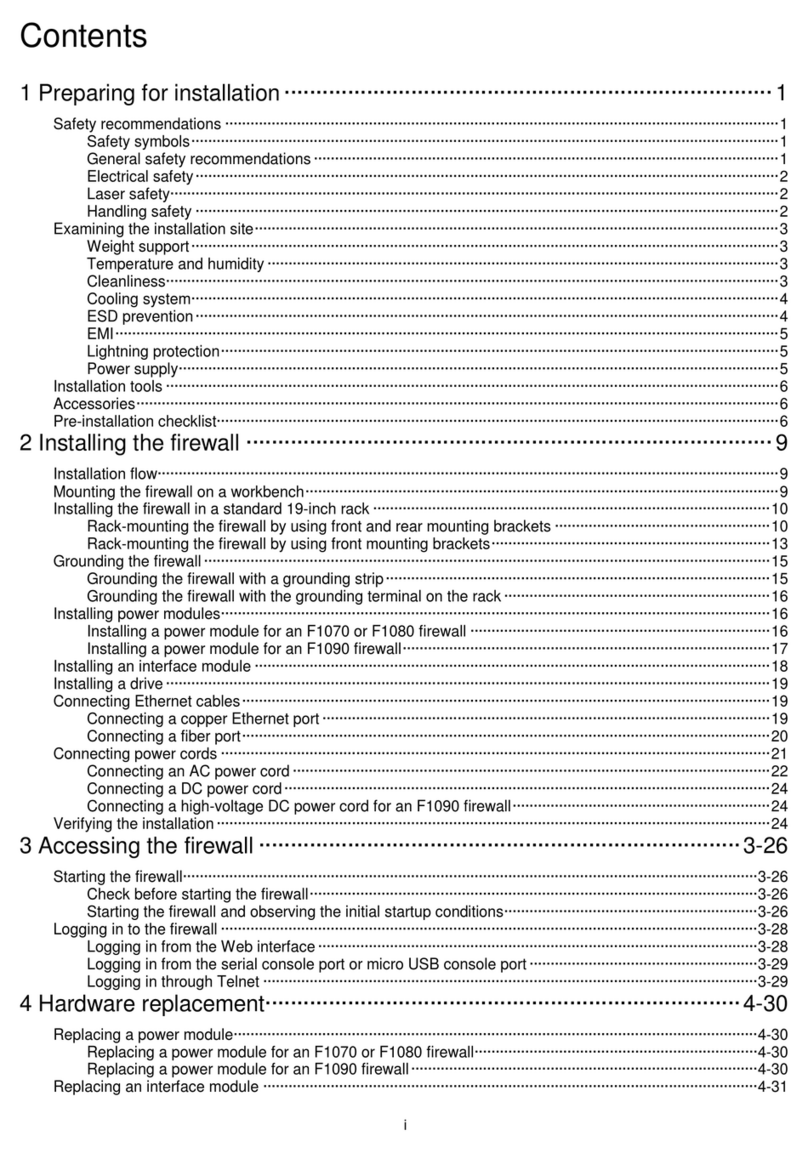

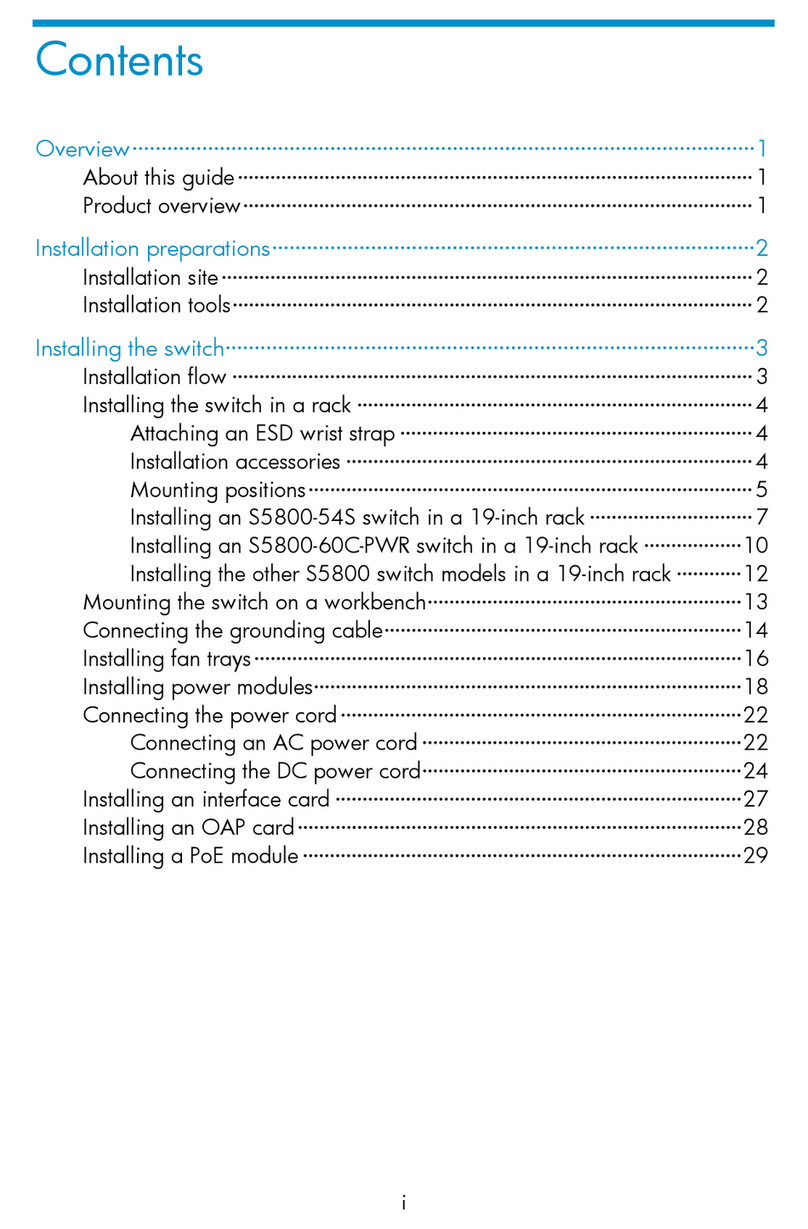

Contents

1 Preparing for installation··········································································1-1

Safety recommendations ································································································································1-2

Examining the installation environment ··········································································································1-3

Cleanliness··············································································································································1-4

Corrosive gas limit···································································································································1-5

Examining the installation site·························································································································1-6

Checking power distribution or power supply environment·············································································1-7

Laser safety·····················································································································································1-7

Installation tools ··············································································································································1-7

Installation accessories···································································································································1-7

2 Installing the switch················································································2-10

Installing the switch in a 19-inch rack············································································································2-11

Installation methods······························································································································2-11

Installation procedure at a glance·········································································································2-13

Rack-mounting the switch by using front mounting brackets································································2-14

Rack-mounting the switch by using front and rear mounting brackets··················································2-19

Mounting the switch on a workbench············································································································2-23

Mounting the switch on a wall·······················································································································2-23

Grounding the switch ····································································································································2-25

Grounding the switch with a grounding strip·························································································2-25

Grounding the switch with a grounding conductor buried in the earth ground······································2-26

Verifying the connection after grounding the switch··············································································2-27

Installing and removing a power supply········································································································2-28

Installing a power supply·······················································································································2-28

Removing a power supply·····················································································································2-30

Connecting the power cord···························································································································2-31

Connecting the AC power cord for the fixed AC power supply·····························································2-31

Connecting the power cord for a PSR360-56A, PSR720-56A, or PSR1110-56A power supply···········2-32

Connecting the DC power cord for a PSR560-56D power supply ························································2-33

Verifying the installation································································································································2-33

3 Accessing the switch for the first time····················································3-35

Connecting the switch to a configuration terminal·························································································3-35

Connecting a DB9-to-RJ45 console cable····························································································3-36

Connecting a USB-to-RJ45 console cable····························································································3-37

Connecting a micro USB console cable································································································3-38

Setting terminal parameters··························································································································3-40

Powering on the switch·································································································································3-40

4 Setting up an IRF fabric·········································································4-42

IRF fabric setup flowchart ·····························································································································4-43

Planning IRF fabric setup······························································································································4-44

Planning IRF fabric size and the installation site···················································································4-44

Identifying the master switch and planning IRF member IDs································································4-44

Planning IRF topology and connections································································································4-44

Identifying IRF physical ports on the member switches········································································4-45

Planning the cabling scheme················································································································4-47

Configuring basic IRF settings······················································································································4-48

Connecting the IRF physical ports················································································································4-49

Verifying the IRF fabric setup························································································································4-49

5 Maintenance and troubleshooting··························································5-50

Fixed power supply failure ····························································································································5-50

Symptom···············································································································································5-50

Solution·················································································································································5-50

Removable power supply failure···················································································································5-50