Habasit Italiana S.p.A.

Vittorio Veneto 31029 (TV)

Tel.: ++39(0)438.9113

Fax. ++39(0)438.200545

Use Manual

Hot Press PM-1056/160

Author: A.T.

INDEX

Edition: 09/2004

Page 7

Replaces:

Hot Press type PM-1056/160

SUMMARY OF THE FIGURES

F

IGURE

1

-

M

ACHINE IDENTIFICATION PLATE

.............................................................................................B-3

F

IGURE

2

-

P

OSITION OF SIGNS ON THE PRESS

.........................................................................................D-4

F

IGURE

3

-

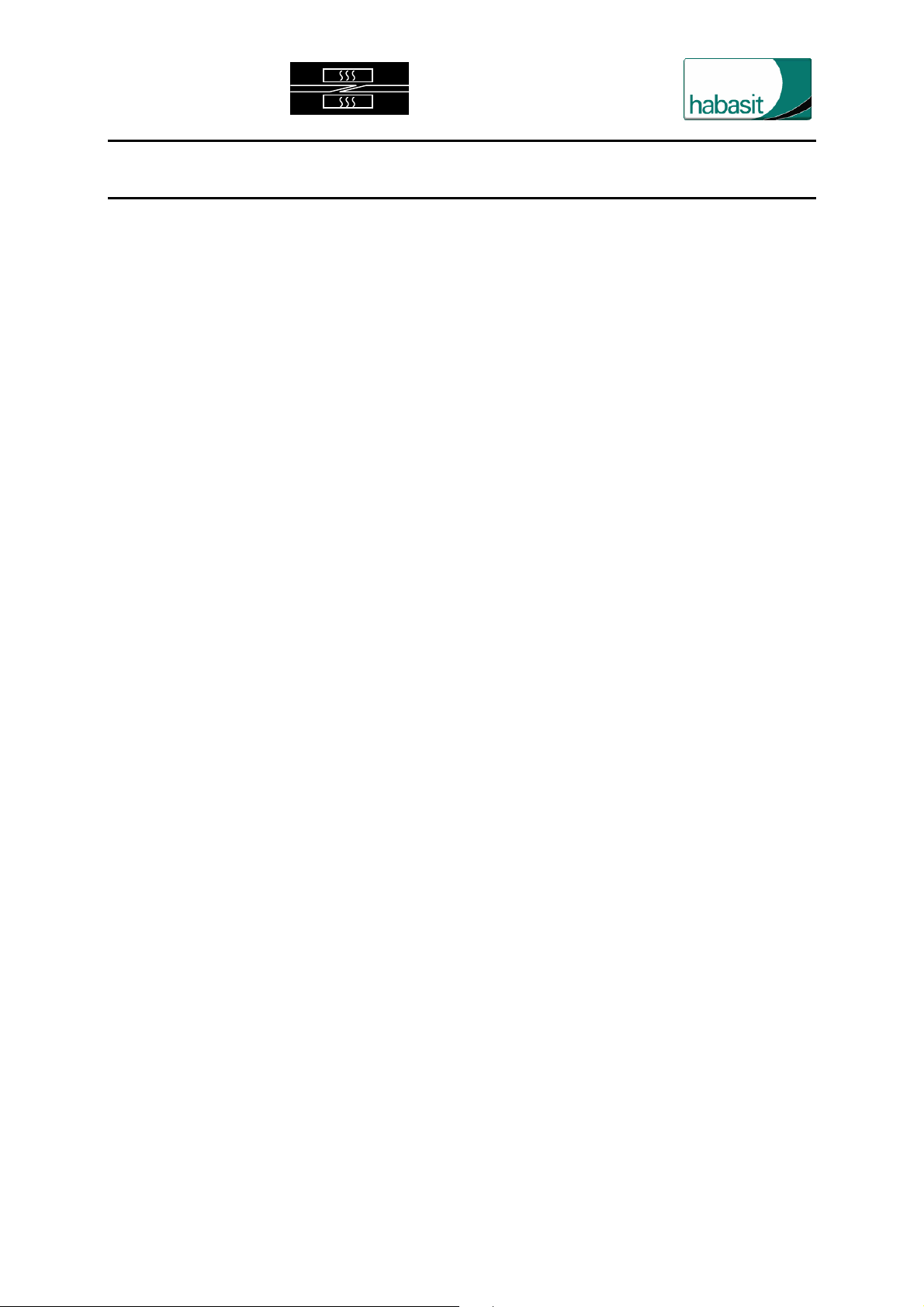

V

IEW OF

PM

1056/160..........................................................................................................D-5

F

IGURE

4

-

M

AIN ELEMENTS OF THE

PM

1056/160...................................................................................D-6

F

IGURE

5

-

C

OMPRESSED AIR CONNECTIONS

............................................................................................D-7

F

IGURE

6

-

F

IXED OPERATION USE WITH

PMR-06

AND

PMC-04................................................................D-8

F

IGURE

7

-

F

IXED OPERATION USE WITH

PMR-06

AND

PMC-06................................................................D-9

F

IGURE

8

-

M

OBILE OPERATION USE WITH

PMR-06 ................................................................................D-10

F

IGURE

9

-

P

RESS WIRING LAY

-

OUT

PM-1056/160...................................................................................G-2

F

IGURE

10

-

I

NTERNAL SPARE PARTS

........................................................................................................ I-2

F

IGURE

11

-

P

RESSER CUSHION SPARE PARTS

.......................................................................................... I-4

F

IGURE

12

-

E

XTERNAL SPARE PARTS

....................................................................................................... I-6

F

IGURE

13

-

B

ELT LOCKING SYSTEM SPARE PARTS

.................................................................................... I-8

F

IGURE

14

-

S

PARE PARTS FOR COMPRESSED AIR CONNECTION

............................................................... I-10

SUMMARY OF TABLES

T

ABLE

1

-

D

ANGER SIGNS

........................................................................................................................A-7

T

ABLE

2

-

P

RESCRIPTIVE SIGNS

...............................................................................................................A-7

T

ABLE

3

-

T

ERMS AND DEFINITIONS

..........................................................................................................A-8

T

ABLE

4

-

Q

UALIFICATIONS

....................................................................................................................A-12

T

ABLE

5

-

E

LECTRICAL CHARACTERISTICS

................................................................................................B-4

T

ABLE

6

-

P

NEUMATIC CHARACTERISTICS

.................................................................................................B-4

T

ABLE

7

-

W

ATER CHARACTERISTICS

.......................................................................................................B-4

T

ABLE

8

-

D

IMENSIONS AND

E

NVIRONMENTAL CHARACTERISTICS

..............................................................B-5

T

ABLE

9

-

C

HARACTERISTICS OF WORKABLE ELEMENTS

............................................................................B-5

T

ABLE

10

-

N

ECESSARY ACCESSORIES FOR FIXED USE

.............................................................................B-6

T

ABLE

11

-

A

CCESSORIES NECESSARY FOR MOBILE USE

...........................................................................B-7

T

ABLE

12

-

R

EGULATING UNIT OPTIONS

(PMR-XX)

(P

RESS

-XX

COMBINATIONS

)........................................B-8

T

ABLE

13

-

C

ONTROL UNIT OPTIONS

(PMC-XX)

(PMR-XX

–

PMC-XX

COMBINATIONS

).............................B-9

T

ABLE

14

-

O

PTIONAL ACCESSORIES

(

FOR BOTH FIXED AND MOBILE USE

)...................................................B-9

T

ABLE

15

-

S

TORAGE CONDITIONS

...........................................................................................................C-8