Page 3 of 21

1. Introduction

1.1 What is an Emergency Voice Communication System?

An Emergency Voice Communication System, or EVCS, is a system that allows voice communication in

either direction between a central control point and several other points throughout a building or

building complex, particularly in a fire or emergency. The control points, or outstations by which they

are more commonly referred, generally comprise of a Type A outstation, a Type B outstation, or a Type

C Combined Type outstation. “Assist Call” emergency assistance alarm systems can also be

incorporated into the EVCS.

EVCS is generally required in the following situations:

●In any building or sports or similar venue where there are disabled people, or people who may

have difficulty negotiating the evacuation route.

●In buildings with phased evacuation and/or firefighting lifts where it facilitates secure

communications for building managers, fire wardens, and attending fire officers.

●At sports venues and similar complexes, where it will assist stewards in controlling the

evacuation of the area in an emergency.

The Haescomm HC-228S use as a Fire Telephone system, Disabled Refuge system or as a combined

system when both Fire Telephones and Disabled Refuge Points are required.

1.2 Suitability

Fire telephone systems are recommended for all public buildings and multi-story buildings over four

floors that require phased evacuation as per BS 9999:2017.

Disabled Refuge systems are required in buildings where the public or staff gains access to any floor

other than the ground floor using lifts. A refuge is a relatively safe waiting area provided at each storey

exit from each protected stairway.

Refuge areas are not just for wheelchair users, they are for anyone who may need assistance i.e.

someone who’s immediate evacuation will impede the egress of others, a pregnant woman over 6

months term or persons with long term injuries, arthritis etc.

2. Product Overview

The Haescomm EVCS, or HC-228S, comprises of a Master Station and one or more outstations.

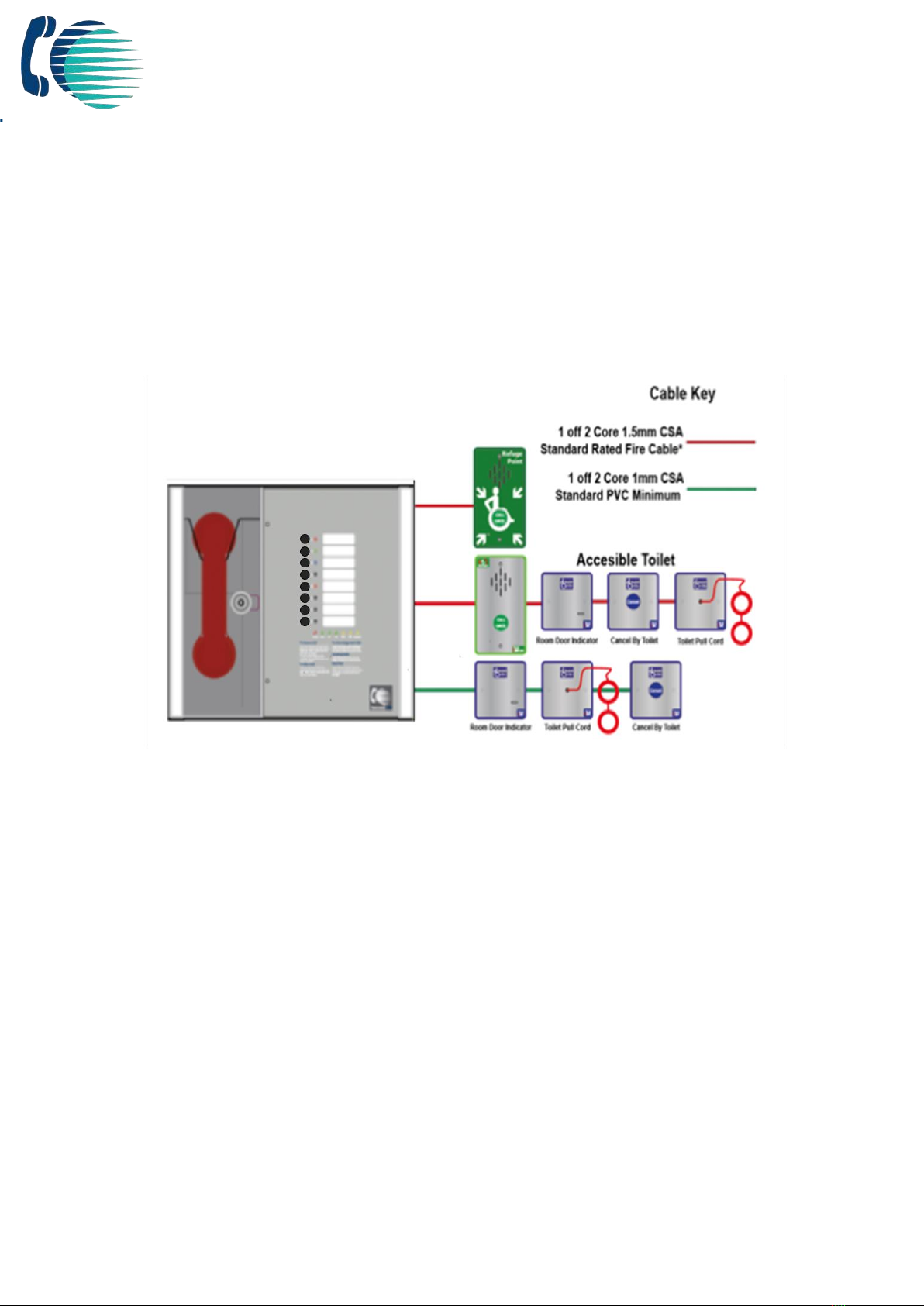

Additionally, the “Assist Call” emergency assistance alarm system can either be connected to the same

line as a Type B outstation or connected to a dedicated line. Neither the outstations nor the “Assist

Call” emergency alarm system require a separate power supply unit as each line is powered from the

Master Station. This has the additional benefit of each line being fully monitored and battery backed up.

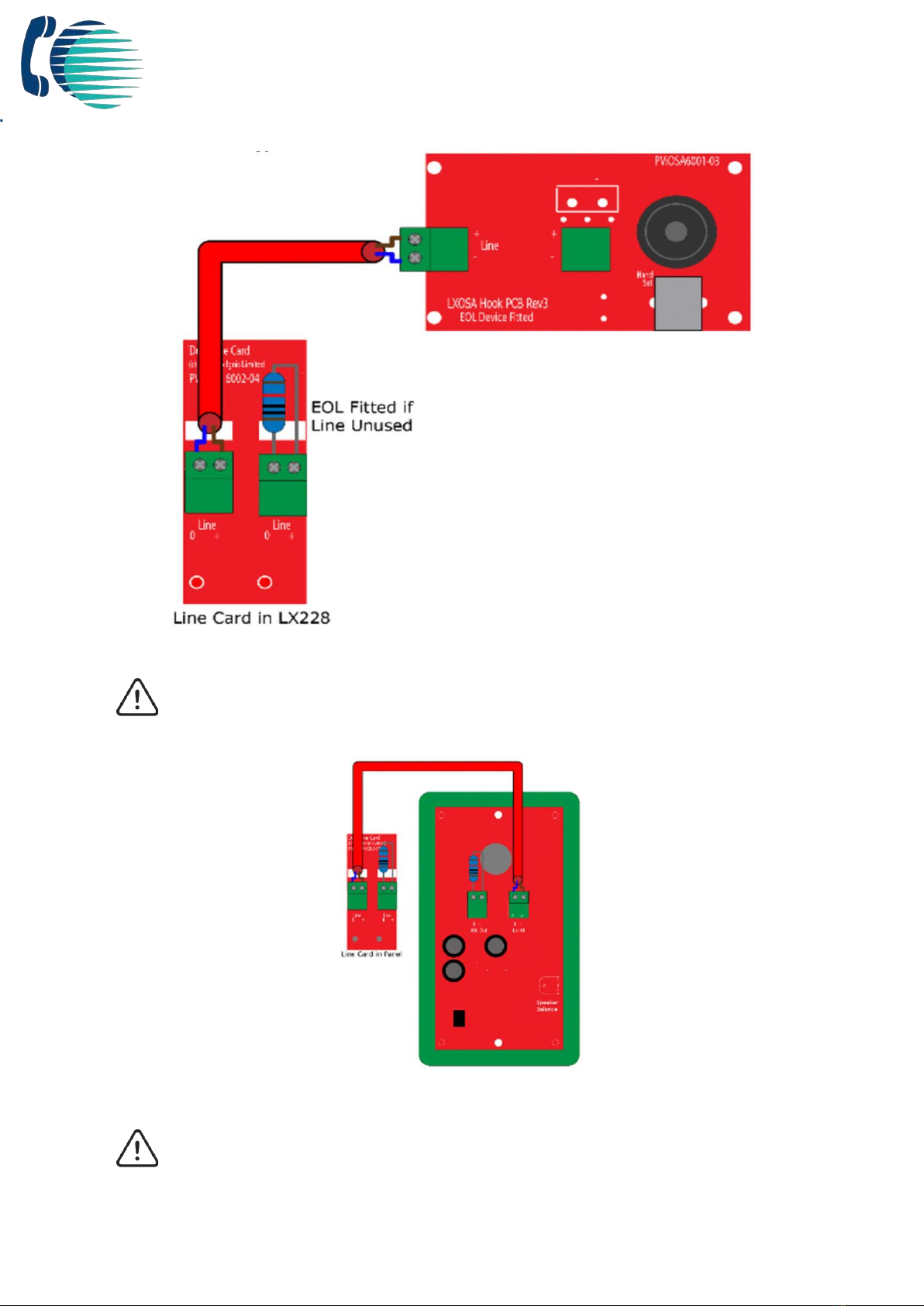

The HC-228S Master Station has been designed for radial star topology. In most cases this will reduce

the cable requirements for all ring-based systems. The topology consists of spurs formed of 1 off two

core 1.5mm CSA cables (soft skin enhanced up to 500m per leg, MICC 200m per leg) to each

outstation.