6LE007315Ab4

HZI855

Optional Aux. Supply

24V (6W)

82 70 76 75 74 73 72 71 6164

OUT 6

LATCHING RELAY OUTPUTS (NC-NO-C) OUTPUTS (NC-NO-C)INPUTS

OUT 5

62 515452

IN1IN2IN3IN4IN5IN6C

81

Config USB

OUT 4

414442

OUT 3

313432

OUT 2

212422

OUT 1

111412

ATSE Controller with communication

ALL OUT: AC1– AC general use Ie: 8A Ue: 250V~ 50/60Hz 1.6kW AC15 – AC pilot duty Ie:2A Ue:250V~ 50/60Hz 175W DC1 – DC general use Ie:5A 24V 120W

N°/ SN:ZRSSAAXXLYYYYFFFFFFFFI Made in France

Test level ; Between SOURCES

When type tested with IEC 60947-6-1 RTSE

TighteningTorques:

RS485:0.22-O.25Nm/1.9-2.2lb.in

All others:0.5-0.6Nm/4.4-5.3lb.in

OperatingTemperature:

-30/70°C

RS485120Ω

ON

OFF

Product

Consumption

on sources

10VA

Hager Electro SAS

BP3

67215 OBERNAICEDEX FRANCE

Notice:http://hgr.io/r/hzi855

IEC 60947-6-1IEC61010-2-201GB/T 14048.11

appendixC

8kV

Voltage Sensing220-227V~ L/N -30 +20% 400-480V~ L/L’ -30+20%

50-60Hz50-60Hz50Hz

110-227V~ L/N -30+20% 190-480V~ L/L’ -30+20% 220V~ L/N -30 +20% 380V~ L/L’ -30 +20%

4kV

OvervoltageCat.

U imp

Frequency

IIIIIIIII

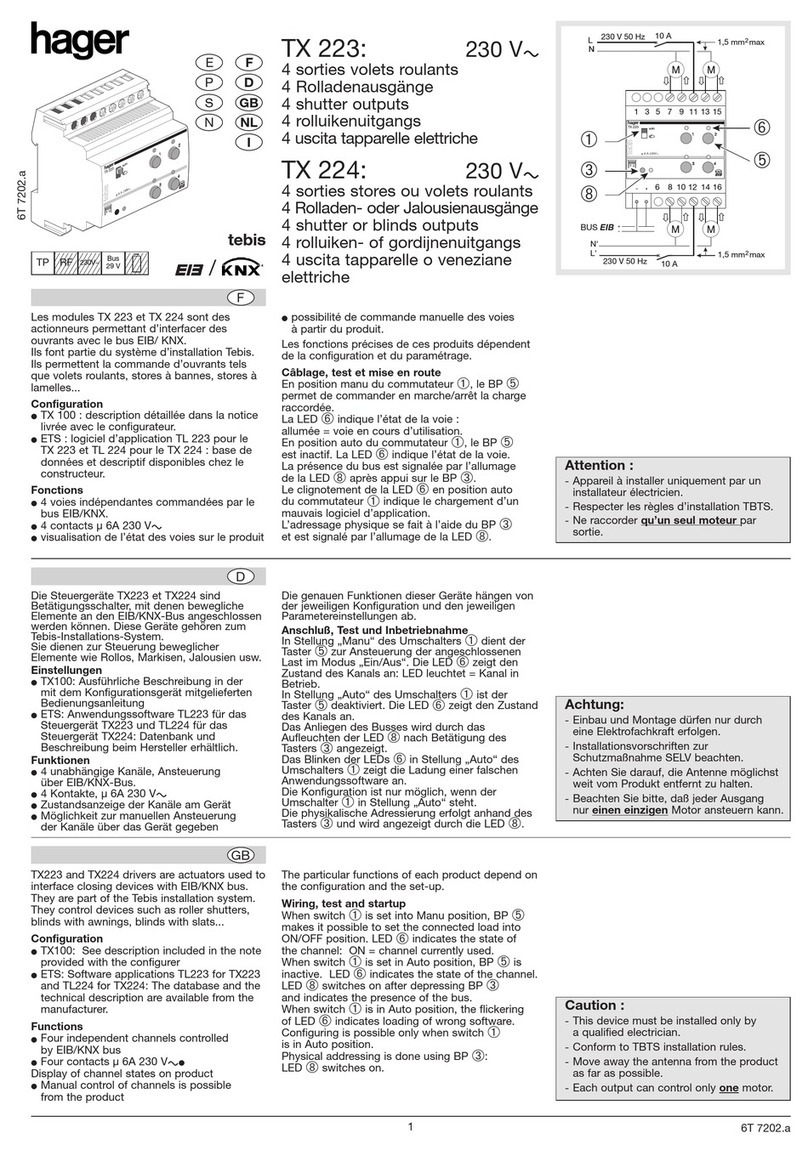

Controller wiring

5. Optional Aux. Supply 24 VDC.

6. Programmable INPUTS.

7. Programmable OUTPUTS.

8. Latching relays.

9. Cong USB.

1. Voltage sensing source 1.

2. Voltage sensing source 2.

3. RS485.

4. RTC battery

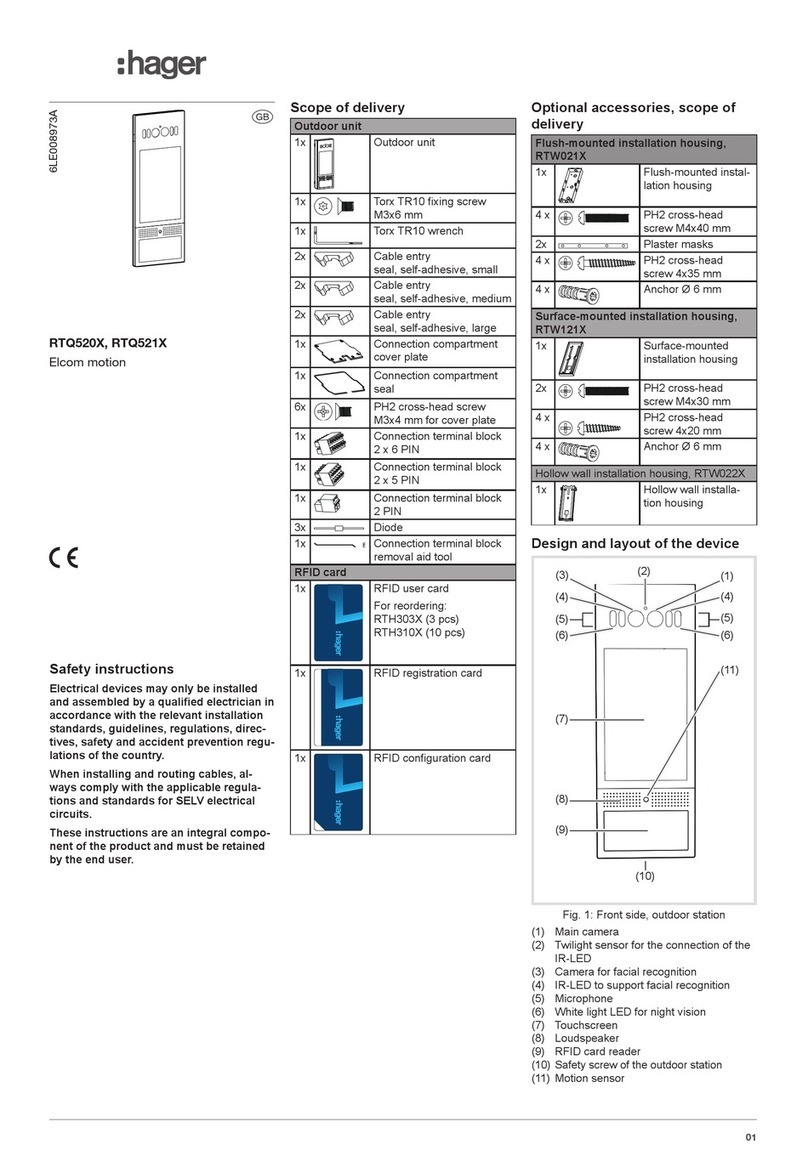

TYPE TERMINAL

N° DESCRIPTION BY DEFAULT CONFIGURATION CHANGES WHEN CHANGING

RTSE TECHNOLOGY CHARACTERISTICS RECOMENDED CROSS

SECTION

Breakers HIB4xxM Contactors

Inputs

71 IN1: programmable input Breaker 1 is in position ON Switch is in position 1 Contactor 1 is in position ON

Do not connect to any

power supply from

terminal 70 common

point.

Congurable type NO or

NC - NO by default

1.5-2.5 mm²

Tightening torque

0.5-0.6 Nm

4.4-5.3 Lb.in

72 IN2: programmable input Breaker 2 is in position ON Switch is in position 2 Contactor 2 is in position ON

73 IN3: programmable input Breaker 1 is in position OFF Switch is in position 0 -

74 IN4: programmable input Breaker 2 is in position OFF Inhibit -

75 IN5: programmable input Breaker 1 is in position TRIP Manual retransfer -

76 IN6: programmable input Emergency stop RTSE in manual -

70 Common point for inputs

Outputs

Logic Impulse Impulse Maintained

Dry contacts

8 A / 277 VAC 50/60 Hz

5 A / 24 VDC

Congurable type NO or

NC - NO by default

1.5-2.5 mm²

Tightening torque

0.5-0.6 Nm

4.4-5.3 Lb.in

12/14/11 OUT1: programmable output Order to close Breaker 1 Order to switch in

position 1 Order to close Contactor 1

22/24/21 OUT2: programmable output Order to close Breaker 2 Order to switch in

position 2 Order to close Contactor 2

32/34/31 OUT3: programmable output Order to open Breaker 1 Order to switch in

position 0 -

42/44/41 OUT4: programmable output Order to open Breaker 2 S1 Available -

Latching

relays

Logic Impulse Impulse Maintained

52/54/51 OUT 5: genset start relay / programmable output - S2 Available -

62/64/61 OUT 6: genset start relay / programmable output Order to start Genset Order to start Genset -

Serial

connection RS485

Connection RS485

-: negative terminal of RS485 bus

+: positive terminal of RS485 bus

NC: ground

- - - RS485 bus insulated

Modbus cable 25 m = HTG485H

LiYCY sheilded twisted pair 0.14

to1.5 mm² /

Tightening torque

0.22-0.25 Nm

1.9-2.2 Lb.in

Aux power

supply 81/82 -: negative terminal for aux supply

+: positive terminal for aux supply - - - 12-24 VDC

Tightening torque

0.5-0.6 Nm

4.4-5.3 Lb.in

Top viewBottom view

Cabling Output relays 1-4 Cabling Output Latching relays 5 & 6

Controller cong STATE (relay)

Normally

Open (NO) (11-14)

Normally

Closed (NC) (11-12)

Normally

Open (NO) (61-64)

Normally

Closed (NC) (61-62)

Output congured as NO

NO by default

OFF (not active) Open Closed Open Closed

ON (activated by rmware) Closed Open Closed Open

Controller not supplied Open Closed Closed* Open*

Output congured as NC OFF (not active) Closed Open Closed Open

ON (activated by rmware) Open Closed Open Closed

Controller not supplied Open Closed Closed* Open*

* HZI855 controller includes two bi-stable relays with backup energy, when the controller loses all sources of power supply outputs 5 and 6 will automatically activate (NO contact will close and

NC contact will open). This is a safety feature designed to ensure power availability to the load in Main-Genset or Genset-Genset application by forcing generators to start in case of total power

loss. It is highly recommended to congure the outputs 5 and 6 to take benet from this function.