hager I-LS02688 User manual

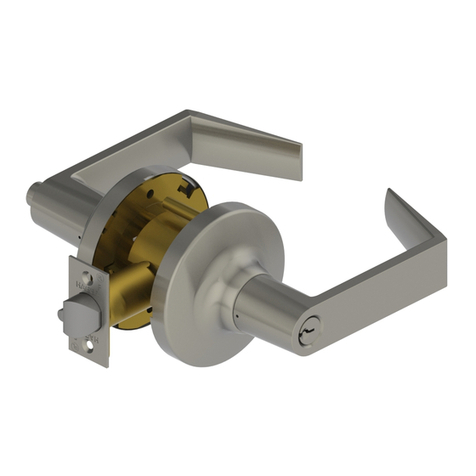

EQ34 GRADE 1 CYLINDRICAL LOCK

INSTALLATION INSTRUCTIONS

I-LS02688

Rev 1, Rev Date: 01/12/2023 [27390107] Page 1 of 7

Hager Companies 139 Victor Street, St. Louis, MO 63104 (800) 325-9995 www.hagerco.com

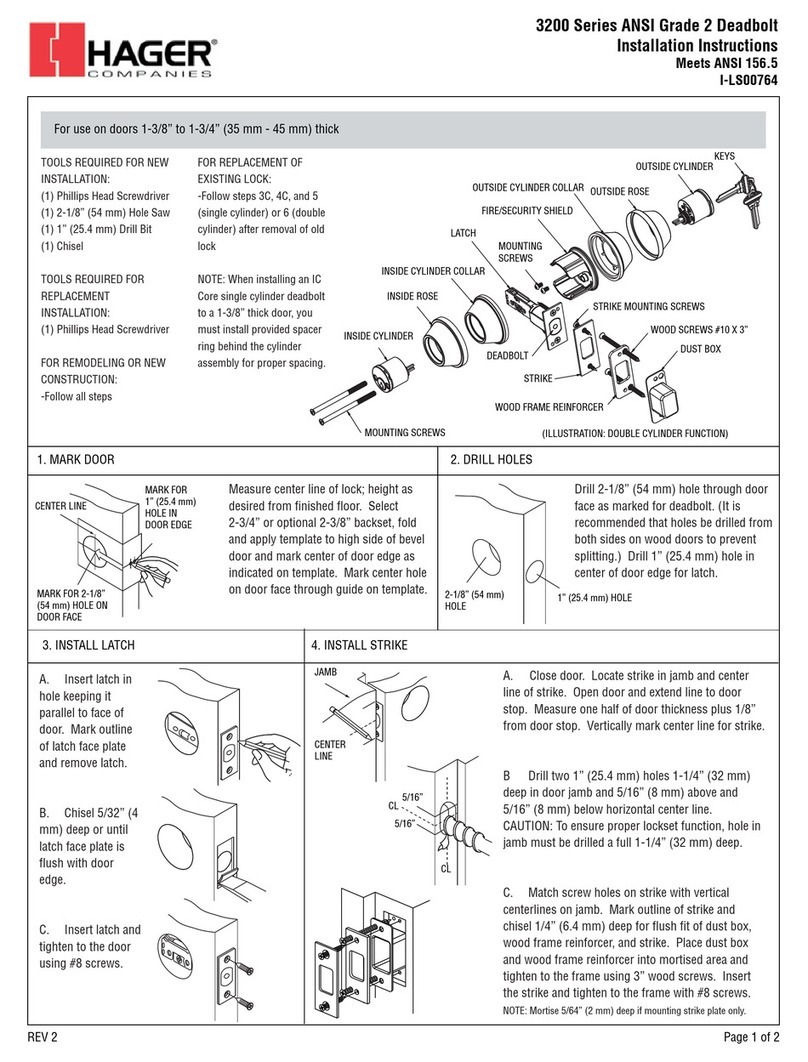

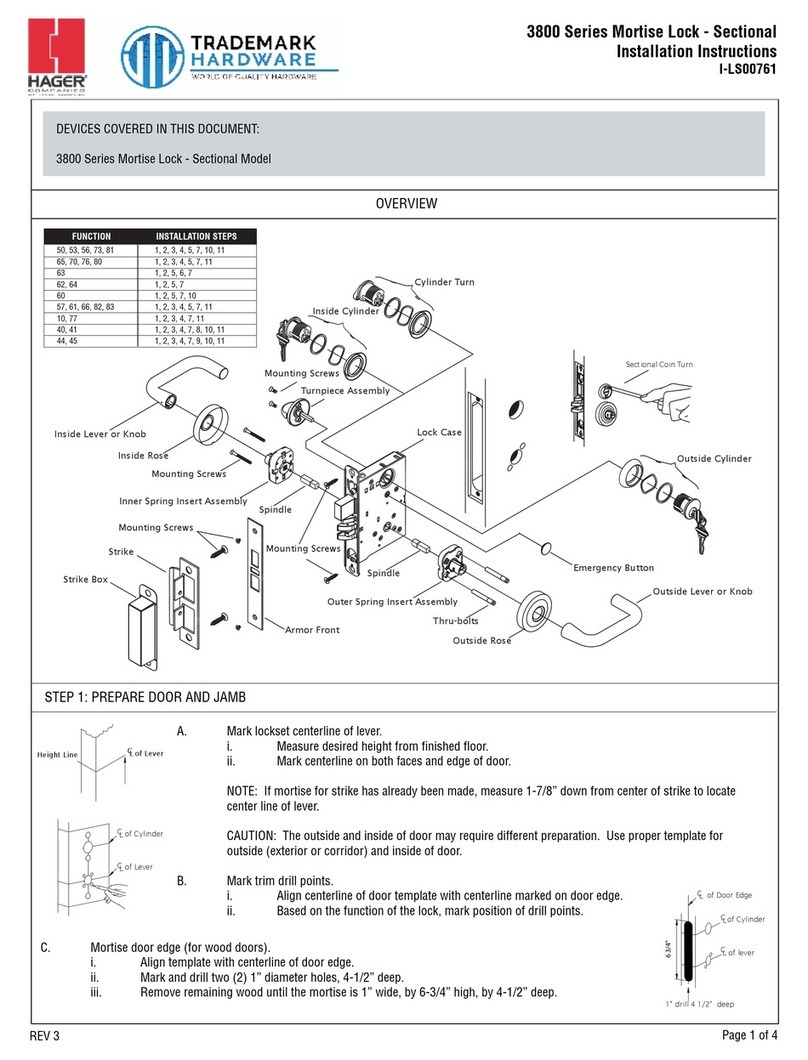

Part Description QTY

1ASA Strike 1

2Rose, Cylindrical 1

3Spring Cage Assembly, Interior 1

4Lock Chassis Assembly 1

5Interior Mounting Plate with RX Switch 1

6Spring Cage Assembly, Exterior 1

7Withnell Lever, Interior 1

8Withnell Lever, Exterior, NKO 1

9Mounting Bracket, Exterior 1

10 Dead Latch 1

11 Screw Pack, EQ34 1

AA Allen Wrench, 3/32” 1

BB Lever Removal Tool 1

CC Screw, #10-32 x 1.4” Oval Head Machine 4

DD Screw, #12-24 X 3/4” Flat Head Combo 2

EE Screw, #8-32 x 3/4” Flat Head Combo 2

12 Set Screw, #10-32 x 1/4”, 3/32” Drive 2

13 Retaining Plate, Lever 2

14 AA Alkaline Batteries 4

15 Escutcheon Assembly, Cylindrical 1

16 Power Pack Assembly 1

17 Screw Pack, Power Pack 1

FF Screw, #12 x ¾” Pan Head 2

GG Screw, #10-32 x ¾” Pan Head Machine 1

HH Hex Standoff, #10-32 x 1.5” Male-Female 1

18 Wiring Harness, Control Board to Reader 1

19 Wiring Harness, Control Board to Lock 1

20 Main Gasket, Cylindrical 1

21 Tailpiece (Key Override Only) 1

22 Cup (Key Override Only)

23 Installation Instructions

24 Template 1

25 Door Thickness Guide 1

AA

BB

CC

DD

FF

EE

GG

HH

23

24

25

EQ34 GRADE 1 CYLINDRICAL LOCK

INSTALLATION INSTRUCTIONS

I-LS02688

Rev 1, Rev Date: 01/12/2023 [27390107] Page 2 of 7

Hager Companies 139 Victor Street, St. Louis, MO 63104 (800) 325-9995 www.hagerco.com

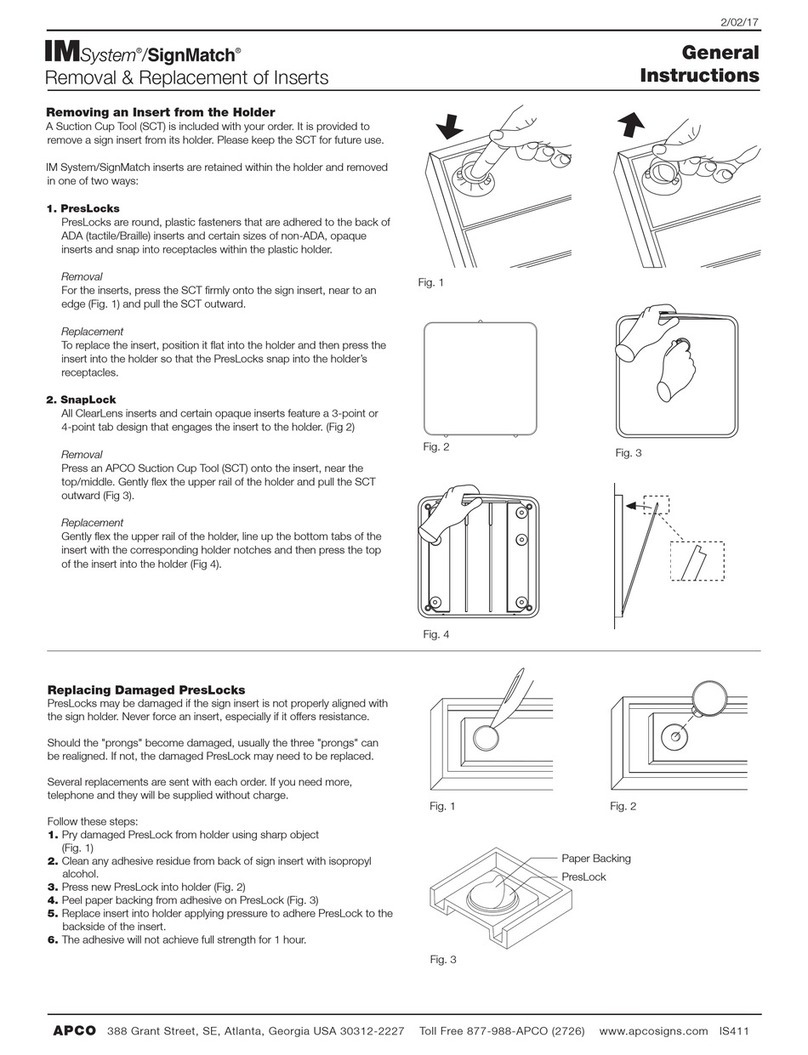

1Safety Information

Carefully read the instructions before installing and using this lock.

WARNING: If the door needs to be drilled, be familiar with how to safely use your tools, and understand all the door preparation steps

before proceeding.

FINISH & CARE NOTES: Either remove the locks or do not install them prior to painting your door to protect the finish. Periodically clean

the locks with mild soap and a soft cloth. Do not use abrasives or harsh chemicals when cleaning or using the lock.

Required Tools

2

T10 PH2 PH3

OPTIONAL OPTIONAL OPTIONAL OPTIONAL

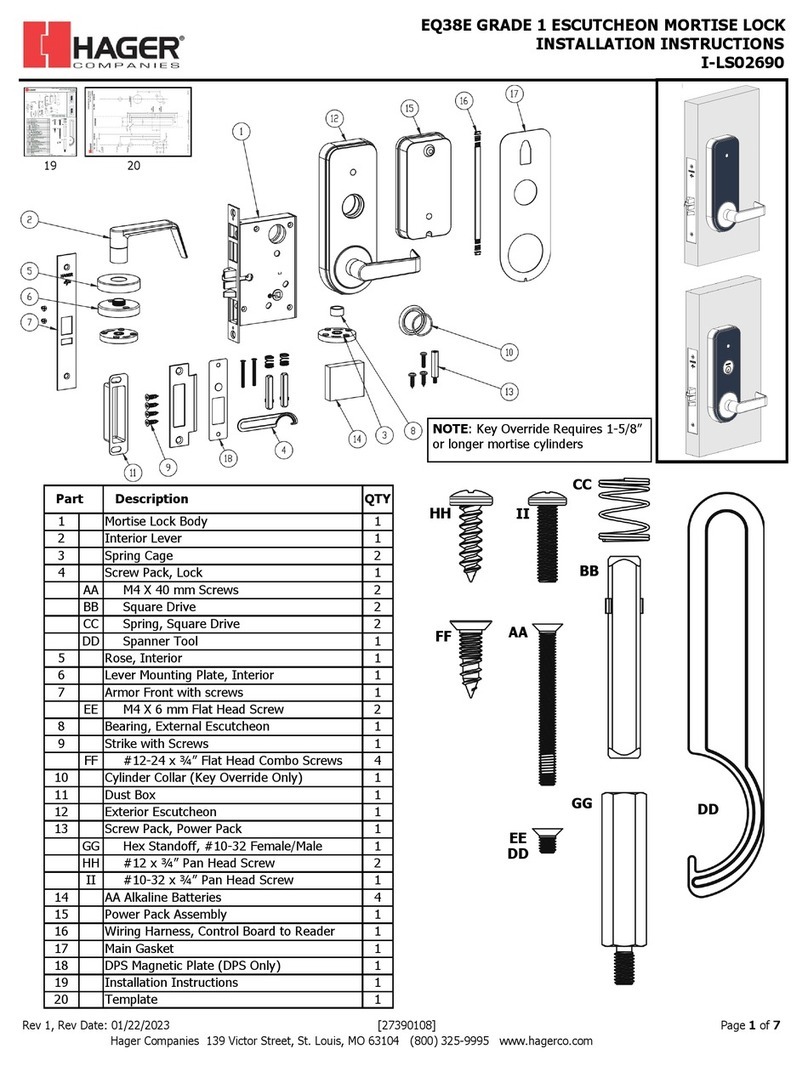

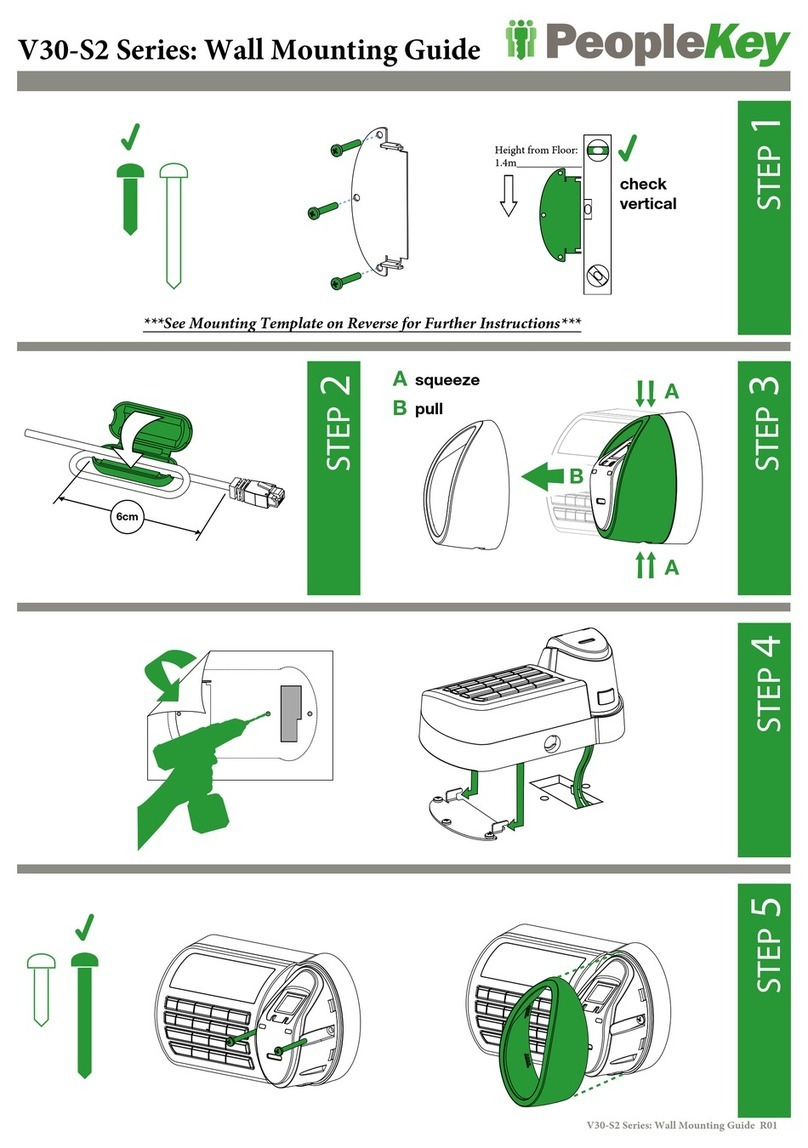

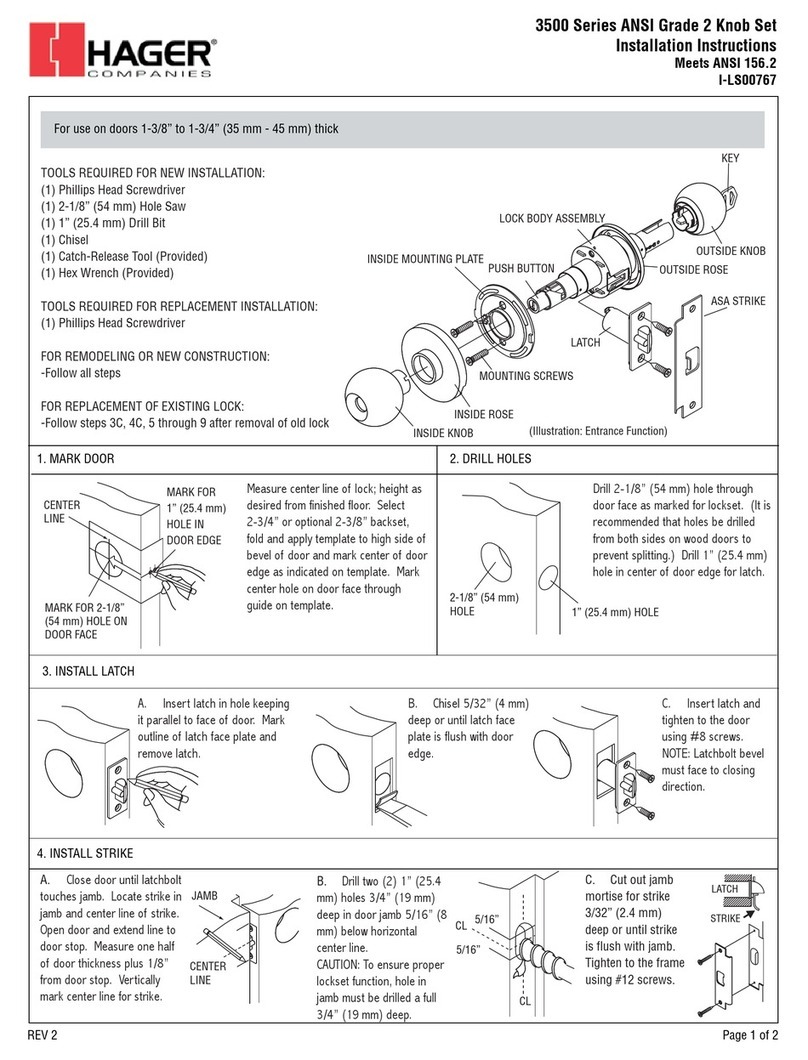

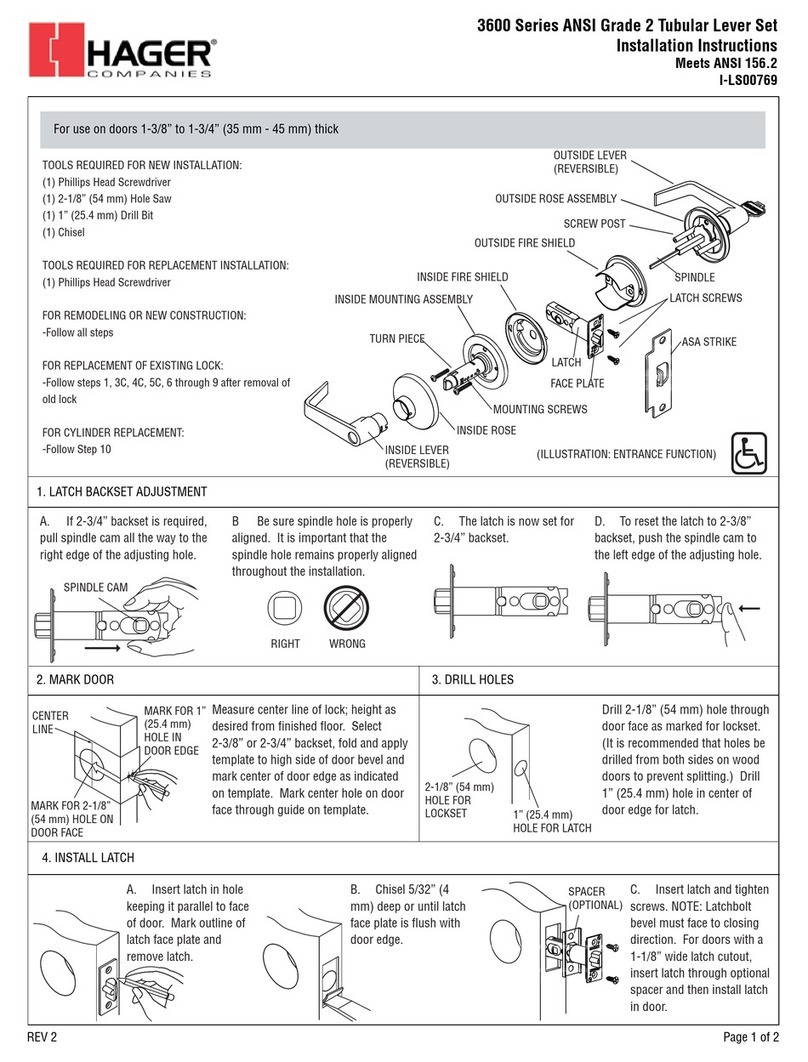

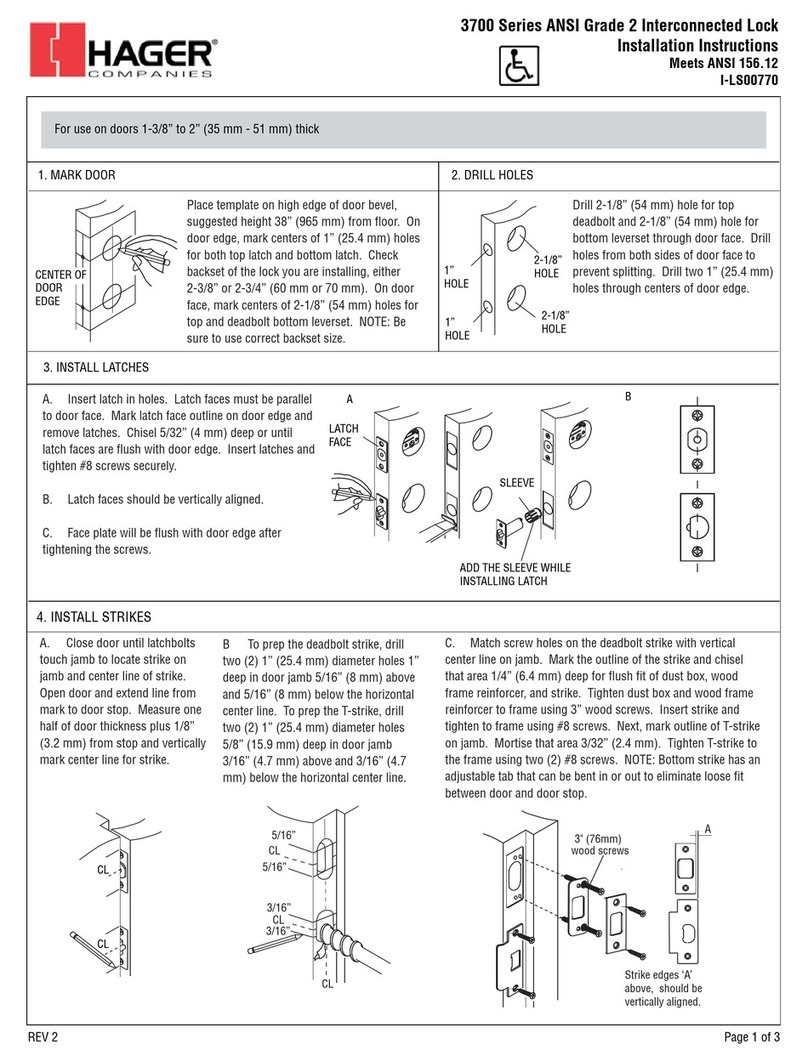

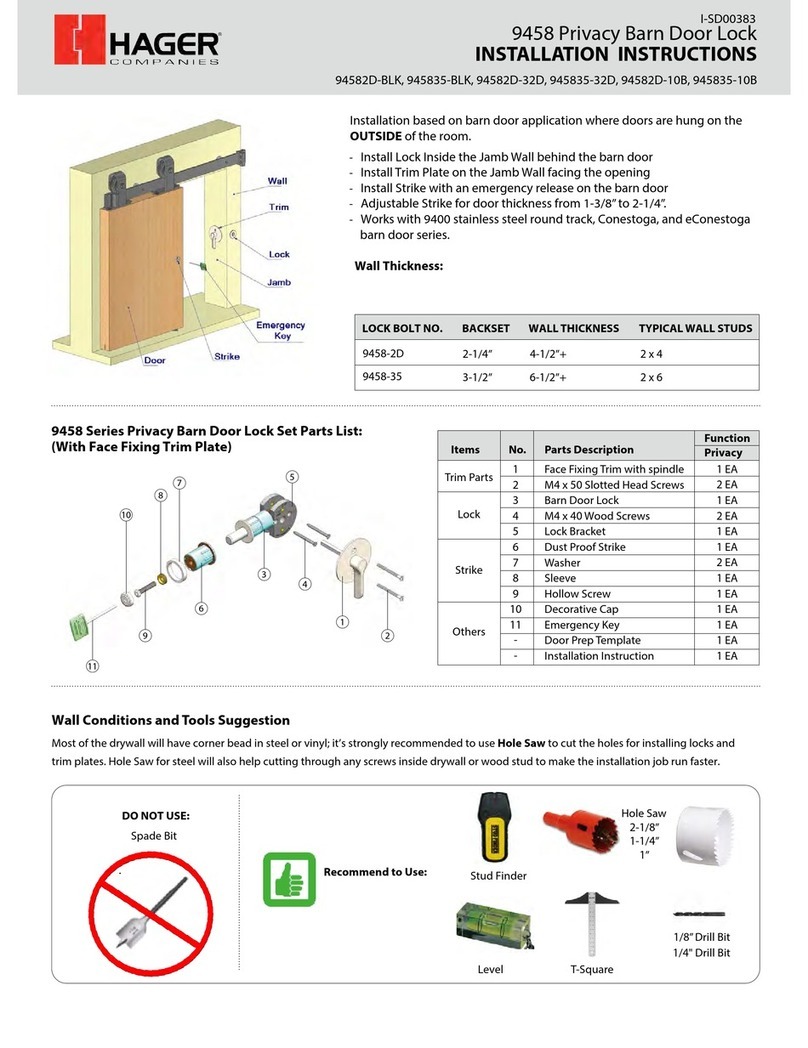

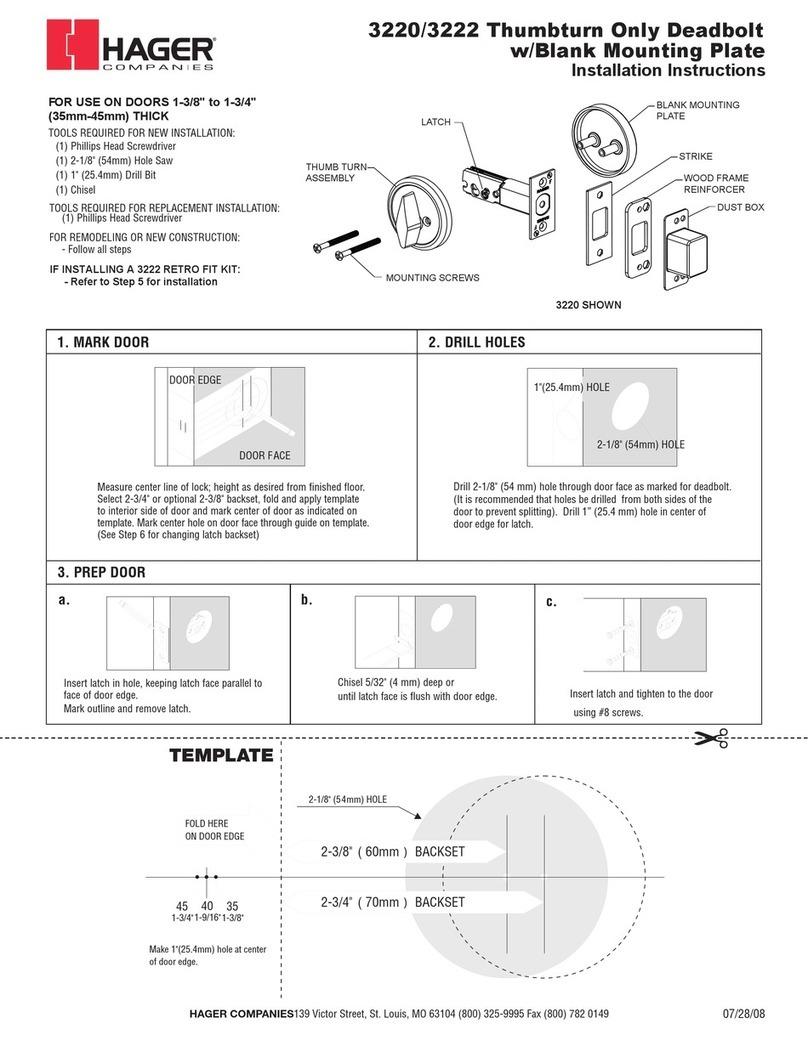

3Prepare Door & Frame / Install Latch & Strike

Skip the prep steps if the door has already been prepared. Just install the latch

and strike as shown below.

1

NOTE: Drill from both sides to avoid splintering the finished surface of wood doors

Distance from

finished floor

2

10

Mark the Lever Centerline on the door face and edge at desired distance from the finished floor. Align the template and

mark the door, drill the holes. Insert latch, trace around face plate and chisel out a mortise pocket. Use a Ø1/8” [3.2 mm]

pilot holes for 2 EE screws. Install #10 latch using two #8 screws, EE.

EE

Drill x2

Chisel out

Mark Jamb for strike as shown below. Drill two Ø1” [25.4 mm] holes 3/4” [19 mm] deep in the jamb 15/16” [8 mm] above

and below the horizontal center line and then chisel out. NOTE: To ensure proper lockset function, the hole in the jamb

must be drilled a full 3/4” [19 mm] deep.

Mark jamb for strike and chisel out to a depth of 3/32” [2.4 mm] or until flush. Drill 2 pilot holes for #12 strike screws.

Install #1 Strike with two #12 screws, DD.

2X PILOT

HOLES

Ø 3/16”

DD

1

EQ34 GRADE 1 CYLINDRICAL LOCK

INSTALLATION INSTRUCTIONS

I-LS02688

Rev 1, Rev Date: 01/12/2023 [27390107] Page 3 of 7

Hager Companies 139 Victor Street, St. Louis, MO 63104 (800) 325-9995 www.hagerco.com

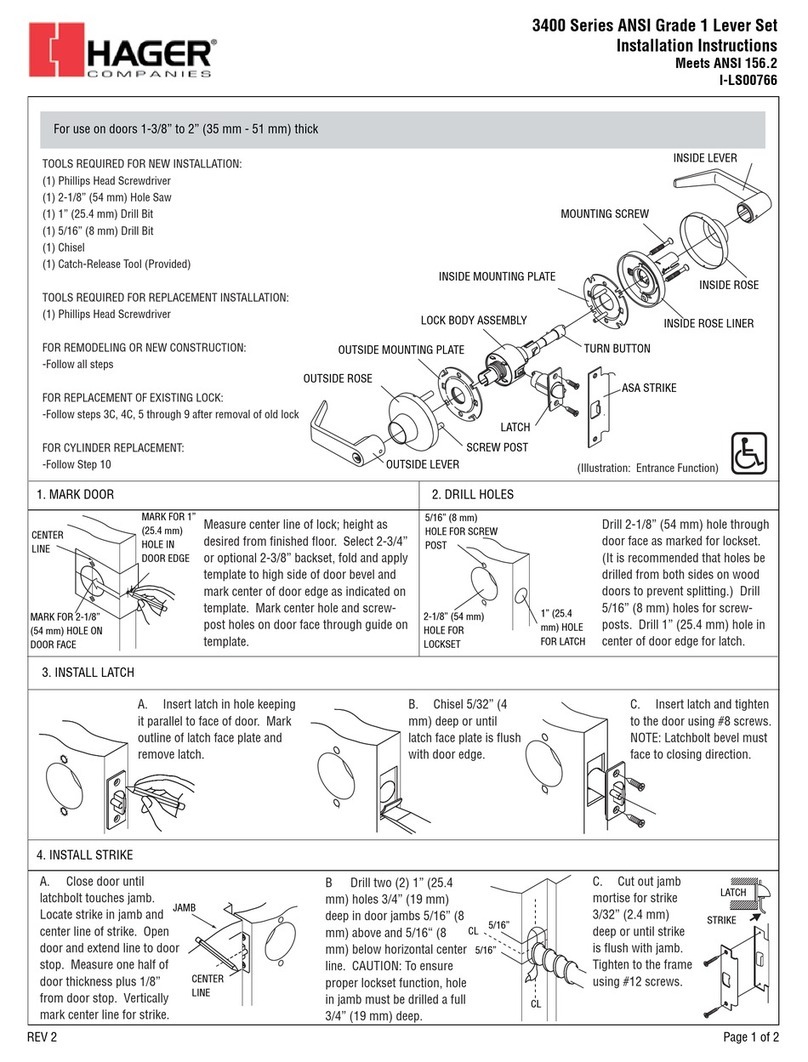

Assemble chassis to spring cage assembly and route wire harness #19.

• Verify the Retractor and Retaining Plate are facing the same direction.

• Route Wire Harness #19 (lock to control board) as shown

• Feed the (2) 2-pin plugs through spring cage assembly. In the back of the spring cage,

through the hole behind the retractor as shown below.

• Adjust harness to line up with the silver line with the face shown. This

should be 3” [76 mm] from the end of the longest 2 pin plug.

4

Remove the lock chassis from the lever assembly and adjust for door

thickness if necessary.

• Note the thickness of the door.

• If it is thicker than 1.75” [44.5 mm], then adjust the chassis assembly

to the proper door thickness using the Door Thickness Guide included

with the product.

Prepare Lock Chassis

1

Remove the lever using the Allen wrench, AA.

• Fully loosen set screw in the base of the lever shown below. Rotate

CCW to loosen.

• Then insert the end of the Allen wrench into a hole in the retaining

plate below and pull back the plate to release the lever. Remove the

lever and set aside.

• KEY OVERRIDE ONLY! To remove the lever, insert lever removal tool

BB and pull the lever off. Set the lever aside for later.

2

3

Retaining

Plate

Retractor

Align line with plate

3” [76 mm]

EQ34 GRADE 1 CYLINDRICAL LOCK

INSTALLATION INSTRUCTIONS

I-LS02688

Rev 1, Rev Date: 01/12/2023 [27390107] Page 4 of 7

Hager Companies 139 Victor Street, St. Louis, MO 63104 (800) 325-9995 www.hagerco.com

5

• Remove the back plate from the exterior escutcheon.

• Note the handing of the door above and assemble the prepared Lock Chassis into the exterior escutcheon.

• Route the wire harness along the side of the escutcheon and over to the center of the lock as shown.

Prepare Exterior Escutcheon

1

INSIDE

OUTSIDE

INSIDE

OUTSIDE

INSIDE

OUTSIDE

INSIDE

OUTSIDE

RH—RIGHT HAND DOOR

RHR—RIGHT HAND REVERSE DOOR

LH—LEFT HAND DOOR

LHR—LEFT HAND REVERSE DOOR

DOOR HANDING Determine the handing of your door opening before preparing the exterior escutcheon.

RH / RHR LH / LHR

Wires Wires

Retractors

• Plug the 6-pin wire harness #18 into the reader board and re-install the back plate.

2

18

EQ34 GRADE 1 CYLINDRICAL LOCK

INSTALLATION INSTRUCTIONS

I-LS02688

Rev 1, Rev Date: 01/12/2023 [27390107] Page 5 of 7

Hager Companies 139 Victor Street, St. Louis, MO 63104 (800) 325-9995 www.hagerco.com

5

• Install Hex Standoff HH.

• Install Main Gasket #20 onto the backplate centered on

the escutcheon.

• Plug 2-pin male wire harness into 2-pin female chassis

wire.

Prepare Exterior Escutcheon, Continued

3

HH

20

4Install lever and tighten down the set screw.

• Press lever onto spindle until it snaps into place.

• Tighten set screw with allen wrench AA by turning CW

until set screw bottoms out against the spindle.

The escutcheon is now ready to install on the door.

KEY OVERRIDE ONLY!

Install KIK cylinder in lever.

1. Insert the cup #22 included in the unit box into the exterior spindle as shown.

2. Install tailpiece #21 included in unit box on the KIK cylinder (purchased separately) inline

with the pin bible as shown.

3. Loosen set screw #12 in lever #8 with Allen wrench AA then remove the retaining plate

assembly #12, 13.

4. Insert the cylinder into the lever #8 followed by the retainer assembly #12, 13.

5. Turn the set screw CCW until secure to keep the retaining plate in place.

6. Insert the key for the cylinder, turn it 90°, and insert the lever onto the lock gently. Verify

the cam in the lock is clear for the now vertical tailpiece to engage. Make sure the tailpiece

engages the cam properly and does not get stuck. DO NOT FORCE THE LEVER.

7. Once the lever locks onto the spindle, turn the key back to the home position and remove

it from the cylinder.

8. Turn the set screw CW until it is tightened down against the spindle using Allen wrench

AA provided.

22

21

8

12, 13

12

3, 4, 5

66

7

6

AA

EQ34 GRADE 1 CYLINDRICAL LOCK

INSTALLATION INSTRUCTIONS

I-LS02688

Rev 1, Rev Date: 01/12/2023 [27390107] Page 6 of 7

Hager Companies 139 Victor Street, St. Louis, MO 63104 (800) 325-9995 www.hagerco.com

6

INSTALL EXTERIOR ESCUTCHEON

• Install escutcheon onto door by guiding wires into wiring hole and the chassis and wires into chassis hole.

• Make sure the retractor engages with the latch.

• Be sure the wires lay in the space provided by the backplate louver so they don’t pinch against the door.

• While holding the escutcheon flat against the door, plug interior mounting plate #5 into wiring harness and stow

the wires in the area behind the chassis. Position the plate over the chassis and fasten down with (2) CC screws as

shown below. Make sure the escutcheon is vertical and flat against the door before tightening down the screws.

Install Lock on Door

1

INSTALL INTERIOR TRIM

• Install interior spring cage #3 with (2) CC screws.

• Install interior rose #2 by aligning grooves in rose and

spring cage.

• Be sure lever retaining plate #13 and set screw #12 are

installed in lever #7.

• Install lever #7 using removal tool BB to start the lever.

Snap into place and then tighten lever set screw with AA

Allen wrench.

2

CC

2

7

3

BB

AA

CC

5

EQ34 GRADE 1 CYLINDRICAL LOCK

INSTALLATION INSTRUCTIONS

I-LS02688

Rev 1, Rev Date: 01/12/2023 [27390107] Page 7 of 7

Hager Companies 139 Victor Street, St. Louis, MO 63104 (800) 325-9995 www.hagerco.com

6Install Lock on Door (continued)

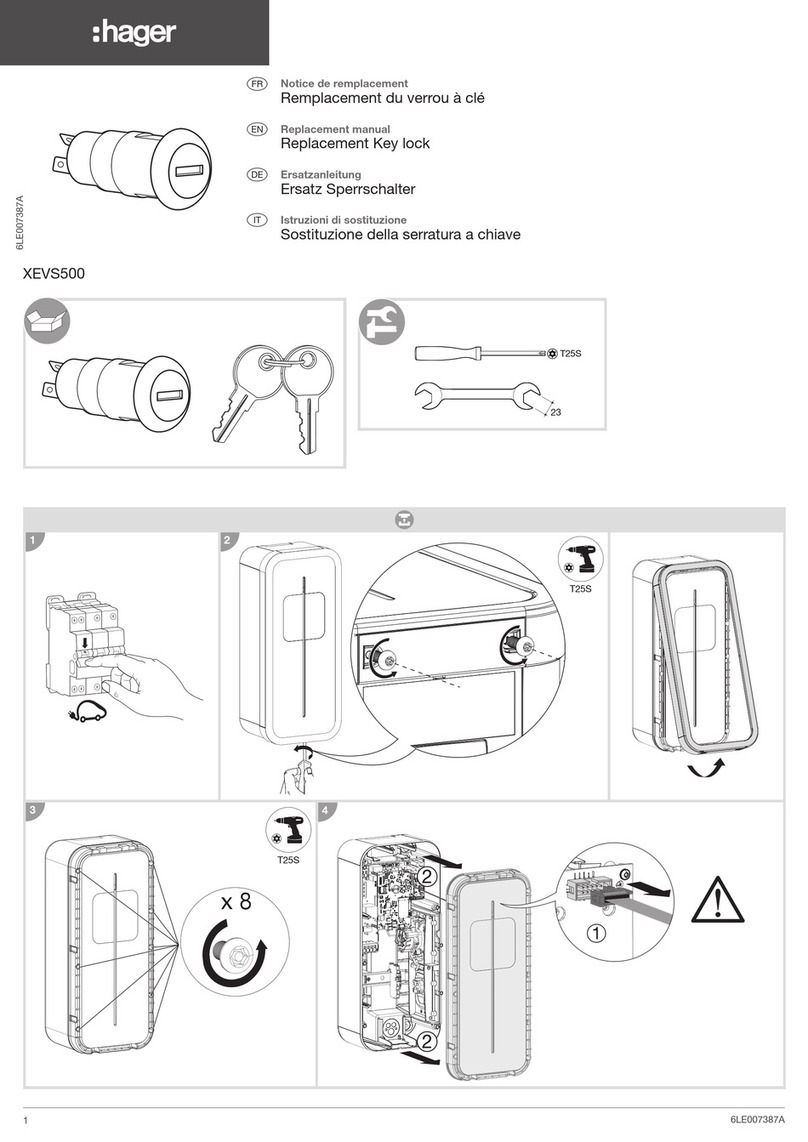

INSTALL POWER PACK

• Remove the cover on the battery pack with a T10 Torx drive

screw driver.

• Position the power pack base onto the door aligning the upper

mounting holes and routing the wires through the bottom wiring

hole.

• While holding the pack, install (2) #12 screws FF into the pre-

pared holes as shown below. Leave loose.

• Install #10-32 screw GG into hex standoff in the escutcheon as

shown.

• Make sure the power pack is straight and vertical then tighten (2)

#12 screws FF then the #10-32 screw GG.

3

CONNECT READER AND LOCK

• Plug in the Reader (6-pin) and Lock (8-pin) wire harnesses as shown

below.

4

GG

FF

EQ34 GRADE 1 CYLINDRICAL LOCK

INSTALLATION INSTRUCTIONS

I-LS02688

Rev 1, Rev Date: 01/12/2023 [27390107] Page 8 of 7

Hager Companies 139 Victor Street, St. Louis, MO 63104 (800) 325-9995 www.hagerco.com

7

INSTALL 4 AA BATTERIES

Install the 4 AA batteries in the battery holder. Follow batterie orientation notes in the

holder.

•

The lights should blink between red and green

•

It is now ready to be tested.

Setup Lock

1

UNADOPTED LOCKS (ORPHAN)

While the lock is powered but before it is adopted into a network, the lock will behave

as shown below.

•

Locked all the time? Unlocked all the time?

•

Anyway to unlock? Provide a card for

3

COMMISSION LOCK

•

GO TO COMMISSIONING PROCEDURE

4

SHOW SELECTION OF OTHER PRODUCTS THAT CAN BE USED

WITH THIS LOCK

HUB

PICTURE

INFO

QR CODE

CYL LOCK

PICTURE

INFO

QR CODE

EXIT DEVICE

PICTURE

INFO

QR CODE

EXTENDER

PICTURE

INFO

QR CODE

READER

PICTURE

INFO

QR CODE

OTHER

PICTURE

INFO

QR CODE

TEST INSTALLED AND POWERED LOCK

While the lock is powered but before it is adopted into a network, test the lock for func-

tionality.

•

Test procedure for cylindrical

2

INSTALL COVER

• Install cover, using T10 screw driver

5

EQ34 GRADE 1 CYLINDRICAL LOCK

INSTALLATION INSTRUCTIONS

I-LS02688

Rev 1, Rev Date: 01/12/2023 [27390107] Page 9 of 7

Hager Companies 139 Victor Street, St. Louis, MO 63104 (800) 325-9995 www.hagerco.com

FCC Statement:

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

—Reorient or relocate the receiving antenna, Increase the separation between the equipment and receiver, Connect the equipment

into an outlet on a circuit different from that to which the receiver is connected, Consult the dealer or an experienced radio/TV

technician for help.

Changes or modifications to the device not expressly approved by the party responsible for compliance could void the user's authority

to operate the equipment.

Canada

This device contains licence-exempt transmitter(s)/receiver(s) that comply with Innovation,

Science and Economic Development Canada’s licence-exempt RSS(s). Operation is subject to the

following two conditions:

(1) This device may not cause interference.

(2) This device must accept any interference, including interference that may cause undesired

To comply with RF exposure requirements, a minimum separation distance of 20cm must be maintained between the user's body and

the device.

Cet appareil contient un ou des émetteurs/récepteurs exempts de licence conformes aux normes Innovation, RSS sans licence de

Sciences et Développement économique Canada. Le fonctionnement est soumis à la suivant deux conditions :

(1) Cet appareil ne doit pas provoquer d'interférences.

(2) Cet appareil doit accepter toute interférence, y compris les interférences susceptibles de provoquer des

Pour se conformer aux exigences d'exposition RF, une distance de séparation minimale de 20 cm doit être maintenue entre le corps

de l'utilisateur et l'appareil.

Table of contents

Other hager Lock manuals

hager

hager 3800 Series User manual

hager

hager 2941 User manual

hager

hager 3500 Series Service manual

hager

hager 3470 User manual

hager

hager 2942 Service manual

hager

hager 3600 Series Service manual

hager

hager 3700 Series Service manual

hager

hager 9458 Service manual

hager

hager 3800 Series User manual

hager

hager 3220 Service manual