M-LOCKS ML6740 User manual

Other M-LOCKS Lock manuals

M-LOCKS

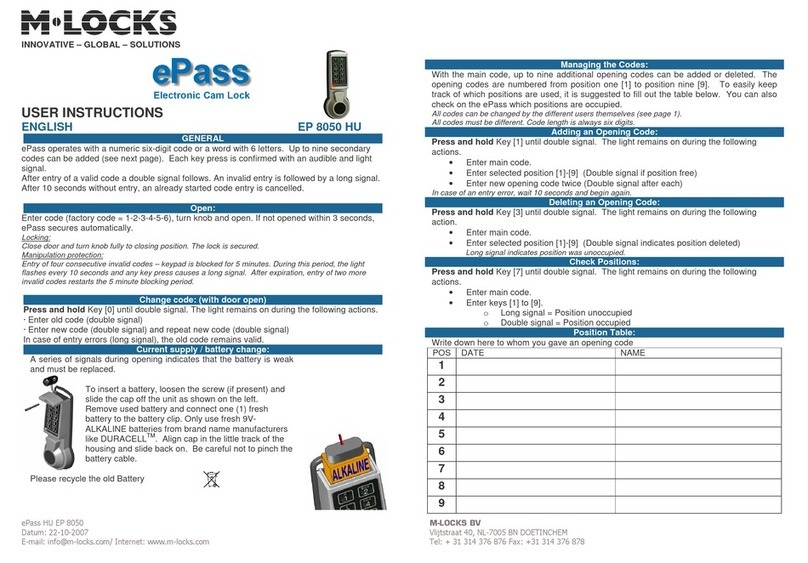

M-LOCKS E-Pass User manual

M-LOCKS

M-LOCKS EM3020 User manual

M-LOCKS

M-LOCKS EP 8050 HU User manual

M-LOCKS

M-LOCKS ML6740 User manual

M-LOCKS

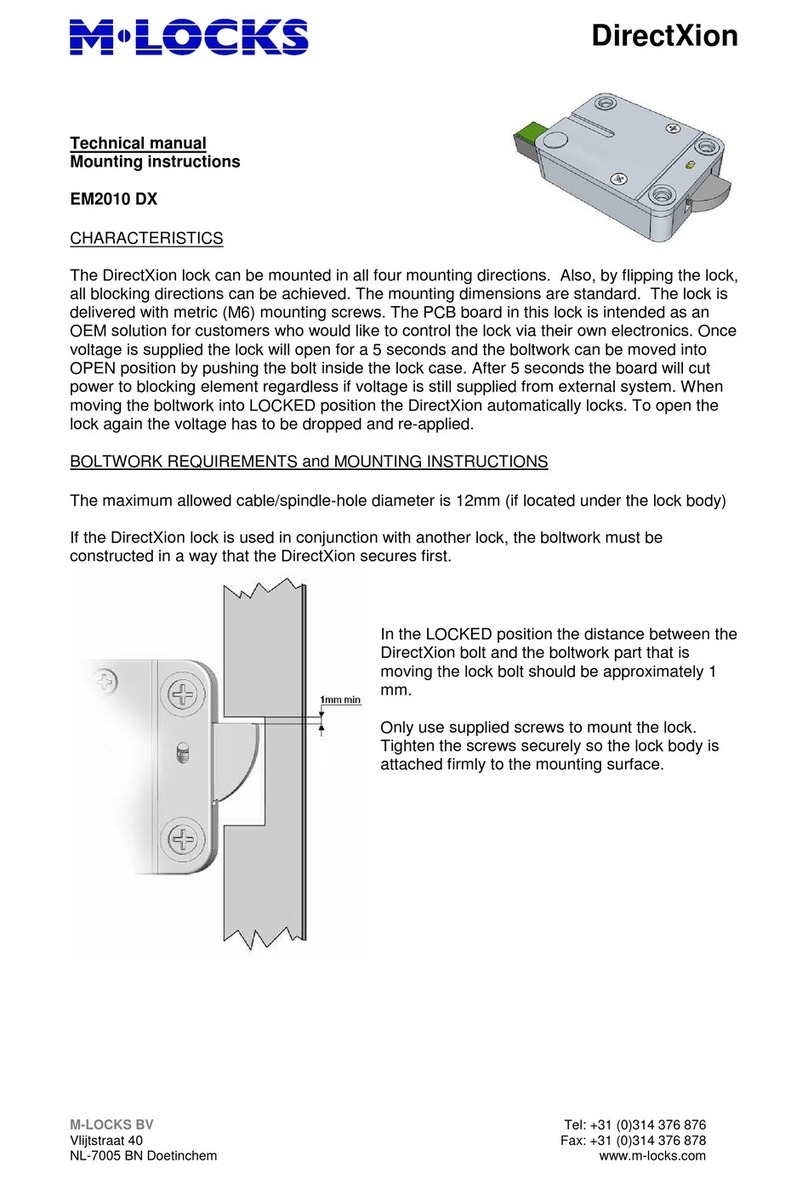

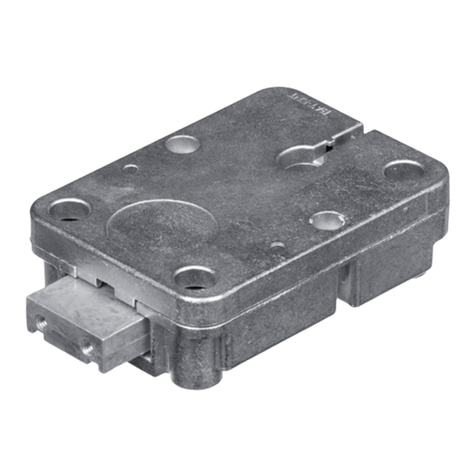

M-LOCKS DirectXion EM2010 DX User manual

M-LOCKS

M-LOCKS T6530 User manual

M-LOCKS

M-LOCKS EM1620 User manual

M-LOCKS

M-LOCKS Rotobolt EM2050 User manual

M-LOCKS

M-LOCKS E-Pass User manual

M-LOCKS

M-LOCKS Tantum Basic User manual

M-LOCKS

M-LOCKS Basic line Series User manual

M-LOCKS

M-LOCKS E-Pass EP8050HL User manual

M-LOCKS

M-LOCKS EuroLine MODULAR Series User manual

M-LOCKS

M-LOCKS EM1620 User manual

M-LOCKS

M-LOCKS RotoBolt User manual

M-LOCKS

M-LOCKS Euroline EC10-40 User manual

M-LOCKS

M-LOCKS EuroLine Modular Series User manual

M-LOCKS

M-LOCKS EC1070 EuroLine series User manual

M-LOCKS

M-LOCKS Rotobolt EM2050 User manual

M-LOCKS

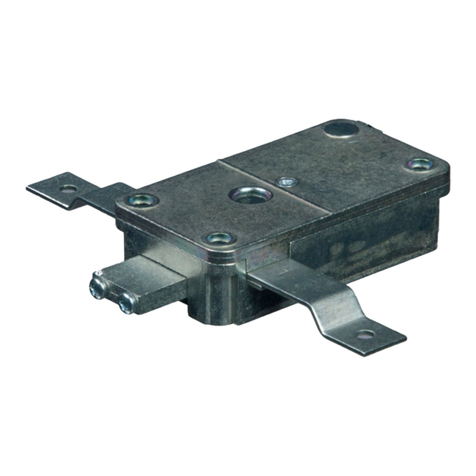

M-LOCKS Straightbolt EM3520 User manual

Popular Lock manuals by other brands

Auslock

Auslock T11 user manual

Stealth SAFES

Stealth SAFES ShadowVault Instructions & Troubleshooting

Knox

Knox KeySecure 5 Admin & user guide

Kwikset

Kwikset 48334/01 Quick installation guide

Metra Electronics

Metra Electronics Door Access Terminal Combo Technical manual

Kilitronik

Kilitronik miniK10m operating manual