1-1

5 - DASH / AUTO

SECTION 1 – INTRODUCTION

A WORD FROM HAGIE

MANUFACTURING COMPANY

Congratulations on the purchase of your

DTS10 Sprayer! Read this operator’s manual

and become familiar with operating procedures

and safety precautions before attempting to

operate your sprayer.

As with any piece of equipment, certain

operating procedures, service, and maintenance

are required to keep your machine in top running

condition. We have attempted herein to cover all

of the adjustments required to fit varying

conditions. However, there may be times when

special care must be considered.

NOTE: The operator is responsible for

inspecting the machine and having parts

repaired or replaced when continued use

of the product causes damage or

excessive wear to other parts.

Hagie Manufacturing Company reserves the

right to make changes in the design and material

of any subsequent sprayer without obligation to

existing units.

Thank you for choosing a Hagie sprayer and

we ensure you of our continued interest and

support in its optimal performance for you. We

are proud to have you as a customer!

ABOUT THIS MANUAL

This manual will aid you in the proper

operation and service of your machine. It is the

responsibility of the user to read the operator’s

manual and comply with the correct and safe

operating procedures, as well as maintain the

product according to the service information

provided in the Maintenance and Storage

Section elsewhere in this manual.

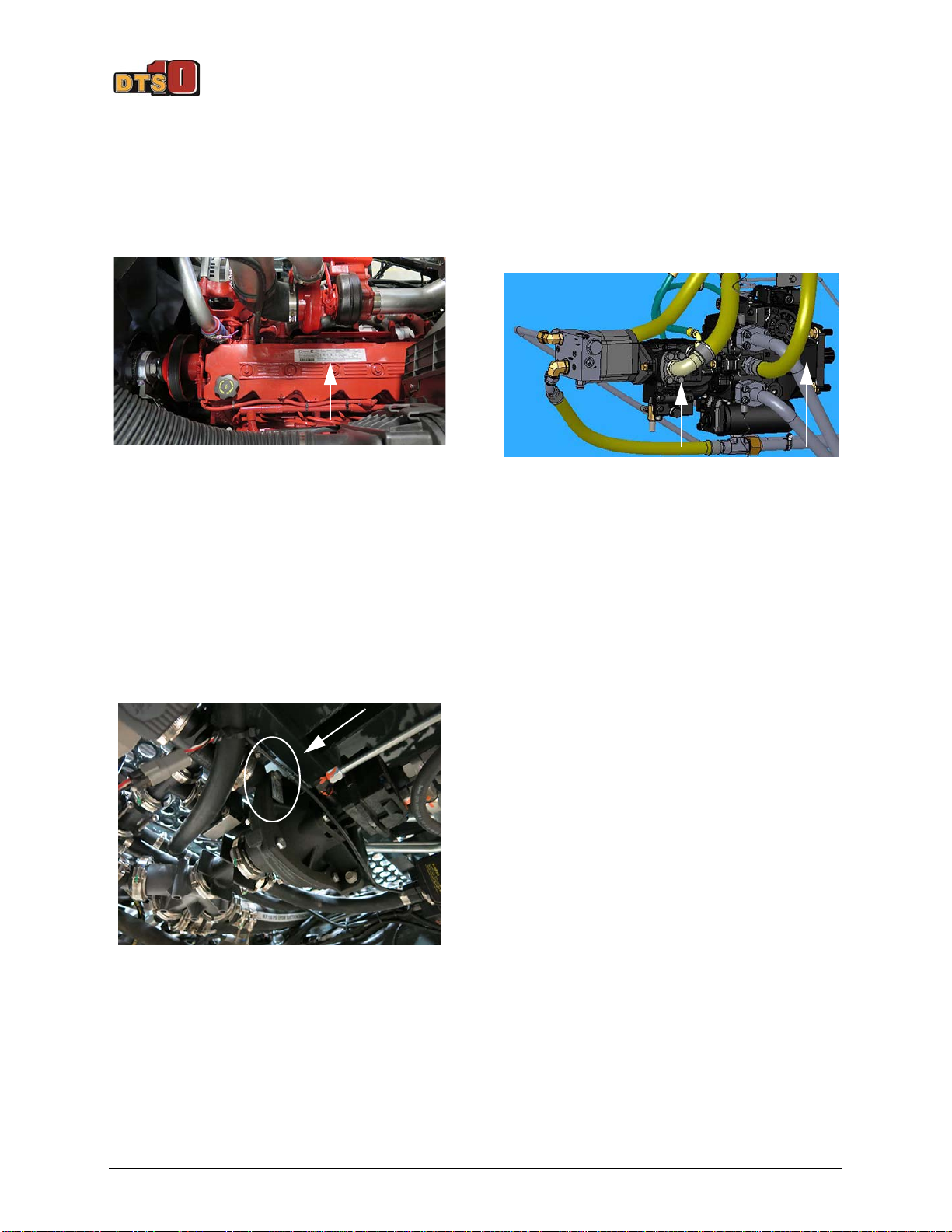

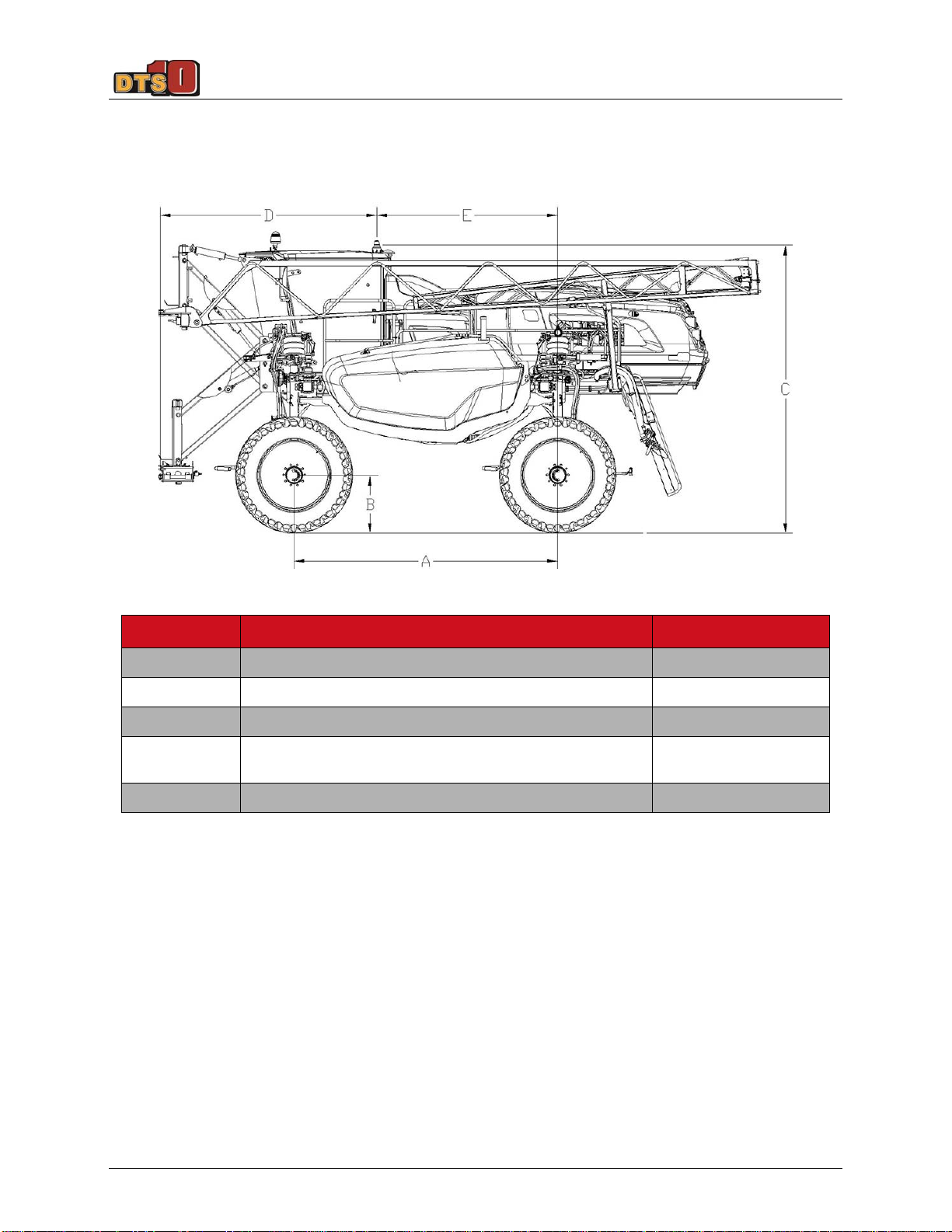

Photographs and illustrations used in this

manual are of general nature only. Some of the

equipment and features shown may not be

available on your machine.

Information described in this manual was

correct at the time of printing. Because of Hagie

Manufacturing Company’s continuous product

improvement, certain information may not be

included in this manual. To obtain the most

current operator’s manual for your machine,

please visit www.hagiehelp.com.

Keep this manual in a convenient place for

easy reference. This manual is considered a

permanent fixture of the product. In the event of

resale, this manual must accompany the

machine.

If you do not understand any part of this

manual or require additional information or

service, contact your local John Deere dealer for

assistance.

SAFETY MESSAGES USED IN

THIS MANUAL

The following safety messages found

throughout this manual alert you of situations

that could become potentially dangerous to the

operator, service personnel, or equipment.

NOTICE

Any pictures or illustrations contained

within this manual that depict situations

with shields, guards, rails, or lids

removed are for demonstration only.

Keep all shields and safety devices in

place at all times.

DANGER

This symbol indicates a hazardous

situation which, if not avoided, will result

in serious injury or death.