for gaugemanifold. Then connect the projection of charge hose (center) for gau-

gemanifold into vacuum pump.

Open the handle at Iow in

2. gaugemanifold, operate vacuum pump. If the scale-

moves of gause (Iow) reach vacuum condition in a moment, check 1. again.

Vacuumize for over 15min.And check the level gauge which should read -0.1MPa

3.

(76 cm Hg) at Iow pressure side. After the completion of vacuumizing, close the

handle ‘Lo’ in gaugemanifold and stop the operation of the vacuum pump. Check

conditionofthescaleandholditfor1- min.Ifthescale-movesbackinspiteof

tightening, make aring work again, the return to the beginning of 3 .

Open

Openthevalverodforthe2-wayvalvetoanangleof4. anticlockwise 90 degrees.

After 6 seconds, close the 2-way valve and make the inspection of gas leakage.

No gas leakage?

5.

Detach the charge hose6. fromtheserviceport,open2-wayvalveand3-way.Turn

thevalverodanticlockwiseuntilhittinglightly.

In case of gas leakage, tighten parts of pipe connection. If

leakagestops,thenproceed6.steps

If it does not stop gas leakage, discharge whole refrigerants from the service

port. After aring work again and vacuumize, ll up prescribed

refrigerant from the gas cylinder.

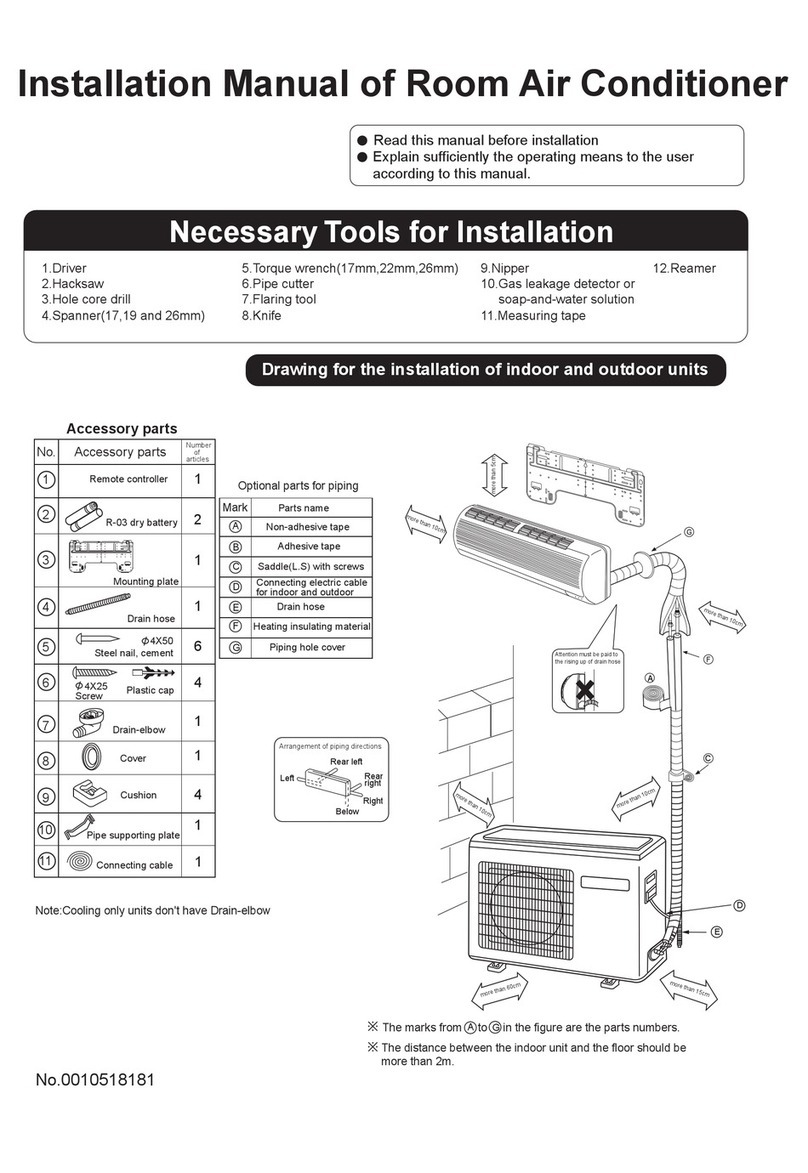

Anti countercurrent joint

Gaugemanifold(for R410A)

2-way valve Liquid Side

3-wayvalveGasSide

Vacuum pump(for R410A)

Tube(for R410A)

Close

2-way valve

3-way valve

Open 90O

2-way valve

3-way valve

2-way valve 3-way valve

2-way valve

3-way valve

Valve rod cap

Valve rod cap

Service port cap

To prevent the gas leakage, turn the service port’scap,thevalve rod’scapfor2-way

valve and 3-way’s a little more than the point where the torque increases suddenly.

After attaching the each caps, check the gas leakage around the caps.

7.

8.

Step 1. Step 2.

Step 3.

Step 7.

Step 6.

Step 4.

The power source must be exclusively used for air

ƽconditioner. (Over I0A)

In the case of installing an air conditioner in a moist place,

ƽplease install an ea-

For installation in other places, use a circuit breaker as far

ƽas possible.

Pipe cutting is carried out with a pipe cutter and burs must

ƽbe removed.

After inserting the are nut, aring work is carried out.

ƽ

Iftherefrigerantoftheairconditionerleaks,itisnecessarytodischargeallthe

ƽ

refrigerant. Vacuumize rst, then charge the liquid refrigerant into air conditio-

neraccordingtotheamountmarkedonthenameplate.

Please do not let other cooling medium, except specied one (R410A), or air

ƽ

enter into the cooling circulation system. Otherwise, there will be abnormal

highpressureinthesystemtomakeitcrackandleadtopersonalinjuries.

Power Source Installation

Cutting and Flaring Work of Piping

CAUTION

FlaretoolforR410A Conventionalaretool

Clutch-type clutch-type(Rigid-type) Wing-nut type (Imperial-type)

A 0~0.5mm 1.0~1.5mm 1.5~2.0mm

rth leakage breaker.

Lean Damage of are Crack Partial Too outside

Correct Incorrect

On Drainage

It becomes

high midway.

The gap with the

ground is too small.

There is the bad

smell from a ditch

It waves.

The end is imm-

ersedinwater.

Pleaseinstallthedrainhosesoastobedownwardslopewithoutfail.

Please don’t do the drainage as shown below.

ƽ

ƽ

Please pour water in the drain pan of the indoor unit, and

ƽ

is carried out surely to outdoor.

In case that the attached drain hose is in a room, please

ƽapplyheatinsulationto

Less than

5cm

conrm that drainage

it without fail.

4

Check Items for Test Run

Put check mark in boxes

Gasleakfrompipeconnecting?

Heat insulation of pipe connecting?

Are the connecting wirings of indoor and outdoor rmly

Is the connecting wiring of indoor and outdoor rmly xed?

Is drainage securely carried out?

Is the earth line securely connected?

Istheindoorunitsecurelyxed?

Is power source voltage abided by the code?

Is there any noise?

Isthelampnormallylighting?

Arecoolingandheating(wheninheatpump)performednormally?

Is the operation of room temperature regulator normal?

Pleasekindlyexplaintoourcustomershowtooperate

throughtheinstructionmanual.

Check for Installation and Test Run

Ƶ

inserted to the terminal block?

Ƶ

1

1+2= kg

R410A

2kg

2=

1=

B

C

D

FE

kg

A

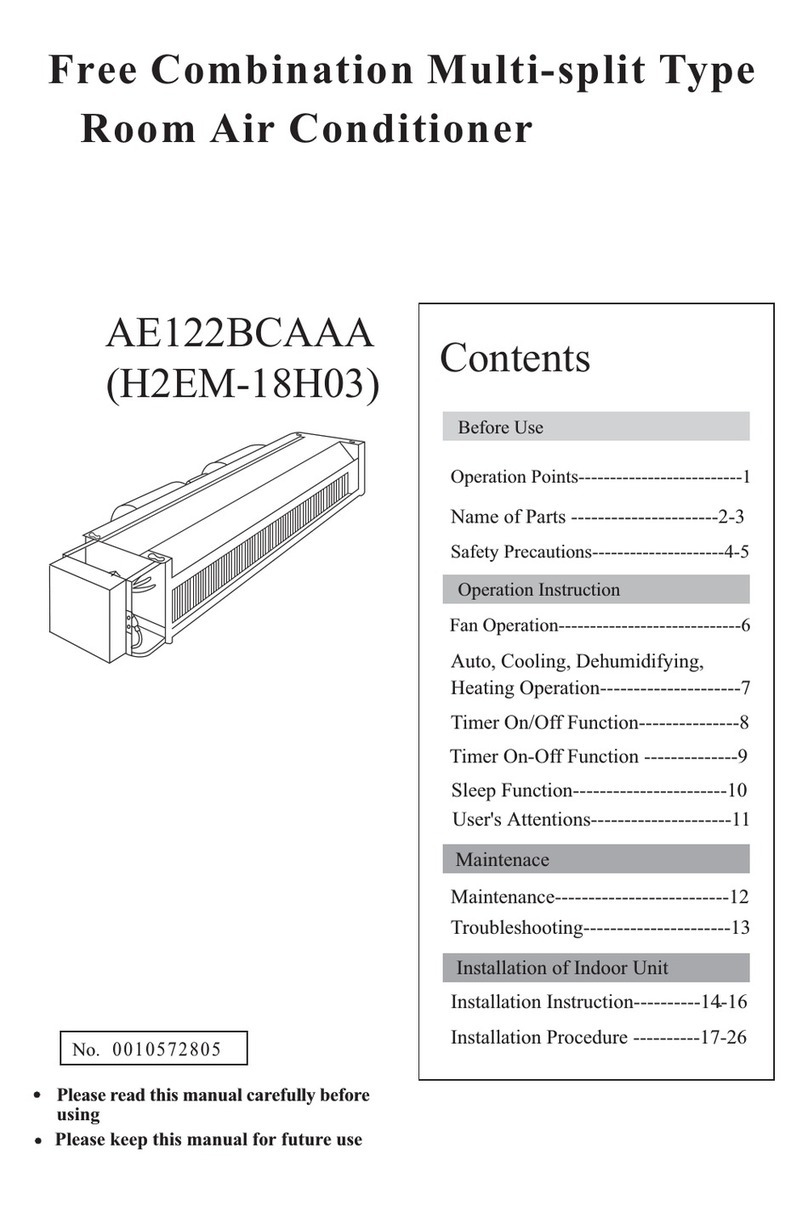

This product contains fluorinated greenhouse gases covered by

the Kyoto Protocol. Do not vent into the atmosphere.

Refrigerant type:R410A

GWP* value:1975

GWP=global warming potential

Please fill in with indelible ink,

on the refrigerant charge label supplied with the product.

The filled out label must be adhered in the proximity of the product

charging port (e.g. onto the inside of the stop value cover).

A contains fluorinated greenhouse gases covered by the Kyoto

Protocol

B factory refrigerant charge of the product: see unit name plate

C additional refrigerant amount charged in the field

D total refrigerant charge

E outdoor unit

F refrigerant cylinder and manifold for charging

Contains fluorinated greenhouse gases

covered by the Kyoto Protocol

Refrigerant charge labelƵ

Flare tooling die 1.Cut pipe 2.Remove burs

3.Insert the are nut 4.Flare pipe

Check Items for Test Run