7. MAINTENANCE

Performing proper and periodical maintenance extends the product life. Efficient soldering depends upon

the temperature, the quality and quantity of the solder and flux. Apply the following service procedure as

dictated by the conditions of the usage.

WARNING

Since the handpiece tip/nozzle can reach a very high temperature, please work carefully. Except the case especially indicated,

always turn the power switch OFF and disconnect the power plug before performing any maintenance procedure.

1 Temperature

2. Cleaning

3. After use

4.

When the unit is not

being used and the

auto power shutoff

is not active.

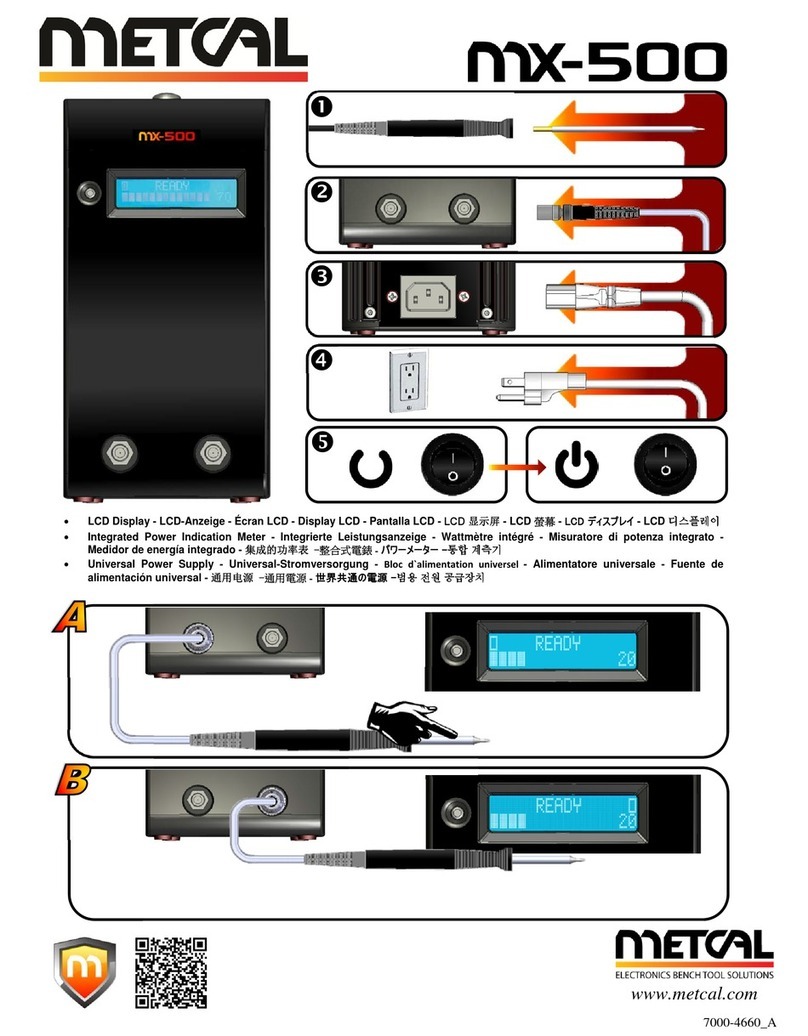

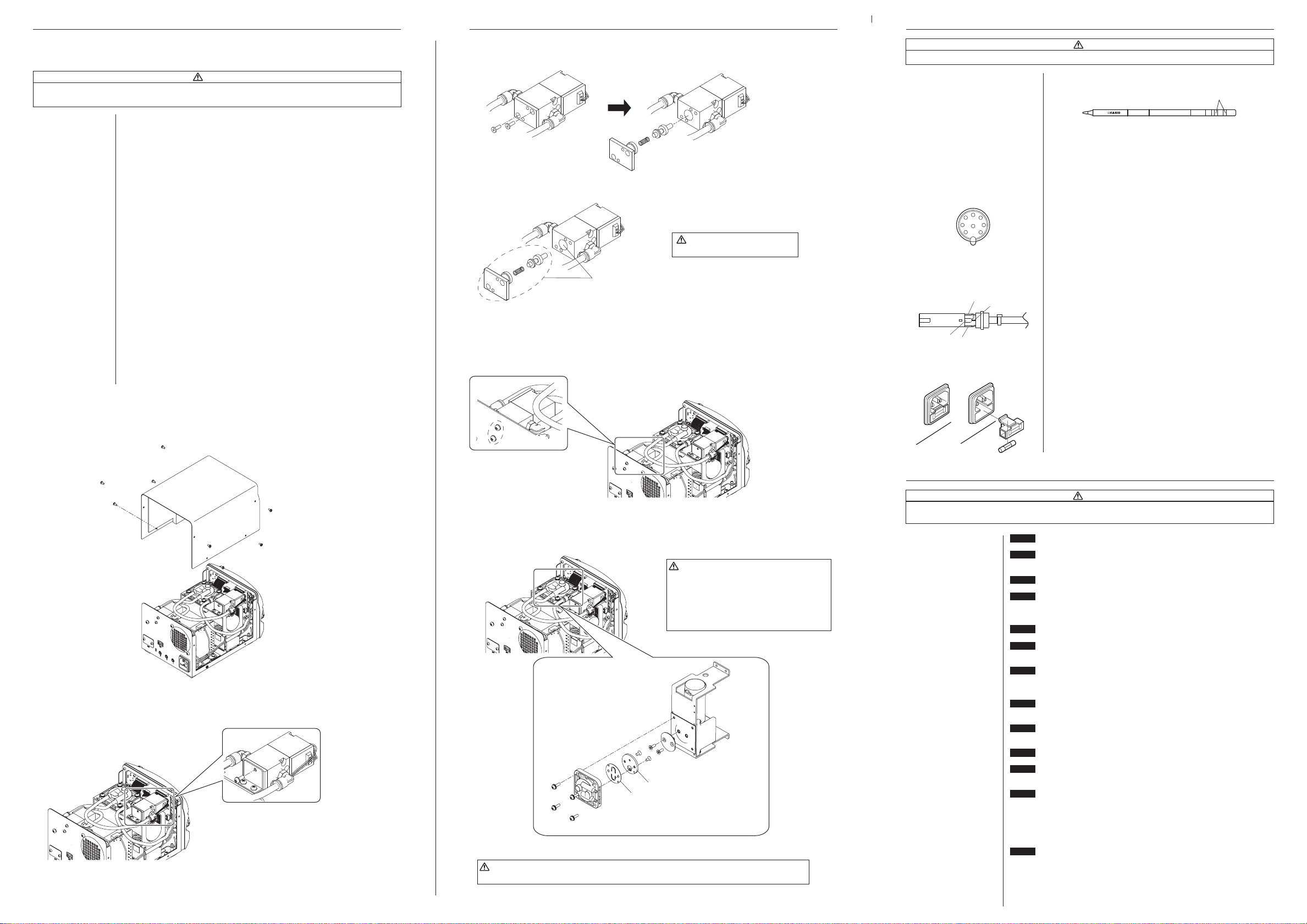

■Maintenance of the electromagnetic valve and pump head

●Remove the cover

When performing maintenance on either the electromagnetic valve or the pump head, remove the

screws holding the cover and take the cover off.

●Electromagnetic valve maintenance

1. Remove the screws holding the electromagnetic valve in place.

2. Remove the bottom of the electromagnetic valve.

3. Clean the parts that have flux attached to them, such as the inside of the electromagnetic valve, with

alcohol.

Clean with alcohol.

Caution

Do not use thinner when cleaning.

4. Assembly is done in the opposite order of disassembly.

*There is one more electromagnetic valve. Remove the screws on the back of the chassis, and from that

point on remove and clean following the same steps.

Remove

the screws.

●Cleaning the pump head

1. Remove the valve and valve guard and remove any attached flux.

Caution

・When the valve guard is difficult to remove,

please warm it with hot air. Please do not try

to forcibly remove it with a screwdriver, etc.

If the valve guard becomes deformed, it will

no longer be airtight.

・Please clean with either alcohol or thinner.

2. Install the valve and valve guard.

Caution

When assembling the pump, please make sure to keep it airtight so that there are no air leaks.

8. CHECKING PROCEDURE

Measure the resistance across this position.

1

4

7

2

8

5

6

3

■Check for a broken heater or

sensor

■Check the grounding line

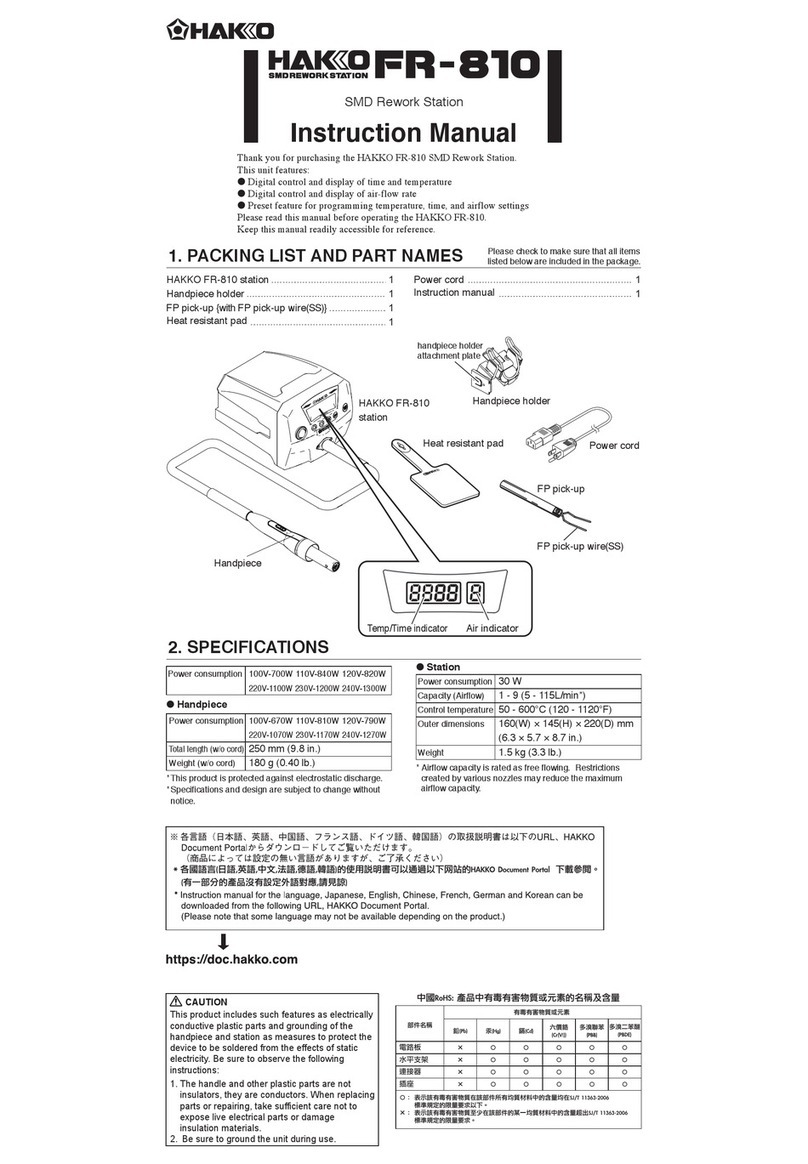

1. Check for a broken heater or sensor

Verify the electrical integrity of the heater and sensor.

Measure the resistance of the heater and sensor while at room

temperature(15〜25℃;59〜77℉). It should be 8 Ω±10%. If

the resistance exceeds these limits, replace the tip.

1. Unplug the connection cord from the station.

2. Measure the resistance value between Pin 2 and the tip.

3. If the value exceeds 2 Ω(at room temperature), perform the

tip maintenance described on section 2, maintenance for the

tip. If the value still does not decrease, check the connection

cord for breakage.

WARNING

Unless otherwise directed, carry out these procedures with the power switch OFF and the power UNPLUGGED.

Black

White

Green Red

■Checking the connection cord

for breakage (HAKKO FM-2027)

■Replacing the fuse

1. Remove the soldering tip and the sleeve assembly.

2. Turn the front piece of the HAKKO FM-2027 counterclockwise

and remove the cover.

3. Measure the resistance values between the connector and the

lead wires at the socket as follows:

Pin 1 – Red Pin 2 – Green

Pin 3 – Black Pin 5 – White

If any value exceeds 0 Ωor is ∞, replace the HAKKO FM-2027.

1. Unplug the power cord from the power receptacle.

2. Remove the fuse holder.

3. Replace the fuse.

4. Put the fuse holder back in place.

High temperatures shorten tip life and may cause thermal shock to components.

Always use the lowest possible temperature. The excellent thermal recovery

characteristics of the HAKKO FM-206 ensure effective soldering at low

temperatures.

Always clean the tip/nozzle before use to remove any residual solder or flux

adhering to it. Use the tip cleaner or cleaning sponge. Contaminants on the tip

have many deleterious effects, including reduced heat conductivity, which

contribute to poor performance.

Always clean the tip/nozzle and coat it with fresh solder after use. This guards

against oxidation.

This procedure, if followed daily, will materially add to tip life.

a. Set the temperature to 250℃(482℉).

b. When the temperature stabilizes, clean the tip and check the condition of the

tip. If the tip is badly worn or deformed, replace it.

c. If the solder plated part of the tip is covered with black oxide, apply fresh

solder, containing flux, and clean the tip again. Repeat until all the oxide is

removed, then coat the tip with fresh solder.

d. Turn the power OFF and remove the tip, using the heat resistant pad. Set the

tip aside to cool.

e. Remaining oxides, such as the yellow discoloration on the tip shaft, are not

harmful but can be removed with isopropyl alcohol.

Never allow the unit to idle at a high temperature for extended periods. This will

allow the tip to become oxidized. Turn the power switch OFF. If it is to be out of

service for several hours, it is advisable to pull the power plug as well.

Valve

Valve guard

Clean the pump head, valve

and valve guard.

Pump head disassembly

*It is resting on its side.

*Please replace the valve if it is

deformed or hardened.

Pump head

CHECK

: Is the power cord and/or the connection plug disconnected?

ACTION

: Connect it.

CHECK

: Is the fuse blown?

ACTION

: Replace the fuse. If the fuse blows again, send the unit in for repair.

CHECK

: Is the tip inserted properly?

ACTION

: Insert the tip completely.

CHECK

: Is the connection cord and/or the heater/sensor broken?

ACTION

: If the cord assembly is broken, replace the soldering iron, desoldering tool or

handpiece.

CHECK

: Is the tip temperature too high?

ACTION

: Set the appropriate temperature.

CHECK

: Is the tip contaminated with oxide?

ACTION

: Remove the oxide

CHECK

: Is the connection cord broken?

ACTION

: If the cord assembly is broken, replace the soldering iron, desoldering tool or

handpiece.

CHECK

: Is the tip contaminated with oxide?

ACTION

: Remove the oxide

CHECK

: Is the handpiece connected?

ACTION

: Remove and reinsert the handpiece.

CHECK

: Is the tip too small for the items to be soldered?

ACTION

: Use a tip with a larger thermal capacity.

CHECK

: Is the setting value for the low-temperature alarm tolerance too low?

ACTION

: Increase the setting value.

CHECK

: Is the appropriate HAKKO tip/nozzle being used?

ACTION

: Turn the power switch OFF and insert the genuine HAKKO tip/nozzle. Turn the

power switch ON.

ACTION

: Turn the power switch OFF and insert the genuine HAKKO tip. Turn the power

switch ON.

CHECK

: Is the tip left on the wet cleaning sponge?

ACTION

: Turn the power switch off. Turn the power switch on again after removing the

tip from the wet cleaning sponge.

ACTION

: Turn off the power switch. Turn on the power switch again.

If the “Zero-Cross Error” / “System Error” continues to be displayed after

turning on the power switch, contact your HAKKO representative.

9. TROUBLE SHOOTING GUIDE

WARNING

BeforecheckingtheinsideoftheHAKKOFM-206orreplacingparts,besuretodisconnectthepower

plug.Failuretodosomayresultinelectricshock.

●The unit does not operate

when the power switch is

turned on.

●The tip does not heat up.

“Sens Error” is displayed.

●Solder does not wet the tip.

●The tip temperature is too

high.

●The tip temperature is too

low.

●“Grip Error” is displayed.

●The low-temperature alarm

tolerance error “Low Temp”

is displayed.

●

Heater terminal short circuit

error “Heater Short Error” is

displayed.

●“Heat up Error” is displayed.

(for MODEL FM-2023)

●“Drive Error” is displayed.

(for MODEL FM-2023)

●“Zero-Cross Error” or

“System Error” is displayed.