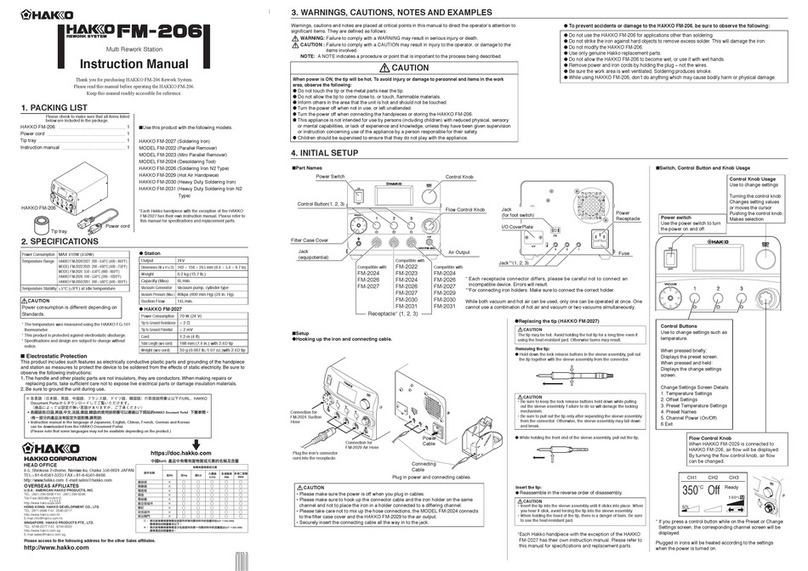

5. OPERATION 5. OPERATION 6. PARAMETER SETTING

Turn the power on while pressing the button. Perform the setting to select the desired parameter No..

Press the or button to change the values, and press the button to execute.

After changing parameters, press and hold the button down for at least two seconds until is displayed.

At this time, you can switch between and by pressing the or button. Select if you

are finished making changes or if you need to go back and make more changes. Press the button to

confirm you selection.

Changes will not be completed until is displayed and you press the button.

Please note that no changes will be made if you turn off the power while making changes.

In addition to the procedure described remove above, HAKKO FR-810B includes a preset mode allowing the

selection of temperature, time, and airflow from the options you define (up to 5 temperature/time/airflow

settings can be programmed). Enter the parameter setting to change the mode.

(Please refer to [6. PARAMETER SETTING].)

Initial preset settings:

The initial number of active presets is set to 5 at the factory.

The default selected preset is set to at the factory.

Example : Changing preset selection from preset No. 3 to No. 1.

Control will begin with new preset setting.

The procedure for making changes to the preset temperatures, timer and air flow is the same as the

“Setting/Changing the Temperature and Timer” and “Setting of the air flow”.

Example: Changing the offset setting from 0℃to -30℃

● Preset mode

● Offset mode {Setting is available within the range of ±50°C (90°F)}

7. TROUBLE SHOOTING GUIDE

WARNING

BeforecheckingtheinsideoftheHAKKOFR-810Borreplacingparts,besuretodisconnectthepower

plug.Failuretodosomayresultinelectricshock.

In this station, when you turn on “Preset mode” and “Chain Presets function” in the parameter settings

and set the timer for each preset, available presets are called in from “P-1” to “P-5” allowing you to

simulate up to a 5 step rework profile.

A preset in which “000” is set in the timer setting is skipped and the next preset is automatically started.

When the handpiece is placed in the holder, the automatic sleep function starts working (by default).

Pressing the START/STOP (HOT AIR) button in this state will not turn on the station. If the handpiece is

placed in the holder while it is blowing hot air, start of automatic cooling is forced before the stop of operation.

The auto shutoff function works by default after the station is idle for 30 minutes and it automatically

enters a power save state.

With this function enabled, if you press the “S” button ( button) again during cooling, cooling is stopped.

This function is used when working temperature is low and you do not have to wait until automatic stop is

made. When the set temperature is 380°C or more, the function is unavailable.

● Chain Presets function

● Auto sleep function

● Auto shutoff function

● Forced cooling bypass function

● Check of settings

Other main functions

CAUTION

When installing this station, do not place flammable substances behind the outlet of the handpiece. If

the handpiece is placed in the iron holder while blowing hot air, serious accidents such as fire may be

caused by hot air.

CAUTION

Please do not use this function at high temperatures.

Each of the set values is displayed for two seconds, and each change is finalized.

Temp. : 100℃ Timer : “−−−” Air flow : 5

Temp. : 300℃ Timer : “−−−” Air flow : 5

Temp. : 500℃ Timer : “−−−” Air flow : 5

Temp. : 200℃ Timer : “−−−” Air flow : 5

Temp. : 400℃ Timer : “−−−” Air flow : 5

CAUTION

If the total of a set value and an offset value exceeds 600°C, the exceeding portion in the offset value is

not effective.

* Timer function

In this product, setting the timer allows you to control the time during which hot air is blown.

Either of the following two modes is selectable by parameter setting: Open Timing in which count is

started from the time when temperature reaches the set temperature and Closed Timing in which count is

started upon start. The timer setting range is 001 to 999 seconds.

(When not using the timer function, select “---”. When set in the timer setting “000” , don't work. )

Select and input three letters for password

from six letters on the right.

Example: The procedure for changing the set temperature when the unit is restricted by a password.

(Password is "AbC")

The unit will move to the change setting screen for each mode after entering the password. Please change

the setting for each mode according to the procedure covered in this manual.

Pressing the button once allows you to check the settings of the set temperature and set

time in this order. 2016.4

MA02790XZ160404

Example : When the set temperature is 350°C and the timer setting is 150 seconds.

Press and hold the

button for more

than one second.

Press the

button once.

Press the

button thrice.

Press the

button.

Press the

button.

Press the

button.

© 2016 HAKKO Corporation. All Rights Reserved.

OVERSEAS AFFILIATES

U.S.A.: AMERICAN HAKKO PRODUCTS, INC.

TEL: (661) 294-0090 FAX: (661) 294-0096

Toll Free (800)88-HAKKO

4 2 5 5 6

http://www.hakkousa.com

HONG KONG: HAKKO DEVELOPMENT CO., LTD.

TEL: 2811-5588 FAX: 2590-0217

http://www.hakko.com.hk

SINGAPORE: HAKKO PRODUCTS PTE LTD.

TEL: 6748-2277 FAX: 6744-0033

http://www.hakko.com.sg

Please access to the following address for the other Sales affiliates.

http://www.hakko.com

HEAD OFFICE

4-5, Shiokusa 2-chome, Naniwa-ku, Osaka 556-0024 JAPAN

TEL:+81-6-6561-3225 FAX:+81-6-6561-8466

● Theunitdoesnotoperatewhenthe

powerswitchisturnedon.

● isdisplayed

● isdisplayed

● isdisplayed

Is the fuse blown?

Investigate why the fuse blew and then replace the fuse. If

the cause can not be determined, replace the fuse. If the fuse

blows again, send the unit in for repair.

Is the sensor broken?

Measure the resistance value of the sensor. When the resistance

value is ∞, replace the heater. Details on the procedure of

resistance value measurement are described in the corresponding

manual in HAKKO Document Portal. Please refer to the document.

Is the heater broken?

Measure the resistance value of the heater. The correct values are

approximately: 17Ω (±10%120V and normal temperature). When

the resistance value is not within the normal range, replace the

heater.

Details on the procedure of resistance value measurement are

described in the corresponding manual in HAKKO Document Portal.

Please refer to the document.

The fan may be broken. Replace the fan with a new one.

CHECK

:

ACTION

:

CHECK

:

ACTION

:

CHECK

:

ACTION

:

ACTION

:

Didn't we just go over the parameters and

what they mean and how to change them?

The document on the portal will contain

information on troubleshooting and

replacement parts.

The HAKKO FR-810B has the following parameters:

Parameter No.

Parameter name

℃ / ℉ selection

Auto sleep ON/OFF setting

Auto shutoff ON/OFF setting

Setting mode selection

The number of preset *

Password setting

Temperature setting mode **

Preset selection mode**

Offset setting mode**

Air flow mode**

Password***

Auto shutoff time setting

Timer mode

Forcedcoolingbypass

PresetconnectionON/OFFsetting

Value

C/F

0:OFF/1:ON

0:OFF/1:ON

0:Normal/1:Preset

(2pcs)〜 (5pcs)

0:Open/1:Partial/2:Restricted

:○/ :×

:○/ :×

:○/ :×

:○/ :×

Select three letters

30〜60min(Set in units of minutes)

o:OpenTiming/c:ClosedTiming

0:OFF/1:ON

0:OFF/1:ON

Initial value

℃

1

1

0

0

-

30

o

0

0

* It is displayed only when "1:Preset mode" is selected in the setting mode.

** It is displayed only when "1:Partial" is selected in the password setting.

***It is displayed only when either "1:Partial" or "2:Restricted" is selected in the password setting.

*Preset selection screen

Press the

button once.

Press the

button twice.

Press the

button.

The letters

for password

Press and hold the

button for more

than one second.

Press the

button once.

Press the

button twice.

Press the

button three times.

Press the

button.

Press the

button.

Press the

button.

CAUTION

・If the password you entered is incorrect, the display will show

three dashes for you to re-enter the password.

・If you enter the password incorrectly twice in a row, the display

will return to the previous screen.

電路板

動力單元

真空泵

插座

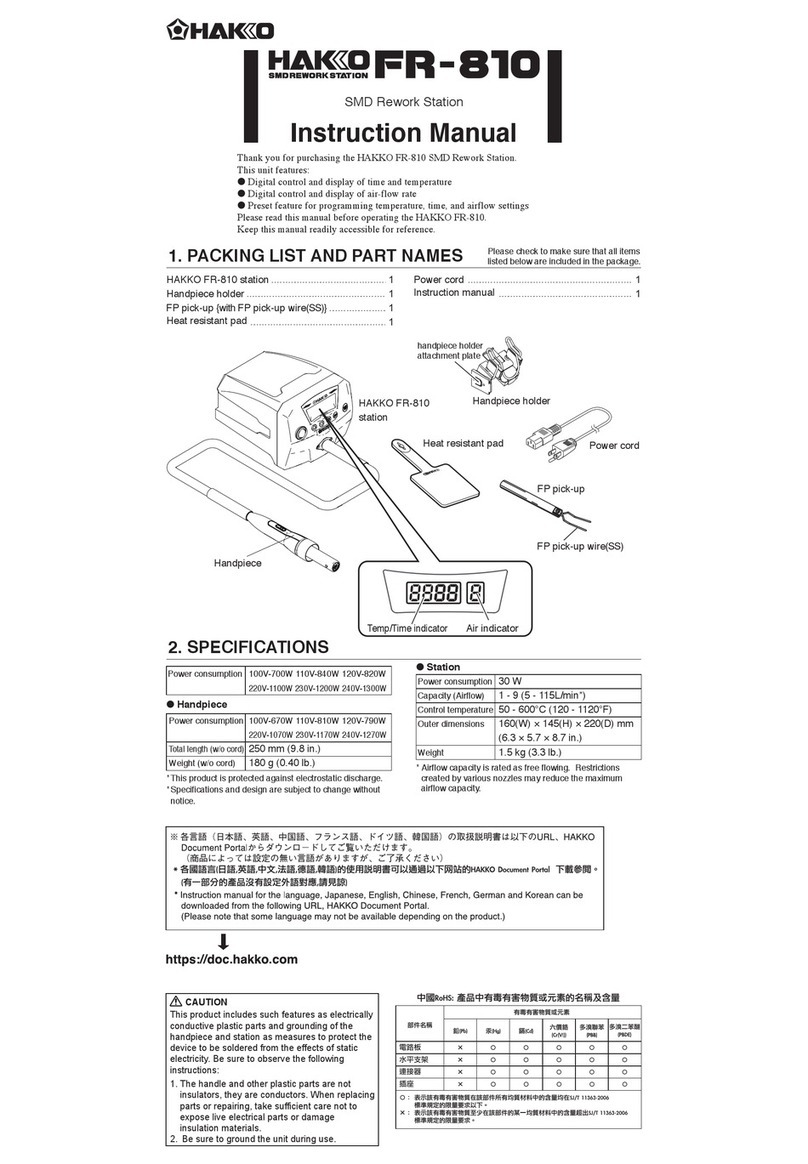

●Setting of the air flow

Pressing the AIR button in the station causes the LED for AIR display to blink and allows

you to change air flow. The air flow setting range is 1 to 9.

Actual airflow may be affected by the size and shape of the nozzle(s) used.

Example: Changing the air flow setting from 5 to 7

Example : When the set temperature is 300°C and the timer setting is ---.

Finished

●Setting/Changing the Temperature and Timer

NOTE:

After accepting the value for the ones digit for temperature, you will have the option to set the timer

starting over with the hundreds digit.

The factory default : "Temperature 300℃" "Timer ーーー(No setting)"

Setting the

Timer

Press the or

button 5 times.

Each of the set values is displayed for

one second, and each change is finalized.

Press the

button.

Press the

button twice.

Press the

button once.

Press the

button twice.

Press the

button.

Press the

button.

Press the

button.

Press the

button.

Press the

button.

Press the

button.

Press the or

button.

Press and hold the

button for more

than one second.

Press the

button 3 times.

1. Setting the Temperature (from 300℃ to 450℃)

2. Setting the Timer (from --- to 130sec)

* When you want to leave the timer "ーーー".

Press the

button once. Finished

● Restriction on setting changes (Password function)

It is possible to restrict certain setting changes to the unit.

There are three choices for the password setting.

Enter the parameter settings to change the mode. (Please refer to [6. PARAMETER SETTING].)

○: You can make changes without entering a password.

△: You can choose whether or not a password is needed to make changes.

×: A password is required to make changes.

Switch to the parameter setting mode

Switch to the temperature setting mode

Switch to the preset selection mode

Switch to the offset setting mode

Make airflow adjustments

0 : Open

○

○

○

○

○

1 : Partial

×

△

△

△

△

2 : Restricted

×

×

×

×

×

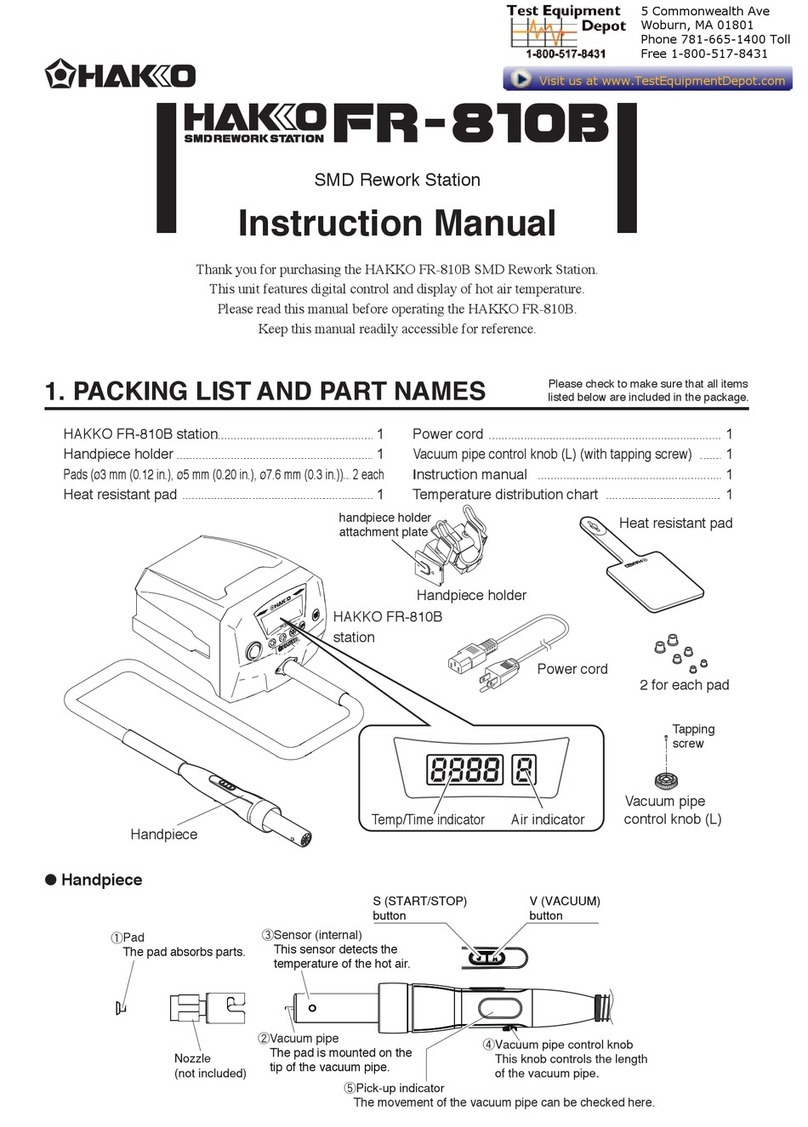

※Vacuum Function

Press the V (Vacuum) button on the handpiece. The vacuum

pump turns ON and the part is held by suction.

P.W.B. P.W.B.

V button

WARNING

Do not stop the hot air by turning the power switch OFF.

If power is turned off after use, there will be no cool-down. To avoid damage to the equipment, do not turn

the power switch OFF until appears on the display.