EN

For your safety

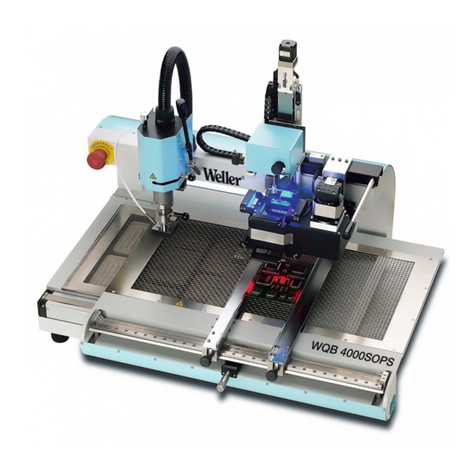

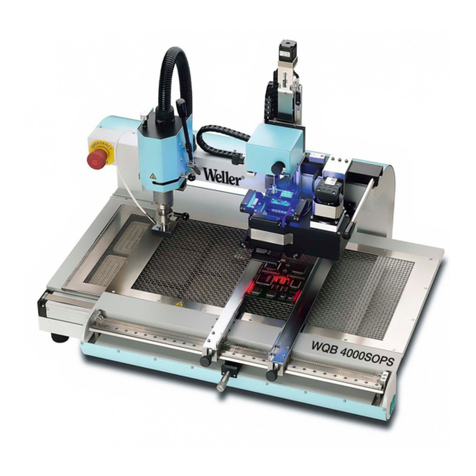

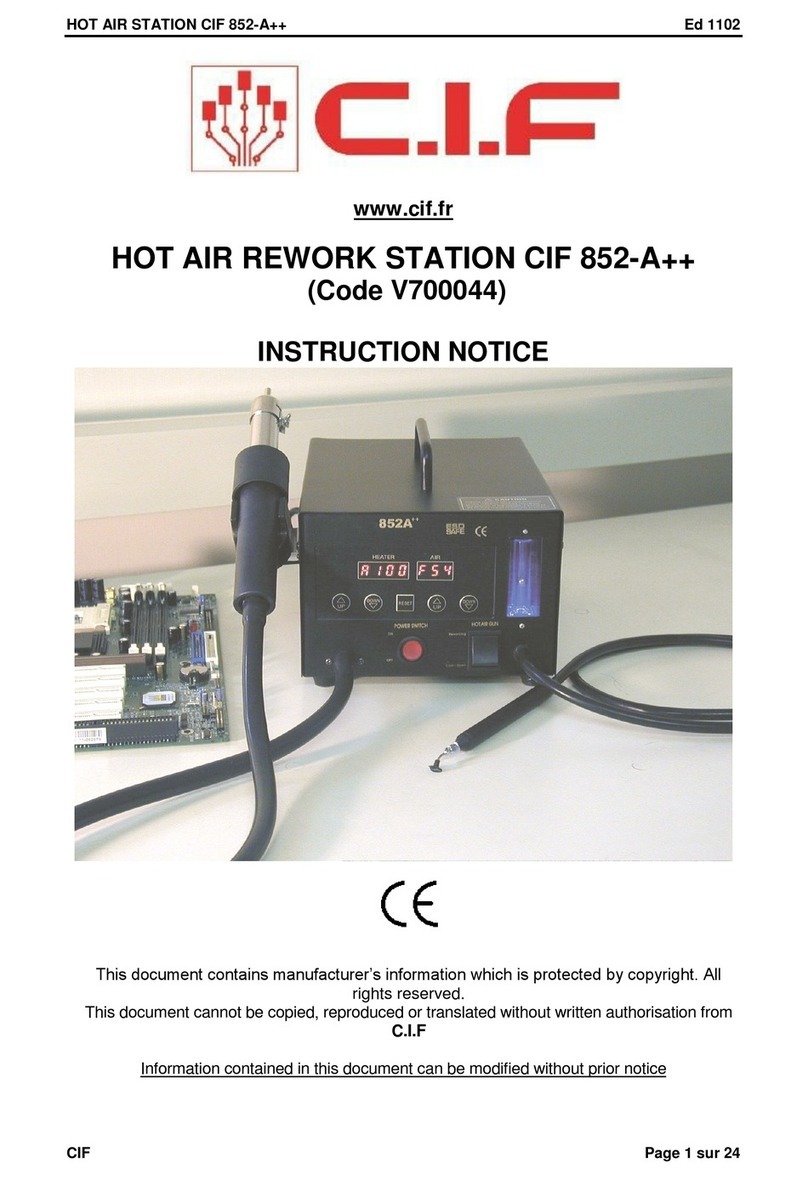

Thank you for the condence you have shown in

buying this device.

The device has been manufactured in accordance

with the most rigorous quality standards which ensu-

re that it operates perfectly.

Read these instructions and the

accompanying safety information

carefully before starting up the device

and starting work with the device.

Keep these instructions in a place that is acces-

sible to all users.

These instructions contain important information

which will help you to start up, operate and service

the device safely and correctly as well as to eliminate

simple faults and malfunctions yourselves.

The device has been manufactured in accordance

with state-of-the-art technology and acknow-

ledged regulations concerning safety.

There is nevertheless the risk of personal injury and

damage to property if you fail to observe the safety

information set out in the accompanying booklet and

the warnings given in these instructions.

Safety information

For safety reasons, children

and youths under the age of 16,

as well as persons who are not

familiar with these operating inst-

ructions, may not use the device.

Children should be supervised in

order to ensure that they do not

play with the tool.

This device is not intended

for use by persons (including

children) with limited physical,

sensory or mental aptitude, or

by persons who lack knowledge

or experience in handling the

device.

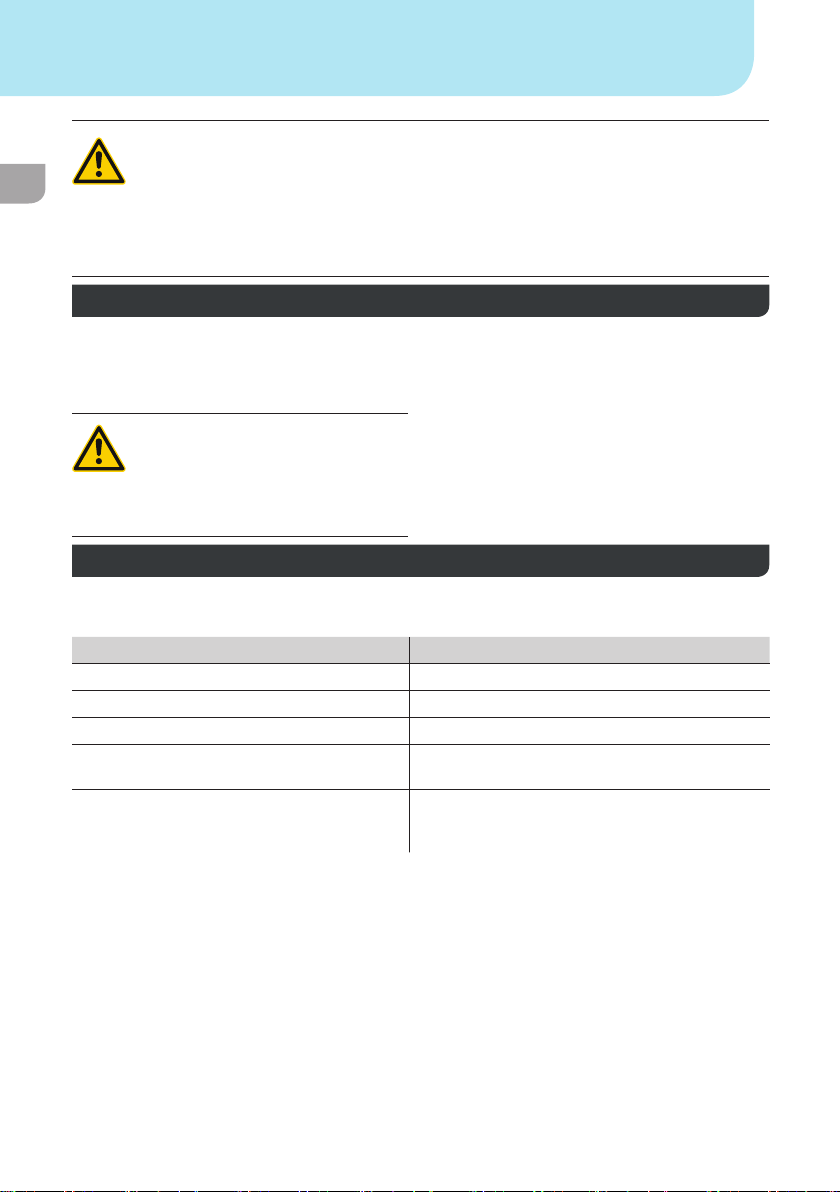

Warning! Electrical shock

Connecting the control unit incorrectly poses a risk of injury due to electric shock and

can damage the device.

Carefully read the attached safety information, the safety information accompanying these

operating instructions as well as the operating instructions for your control unit before putting

the control unit into operation and observe the safety precautions specied therein.

Only connect WELLER WX tools.

Never use the USB port as a power supply for third-party devices.

If the device is faulty, active electrical conductors may be bare or the PE conductor

may not be functional.

Repairs must always be referred to a Weller-trained specialist.

If the electrical tool‘s power supply cord is damaged, this must be replaced with a specially

prefabricated power supply cord available through the customer service organisation.

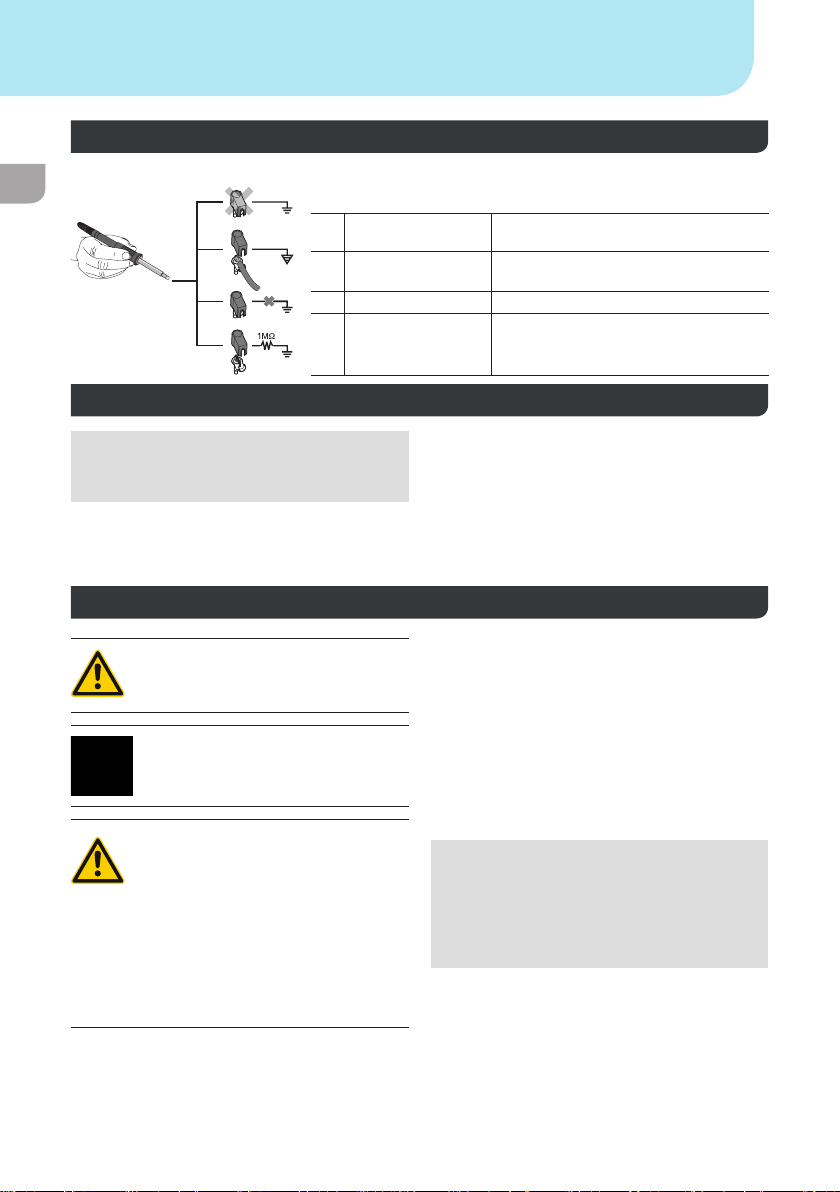

Warning! Risk of burns

Risk of burns from the soldering tool while the control unit is operating. Tools may

still be hot long after they have been switched off.

Always place the soldering tool in the safety rest while not in use.

Only connect the vacuum and hot air at the designated points.

Do not direct hot air soldering tools at people or inammable objects.