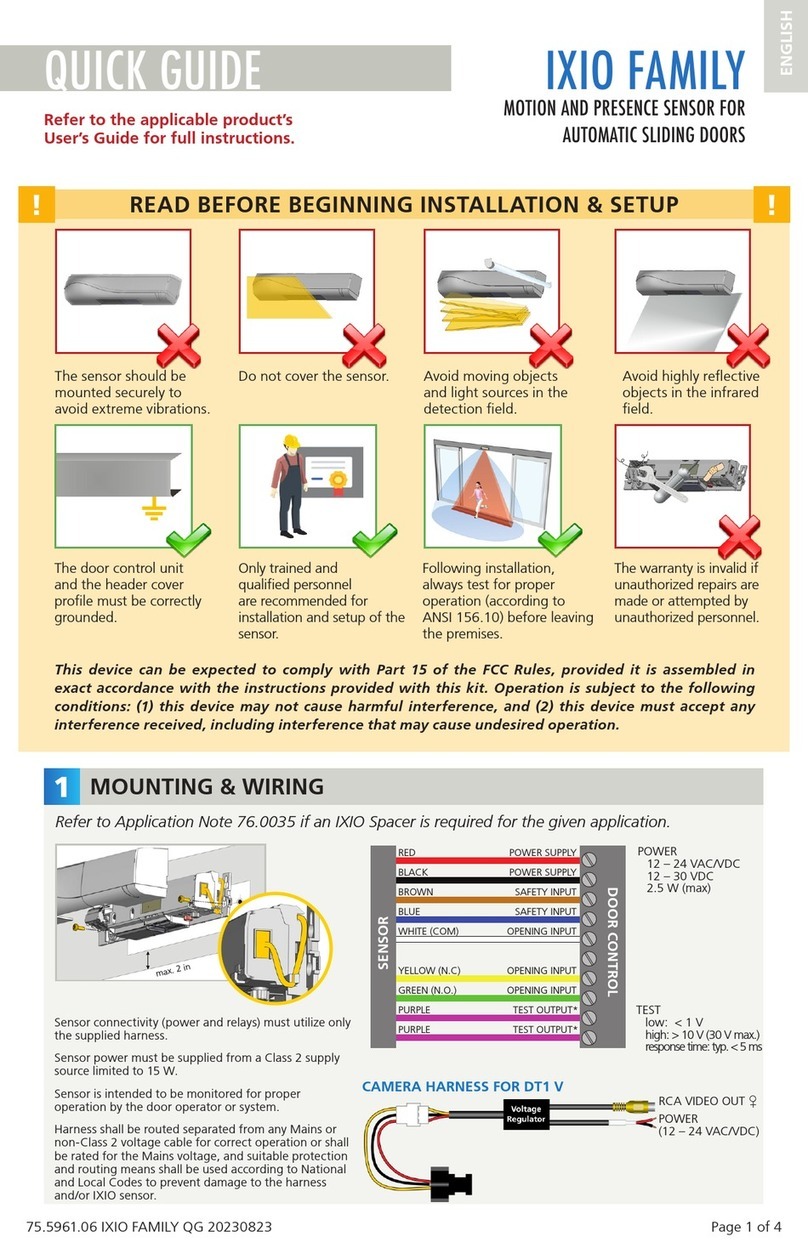

4Sensor Wiring

1. When connecting to a microprocessed control box, the motion output and presence output wires may be connected to separate inputs or may

also be connected to a mutual input. Some controls may only have an activation input, while others may have an activation input, as well as a

safety (or presence) input.

Wiring the G3 to an Automatic Door Control with Separate Activation and Safety Inputs

O

P

T

I

O

N

1

Color Microprocessed Controls

Red 12 to 24 VAC / VDC: -5% to +10%

Black 12 to 24 VAC / VDC: -5% to +10%

White Common at Door Control

Green Activation Input at Door Control

Brown Common at Door Control

Blue Safety Input at Door Control

Wiring the G3 to an Automatic Door Control with Activation and Safety Wired to One Input

O

P

T

I

O

N

2

Color Controls Without Safety Circuit

Red 12 to 24 VAC / VDC: -5% to +10%

Black 12 to 24 VAC / VDC: -5% to +10%

White Common at Door Control

Green Activation Input at Door Control

Brown Common at Door Control

Blue Activation Input at Door Control

Wiring the G3 to an Automatic Door Control with Activation and Safety Signal through Relay Only

O

P

T

I

O

N

3

Color Controls Without Safety Circuit

Red 12 to 24 VAC / VDC: -5% to +10%

Black 12 to 24 VAC / VDC: -5% to +10%

White Common at Door Control

Green Activation Input at Door Control

Brown Not Used

Blue Not Used

5 Installation (Continued)

2Mount Sensor

1. Using scale on template, position drawing of sensor on template

0” to 2” from bottom of header.

NOTE: Flush mount with bottom of header is necessary for all

negative IR angles.

2. Drill hole marked for wire passage and drill pilot holes for screw

mounting. Remove template prior to sensor installation.

3. Insert mounting screws approximately halfway in and install the G3

on the screws. When in place, tighten screws to secure to header.

NOTE: Leave cover off until mechanical adjustments are complete.

1/4

1/2

3/4

1

1-1/4

1-1/2

1-3/4

2

1/4

1/2

3/4

1

1-1/4

1-1/2

1-3/4

2

G3 MOUNTING TEMPLATE

Drill1/8” hole Drill1/8” hole

Drill 1/2”wire passage hole anywhere within this area

Do not mount lower than this line

Do not mount lower than this line

3Cable Routing

1. With G3 in place, locate the enclosed cable and feed the stripped

end through the wire passage hole in the header.

2. Leave enough slack to allow connection to the G3 and proper

routing of wire around the plastic post.

NOTE: Observe proper routing of the cable as shown. This is

to divert rainwater from the G3 if water should run down

the cable. Proper routing of the wire also provides easier

installation of the cover.

Plastic Post

Cable / Wire

75.5640.04 20110726 Page 3 of 15

W

I

Z

A

R

D

• PWR: Red - 12 to 24 VAC / VDC: -5% to +10%

• PWR: Black - 12 to 24 VAC / VDC: -5% to +10%

•COM: White - Common at Door Control

• ACTIV: Green - Activation at Door Control

C

O

N

T

R

O

L

White and Green provide output for motion and presence detection

On Remote Control Set: To

F1 1

W

I

Z

A

R

D

• PWR: Red - 12 to 24 VAC / VDC: -5% to +10%

• PWR: Black - 12 to 24 VAC / VDC: -5% to +10%

•COM: White - Common at Door Control

• ACTIV: Green - Activation at Door Control

• COM: Brown - Connected to White Common

• SAFETY: Blue - Connected to Green Activation

C

O

N

T

R

O

L

Brown and Blue may be connected to White and Green

W

I

Z

A

R

D

• PWR: Red - 12 to 24 VAC / VDC: -5% to +10%

• PWR: Black - 12 to 24 VAC / VDC: -5% to +10%

•COM: White - Common at Door Control

• ACTIV: Green - Activation at Door Control

• COM: Brown - Common at Door Control

• SAFETY: Blue - Safety at Door Control

C

O

N

T

R

O

L

For Secondary Activation see important note on page 6.

For One Way Evening Mode see addendum 5 on page 15.