35

Subject to change without notice

Specifications

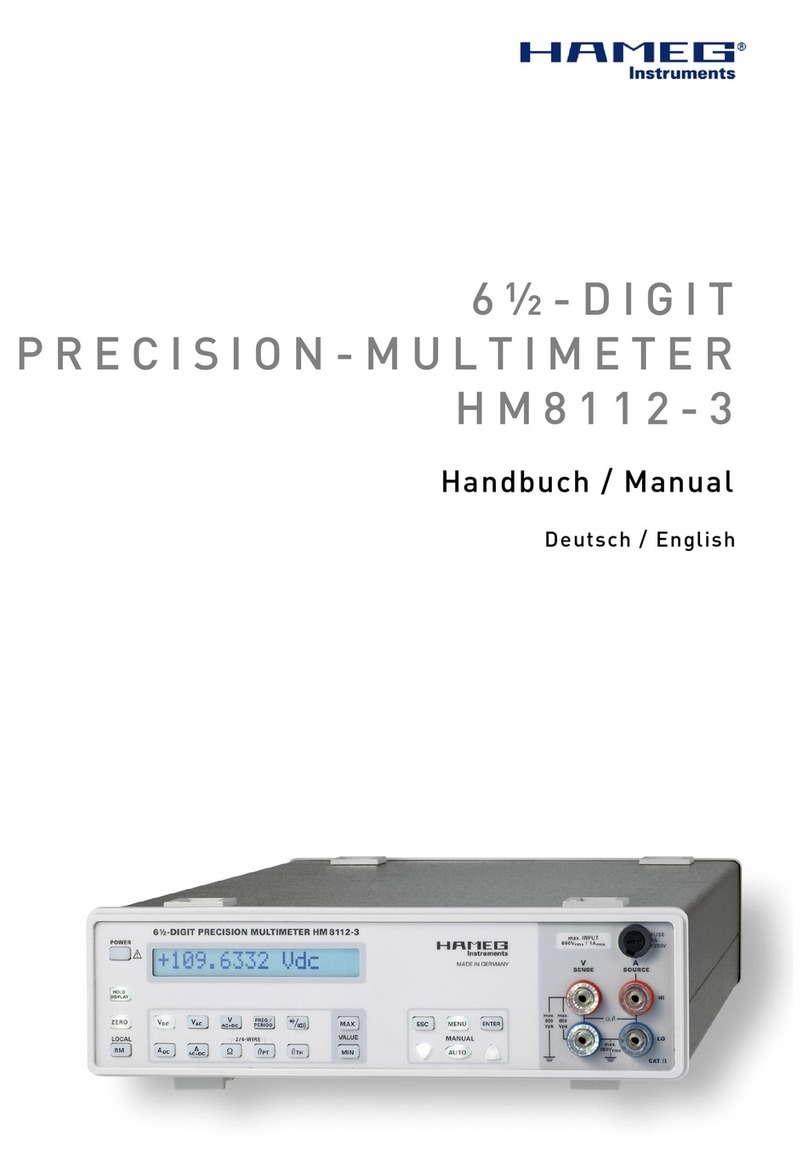

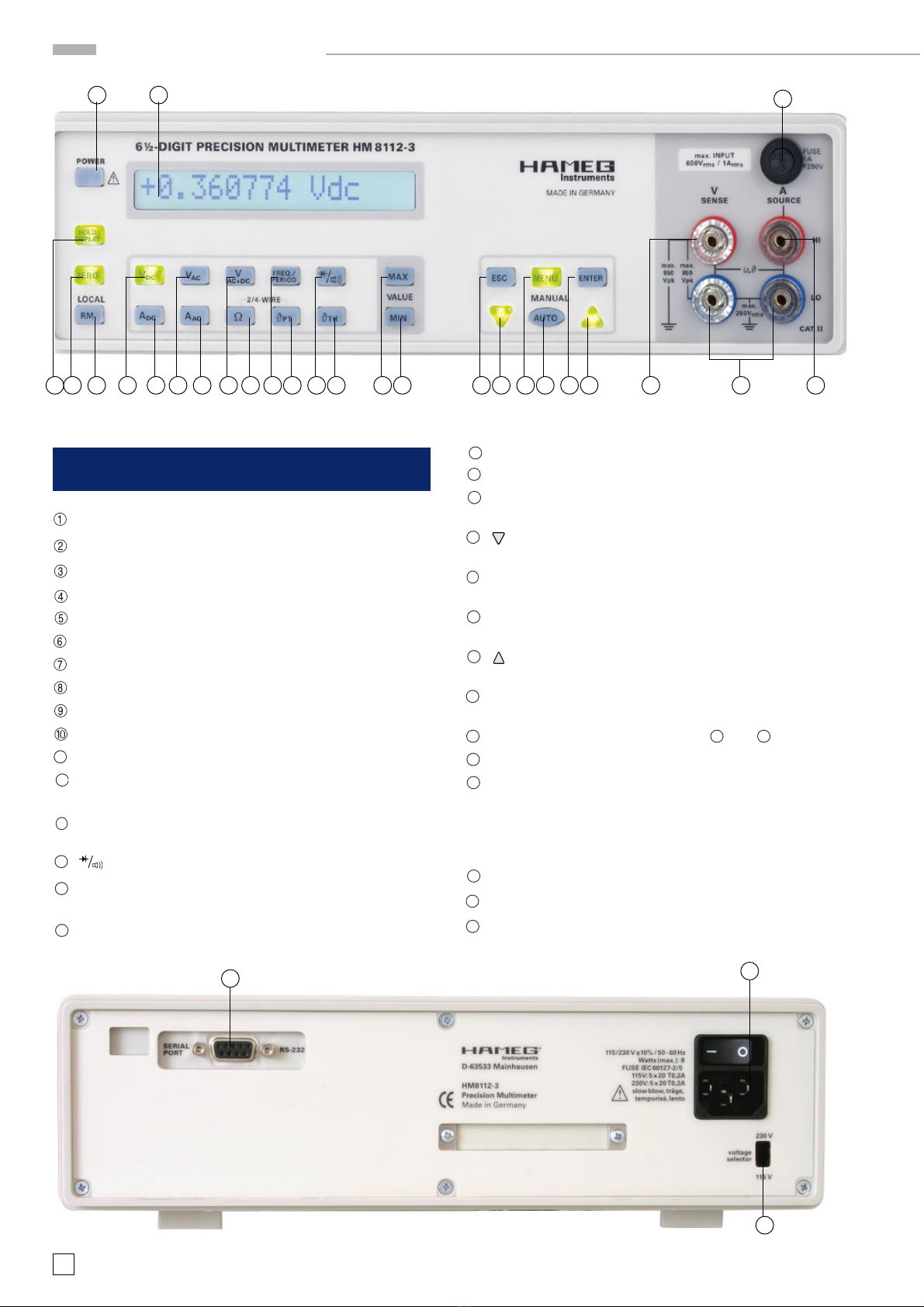

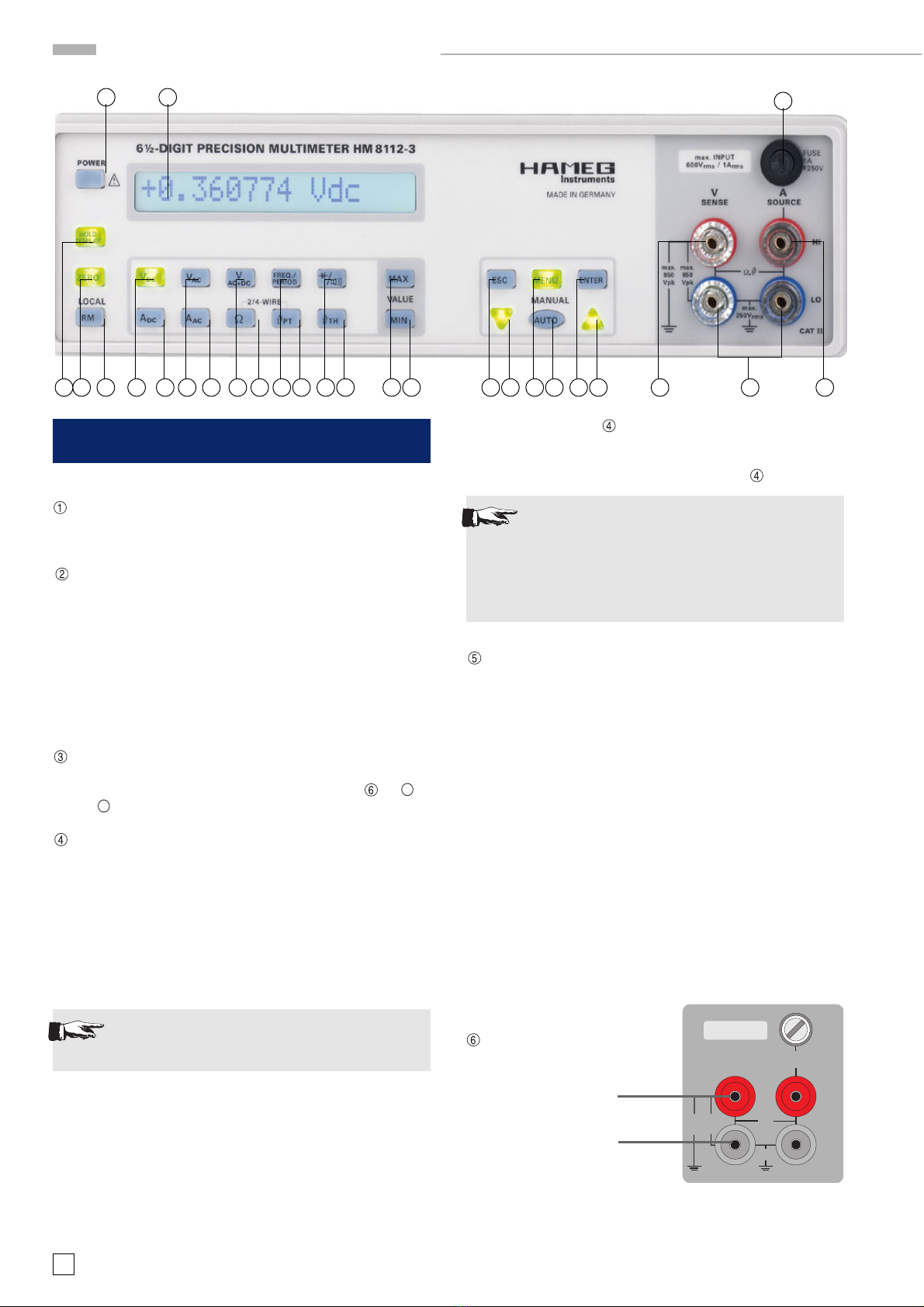

6½-Digit Precision-Multimeter HM8112-3

SPECIFICATIONS

Valid at 23 degrees °C after a 30 minute warm-up period

Included in delivery:

Multimeter HM8112-3, line cord, manual, HZ15 measuring cables

Accessories optional:

HZ887: Temperataure sensor (PT100; -50°C...+400°C )

HZ42:19" Rackmount-kit 2RU for frame height 75mm

DC Specifications

Ranges: 0.1 V; 1 V; 10 V; 100 V; 600 V

Input impedance:

0.1 V; 1.0 V >1 GΩ

10 V; 100 V; 600 V 10 MΩ

Accuracy: Values given are in ±(% of reading + % of full scale)

1 year; 23 ±2 °C Temperature coefficient

Range % rdg. + % f.s. 10...21 °C + 25...40 °C

0.1 V 0.005 + 0.0006 0.0008

1.0 V 0.003 + 0.0006 0.0008

10.0 V 0.003 + 0.0006 0.0008

100.0 V 0.003 + 0.0006 0.0008

600.0 V 0.004 + 0.0006 0.0008

Integration time: 0.1 sec 1 to 60 sec

Display range: 120,000 digit 1,200,000 digit

600 V range: 600,00 digit 600,000 digit

Resolution: 1 µV 100 nV

Zero point

Temperature coefficient: ≤0,3 µV/°C

Long term stability: ≤3 µV for 90 days

AC specifications

Ranges: 0.1 V; 1 V; 10 V; 100 V; 600 V

Measuring method: true rms DC or AC coupled

(except 0.1 V range)

Input impedance:

0.1 V: 1 GΩII <60 pF

1 V to 600 V: 10 MΩII <60 pF

Response time: 1.5 sec to within 0,1% of rdg.

Accuracy: For sine wave signals >5% of range.

Values given are in ±(% rdg. +% f.s.);23 ±2 °C for 1 year

Range 20 Hz – 1 kHz – 10 kHz – 50 kHz – 100 kHz –

1 kHz 10 kHz 50 kHz 100 kHz 300 kHz

0.1 V 0.10 +0.08 5+0.5 (5 kHz)

1.0 V 0.08 +0.08 0.15+0.08 0.3+0.1 0.8+0.15 7+0.15

10.0 V 0.08 +0.08 0.10+0.08 0.3+0.1 0.8+0.15 4+0.15

100.0 V 0.08 +0.08 0.10+0.08 0.3+0.1 0.8+0.15

600.0 V 0.08 +0.08 0.10+0.08

Temperature coefficient 10...21°C and 25...40°C; (%rdg. + %f.s.)

at 20 Hz - 10 kHz: 0.01 + 0.008

at 10 kHz - 100 kHz: 0.08 + 0.01

Crest factor: 7:1 (max. 5 x range)

Integration time: 0.1 sec 1 to 60 sec

Display range: 120,000 digit 1,200,000 digit

600 V range: 60,000 digit 600,000 digit

Resolution: 1 µV 100 nV

Overload protection:

(V-HI to V- LO) and to chassis:

Measurement ranges: all

all the time 850 Vpeak or 600 VDC

Maximum input voltage LOW against

chassis/safety earth: 250 Vrms at max. 60 Hz or 250 VDC

Current specifications

Ranges: 100 µA; 1 mA; 10 mA; 100 mA; 1 A

Integration time: 0.1 sec 1 to 60 sec

Display ranges: 120,000 digit 1,200,000 digit

1 A range: 100,000 digit 1,000,000 digit

Resolution: 1 nA 100 pA

Accuracy: DC 45 Hz–1 kHz 1 kHz–5 kHz

(1 year; 23 ±2 °C) 0.02+0.002 0.1+0.08 0.2+0.08

Temperature coefficient: 10...21 °C 25...40 °C

(% rdg. + % f.s.): 0.002+0.001 0.01+0.01

Voltage: <600 mV to 1,5 V

Response time: 1.5 sec to within 0.1% of rdg.

Crest factor: 7:1 (max. 5 x range)

Overload protection: Fuse FF 1 A 250 V

Resistance specifications

Ranges: 100Ω, 1kΩ, 10kΩ, 100kΩ, 1MΩ, 10MΩ

Integration time: 0.1 sec 1 to 60 sec

Display ranges: 120,000 digit 1,200,000 digit

Resolution: 1mΩ100 µΩ

Accuracy: Values given are in ±(% rdg. + % f.s.)

1 year; 23 ±2°C Temperature coefficient/°C

Range %rdg. + %f.s. 10...21 °C and 25...40 °C

100 Ω0.005 + 0.0015 0.0008

1 kΩ0.005 + 0.001 0.0008

10 kΩ0.005 + 0.001 0.0008

100 kΩ0.005 + 0.001 0.0008

1 MΩ0.05 + 0.002 0.002

10 MΩ0.5 + 0.02 0.01

Measuring current: Range Current

100 Ω, 1kΩ1 mA

10 kΩ100 µA

100 kΩ10 µA

1 MΩ1 µA

10 MΩ100 nA

max. measuring voltage: approx. 3 V

Overload protection: 250 Vpeak

Temperature measurement specifications

PT100 / PT1000 (EN60751) 2- or 4-wire measurements

Range: –200 °C to +800 °C

Resolution: 0.01 °C; measuring current 1mA

Accuracy: ±(0.05 °C + tolerance of sensor +0.08 K)

Temperature coefficient

(10...21 °C + 25...40°C: <0.0018 °C/°C

NiCr-Ni (K-Type)

Range: –270 °C to +1372 °C

Resolution: 0.1 °C

Accuracy: ±(0.7% rdg. +0.3 K)

Fe-CuNi (J-Type)

Range: –210 °C to +1200 °C

Resolution: 0.1 °C

Accuracy: ±(0.7% rdg. +0.3 K)

Frequency and period specifications

Range: 1 Hz to 100 kHz

Resolution: 0.00001 Hz to 1 Hz

Accuracy: 0.05% (rdg.)

Measuring time: 1 to 2 sec

RS-232 Interface

RS-232 standard: 9600 or 19200 Baud

Functions: Control / Data fetch

Inputs: Function, range, integration time, start

command

Outputs: Measurement results, function, range,

integration time (10 ms to 60 s)

Miscellaneous

Time to change range or function:

approx. 125 ms with DC voltage, DC current, resistance

approx. 1 sec with AC voltage, AC current

Memory: 30.000 readings / 128 kB

Protective class: I, EN 61010 (IEC 1010)

Power supply: 105–254 V; 50/60 Hz

Power consumption: approx. 8 W

Operating temperature: +10 °C....+40 °C

Storage temperature: –40 °C....+70 °C

Humidity: <75 %, no condensation

Size (W x H x D): 285 x 75 x 365 mm

Weight: approx. 3 kg

Optionen: USB- bzw. IEEE-Schnittstelle

Subject to change without notice

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com