© 2015Harmar Mobility, LLC • All Rights Reserved

| www.harmar.com

2

Pinnacle 101 Stair Lift CONTENTS

Read and understand this manual prior to

attempting stair lift installations. Please

refer to the Owner’s Manual for Limited

Warranty information and operating instructions.

The Owner’s Manual must be given to the owner

of the lift before it is put into service.

Any alterations to the equipment without written

authorization by the manufacturer may void

the warranty.

Harmar lifts are designed to install with as little

assembly by the installer as possible. If you have

questions, concerns or comments, please contact

Harmar’s Technical Service Department.

Contents

PRELIMINARY CHECKS 3

Tools Required ...............................3

Included Parts ................................3

INSTALLATION PROCEDURES 4-12

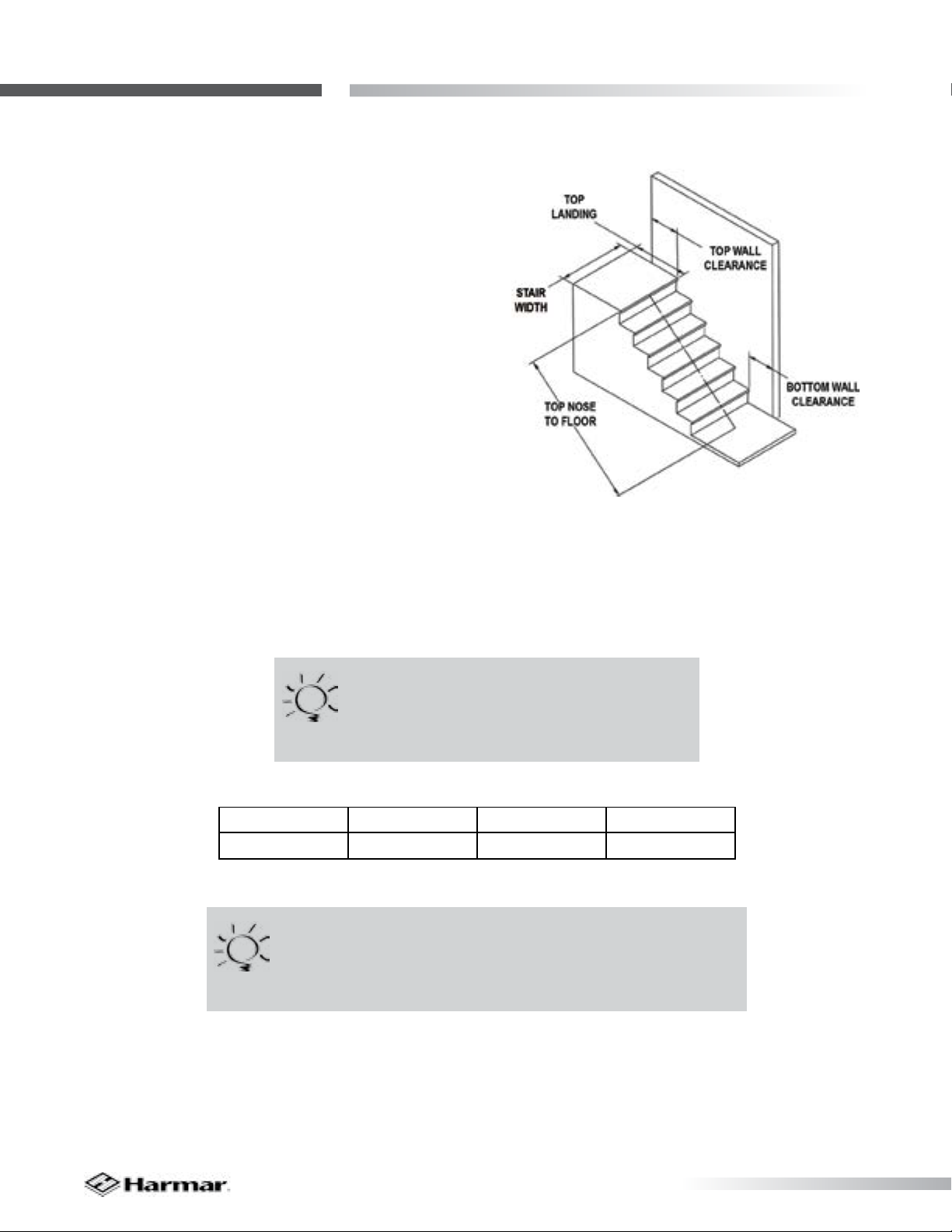

Determine Rail Length ........................4

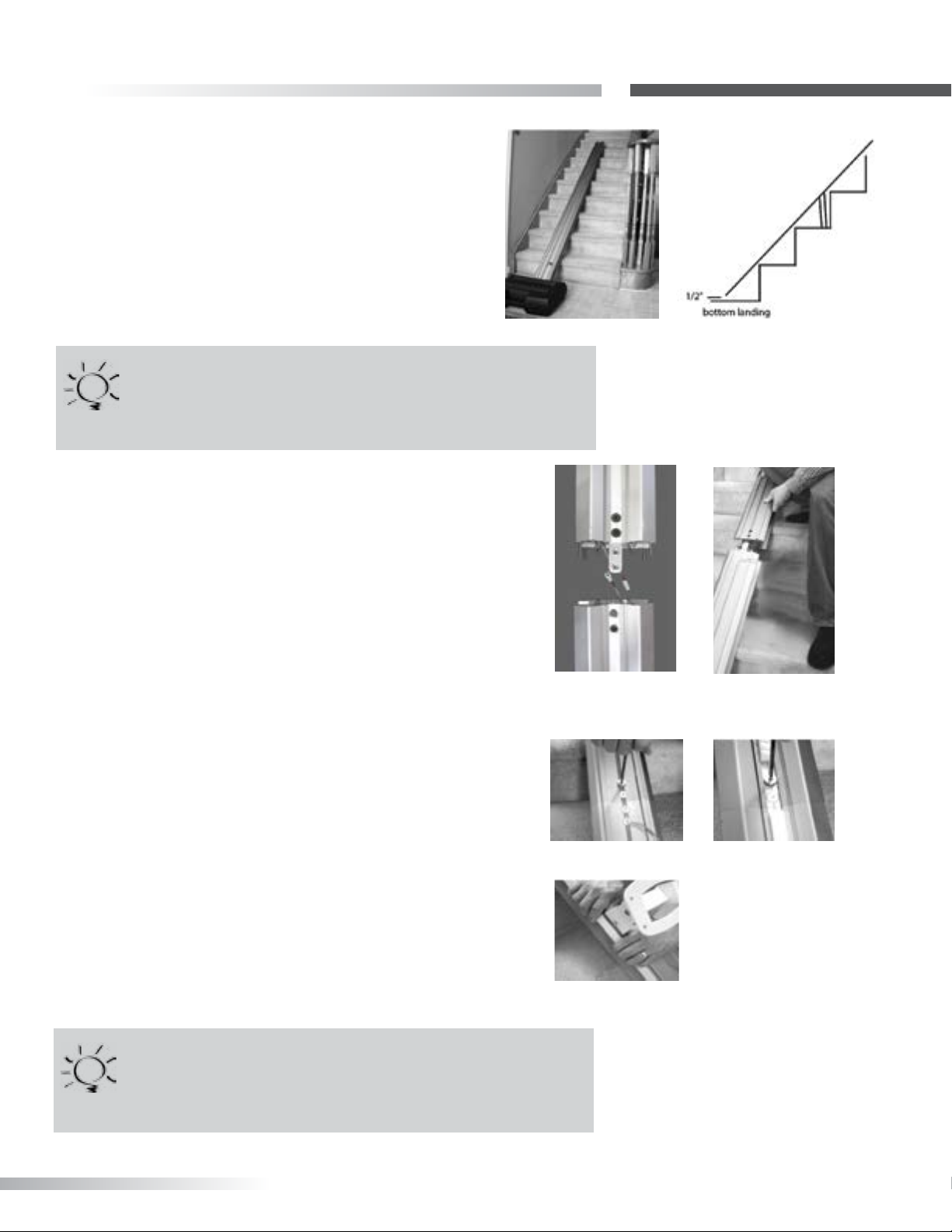

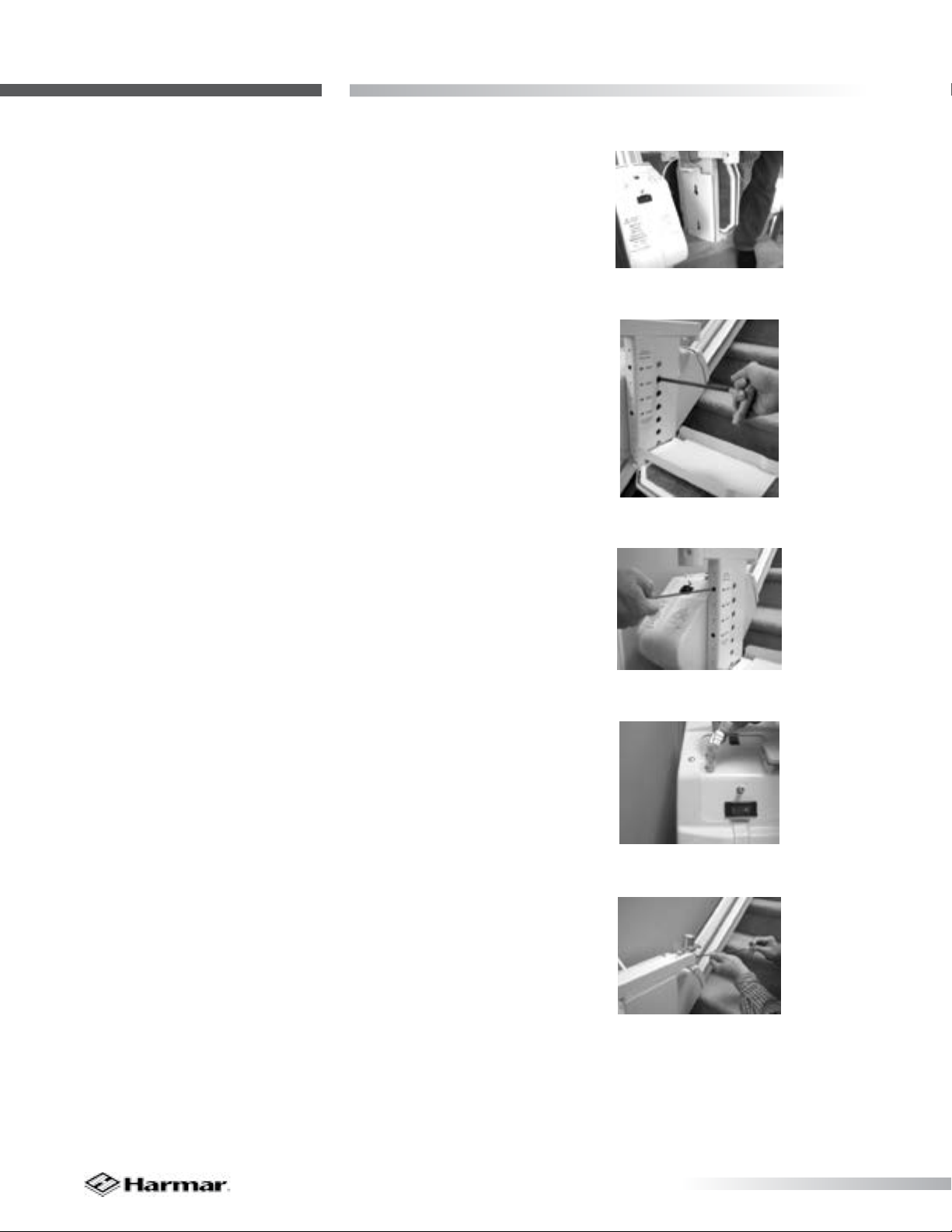

Rail Installation .............................5-6

Chassis Installation............................7

Final Rail Installation ........................8-9

Footrest And Seat Installation .............10-12

REMOTE CONTROL OPERATION 13

Remote Control Operation ...................13

Remote Control Reprogramming .............13

COMPLETION PROCEDURES 14-15

Test Armrest Control Switch..................14

Tighten Brackets .............................14

Set Upper And Lower Travel Limits............14

Test Safety Stop Switches..................14-15

Additional System Checks ....................15

SAFETY SYSTEMS TESTING 16

FOLDING RAIL INSTALLATION 17-20

SYMBOLS USED IN THIS MANUAL

READ MANUAL - Pay close attention to

the instructions in the manual.

CAUTION - Hazardous situation. If not

avoided, could result in serious damage

to property.

WARNING - Hazardous situation. If not

avoided, could result in serious injury to

installer or user.

TIP - Helpful tips that will facilitate ease

of installation.

INDICATIONS OF USE STATEMENT

The Pinnacle 101 Stair Lift is to assist transfer of

patients or mobility impaired persons, up and down

between levels of a residential or private facility.