Turbo Vac TV60R

14

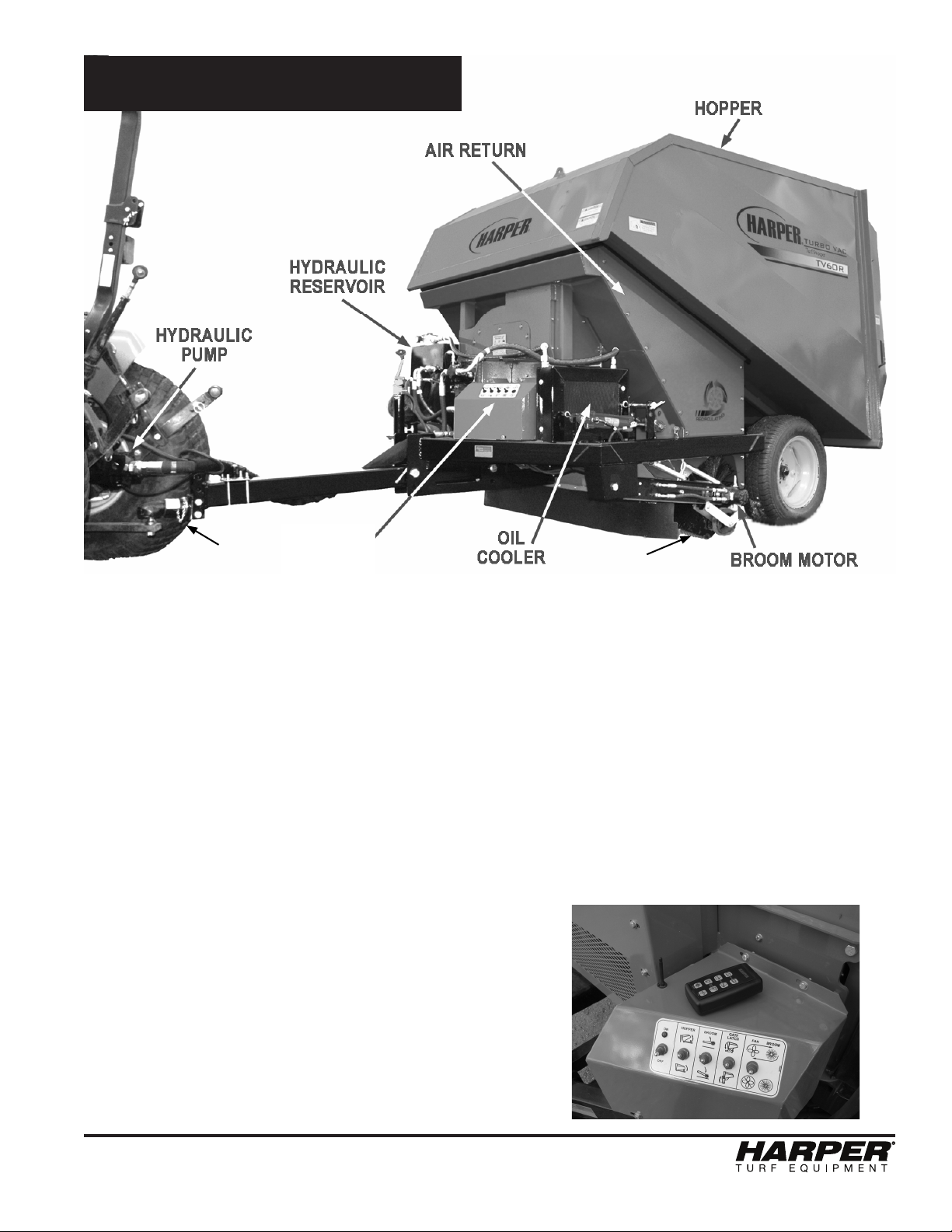

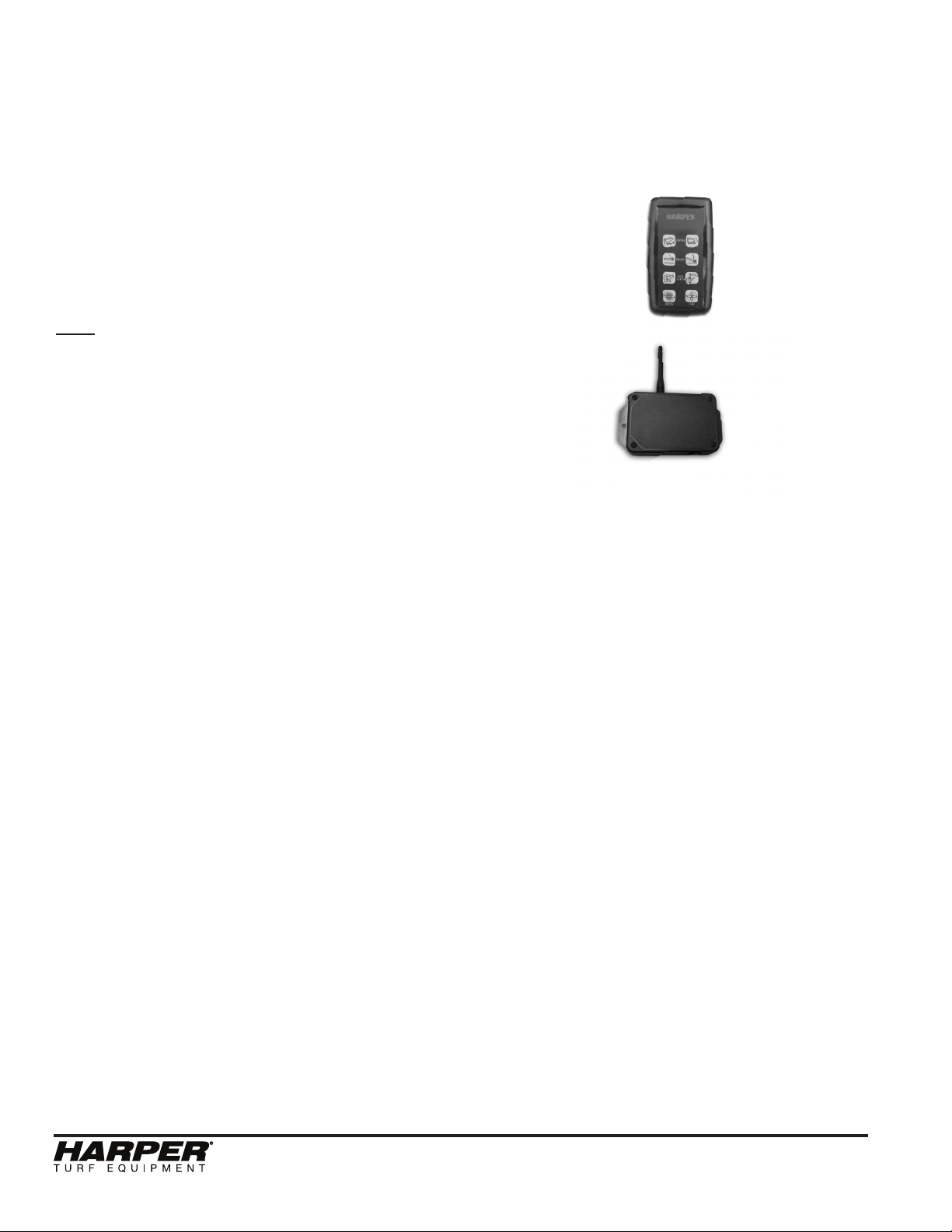

Remote and Receiver

System Operation

Press and hold the power button the trans-

mitter until both LEDs turn on, then release.

The greed LED will ash rapidly when com-

munication has been established. When the

receiver is off, the red LED will ash slowly

indicating this. With the receiver on, press

the corresponding buttons on the transmitter

keypad to turn on and off each of the outputs.

Cloning

1. On transmitter A (the teacher), press the

POWER button, LOWER HOP, and

BROOM ON/OFF simultaneously. At this

point, both LEDs will ash on the rst

transmitter.

2. On transmitter B (the learner), press the

POWER button to turn it on, the press

LIFT HOP, LOWER BROOM, RAISE

BROOM, and BROOM ON/OFF

simultaneously. Both green and red LEDs

will begin ashing.

3. Release buttons and wait for 1 second or

until the green and red LEDs stop ashing

on both units. Both transmitters will have

the same ID at this point.

Sleep Time

The transmitter is factory set to turn off

(sleep) after 15 minutes. To change the time,

the transmitter waits before going to sleep,

use the following procedure:

1. On the transmitter, press and hold POWER

and buttons 3,4, and 8.

2. Release the buttons. At this point, both

lights will blink once per second.

3. On the transmitter, press one of the follow-

ing buttons to adjust the sleep time:

a. 1=15 min.

b. 2=30 min.

c. 3=1 hr.

d. 4=2 hrs.

e. 8=sleep disabled

4. Sleep time programming complete.

Indicator Lights

The transmitter has two LED indicators, the

red BATTERY/DIAGNOSTIC indicator and

the green TRANSMIT indicator.

The green TRANSMITTER indicator ashes

rapidly whenever there is communication

between the transmitter and the receiver.

The red BATTERY/DIAGNOSTIC indicator

starts blinking once every second when the

battery voltage is low and requires replace-

ment. It also blinks when there is a problem

with the system in the form of an error code.

Refer to the ERROR CODE CHART tables

for more information.

Note: To check for low battery, turn the re-

ceiver off and leave the transmitter on. If the

transmitter red LED continues to blink, the

battery is low and requires replacement. If

the red LED blinks only when the receiver is

on, count the number of blinks and refer to

ERROR CODE CHART tables for additional

information.

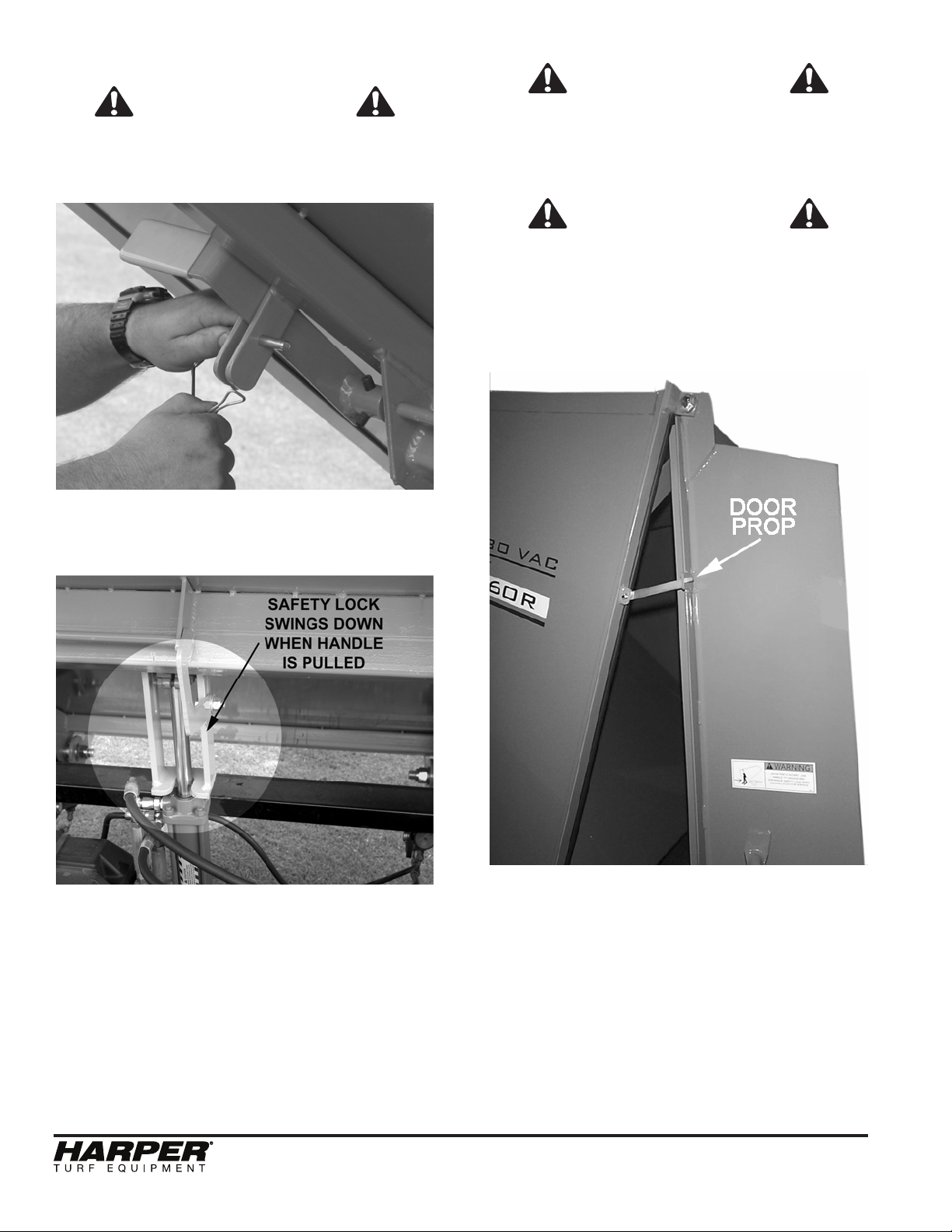

Teach ID Code

To synchronize a new transmitter and receiv-

er together, refer to Fig. 1 and use the follow-

ing procedure:

1. Remove receiver cover

2. Apply power to receiver

3. Place a jumper across the TEACH ID

jumper inside the receiver, green LED will

go steady inside the receiver. Remove the

jumper and store it on one pin.

4. To get the transmitter into TEACH ID

mode, press and hold the POWER button,

LOWER HOP and BROOM ON/OFF.

5. Release the POWER button and wait for

1 second or until the green LED goes from

steady to blinking in the receiver. Release

the other buttons.

6. Teach complete