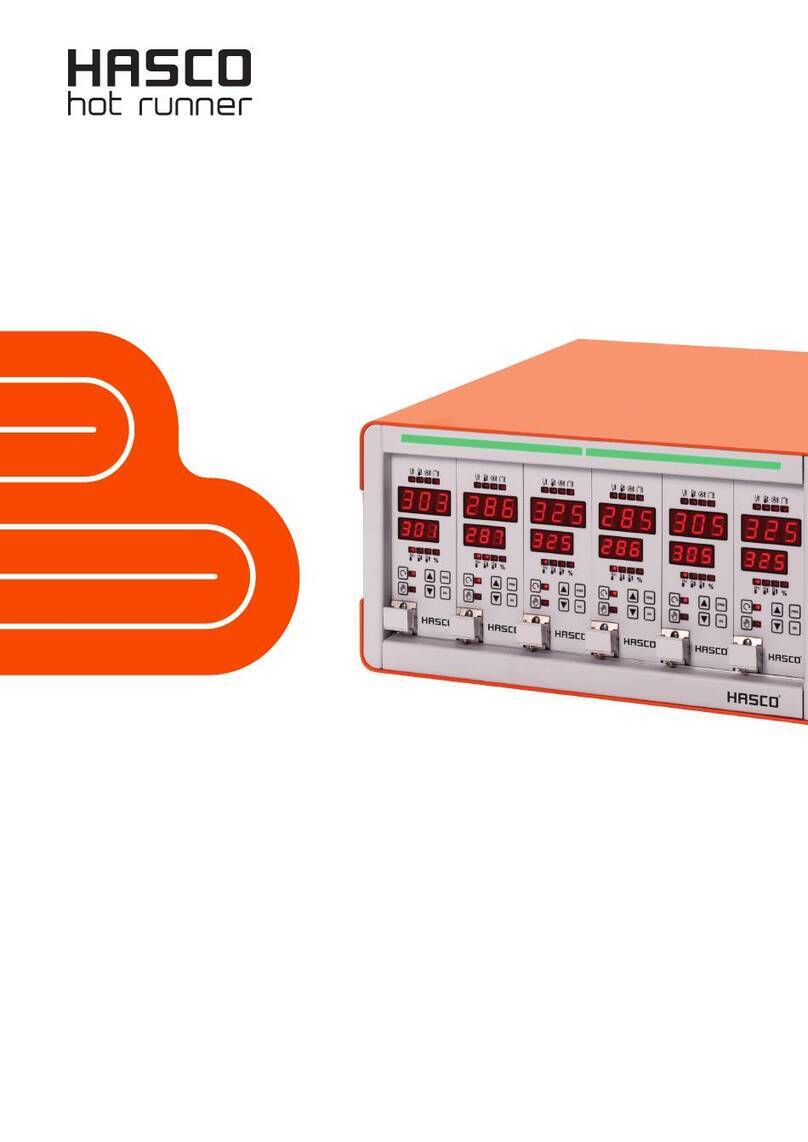

Hasco H1252 User manual

D 07 / 21 HK

Operating Instructions

H1252/...

Valuezone

Control unit

Instruction manual H1252

HASCO hot runner 3

Foreword

Thank you for choosing a HASCO hot runner product.

These operating instructions are intended for everyone who works with HASCO hot runner technology and explain

how to safely handle HASCO hot runner products.

These operating instructions must be read carefully by personnel whenever a product is brought into operation for the

first time. They must always be readily available during operation.

The operating instructions form the basis for the safe handling of HASCO hot runner technology. The instructions and

information given here, and particularly the safety rules, must be followed under all circumstances.

The general safety regulations and accident prevention regulations at the location in question must always also be

observed by personnel.

The operating instructions contain illustrations which serve for a better understanding only. In addition, the scope of

delivery for special versions or the latest technical changes can lead to deviations from the actual version supplied.

With this edition, all previous versions lose their validity.

Read carefully prior to use

and keep for future reference.

4 HASCO hot runner

Table of contents

List of Figures......................................................................................................................................5

1 Important information ............................................................................................................6

1.1 Symbols used 6

1.2 General safety information 6

1.3 Service address 6

2 Features and functionality......................................................................................................6

2.1 General information 7

2.2 Structure 7

2.2.1 H1252/6x16 8

2.2.2 H1252/12x16 9

2.3 Technology 10

2.3.1 Fuses 10

2.3.2 Mains voltage protection 10

2.3.3 Alarm contact/digital input 10

2.3.4 Pin assignment 11

2.4 Type plate 11

2.5 Electromagnetic compatibility 11

2.6 Technical data 12

3 Commissioning ...................................................................................................................13

3.1 Electrical connection 13

3.2 Operating and display elements 14

3.3 Quick start 17

4 Operation ...........................................................................................................................18

4.1 Zone selection 18

4.1.1 Selecting a single zone 18

4.1.2 Selecting several zones 18

4.1.3 Selecting several successive zones 19

4.1.4 Selecting all the zones 19

4.2 Mode of operation 20

4.3 Setpoint values 21

4.4 Output level 22

4.5 Parameters 23

4.5.1 Zone parameters 23

4.5.2 System parameters 24

4.6 Boost 25

4.7 Standby 26

5 Warnings and error messages .............................................................................................26

5.1 Warnings 27

5.2 Alarms 28

6 Functions and parameter setting..........................................................................................31

6.1 Basic settings 31

6.1.1 Access authorisations 31

6.1.2 Fahrenheit display 32

6.1.3 Thermocouple type 32

6.2 Control mode 32

6.2.1 Control parameter P I D 32

6.2.2 Rated value output level 33

6.2.3 Maximum output level 33

6.3 Heating 34

6.3.1 Gentle heating (soft start) 34

6.3.2 Combined heating 34

6.4 Hot runner monitoring 35

6.4.1 Temperature monitoring 35

6.4.2 Mean output level 37

6.4.3 Sensor fracture 37

6.4.4 Monitoring the heating current 38

6.4.5 Triac monitoring 38

Instruction manual H1252

HASCO hot runner 5

6.5 Special functions 39

6.5.1 Temperature increase BOOST 39

6.5.2 Temperature reduction STANDBY 39

6.5.3 Standard parameters 40

7 Parameter overview ............................................................................................................40

7.1 Zone parameters 40

7.2 System parameters 41

8 Spare parts + accessories ...................................................................................................42

9 Annex.................................................................................................................................43

9.1 Terminal diagram plug system 43

9.2 Clamping bridges for the star/triangle supply 43

9.2.1 Clamping bridges in the star network (state as delivered!) 43

9.2.2 Clamping bridges in the triangular network 43

List of Figures

Figure 1 - Housing front H1252/6x16 8

Figure 2 - Housing rear H1252/6x16 8

Figure 3 - Housing front H1252/12x16 9

Figure 4 - Housing rear H1252/12x16 9

Figure 5 - Side view H1252/12x16 10

Figure 6 - Operating and display elements 14

Figure 7 - Star network 45

Figure 8 - Triangular network 45

6 HASCO hot runner

1Important information

1.1 Symbols used

Caution! If this information is not heeded, disruptions or malfunctions can result.

Warning! If this warning is not heeded, damage to persons and/or damage to the machine can

result.

1.2 General safety information

For your safety, it is essential to observe the following information on the installation, commissioning and operation of the

controller:

- The controllers are operated on the low-voltage network. The relevant safety instructions must be observed when

connecting up and servicing the controller.

- The local and general regulations governing the installation and operation of the units must be complied with.

- The units may only be wired up and brought into operation by authorised specialists using the correct tools.

Specialist personnel in the terms of these Operating Instructions are persons who can recognise and assess the

dangers associated with the work entrusted to them on the basis of their specialist training, their experience and

their knowledge of the application of standards.

- To ensure reliable and safe operation, each user is obliged to observe the information and warnings.

- In the event of subcontracting, this documentation must be included and attention drawn to the need to observe

this safety information.

- The manufacturer and vendor of this unit are not liable for any direct or indirect damage due to its incorrect handling

or treatment.

The unit is checked carefully prior to delivery and has passed the tests specified in the test plan for production in conformity

with the manufacturer’s valid quality guidelines. To prevent any damage to the controller, it must be transported and stored

in the correct manner.

Further safety-related notices are marked in the individual sections of this documentation.

1.3 Service address

For technical enquiries and in case of complaint please contact us:

HASCO Austria GmbH

Industriestrasse 21

A-2353 Guntramsdorf

Austria

Phone +43 (0)2236-202-0

Fax +43 (0)2236-202-200

www.hasco.com

Instruction manual H1252

HASCO hot runner 7

2Features and functionality

2.1 General information

Hot runner controllers H1252/6x16 and H1252/12x16 are especially suited to the temperature control of hot runner moulds

on injection moulding machines. The controllers are linked directly to the mould via a cable connection.

During operation, hot runner controllers deliver electric current to the heating units on an injection mould. The so-called

heating current leads to an adjustable temperature increase in the heating units and hence in the mould. In parallel,

continuous temperature monitoring takes place via thermocouples that are connected up. In the event of deviations between

the current temperature recorded and the temperature set on the hot runner controller, the heating current is automatically

adjusted via a self-adapting PID control algorithm until the two temperatures are identical.

The controller variants of H1252/6x16 and H1252/12x16 differ solely in terms of the number of control circuits that are

possible. These are also referred to as heating zones. Depending on the variant, units are available with either 6 or 12 heating

zones.

2.2 Structure

Housing front: The hot runner controllers H1252/6x16 and H1252/12x16 are operated via the front of the housing (Figure

1). Alongside the three-pole main switch for switching the controller on and off, there are 12 buttons ensuring convenient

operation. The front of the unit also contains all the visualisation elements. The setpoint values and actual values of the

individual zones are portrayed via 7-segment displays. If required, the display can be switched to heating current and output

level. In addition, status LEDs provide information on operating modes and messages for the individual zones. The controller

status is visualised in colour via a fault-message display that is visible from a long way off. In normal operation, this display is

lit up green. In the event of a warning or an alarm, the display switches to yellow or red (traffic light status). This enables the

controller status to be readily assessed from a distance. A detailed description of the display and operating functions may

be found in Chapters 3.2 and 4.

Housing rear: All the connections and fuses of the hot runner controller are located on the rear of the housing (Figure 2). In

addition to the connection lead used to connect the controller to the mains electricity, the controllers have a further

connection for a potential-free alarm contact and a 24V digital input for external control of reduced-temperature (standby)

operation. The connection to the hot runner mould is achieved via 24-pole plug systems. The centrepiece of the hot runner

controller is the integral I/O board that is mounted on the rear of the controller housing. Each board contains the electronics

for 6 heating zones, the corresponding fuses and a cooling element. To ensure easy handling in the event of an error, all the

fuses for the I/O board are accessible on the rear of the housing.

8 HASCO hot runner

2.2.1 H1252/6x16

Figure 1 - Housing front H1252/6x16

Figure 2 - Housing rear H1252/6x1

Instruction manual H1252

HASCO hot runner 9

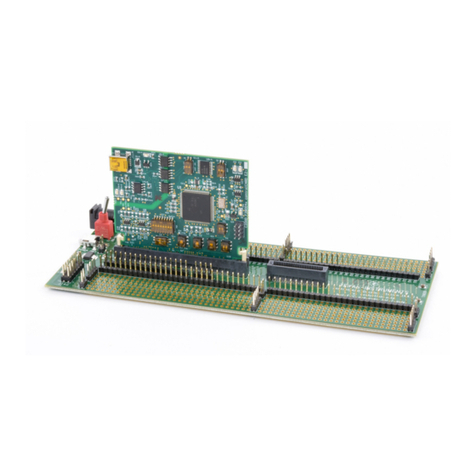

2.2.2 H1252/12x16

Figure 3 - Housing front H1252/12x16

Figure 4 - Housing rear H1252/12x16

10 HASCO hot runner

Figure 5 - Side view H1252/12x16

2.3 Technology

2.3.1 Fuses

The fuses for the load outputs and the control fuse are located on the rear of the controller housing. The specifications of the

fuses may be found in the technical data.

2.3.2 Mains voltage protection of sensor inputs

The hot runner controllers are equipped with mains voltage protection. This is designed to protect the sensitive electronics

in the sensor input zone against excessive high voltages. Voltages of this type can be caused by wiring errors or by

defective heating units, for example.

As soon as a voltage in excess of 6V is registered at the sensor inputs to the I/O board,

the zone in question is switched off via a relay.

The controller displays ‘sensor fracture’for this channel.

2.3.3 Alarm contact/digital input

The H1252 hot runner controllers have a potential-free alarm contact and a digital input that are fed out of the controller via

a socket on the rear.

The digital input is SPS-compatible, in other words it operates over a voltage range of 13..30 VDC with a typical current

consumption of approx. 8.5 mA. The potential-free alarm contact opens as soon as there is an error message. Chapter 5.2

contains a list of the possible error messages.

Alarm contact/digital input socket

Contact Function

1+3 Alarm contact Opener

Instruction manual H1252

HASCO hot runner 11

2 Digital input 0V reduced-

temperature (standby)

mode

6 Digital input 24V reduced-

temperature (standby)

mode

2.3.4 Pin assignment

The plug-in connections for the temperature sensors and heating elements are available on the rear of the controller.

These correspond to the terminal diagram in Annex 9.1.

2.4 Type plate

The type plate is on the right-hand side of the controller.

It contains the type designation with the number of zones, the electrical

connection data and the manufacturer’s data.

2.5 Electromagnetic compatibility

Emitted interference

The unit is interference-suppressed as per EN 55011/B (emitted interference).

Compatibility level:

VDE 0839 Part 10

Reliability class Z2

Environmental classes S2, I4, E3

Interference immunity:

VDE 0843 Part 2,3,4

IEC 801 Part 2,4,5

Environmental class 3

Severity 3, with external filter 4

H1252/ Year: XX/2017

Serial No. XXXXX

Mains supply: [ ] Y 230/400VAC [ ]50Hz

Max. 3x 32A [ ] ▲220VAC [ ]60Hz

12 HASCO hot runner

2.6 Technical data

HASCO Type H1252/6x16 Type H1252/12x16

Number of zones 6 12

Housing

Dimensions (WxHxD) 434 mm x 226 mm x 365 mm*1

Weight 13.5 kg 15.5 kg

Housing material Steel, galvanised

Protection IP 20

Ambient conditions

Service temperature 0...50°C

Max. housing surface temp.*2 55°C

Air humidity 0…90% rel. humidity, no condensation

Storage temperature -25...+75°C

Operation and display

Display per zone 2x three-digit 7-segment

Operating panel 12 buttons

Electrical connection

Connection cable with CEE plug 3 x 32 A

Supply voltage 3 x 190 –400 V AC, N, PE

Switchable to 3 x 110 –230 V AC, N, PE

Tolerance + 5% / -15%

Main switch 40 A 3-pole

Mains electricity fuses

Control voltage electronics 1 x 4A medium time-lag (6.3 x 32mm)

Heating outputs external each 16A gRL (6.3 x 32mm)

Additional fuses internal each 16A time-lag (6.3 x 32mm)

Power consumption Max. 30 W when idling

Thermocouple inputs

Thermocouple Fe-CuNi Type J - 0…700°C

switchable to NiCr-Ni Type K

Cold junction compensation internal

Measuring accuracy ±0.25 K

Temperature polling 4x128 / second

Instruction manual H1252

HASCO hot runner 13

Load outputs Bistable, electrically isolated

Per zone 1x heating, 230VAC switching

Shortest controller reaction 10ms at 50Hz

Current per zone max. 16A at 80% operating time

Important warning! Observe the overall capacity of the electrical connection lead

Minimum load 100 W

Control mode PI, PD or PID set separately for all zones

Other connections

Alarm output (relay contact) - potential-free

Maximum voltage 250V AC

Maximum current 4A at cosj= 1; 2A at cosj= 0.5

Digital input –isol. potential-free 13 –30V DC

1 Depth dimension without mould connection

*2: for an air temperature of 20°C

3Commissioning

3.1 Electrical connection

The electrical connections must be performed by a trained electrician. Commissioning and

operation while the controller is running are only to be carried out by authorised qualified

personnel.

Switching off all the outputs or individual zones will not protect any of the outputs against

hazardous voltages. Before working on the connected heating elements, the associated

connections must be unplugged, or the entire unit disconnected from the mains power. Before

the unit is opened, it must be disconnected from the mains power.

Mains electricity

Before connecting the unit to the mains voltage, a check must be conducted to see that the mains electricity system is

correct. The hot runner controllers H1252/6x16 and H1252/12x16 are prepared by default for operation in a star network

(3x400VAC + N + PE), but can also be operated in a triangular network (3x230VAC + PE). For operation in a triangular

network without a neutral conductor, it is essential to observe the local regulations for the installation of electrical systems.

The terminals in the controller must be bridged accordingly for use in a star or triangular network. Annex 9.2 contains a clear

terminal connection diagram.

Connection to the mains electricity:

To ensure correct operation, the hot-runner controller is connected to the low-voltage mains by means of the connection

lead attached to the unit.

Connection of the mould:

To connect the individual control zones to the corresponding injection mould, use must be made of appropriate leads for the

sensor and heating unit connection.

Figure 2 - Housing rear H1252/6x16 shows the plug system for connecting the H1252/6x16 controller to the mould by way

of example.

14 HASCO hot runner

3.2 Operating and display elements

The following diagram shows the front view of the controller, with all the operating

and display elements.

Figure 6 - Operating and display elements

Operating/display element Description

Fault-message display

Green shows that everything is in order.

The controller is operating normally.

Yellow indicates warning messages about a

deviation from the normal state.

Red indicates alarms. Depending on the fault,

the outputs of the corresponding zones may be

deactivated.

Instruction manual H1252

HASCO hot runner 15

Zone selection

Each time the arrow buttons are pressed, the

display moves on to the next zone.

Value change with confirmation button

Confirmation button/acknowledge fault

Boost

Standby

Change operating mode

Set parameters/system information

Hand-operated (yellow)

Flashing = operated by hand due to incident

Regular operation (green)

Alarm warning (red)

Flashing = alarm

Displays the last selected zone

16 HASCO hot runner

Basic view: display of all zones/ cancel entry

Button for switching the zone display

Display: actual value (X) and setpoint value

(W)

Display: current (I) and output level (Y)

Activate/deactivate controller

outputs

Temperature unit used for display

Main switch for switching on the controller.

Instruction manual H1252

HASCO hot runner 17

3.3 Quick start

1. Connect up the heating and sensor lines. The plug system assignment is set out in Annex 9.1.

2. Connect up to the mains as per Chapter 3.1

3. Switch on the controller at the main switch

4. Select the control zones required (Chapter 4.1)

5. Switch the operating mode of the required zones from “off”(control zone switched off) to “on”(normal control

mode) (Chapter 4.2)

6. Set the individual setpoint values for the required control zones (Chapter 4.3)

7. Activate the controller outputs

The alarm limits for an excessively high temperature (parameter ) and the upper temperature limit

(parameter ) should be aligned to the production conditions to prevent incorrect heating.

After the controller outputs have been activated, the control parameters will automatically be aligned to the control loop.

Following this, the system will move towards the specified setpoint values, with the relevant functions such as soft start and

combined heating being active. These functions can also be deactivated as per Chapter 6.3.

18 HASCO hot runner

4Operation

4.1 Zone selection

4.1.1 Selecting a single zone

Step Operation Description

1.

Each time the arrow buttons are pressed, the display

moves to the next zone.

All other zones that have not been selected are blanked

out.

4.1.2 Selecting several zones

Step Operation Description

1.

Select zone

2.

Confirm the zone.

…repeat 1 and 2 in order to select any desired zones

Instruction manual H1252

HASCO hot runner 19

4.1.3 Selecting several successive zones

Step Operation Description

1.

Choose the 1st zone that is to be selected.

2.

Keep the confirmation button pressed.

3.

Each time the button is pressed a zone is added to the

zones selected.

4.

Release the confirmation button

4.1.4 Selecting all the zones

Step Operation Description

1.

The following fundamentally applies:

In the basic view, all the zones can be operated and are

thus already selected for a value change, as it were.

“The zones that you can see, you can also operate.”

20 HASCO hot runner

4.2 Mode of operation

Step Operation Description

1.

Select zones as described under 4.1

2.

Select the operating mode

Each time the button is pressed the display changes

between

Manual operation

Normal operation

Zone off

Note: the display flashes and must be confirmed within 5

seconds.

3.

Confirmation of the entry made.

The display no longer flashes.

4.

Press the home button to return to the

display of all the zones.

Table of contents

Other Hasco Control Unit manuals

Popular Control Unit manuals by other brands

Quintex

Quintex Cheetah C3 CUB operating & maintenance manual

Millenium

Millenium HD-120 user manual

Beta LaserMike

Beta LaserMike LASERSPEED 8000 Instruction handbook

National Instruments

National Instruments NI-9244 User manual and specifications

Texas Instruments

Texas Instruments Piccolo F280049C user guide

WAGO

WAGO WAGO-I/O-SYSTEM 750 Series manual