Hasco H1280 Series User manual

D / GB / F 07 / 19 HK

H1280/...

Multi-zone control unit

Operating instructions

Bedienungsanleitung H1280

HASCO hot runner 3

Foreword

Thank you for choosing a HASCO hot runner product.

These operating instructions are intended for everyone who works with HASCO hot runner technology and explain

how to safely handle HASCO hot runner products.

These operating instructions must be read carefully by personnel whenever a product is brought into operation for the

first time. They must always be readily available during operation.

The operating instructions form the basis for the safe handling of HASCO hot runner technology. The instructions and

information given here, and particularly the safety rules, must be followed under all circumstances.

The general safety regulations and accident prevention regulations at the location in question must always also be

observed by personnel.

The operating instructions contain illustrations which serve for a better understanding only. In addition, the scope of

delivery for special versions or the latest technical changes can lead to deviations from the actual version supplied.

With this edition, all previous versions lose their validity.

Read carefully prior to use

and keep for future reference.

4 HASCO hot runner

1 Introduction .................................................................................................................................... 6

1.1 Symbols used ........................................................................................................................... 6

1.2 Notations .................................................................................................................................. 6

2 Safety instructions ......................................................................................................................... 6

2.1 Intended use ............................................................................................................................ 6

2.2 Information for operators and users ......................................................................................... 6

3 Structure and functionality ........................................................................................................... 7

3.1 General information ................................................................................................................. 7

3.2 Structure ................................................................................................................................... 7

3.2.1 Display (1) ......................................................................................................................... 9

3.2.2 LED strip (3) ...................................................................................................................... 9

3.2.3 Power boards (13) ............................................................................................................ 9

3.2.4 Connections ...................................................................................................................... 9

3.2.4.1 USB connection (2) ...................................................................................................... 9

3.2.4.2 Ethernet connection(9) ................................................................................................. 9

3.2.4.3 RS485 connection (8) .................................................................................................. 9

3.2.4.4 Alarm contacts (7) ........................................................................................................ 9

3.2.4.5 Digital inputs (10) ......................................................................................................... 9

3.3 Identification marking on the controller .................................................................................. 10

3.3.1 Wiring of the plug systems .............................................................................................. 10

4 Commissioning ............................................................................................................................ 10

4.1 Electrical connection .............................................................................................................. 10

4.1.1 Mains electricity .............................................................................................................. 11

4.1.2 Connection to the mains electricity ................................................................................. 11

4.1.3 Connection of the mould ................................................................................................. 11

4.2 Operating and display concept .............................................................................................. 11

4.2.1 Main switch ..................................................................................................................... 11

4.2.2 Status display .................................................................................................................. 11

4.2.3 Operation ........................................................................................................................ 11

5 Start menu .................................................................................................................................... 12

5.1 Navigation bar ........................................................................................................................ 13

5.2 Selection of zones and groups for operation ......................................................................... 14

5.3 Navigation menu .................................................................................................................... 14

5.3.1 Setup ............................................................................................................................... 16

5.3.1.1 Quick start .................................................................................................................. 16

5.3.1.1.1 Groups ................................................................................................................. 16

5.3.1.1.2 Operating mode ................................................................................................... 16

5.3.1.1.3 Setpoint values .................................................................................................... 17

5.3.1.2 Monitoring .................................................................................................................. 18

5.3.1.2.1 Temperature monitoring ....................................................................................... 18

5.3.1.2.2 Sensor fracture monitoring................................................................................... 19

5.3.1.2.3 Residual current monitoring ................................................................................. 20

5.3.1.2.4 Output level monitoring ........................................................................................ 20

5.3.1.2.5 Heating current monitoring................................................................................... 21

5.3.1.3 Heating ....................................................................................................................... 21

5.3.1.4 Mould test ................................................................................................................... 22

5.3.1.5 Others ........................................................................................................................ 23

5.3.1.5.1 Sensor type .......................................................................................................... 23

5.3.1.5.2 Max. output level .................................................................................................. 23

5.3.2 Operation ........................................................................................................................ 24

5.3.2.1 Home view ................................................................................................................. 24

5.3.2.1.1 General presentation ........................................................................................... 24

5.3.2.1.2 Changing the setpoint value and output level ...................................................... 29

5.3.2.1.3 Activating the boost function ................................................................................ 29

5.3.2.1.4 Changing the operating mode ............................................................................. 30

Bedienungsanleitung H1280

HASCO hot runner 5

5.3.2.2 Diagnosis ................................................................................................................... 30

5.3.2.2.1 Faults ................................................................................................................... 30

5.3.2.2.2 Events .................................................................................................................. 30

5.3.2.2.3 Fault handling ...................................................................................................... 30

Warnings and alarms ............................................................................................................. 31

5.3.2.3 Plotter ......................................................................................................................... 33

5.3.2.4 Control ....................................................................................................................... 34

5.3.2.4.1 Control dynamics ................................................................................................. 34

5.3.2.4.2 Heating signal ...................................................................................................... 35

5.3.2.5 All parameters ............................................................................................................ 36

5.3.3 Settings ........................................................................................................................... 36

5.3.3.1 Device ........................................................................................................................ 36

5.3.3.1.1 Language ............................................................................................................. 36

5.3.3.1.2 Temperature unit ................................................................................................. 37

5.3.3.1.3 Date / Time .......................................................................................................... 37

5.3.3.1.4 Timer .................................................................................................................... 37

5.3.3.1.5 User administration .............................................................................................. 38

5.3.3.1.6 File management ................................................................................................. 39

5.3.3.2 Communication .......................................................................................................... 40

5.3.3.3 Service ....................................................................................................................... 40

5.4 Index of keywords .................................................................................................................. 41

5.5 Switch all outputs on and off .................................................................................................. 41

5.6 Standby operation .................................................................................................................. 42

6 Technical data .............................................................................................................................. 43

7 Dimensions ................................................................................................................................... 44

7.1 12-zone controller .................................................................................................................. 44

7.2 24-zone controller .................................................................................................................. 44

7.3 36-zone controller .................................................................................................................. 45

8 Appendix ....................................................................................................................................... 46

8.1 Terminal bridges for the star-delta supply ............................................................................. 46

8.1.1 Terminal bridges in star supply network (status as delivered) ....................................... 46

8.1.2 Terminal bridges in triangle supply network ................................................................... 46

8.2 Pin assignment alarm socket ................................................................................................. 47

8.3 Pin assignment digital input ................................................................................................... 47

9 Index of keywords........................................................................................................................ 48

6 HASCO hot runner

1 Introduction

1.1 Symbols used

Caution/Warning

Information on possible damage to property or personal injury

Information Important information

1.2 Notations

Menu structures between words are indicated by the > symbol and depicted in the same way on the device.

Interaction with the operator is denoted by the finger symbol.

2 Safety instructions

Please read this document completely and carefully before commissioning or operating

the device.

2.1 Intended use

The hot runner controller is used to control the temperature of heating circuits and is designed for use under precisely

defined conditions, such as supply voltage and temperature. The operator must therefore ensure that the controller is

only used under operating conditions that comply with the technical data. The manufacturer is not liable for damage

resulting from non-compliance with the intended use.

The hot runner controller is not suitable for use beyond the limits defined in the technical data and during its design. In

addition, the use of spare parts from third parties and the implementation of non-described maintenance activities

constitute failure to comply with the intended use.

Alterations, conversions and other modifications are made exclusively at the operator’s own risk and could pose safety

hazards. The manufacturer and distributor of this device cannot be held liable for direct and indirect damage resulting

from improper handling or treatment.

2.2 Information for operators and users

The controllers are operated on the low-voltage network. The relevant safety regulations must be observed when

connecting up the controller and performing maintenance on it. In addition, the local and general safety regulations must

be observed for its installation and operation. The operator is responsible for compliance with these regulations. The

operator must additionally make this documentation available to the user and provide instruction in the correct operation

of the device. The user must be familiar with this documentation. In order to ensure reliable and safe operation, the

individual user is required to observe the information and warnings.

The controllers may only be brought into operation by authorised specialist personnel. Under the terms of these

operating instructions, specialist personnel are persons who can recognise and assess the dangers associated with the

work entrusted to them on the basis of their specialist training, their experience and their knowledge of standards.

The device is checked carefully prior to delivery and has passed the tests specified in the test plan for its production, in

conformity with the manufacturer’s valid quality guidelines. To prevent any damage to the controller, it must be

transported and stored in the correct manner. Further safety-related notices are marked in the individual sections of this

documentation.

Bedienungsanleitung H1280

HASCO hot runner 7

3 Structure and functionality

3.1 General information

The H1280 hot-runner controllers are especially suited to the temperature control of hot runner moulds on injection

moulding machines. In use, the controllers are connected directly to the mould via cables.

During operation, the hot runner controllers deliver electric current to the heating units for an injection mould. The so-

called heating current leads to an adjustable temperature increase in the heating units and hence in the mould.

Continuous temperature monitoring takes place in parallel via connected thermocouples. In the event of deviations

between the actual temperature recorded and the temperature set on the hot runner controller, the heating current is

automatically adjusted until the two temperatures are identical.

The controllers are available in different variants. These differ solely in terms of the number of control circuits that are

possible – which are also referred to as heating zones. Depending on the variant, hot runner controllers are available

with either 6, 12, 18, 24 or 36 heating zones.

3.2 Structure

A 12-zone controller is shown by way of example in the figures that follow. All the designated components are identical

on controllers with more than 12 heating zones.

Figure 1 - Housing front

8 HASCO hot runner

Figure 2 - Housing rear

Figure 3 - Housing side view

The following overview describes the main components of the hot runner controller.

(1) Touch display (2)

USB connection (3)

LED strip

(4) Connection line (5)

Main switch (6)

Plug system (example)

(7) Alarm socket (8)

RS485 connection (9)

Ethernet connection

(10) Digital input (11)

Fuse (12)

Status LED

(13) Power board

Bedienungsanleitung H1280

HASCO hot runner 9

3.2.1 Display (1)

The resistive touch display reacts to finger pressure or can be operated with standard commercial pens that have a

rounded plastic tip. For optimum operation, the display can be adjusted to four different positions. This allows an ideal

reading and operating angle to be obtained.

Please note: sharp, pointed objects can damage the display.

3.2.2 LED strip (3)

The controller status is depicted in colour in an LED strip that is visible from a long way off. This permits a rapid

assessment of the current controller and mould status.

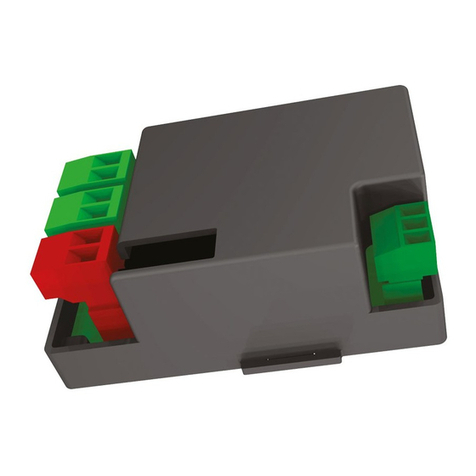

3.2.3 Power boards (13)

The connected heating units are controlled via compact power boards, as is the temperature measurement of the

thermocouples. Each power board contains the electronics for heating and measuring six heating zones. The

individual boards are mounted at the side of the housing. The cooling element visible from the outside is used for

optimum heat elimination and thus increases the service life of the installed electronics. The fuses for the load outputs

(11) are located beneath the cooling element.

Each zone is switched off separately via relays on the power board so that individual zones can be switched off

individually, and seamless production is always guaranteed.

In addition to the fuse for the load outputs, each power board (13) contains an internal second fuse that is necessary for

operation in triangular supply networks. There is also a control fuse on the internal wiring terminals.

3.2.4 Connections

In addition to the tiltable display, the front of the housing also has a USB connection. All the other connections are on

the rear of the housing. Apart from the thermal and load connections, each controller has alarm contacts, digital inputs

and an Ethernet connection.

3.2.4.1 USB connection (2)

The USB connection makes it possible to save and load controller settings, export service files and also load firmware

updates via a USB stick.

3.2.4.2 Ethernet connection (9)

The Ethernet connection is used for communication with additional controllers or an injection moulding machine and is

located on the rear of the housing.

3.2.4.3 RS485 connection (8)

The RS485 interface is used for communication with injection moulding machines and is located on the rear of the

housing.

3.2.4.4 Alarm contacts (7)

Each controller has three potential-free alarm contacts that are fed out via a socket on the rear of the housing. The alarm

contacts open as soon as the controller issues a warning or an alarm. A list of the possible messages is given in Chapter

5.3.2.2.4. A wiring diagram of the alarm contact socket is shown in Chapter 8.2.

3.2.4.5 Digital inputs (10)

The controller evaluates 24V DC signals via a 15-pole D-SUB input. The digital inputs are used for the external activation

of functions such as standby, switching the setpoints or locking the outputs. Chapter 8.3 shows the assignment plan for

the digital inputs with the corresponding functions.

The digital inputs are PLC compatible, i.e. they operate over a voltage range of 13...30 VDC with a typical current

consumption of approx. 8.5 mA.

10 HASCO hot runner

3.3 Identification marking on the controller

The type plate is mounted on the side of the controller housing. It contains the type designation with the number of

zones, the electrical connection data and the manufacturer’s data.

Figure 4 - Type plate

3.3.1 Wiring of the plug systems

The plug-in connectors for connecting up the temperature sensors and heating elements to a hot runner are available

on the rear of the controller. The customer-specific wiring plan for the plug-in systems is located on the side of the

controller housing (see Figure 6 for an example).

Figure 5 - Wiring of plug systems

4 Commissioning

4.1 Electrical connection

Important! Before the device is connected to the supply voltage, a check must first be

performed to ensure that the mains electricity conditions comply with the specifications on

the type plate.

The electrical connections must be performed by a qualified electrician. Commissioning

and operation while the controller is running are only to be carried out by authorised

qualified personnel.

Switching off all the outputs or individual zones will not protect any of the outputs against

hazardous voltages. Before working on the connected heating elements, the associated

connections must be unplugged, or the entire device disconnected from the mains power.

Before the device is opened, it must be disconnected from the mains power.

Bedienungsanleitung H1280

HASCO hot runner 11

4.1.1 Mains electricity

Before connecting the device to the mains voltage, a check must be conducted to ensure that the mains electricity

system is correct. The hot runner controllers are prepared by default for operation in a star network (3x400VAC + N +

PE) but can also be operated in a triangular network (3x230VAC + PE). For operation in a triangular network without a

neutral conductor, it is essential to observe the local regulations for the installation of electrical systems. The terminals

in the controller must be bridged accordingly for use in a star or triangular network. Annex 8.1 contains a clear terminal

connection diagram.

4.1.2 Connection to the mains electricity

To ensure correct operation, the hot-runner controller is connected to the low-voltage mains by means of the connection

lead attached to the device.

4.1.3 Connection of the mould

To connect the individual control zones to the corresponding injection mould, use must be made of appropriate leads

for the sensor and heating unit connection.

Please note: it must always be ensured that the internal wiring, the wiring of the cable

set and the wiring in the mould are suitably coordinated with each other.

Important! To exclude any effects of potential shifts, the injection moulds that are

connected up must be properly earthed in all cases.

4.2 Operating and display concept

4.2.1 Main switch

The main switch is located on the rear of the housing. The switch must

be activated to switch the controller on and off.

4.2.2 Status display

The controller status is indicated on a circulating LED strip. In normal operating mode, this display will be green. In the

event of a warning or an alarm, the display will change to yellow or red (traffic light system).

4.2.3 Operation

The hot runner controller is operated exclusively via the integral 7” touch display (Figure 1) on the housing front.

Please note: The cooling unit can become hot during heating. Avoid touching the

heating unit.

12 HASCO hot runner

5 Start menu

A few seconds after the controller has been switched on, the starting page of the user interface appears. In addition to

selecting the user language, the most important areas of the controller can be accessed from here.

Quick start

The main settings for bringing a new mould into operation.

Start with saved settings

Start the heating process with the saved settings.

Start with a recipe

Load controller settings that have previously been saved in a recipe.

If the user does not enter anything at this point, the controller will automatically switch to the operating view after 30

seconds.

Deutsch

English

Quick start

New mould

Start

Saved settings

Start

With recipe

Figure 6 - Home screen

Bedienungsanleitung H1280

HASCO hot runner 13

5.1 Navigation bar

The navigation bar is always visible at the top of the screen and contains the most important control elements for the

controller.

Figure 7 - Navigation bar

Description of the function buttons in the navigation bar

Symbol Brief description Explanation

Show and hide the

main menu

The main menu lists all the setting and display

options for the controller in its three main

areas: setup, operation and settings

Show and hide the

index of keywords

The keyword index is an alphabetically

arranged list of all the functions including a

lookup function and a direct access option.

Fehler! Verweisquelle konnte

nicht gefunden werden.

The home view during normal operation

shows the most important information at a

glance.

Switch all outputs on and off

Once all the zone settings have been made,

this button releases all the control outputs.

The button must be pressed at length so as to

avoid unintentional operating errors.

The symbol appears with a different

background colour when outputs are switched

on.

Switch all outputs on and off

Pressing this button switches off all the control

outputs.

The button must be pressed at length in order

to avoid unintentional operating errors.

Switch Standby operation

on and off

To reduce the setpoint temperatures during

production breaks. This button must be

pressed at length in order to avoid

unintentional operating errors.

The symbol has a different background colour

when the temperature is being lowered.

Diagnosis

This symbol is only visible if faults have

occurred. When pressed, it opens the fault

overview with the fault handling.

User level

This symbol is only visible if operation in the

corresponding user level is blocked. Once a

user level has been released with the

corresponding password, the following symbol

will appear:

Navigation menu

20.02.2019 12:30:42

Rezeptdatei.rzp

14 HASCO hot runner

It indicates that the current user level has

been released.

Timer

This symbol is only visible if the timer is

activated and the device is switched on or off

at the pre-programmed time.

xxxx.rzp Recipe file

Name of the last recipe loaded. If values have

been added after activation of the recipe, an *

is added to the name.

5.2 Selection of zones and groups for operation

The page for the operation of zones is divided in two. The left side of the screen always shows the zone or zone groups

that are to be operated. The actual input is then made on the right side.

Figure 8 - Sample page for entering setpoint values

Before zones are operated, they must first be selected. This is done by clicking on the desired zone. A selected zone

has a white surround. A selected zone can be deselected by clicking on it again (toggle function). Rapid selection of a

number of zones can be performed by running a finger over them in one go.

Zones can be allocated to a freely named group. Zones that belong to a group display their group colour under the zone

name. To select an entire group of zones, click on the respective group button (above the zone display). To

select/deselect all the zones, click on the “All” button. Operation of the zones is performed on the right side.

5.3 Navigation menu

For a better overview, the navigation menu has been divided into three levels.

Setup For setting and configuring the mould-specific settings for all the control zones.

Operation For displaying and modifying values and displaying faults during operation.

Settings For the general configuration and readout of information about the controller.

Each of these three main areas is, in turn, divided into subareas that are explained in more detail below.

Setpoint value

Standby temperature

Boost

Boost duration

Groups Operating mode Setpoint values Finish

All

None

Group 1

Group 2

1. Select zones and parameters

2. Enter value, repeat if necessary

then continue with Finish

Selection

Setup > Quick start > Setpoint values

20.02.2019 12:30:42

Bedienungsanleitung H1280

HASCO hot runner 15

Figure 9 - Navigation menu

Navigation menu

20.02.2019 12:30:42

Quick start

Monitoring

Heating

Mould test

Others

Home view

Diagnosis

Plotter

Control

All parameters

Device

Communication

Service

Setup

Operation

Settings

Mould-specific

Controller-specific

Groups

Operating mode

Setpoints

Temperature

Sensor fracture

Residual current

Output level

Heating group

Ramp gradient

Soft start

Run

Settings

Sensor type

Output level

Setpoint values

Operating mode

Boost

Malfunctions

Events

Control dynamics

Heating signal

Overview

Recipe

Language

Date / Time

User management

File management

Device info

Service file

Firmware update

Support

16 HASCO hot runner

5.3.1 Setup

All the mould-specific settings must be made during setup. The quick start guides users through the key settings for

bringing the controller into operation as quickly as possible. The "Monitoring" menu item is used for monitoring process

values and setting the corresponding limits. "Heating" contains all the functions that can influence the heating process.

"Mould test" is used to test the correct wiring of sensors and heating units. This function is particularly useful after initial

installation or after mounting operations.

Figure 10 - Setup

The individual functions are explained in more detail below.

5.3.1.1 Quick start

1. 2.

Setup > Quick start

The basic zone settings can be entered in quick start. Zones can be grouped here and setpoint temperatures and

operating modes entered for the zones.

5.3.1.1.1 Groups

1. 2. 3.

Setup > Quick start > Groups

Zones can be combined into groups, considerably facilitating operation. It makes sense, for example, to allocate the

zones for nozzles and manifolds to different groups. In this way, the grouped zones can be easily selected for

simultaneous operation later on. If no groups are to be defined, this section can be skipped.

Procedure: First select the zones on the left that are to be made into a group. Then, on the right side, click on one of the

predefined groups and adopt it with . The names of the groups are pre-set by default to Group 1... Group 9 and can

be adapted with the symbol where required. In addition, each group is represented by a colour. Zones that are

assigned to a group indicate this by the corresponding group colour beneath the zone name. See Figure 8 - Sample

page for entering setpoint values.

Factory setting:

All zones without a group

5.3.1.1.2 Operating mode

1. 2. 3.

Setup > Quick start > Operating mode

In the "Operating mode" menu item, a specific operating mode can be entered for each zone.

Procedure:

First select the zones on the left whose operating mode is to be changed.

Quick start

Monitoring

Heating

Mould test

Others

Setup

Mould-specific Groups

Operating mode

Setpoint values

Temperature

Sensor fracture

Residual current

Output level

Heating group

Ramp gradient

Soft start

Run

Settings

Sensor type

Output level

Bedienungsanleitung H1280

HASCO hot runner 17

Then, on the right side, select one of the operating modes.

Accept the selection with .

The following operating modes are defined:

Operating mode Function

Normal operating mode

In normal operating mode, the hot runner controller will control the output in

such a way that the measured temperature attains a specified setpoint

value. The output level (0...100%) at the output is calculated automatically.

In steady state operation, the actual value and setpoint value will be

identical.

Manual operation

During manual operation, a constant output level will be maintained at the

heating output. 0% means that the heating output is permanently off, 100%

means that the heating output is permanently on. Manual operation can be

used, for example, to manually maintain operation of the control zone until

a defective sensor is replaced.

OFF Zone inactive = switched off. If the sensor is connected, the temperature

monitoring of the cut-off temperature remains active.

Monitoring operation

cs

With this setting, a zone can only be used for display and temperature

monitoring. No output power is emitted.

5.3.1.1.3 Setpoint values

1. 2. 3.

Setup > Quick start > Setpoint values

It is possible to enter setpoint values as the specified temperatures for different situations:

for normal operating mode, the standby value and the specified value for boosting.

Procedure:

First select the zones on the left whose setpoint value is to be displayed or changed.

On the right side, select one of the setpoint values described below

Open the box for entering the setpoint value with

Enter the desired value in the input box

Confirm with OK.

Value Setting limits

Factory setting:

All zones will be switched off (OFF).

18 HASCO hot runner

Setpoint

value

Specified temperature for a zone in normal operating

mode.

Min:

Max:

Standard:

0 °C

600 °C

0 °C

Standby

temperature

It is recommended that use be made of the standby

function to protect the plastic melt and reduce energy

costs. The standby temperature can be specified here

as a function of the materials used. This determines the

value to which the zones should cool down. The

standby function is activated in the menu bar with the

“Pause” button or, alternatively, via a control input.

Min:

Max:

Standard:

0 °C

300 °C

150 °C

Boost

increase

By implementing the boost function, the setpoint

temperature for individual zones or groups is raised by

an adjustable value for a specified period of time. This

function can be used to heat up nozzle tips in order to

clear them prior to start-up. The boost function is

activated from the home view. The editor with the boost

button can be opened by clicking on a zone.

Min:

Max:

Standard:

0 K

50 K

0 K

Boost

duration

For setting the time mentioned above for which a zone

is to be boosted.

Min:

Max:

Standard:

0 sec

900 sec

60 sec

5.3.1.2 Monitoring

5.3.1.2.1 Temperature monitoring

1. 2. 3.

Setup > Monitoring > Temperature

Different temperature limits can be set on the temperature monitoring page.

Procedure:

First select the zones on the left whose temperature limit is to be changed

(see chapter Selection of zones and groups for operation)

On the right side, select one of the values described below

Open the box for entering the setpoint value with

Enter the desired value in the input box

Confirm with OK.

1)

Value Setting limits

Limit for

excessively

high

temperature

If the actual value exceeds the limit value set

here, the corresponding zone will depict a

corresponding symbol:

The LED strip will light up red and the zone will

temporarily turn off its output. A potential-free

contact can signal this alarm to the outside. If

the actual value falls below this limit value, this

alarm will automatically deactivate.

Min:

Max:

Standard:

0 °C

600°C sensor type

L

800°C sensor type

K

400 °C

Bedienungsanleitung H1280

HASCO hot runner 19

Tolerance

range

For temperature monitoring, a tolerance range

can be specified above and below the setpoint.

If the actual value is outside the tolerance range,

this will be signalled as a warning. This is

depicted on the relevant zone with a warning

symbol( or )

The LED strip will light up yellow.

A potential-free contact can signal this alarm to

the outside.

The outputs will not be switched off.

Min:

Max:

Standard:

1 K

600 K

15 K

Limit for

excessively

low

temperature

If the actual temperature falls below the limit

value set here, the relevant zone will be marked

with a corresponding alarm:

The LED strip will light up red.

A potential-free contact can signal this alarm to

the outside. If the actual value exceeds this limit

value, the alarm will be automatically

deactivated.

Min:

Max:

Standard:

0 °C

600 °C

0 °C

Switch-off

temperature

If the actual value of one zone exceeds the

switch-off temperature set here, all the zones

will be switched off. The relevant zone will be

marked with a corresponding alarm:

The LED strip will light up red.

A potential-free contact can signal this alarm to

the outside.

The controller can only be operated again with

an error acknowledgement or a restart.

Min:

Max:

Standard:

0 °C

600 °C

500 °C

5.3.1.2.2 Sensor fracture monitoring

1. 2. 3.

Setup > Monitoring > Sensor fracture

The controller behaviour in the event of sensor fracture during normal operation is set out here.

Behaviour

Output level 0% The zone reports an alarm and adjusts the output level to 0%.

Mean output level

YM

The zone reports a warning under sensor fracture and then switches to the

previously averaged output level.

Defined output

level

The zone reports a warning under sensor fracture and then switches

permanently to the output level that can be adjusted here. The output level

can be specified after pressing the button and is displayed at the zones.

20 HASCO hot runner

Output level of

reference zone

The zone reports a warning under sensor fracture and then switches to the

output level of a reference zone that can be defined here. The reference

zone can be specified after pressing the button and is displayed on the

zones with Zxxx (xxx = number of the reference zone).

5.3.1.2.3 Residual current monitoring

1. 2. 3.

Setup > Monitoring > Residual current

Behaviour

Do not report Residual current monitoring is switched off

Report only Residual current monitoring detects residual currents that flow on account of

moisture in the mould or insulation damage.

If “Report only” is selected, residual current monitoring is activated and a warning is

generated if the limit value is exceeded.

Report and dry

out

If “Report and dry out” is selected, residual current monitoring is activated. If the limit

value is exceeded, a warning will be generated and, in addition to drying out, all the

zones will be heated up to 100°C until the residual current falls below the limit value

again.

The factory setting is: Report and dry out

5.3.1.2.4 Output level monitoring

1. 2. 3.

Setup > Monitoring > Output level

Value Setting limits

Output level

reference

value

The output level calculated during normal

operating mode can be monitored. If the

calculated value deviates from this reference

value, it could be a sign of an irregularity in the

controlled system. There could perhaps be

leakage in the nozzle.

Setting this to “0” switches off the monitoring.

Min:

Max:

Standard:

0 %

100 %

0% (off)

Output level

tolerance

If the current output level exceeds or falls below

the reference value by the set tolerance, a

warning is generated. The LED strip lights up

yellow and, on the touch display, the relevant

zone is marked with a warning symbol .

A potential-free contact can signal this alarm to

the outside.

Min:

Max:

Standard:

0%

100 %

100 %

Bedienungsanleitung H1280

HASCO hot runner 21

The outputs will not be switched off.

Adopt output

level

By pressing “Adopt mean output level”, the

current average output level that has been

calculated will automatically be set as the new

reference value for output level monitoring.

5.3.1.2.5 Heating current monitoring

1. 2. 3.

Setup > Monitoring > Heating current

Heating current monitoring is used to detect defective heating units or supply lines. A message is generated if the

measured current deviates from the specified reference value.

Value Setting limits

Heating

current

reference

value

The heating current to be monitored can be

specified here. Any deviation is calculated on the

basis of this reference value. Entering a setting of

0.0 A will switch off the monitoring. The current

will, however, continue to be displayed.

Min:

Max:

Standard:

0.0 A

25.0 A

0.0 A

Heating

current

tolerance

The tolerance set here is the maximum permitted

deviation of the present heating current measured

from the reference value. If the heating current

exceeds or falls below the tolerance, a warning

will be generated. The LED strip will light up

yellow and, on the touch display, the relevant

zone will be marked with a warning symbol

.

Min:

Max:

Standard:

0.0 A

16.0 A

0.5 A

Adopt heating

current

When the “Adopt heating current” button is

pressed, the present heating current measured

will automatically be set as the new reference

value for current monitoring.

5.3.1.3 Heating

1. 2.

Setup > Heating

The heating behaviour of each individual zone can be selected here.

Function Description

Sequence in a

heating group

A heating group ensures the uniform heating of all the zones. This avoids stresses in

the mould and premature overheating of fast individual nozzles.

Table of contents

Other Hasco Control Unit manuals

Popular Control Unit manuals by other brands

etp

etp HYDRO-GRIP GEW2 Assembly instructions

AGFEO

AGFEO AM 20 Installation

Lennox

Lennox 13J76 installation instructions

Olimpia splendid

Olimpia splendid Bi2 B0659 Instructions for mounting and use

SEW-Eurodrive

SEW-Eurodrive MOVISAFE UCS50B operating instructions

SmartOne

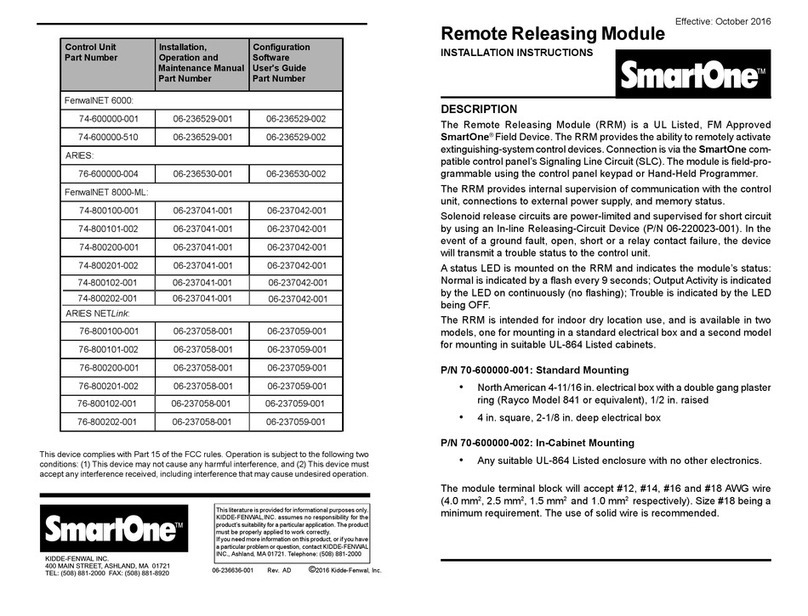

SmartOne 70-600000-001 installation instructions