Hasco Hotrunner H1270 Series User manual

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

Hotrunner control unit

Operating Instructions

Precision

for

Mouldmaking.

2

Contents P

P

a

a

g

g

e

e

1. Introduction 3

2. Special features 3

3. Technical data 3

4. Electrical connection 4

4.1 Pin diagram 4

5. Function description of displays and buttons 5

6. Displays 6

6.1 Function buttons 7

7. Controller start-up 7

7.1 Switching on / soft start 7

8. Open-loop control 8

9. Programming 8

10. Menu items 8

11. Alarm pin configuration 9

12. Safety information 10

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

2

Precision

for

Mouldmaking.

3

1. Introduction

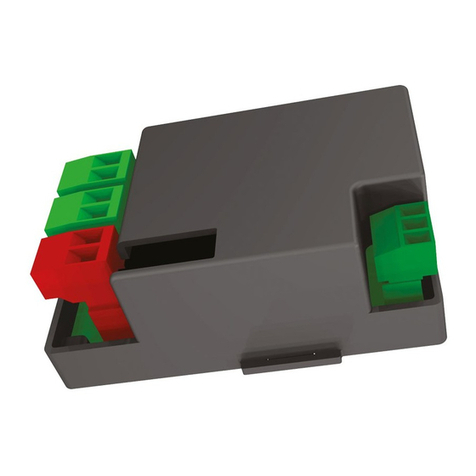

The HASCO control unit Z 1270 ensures precision control and practically-orientated operation.

2. Special features

- 3 to 6 control zones

- Modular units with 3600 W / 16A per control circuit

- Permanent indicator for two monitoring states

OK - green / Error – RED

- Improved control characteristics

- Programmable soft start

- Power output in amps and % output level

- Unmistakable alarm diagnosis

- Alarm input and output as standard

- Manual or automatic switch to open-loop control

- Boost function

- Temperature reduction

- Sensor monitoring

- Heating monitoring

The H 1270…control unit satisfies the key protection requirements as per the EU Directives.

3. Technical data

H 1270/n x 16

Dimensions (W x H x D)

Mains voltage standard

400V 3N ~ ±10% / 50Hz

Unit protection, external

32A / phase

Power output

Contactless semiconductor end step, 250V~, max. 16 A, zero-voltage switching

Thermocouple

Fe-CuNi type J

Operating range

30 – 500°C

Operating precision

< 1°C under optimum conditions

Ambient temperature

10 – 40°C

Power fuse

FF 16A / 500V

Control input

2 potential-free normally open contacts

Alarm output

1 potential-free normally open contact max. 50V 2A

Degree of protection

IP 21 / EN 60529

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

3

Precision

for

Mouldmaking.

4

4. Electrical connection

The power/signal connector Z 1225/... is used for the electricity and thermocouple connections between the

mould and the control unit.

If all the control zones in the H 1270 /... are used, it is essential to observe the following:

The maximum power consumption of 21600 W must not be exceeded!

H 1270/n x16

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

4

Precision

for

Mouldmaking.

5

5. Function description of displays and buttons

5.1 Displays

LED strip

The LED strip shows two possible monitoring results.

Green = ready for operation

Red = alarm

Actual value display

Actual temperature in °C

Menu items parameter.

Setpoint value display

Setpoint temperature in °C

Power output in amps and heating output in % - see automatic control and PRG buttons.

Operating modes

MANUAL

Reduced temperature

Boost function

Parameter values

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

5

Precision

for

Mouldmaking.

6

Alarm displays

Thermocouple error

Constantly lit for sensor fracture or reverse polarity, "- - -" appears in the actual value display.

If the automatic open-loop control function is activated, the current heating output of the module will appear

after a short time. Alarm output active.

Temperature deviation

Lights up during the heating phase until the setpoint temperature has been

reached.

Is constantly lit if the set limit temperatures are exceeded or not reached.

Alarm output active.

Excess current

Lights up if the set maximum current is exceeded.

Alarm output active.

Heating circuit interrupted

Lights up in the event of a defective fuse FF16A on the module, heating failure or cable fracture.

Alarm output active.

Function displays

Setpoint value

Temperature display °C

Second setpoint value temperature reduction

Display for lowering the setpoint temperature, factory setting 151°C.

The temperature can be changed with the arrow buttons.

This function is activated via an external switch - see Activating the reduced temperature

Third setpoint value temperature increase

Display for raising the setpoint temperature, factory setting 251°C.

This can be changed with the arrow buttons.

This function is activated via an external switch - see Activating the boost temperature

Heating output

This setpoint value display shows the current heating output in %.

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

6

Precision

for

Mouldmaking.

7

5.2 Function buttons

On/off button

This switches the controller module on and off.

Up/down buttons

Select setpoint value for temperature.

Change parameter values.

Open-loop control button

Activate open-loop control

Automatic control / current key

Activate automatic control.

Current measurement.

6. Controller start-up

6.1 Switching on / soft start

After a careful check of the cables, connect the mould to the control unit.

Switch on the control unit at the main switch.

Use the arrow buttons to activate the setpoint display and enter the desired setpoint value.

The controller module is switched on and off with the I/O button and the soft start activated.

SOF appears in the setpoint value display. After the soft start has been completed, the setpoint value that was

entered will be displayed.

The control unit now heats up the mould uniformly, drying out moist heating elements.

The "Temperature deviation" alarm display will light up.

Once the setpoint temperature that was entered has been reached, production can be run with the calculated

parameters.

The "Temperature deviation" alarm display will go out.

If malfunctions occur during start-up, the reason for the error will be shown by the appropriate displays on the

control unit (see Page 6).

The soft start can be bypassed by pressing the automatic control / PRG button combination.

The automatic control button must be pressed first in this case.

After switching the unit off and on with the mains switch, the soft start will be active again.

The soft start can be permanently deactivated via parameter 17 (page 8).

Note! The soft start provides protection for the electric components.

It is recommended to run a soft start!

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

7

Precision

for

Mouldmaking.

8

6.2 Open-loop control

Manual operation is called up by pressing the "Open-loop control" button. The desired heating output (%) is set

with the aid of the arrow buttons.

7. Programming

Programming mode is activated by pressing the PRG button (for about 3 sec.).

The first menu item "P00" appears in the actual value display. The setpoint value display shows the value of the

parameter.

This can be changed with the arrow buttons.

Pressing the PRG button twice again will call up the next parameter.

To exit program mode, press the PRG button for approx. 3 sec.

The control unit confirms that the changed parameters have been permanently saved through the decimal point in

the top right-hand display blinking for a short time.

The temperature control continues to operate normally in parameter mode.

7.1. Factory settings

To return all the parameters to the factory setting, keep the "PRG" button pressed when the operating voltage is

switched on.

8. Menu items

Menu items

ex-works

Value range

Comment

P00

Offset cold junction temperature

0

-9.9 – 9.9

°C

P01

Free

P02

Determine control parameters

again

0 0 - 1 1= activated

P03

Edit established dead time

X

0 - 100

P04

Enter dead time manually

0 - 100

P05

Display residual time soft start

X

sec.

P06

Soft start duration

300

120 - 999

sec.

P07

Upper temperature alarm limit

10

0 - 500

0 = deactivated

P08

Lower temperature limit

10

0 – 500

0 = deactivated

P09

Temperature alarm mode

1

0 = Off / 1 = ON

P10

Min. load current

0.3A

0 – 16A

0 = deactivated

P11

Max. heating output for soft start

35%

0 – 100%

P12

Max. heating output after soft start

100%

0 – 100%

P13

Max. heating output with open-

loop control

0% 0 – 100%

P14

Identifier for external setpoint

2

2 - 3

P15 Language 0 0 - 1

0 = German

1 = English

P16

Display brightness

0

0 - 1

P17

Soft start ON = 1 / OFF = 0

1

0 -1

P18

No soft start from actual

temperature

100°C

50 – 100°C

P19

Max. setpoint value

500°C

30 – 500°C

P20

Automatic open-loop control

0

0 -1

0 = deactivated

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

8

Precision

for

Mouldmaking.

9

9. Connector pin assignment

Control unit alarm output

4 3 2

Potential-free relay contact max. 50V 2A

U

U

N

N

T

T

E

E

M

M

P

P

Start-up to setpoint value . . . .Pin 3+4 C active

Setpoint value attained. . . . . Pin 2+3 O active

If the temperature falls below

the temperature alarm range.. Pin 3+4 C active

O

O

V

V

T

T

E

E

M

M

P

P

Start-up to setpoint value . . . . Pin 3+4 C active

Setpoint value reached. ....... Pin 2+3 O active

If the temperature falls below the

temperature alarm range....... .Pin 3+4 C active

Connecting the injection moulding machine to the control unit

Normally open contacts

Reduced temperature…….Pin 3+4

Boost………………………. Pin 2+4

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

9

Precision

for

Mouldmaking.

10

10. Safety information

Connecting cable Z 1225 /. . . and connection housing Z 1227/. . . are to be used for the electrical connections

(power and thermocouple connections) between the control unit and the mould.

This will ensure optimum control accuracy.

The control units are coordinated with the HASCO standard components range.

If parts from other manufacturers are used, perfect operation cannot be guaranteed.

Connection, repair and maintenance work may only be carried out by trained electrical technicians.

During work on the control unit and on the cables, devices, machines and tools connected to them, all parts must

be disconnected from the mains power.

The system must also be safeguarded against being unintentionally turned on again.

The power/signal connectors Z 1225 /. . . must be regularly inspected for mechanical damage and replaced when

necessary.

The units must be free-standing to ensure sufficient ventilation and cooling.

The control units must be protected against dampness and wet.

The units are to be used in a technically meaningful way.

Before changing the fuse, disconnect the unit from the mains power.

11.15 / Lin

© by HASCO Hasenclever GmbH + Co KG, Postfach 1720, D-58467 Lüdenscheid,

Subject to technical modifications

Please always check all the data against the product information we publish in the internet.

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

D / GB / F 06 / 19 HK

H1270/...

Heißkanal Regelgerät

Hotrunner control unit

Régulateur multi-systèmes

10

Table of contents

Other Hasco Control Unit manuals

Popular Control Unit manuals by other brands

etp

etp HYDRO-GRIP GEW2 Assembly instructions

AGFEO

AGFEO AM 20 Installation

Lennox

Lennox 13J76 installation instructions

Olimpia splendid

Olimpia splendid Bi2 B0659 Instructions for mounting and use

SEW-Eurodrive

SEW-Eurodrive MOVISAFE UCS50B operating instructions

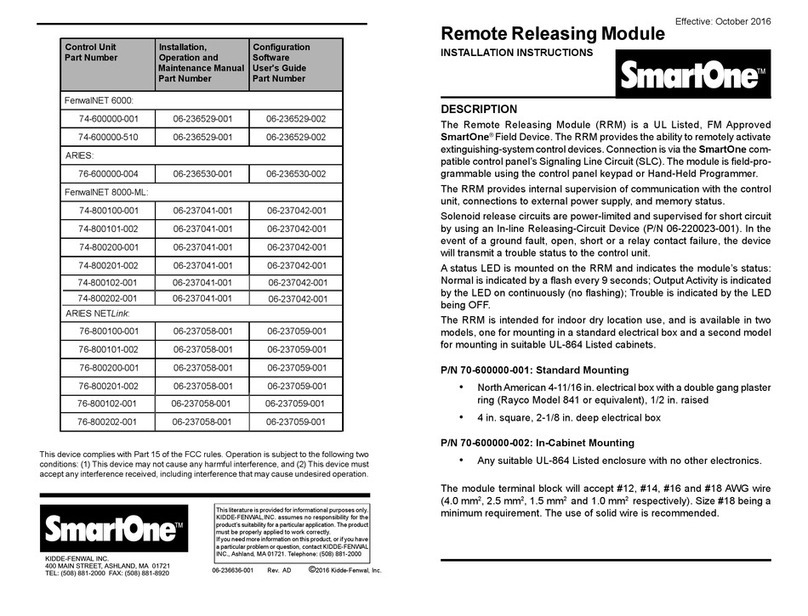

SmartOne

SmartOne 70-600000-001 installation instructions