Hasco H1250 Series User manual

This manual suits for next models

3

Table of contents

Other Hasco Control Unit manuals

Popular Control Unit manuals by other brands

Radio Shack

Radio Shack Color Graphics Option installation instructions

National Instruments

National Instruments Phase Matrix PXI-1430B quick start guide

IKEA

IKEA tradfri manual

GOK

GOK HS-V.2 Assembly and operating manual

Zator

Zator MZL100 User and maintenance manual

Acromag

Acromag AcroPack AP445 Series user manual

DSC

DSC PC5720 installation manual

Artel

Artel DigiLink DLC910 Installation and operation manual

Comparato

Comparato COMPACT CRONO installation manual

National Instruments

National Instruments NI 9870 Getting started guide

schmersal

schmersal SRB 220XV2 V.2 operating instructions

Mortara

Mortara WAM user manual

Gasboy

Gasboy 52 Installation & parts manual

Mark-10

Mark-10 Series 5 user guide

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS CTM-EF 3 3 Series Operating and maintenance instructions

Dungs

Dungs DMV 11 eco Series Operation and assembly instructions

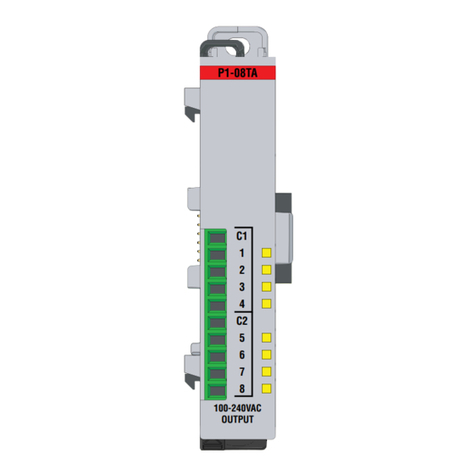

Automationdirect.com

Automationdirect.com Productivity 1000 P1-08TA manual

indie

indie iND83405 Quick start user guide