TABLE OF CONTENTS

Table of Contents

Section Page#

SECTION 1 – GETTING ACQUAINTED ________________________________________________ 5

SAFETY PRECAUTIONS ________________________________________________________________ 5

PACKAGING/SHIPPING ________________________________________________________________5

CONTENTS _________________________________________________________________________5

SYSTEM REQUIREMENTS ______________________________________________________________5

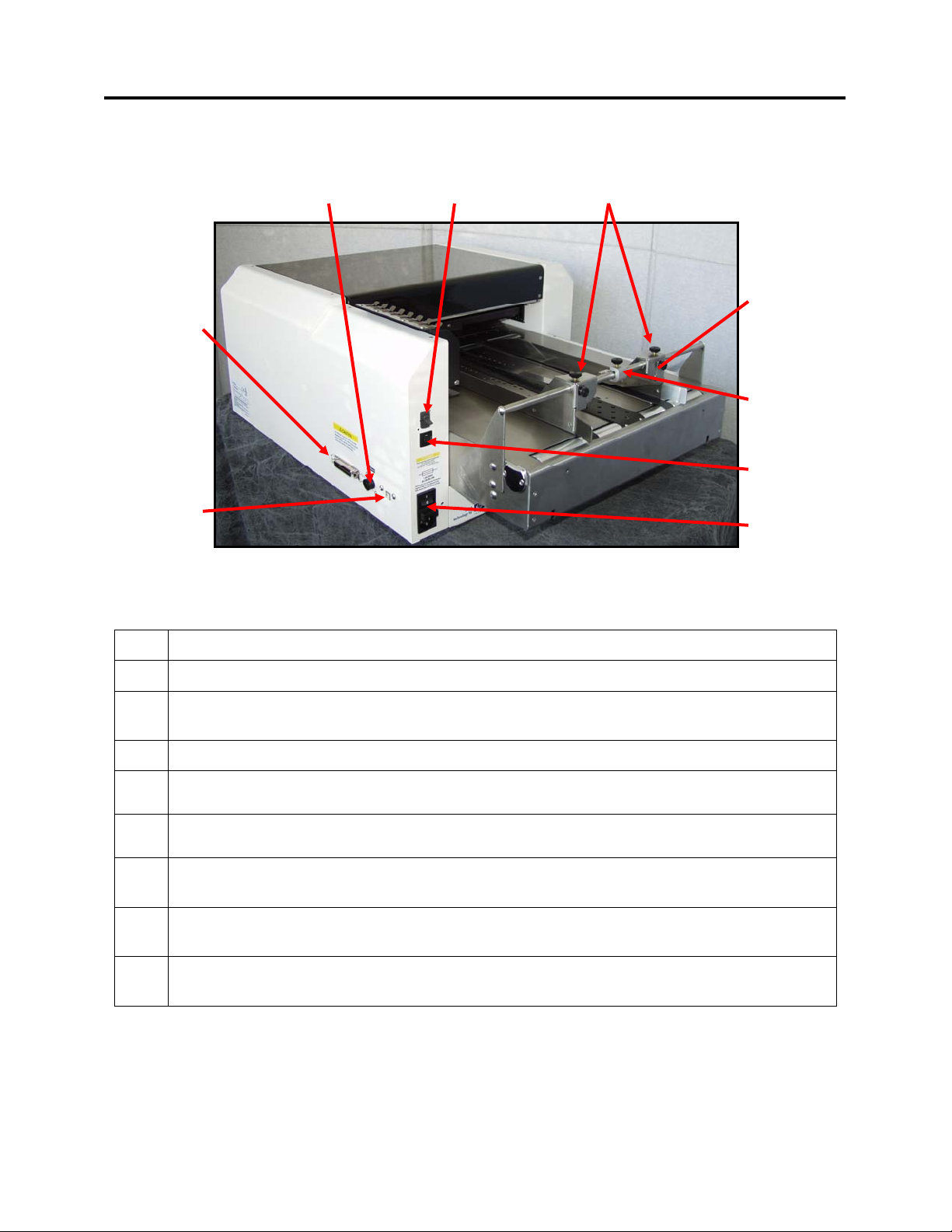

OPERATOR VIEW ____________________________________________________________________6

REAR VIEW ________________________________________________________________________7

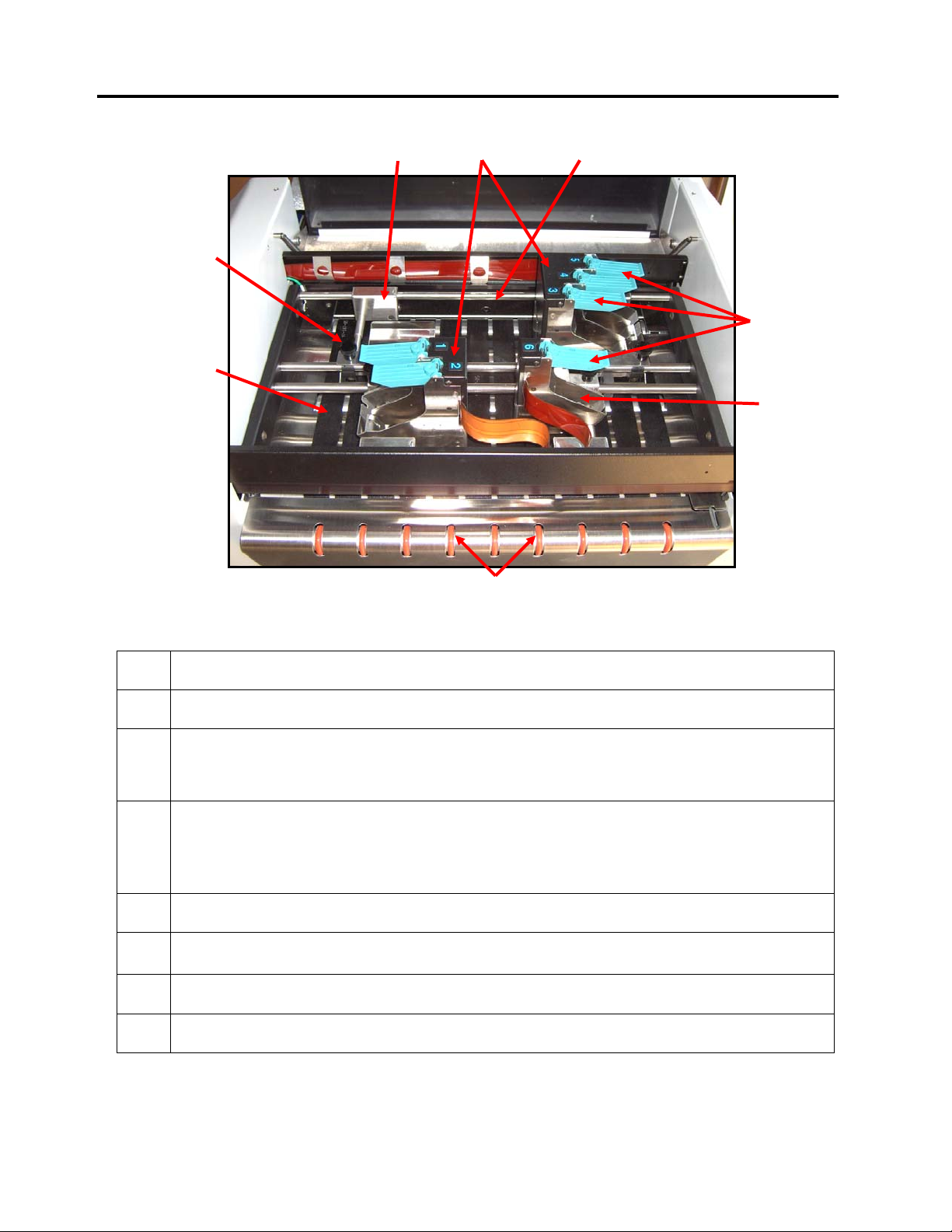

PRINT CARRIAGE VIEW _______________________________________________________________8

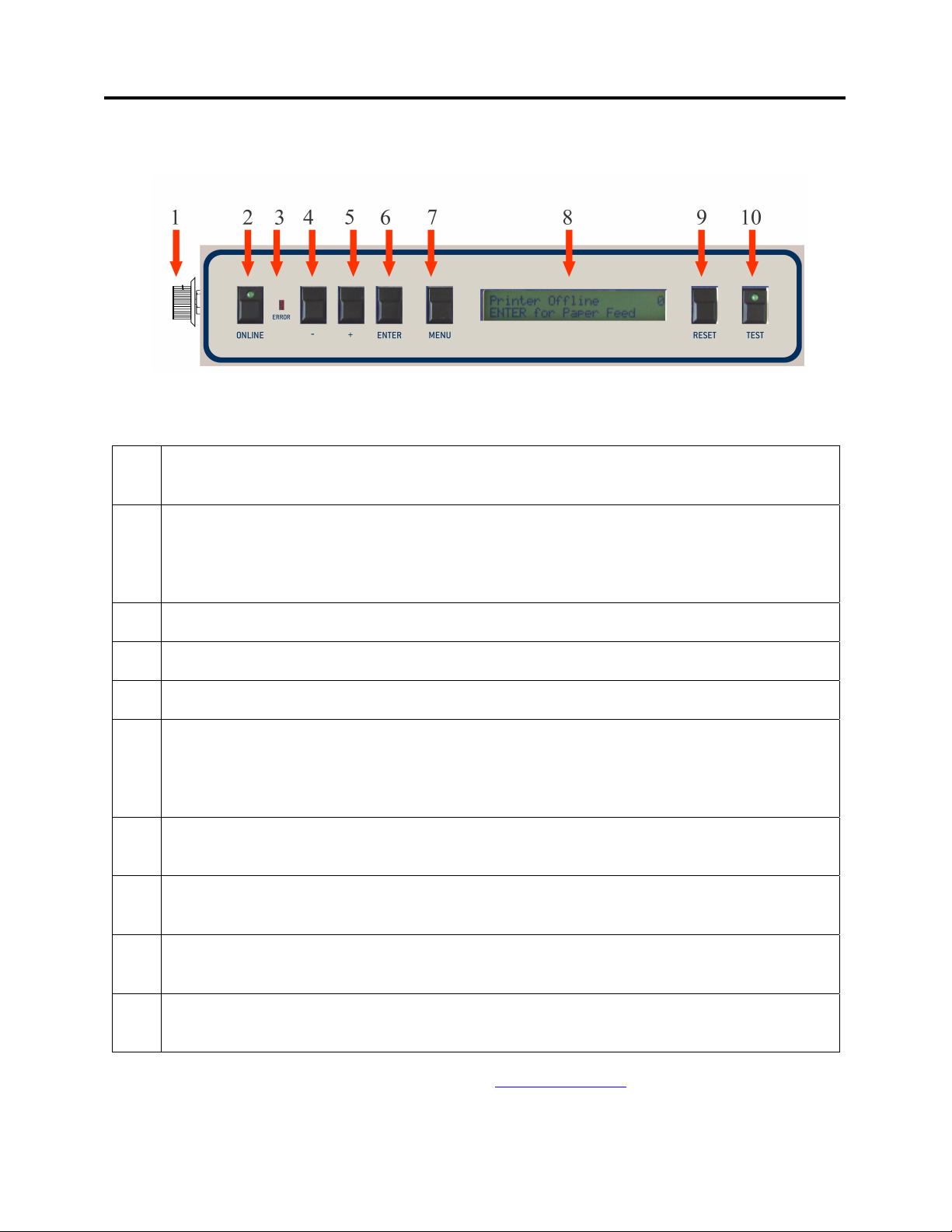

CONTROL PANEL ____________________________________________________________________9

SECTION 2 – PRINTER INSTALLATION AND SETUP __________________________________ 11

CHOOSE A LOCATION ________________________________________________________________ 11

CONNECTING POWER TO THE PRINTER ___________________________________________________ 11

CONNECTING TO THE COMPUTER _______________________________________________________ 11

CONNECTING THE OPTIONAL FEEDER TO THE PRINTER ______________________________________ 12

INSTALLING THE INK CARTRIDGES______________________________________________________ 13

Ink Level Monitor Reset____________________________________________________________ 13

SETTING UP THE TRANSPORT SYSTEM ___________________________________________________ 14

Media Side Guide and Transport Belt Adjustment __________________________________ _____14

Media Thickness Adjustment________________________________________________________ 16

PRINT UNIT POSITIONING (VERTICAL ADDRESS POSITIONING) ________________________________ 17

Print Area ______________________________________________________________________ 18

PAPER FEED (MEDIA TRANSPORT)TEST _________________________________________________ 18

TEST PRINT _______________________________________________________________________ 18

SECTION 3 – OPERATING THE PRINTER _____________________________________________19

PRINTER CONTROL PANEL &MENU FEATURES __________________________________ _________19

PRINT RECOVERY AFTER A JAM________________________________________________________ 21

INSTALLING THE PRINTER DRIVER __________________________________________________22

USB Port Selection and Verification Process______________________________ ________26

Print Driver Properties _____________________________________________________ _______28

Print Head Alignment______________________________________________________________28

SOFTWARE SETUP EXAMPLES _____________________________________________________30

Printing from Satori Bulk Mailer® 5.0 _______________________________________________30

Printing from Microsoft Word _______________________________________________________32

SECTION 4 – MAINTENANCE _______________________________________________________34

INKJET CARTRIDGE MAINTENANCE _____________________________________________________34

Replacing the Inkjet Cartridge:______________________________________________________34

Inkjet Cartridge Storage ___________________________________________________________35

Cartridge Disposal _______________________________________________________________35

Cleaning the Inkjet Cartridge (Printhead) _____________________________________________35

Purging the Nozzles_______________________________________________________________36

JAMS IN THE PRINTER ________________________________________________________________36

Removing Jammed Media __________________________________________________________36

CLEANING THE PRINTER______________________________________________________________36

Upper Pressure Rollers & Exit Rollers ________________________________________________37

Media Transport Belts_____________________________________________________________37

Limitations of this document: The information presented herein is subject to change. 10/14/2009 Neopost USA Inc. assumes no liability

whatsoever for any losses or damages resulting from use of this information. © 2009 Neopost USA Inc. All rights reserved.