163-112009 HFM-HFC-D_301/303/305 and 307 Page 3 of 43

Table of Contents

1. GENERAL INFORMATION............................................................................................................................................ 4

1.1. Features.......................................................................................................................................................................... 4

1.2. Specifications................................................................................................................................................................. 5

1.3. Other Accessories.......................................................................................................................................................... 6

2. INTRODUCTION..............................................................................................................................................................7

3. INSTALLATION & OPERATION.................................................................................................................................. 8

3.1. Receiving Inspection.....................................................................................................................................................8

3.2. Power Requirements.....................................................................................................................................................8

3.3. Output Signal ................................................................................................................................................................. 8

3.4. Quick Start ..................................................................................................................................................................... 8

4. SETUP................................................................................................................................................................................. 9

4.1. Mechanical Connections...............................................................................................................................................9

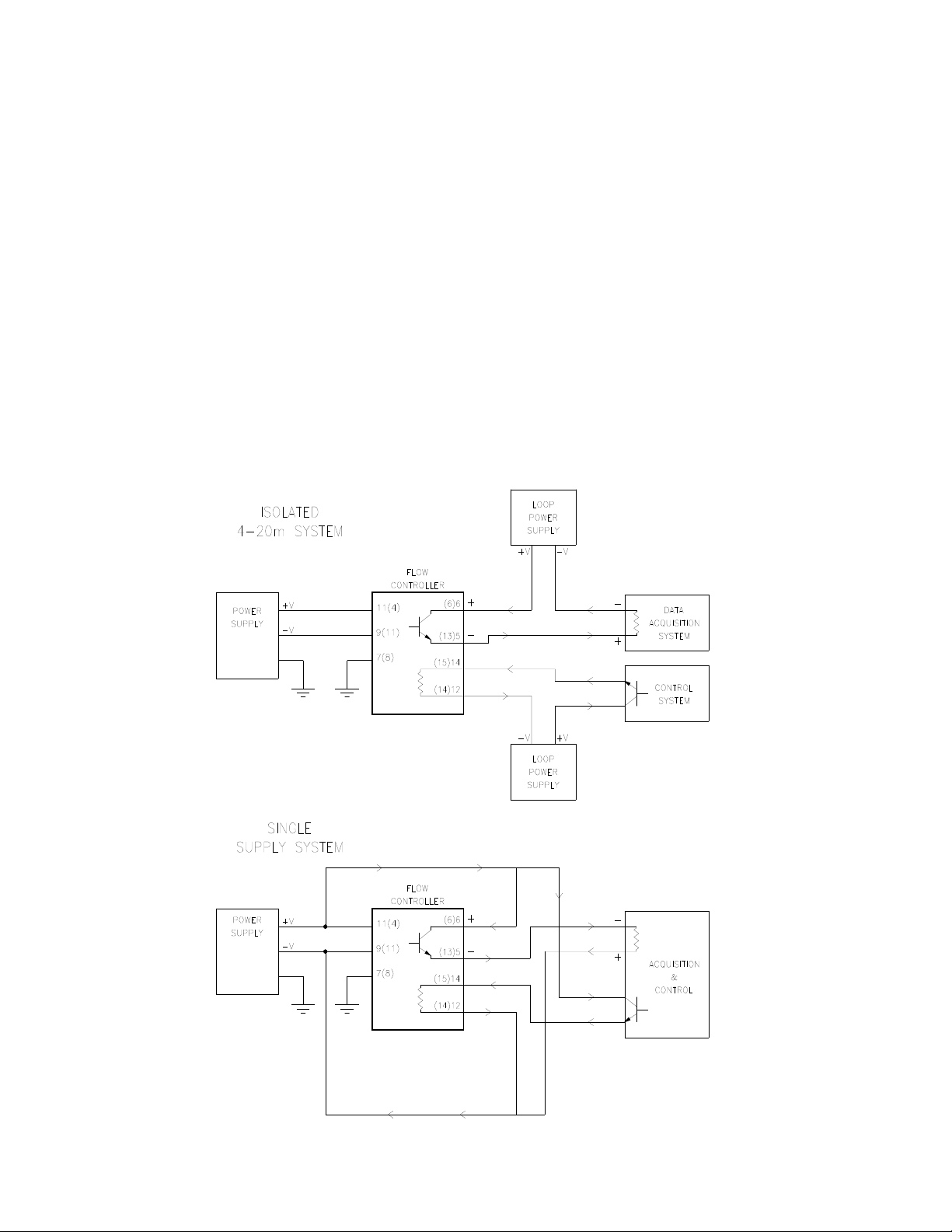

4.2. Electrical Connections..................................................................................................................................................9

5. DIGITAL COMMUNICATION.....................................................................................................................................14

5.1. Basics.............................................................................................................................................................................14

5.2. Operating States..........................................................................................................................................................15

5.3. Digital Control ............................................................................................................................................................. 15

6. OPERATION....................................................................................................................................................................20

6.1. Operating Conditions.................................................................................................................................................. 20

6.2. Zero Check ...................................................................................................................................................................20

6.3. High Pressure Operation ............................................................................................................................................20

6.4. Blending of Gases........................................................................................................................................................22

6.5. Controlling Other Process Variables ........................................................................................................................ 22

6.6. Command Input ........................................................................................................................................................... 23

6.7. Valve Override Control............................................................................................................................................... 23

7. THEORY OF OPERATION...........................................................................................................................................24

7.1. Overall Functional Description .................................................................................................................................24

7.2. Sensor Description ......................................................................................................................................................24

7.3. Sensor Theory .............................................................................................................................................................. 25

7.4. Base ...............................................................................................................................................................................26

7.5. Shunt description ........................................................................................................................................................ 28

7.6. Shunt Theory................................................................................................................................................................ 28

7.7. Control Valve ............................................................................................................................................................... 32

8. MAINTENANCE..............................................................................................................................................................34

8.1. Authorized Maintenance ............................................................................................................................................34

8.2. Troubleshooting...........................................................................................................................................................34

8.3. End Cap Removal.........................................................................................................................................................38

9. GAS CONVERSION FACTORS....................................................................................................................................39

10. REFERENCES .................................................................................................................................................................42

11. WARRANTY AND REPAIR .......................................................................................................................................... 43

11.1. Warranty Repair Policy ..............................................................................................................................................43

11.2. Non-Warranty Repair Policy ......................................................................................................................................43