© 2022 Hatco Corporation2

2. Install the glass panel.

a. Loosen the thumb screw/hex cap screw on each Orbit

bracket, and adjust the brackets so that the glass panel will

be in the horizontal position during installation.

b. Install a nylon washer on top of each Orbit bracket.

NOTE:Alwayspositionnylonwasherswiththeraisedlipfacingthe

glass.

c. Position the glass panel on top of the nylon washers.

d. Place a nylon washer followed by a top plate on top of the

glass panel aligned with each Orbit bracket, and secure in

position using an included machine screw. Tighten the screw

until it holds the glass securely—do not over-tighten.

Nylon

Washer

Orbit Bracket

Top Plate

Machine

Screw

Thumb Screw

Glass Panel

installed onto

post using

Orbit bracket.

Lip

3. Adjust the angle of the glass panel, if necessary. NOTICE: Two

people are required for this step.

• The angle of the glass panel can be adjusted in 15°

increments.

• Simultaneously loosen the thumb screw/hex cap screw on

each Orbit bracket, carefully rotate the glass panel to the

desired position, and re-tighten the thumb screws/hex cap

screws securely.

Cleaning/Maintenance

Clean the unit daily using non-abrasive cloths and cleaners.

• Always spray/apply cleaner to the cloth, then wipe down the

sneeze guard. Do not spray cleaner directly onto the sneeze

guard.

9. IMPORTANT! Refer to the “Securing the Glass” procedures on

this sheet before beginning installation of any glass panels.

10. Install the glass Top Shelf(s) by sliding it into the glass clips

from the front or rear. Secure the glass.

11. Install the glass Face Panel(s). Refer to “Orbit Brackets” in the

“Securing the Glass” section.

12. Install each glass End Panel by sliding them into the glass clips

from the front or rear. Secure the glass.

13. For NSF compliance, apply NSF-approved silicone sealant to

the screw heads of all set screws and nylon set screws.

NOTE:For NSFcompliance,the bottom edgeofall End Panels

cannotbepositionedhigherthan1-1/2″(38mm)abovethe

installationsurface.

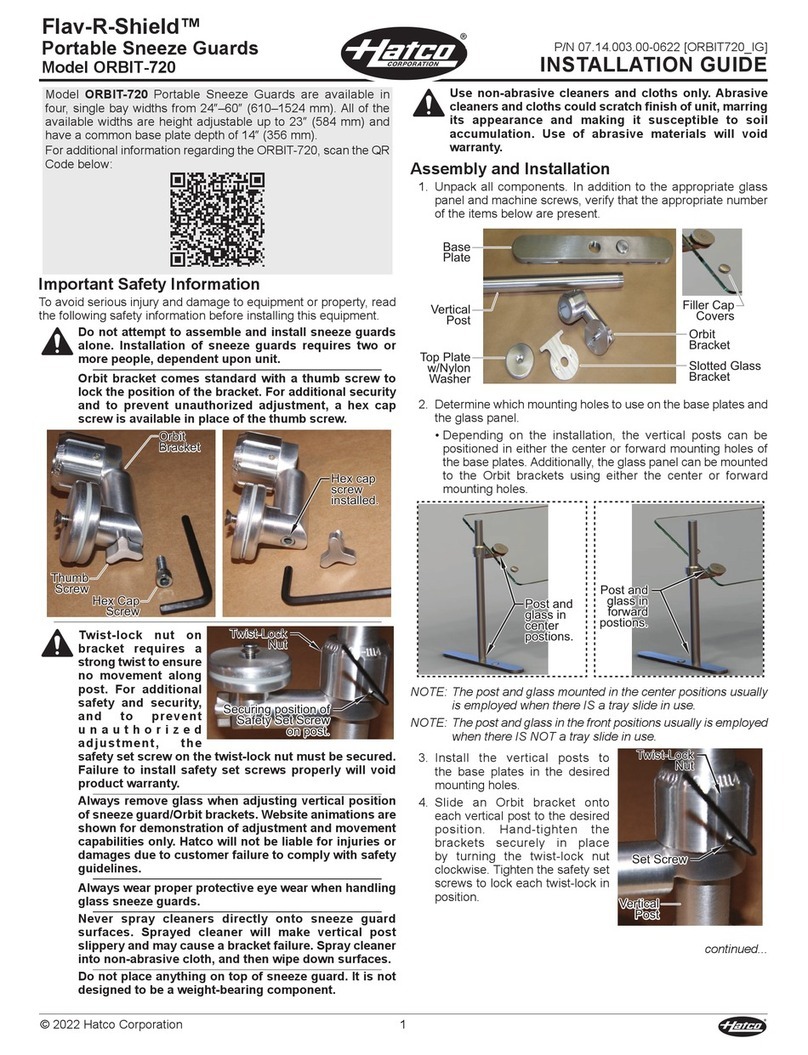

Securing the Glass

Glass panels are attached to support posts using either integrated

glass clips or adjustable Orbit brackets. CAUTION! Always wear

proper protective eye wear when handling glass.

Glass Clips

The glass End Panels and Top Shelf panels are attached to the

support posts using integrated glass clips. A nylon set screw on

each glass clip secures the glass panel in the clip.

Glass

Panel

Scuffed

Area

Nylon

Set Screw

Glass

Clip

Post Assembly

NOTE:Duringinstallationofallvertical

and angled glass panels,

Hatco strongly recommends

that an abraded surface be

created where the nylon set

screw contacts the glass.

Thiswillcreateastrongbond

betweenthesetscrewandthe

glass.Use320-gritsandpaper

toscufftheglasswhereeach

nylon set screw will contact

theglass.

Turn Nylon

set screw

1/4-turn

clockwise

after contact.

Turn Nylon

set screw

1/4-turn

clockwise

after contact.

Post Assembly

1. Abrade the surface of the glass

panel where each nylon set screw

will contact the glass.

2. Insert the glass panel into the

glass clips.

3. Carefully turn the nylon set screw

clockwise just until the screw

contacts the glass. Then, turn the

screw an additional 1/4-turn to

secure the glass.

Orbit Brackets

The glass Face Panel(s) is attached to the support posts using

adjustable Orbit brackets.

1. Prepare to install the glass panel.

• There are two mounting holes provided on each side of the

glass panel. Choose the hole position that will work for the

installation. Install the provided filler cap assembly in the

unused holes using a coin to hand-tighten.

Filler Cap

Cover

Filler Cap

Cover

Use coin

here.

Underside

of glass

panel.

Filler Cap

Assembly

installed.

Top side

of glass

panel. HATCO CORPORATION

P.O. Box 340500

Milwaukee, WI 53234-0500 U.S.A.

414-671-6350

www.hatcocorp.com

Custom Units

Scan this QR code or click the link

below to access information regarding

custom units including sizes, glass,

hardware, and lighting.

www.hatcosneezeguards.com