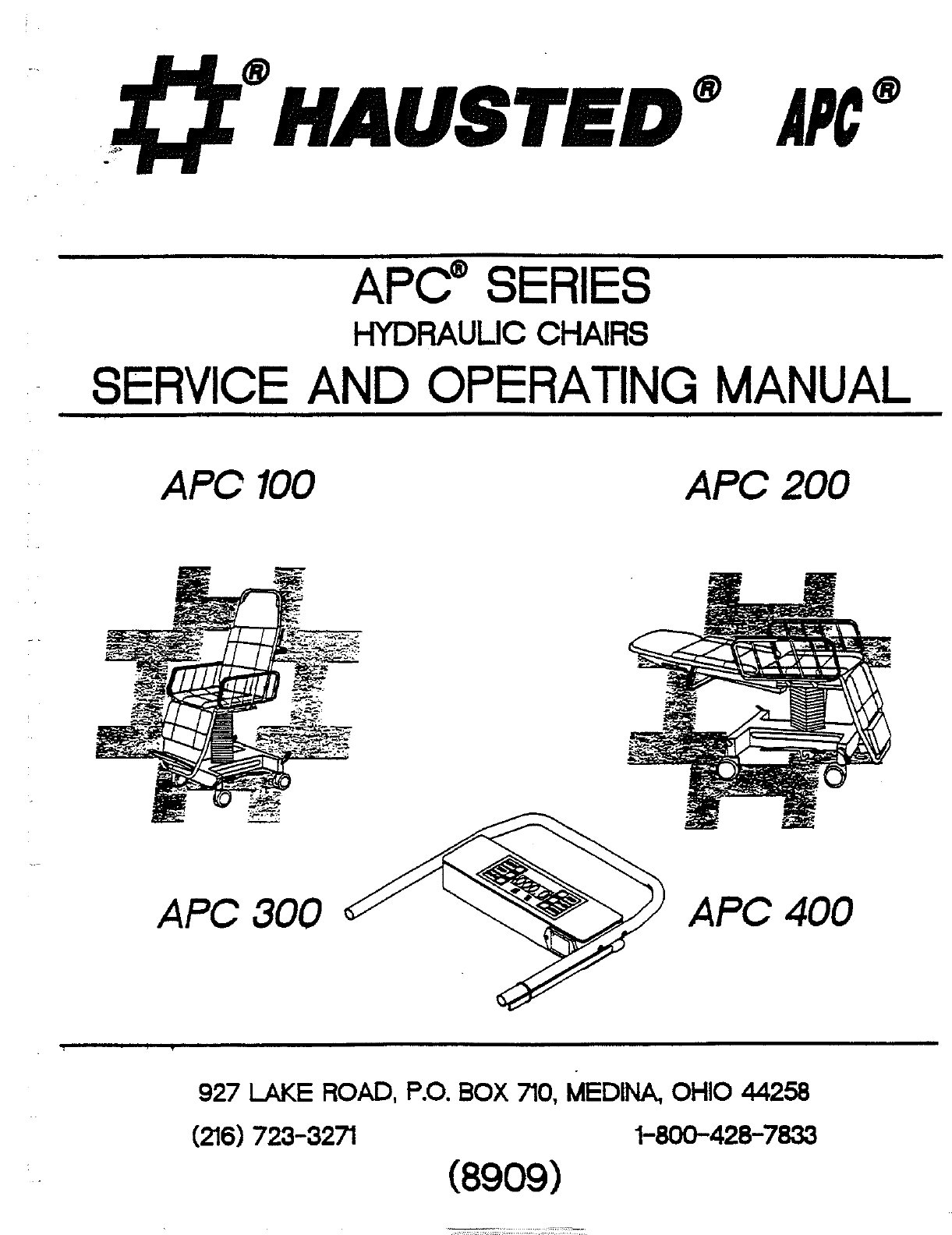

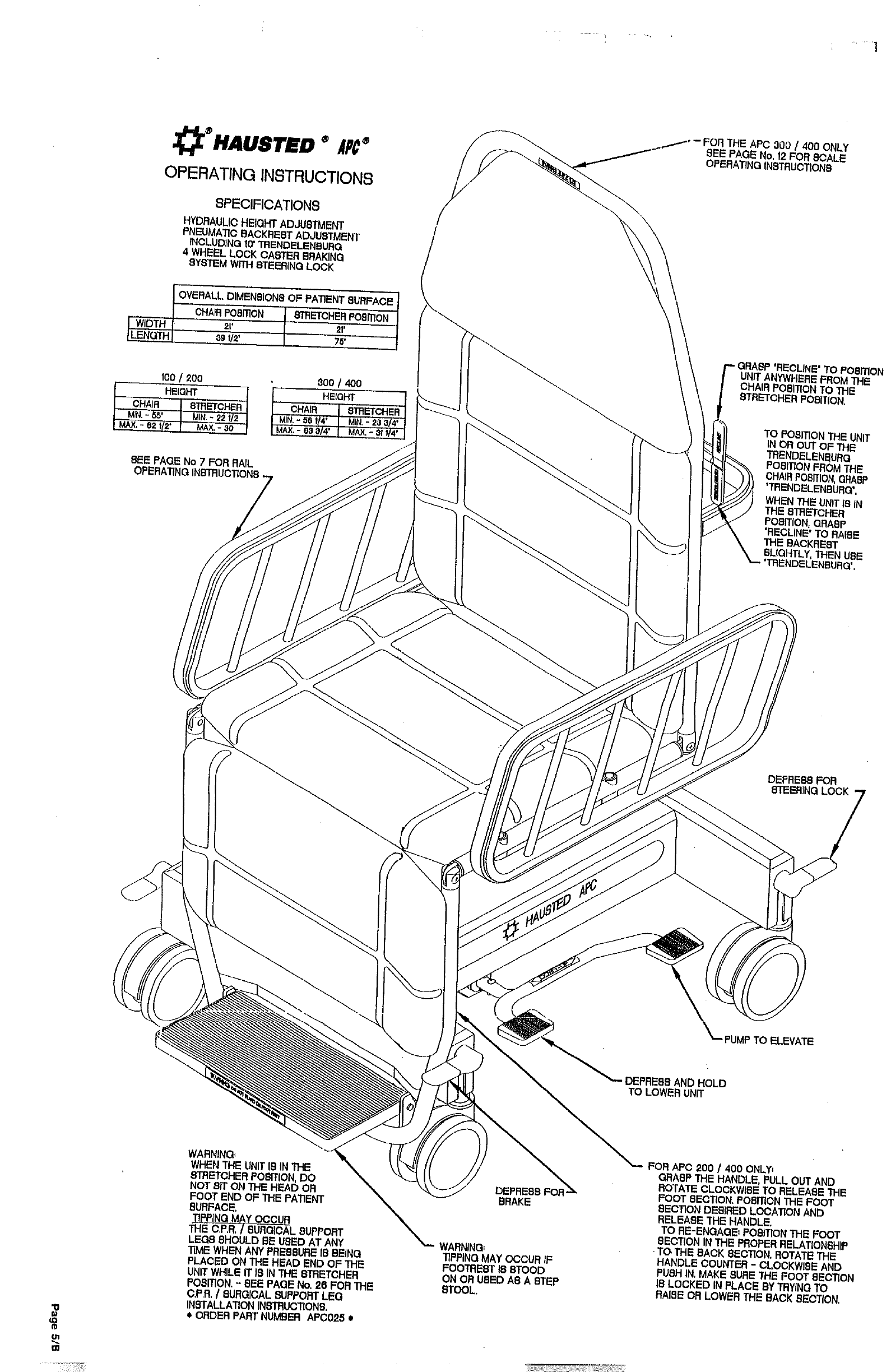

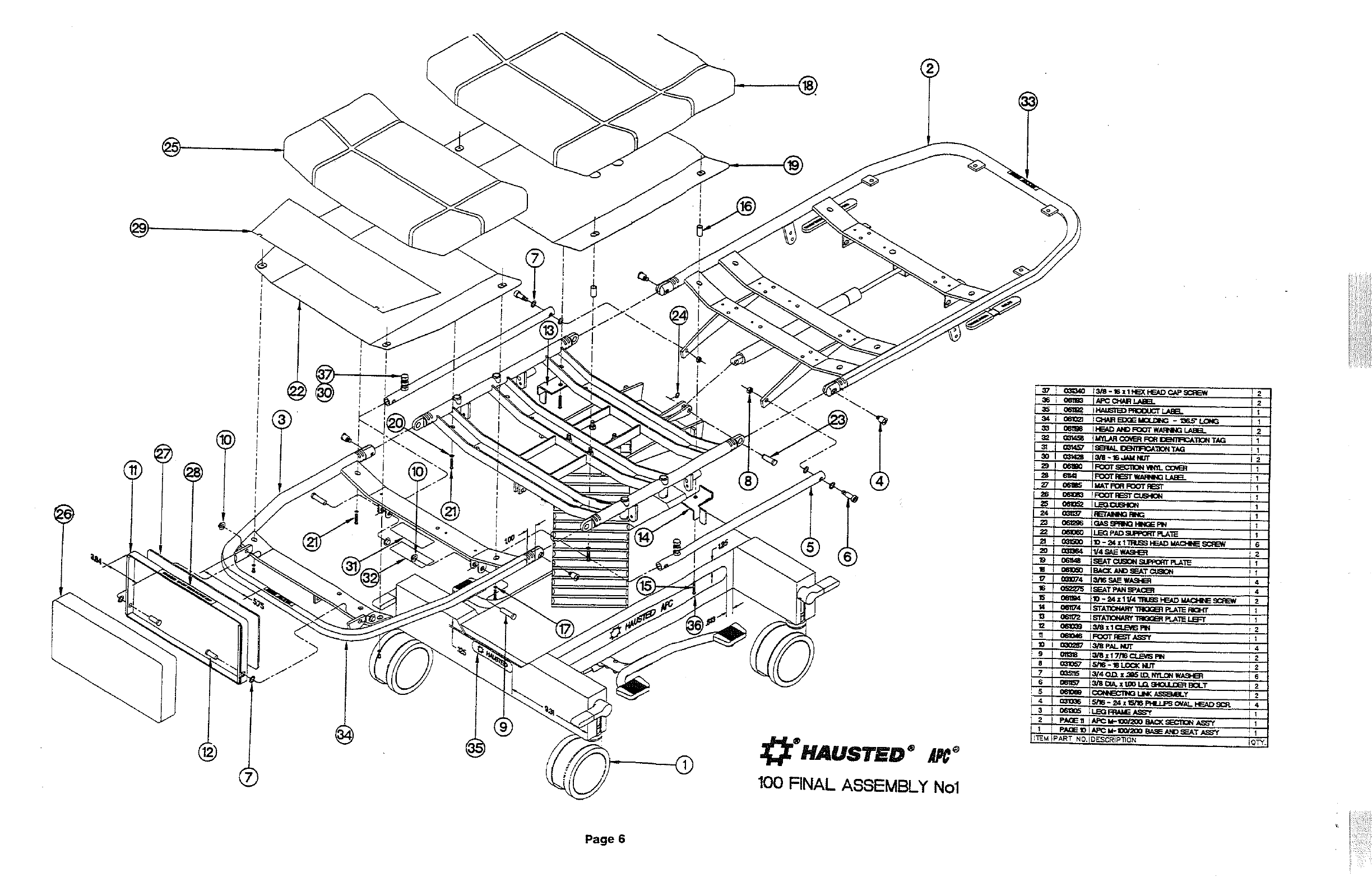

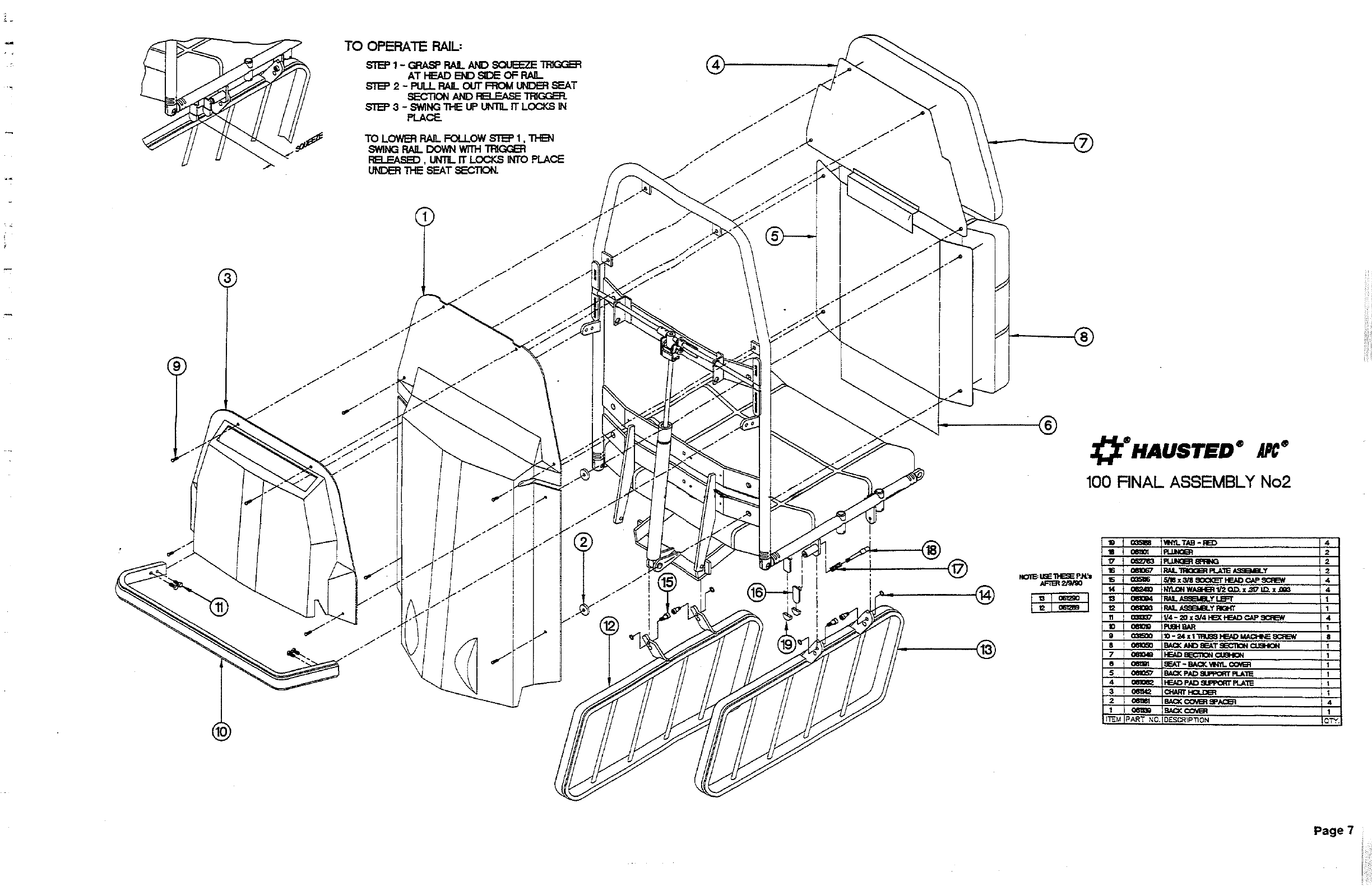

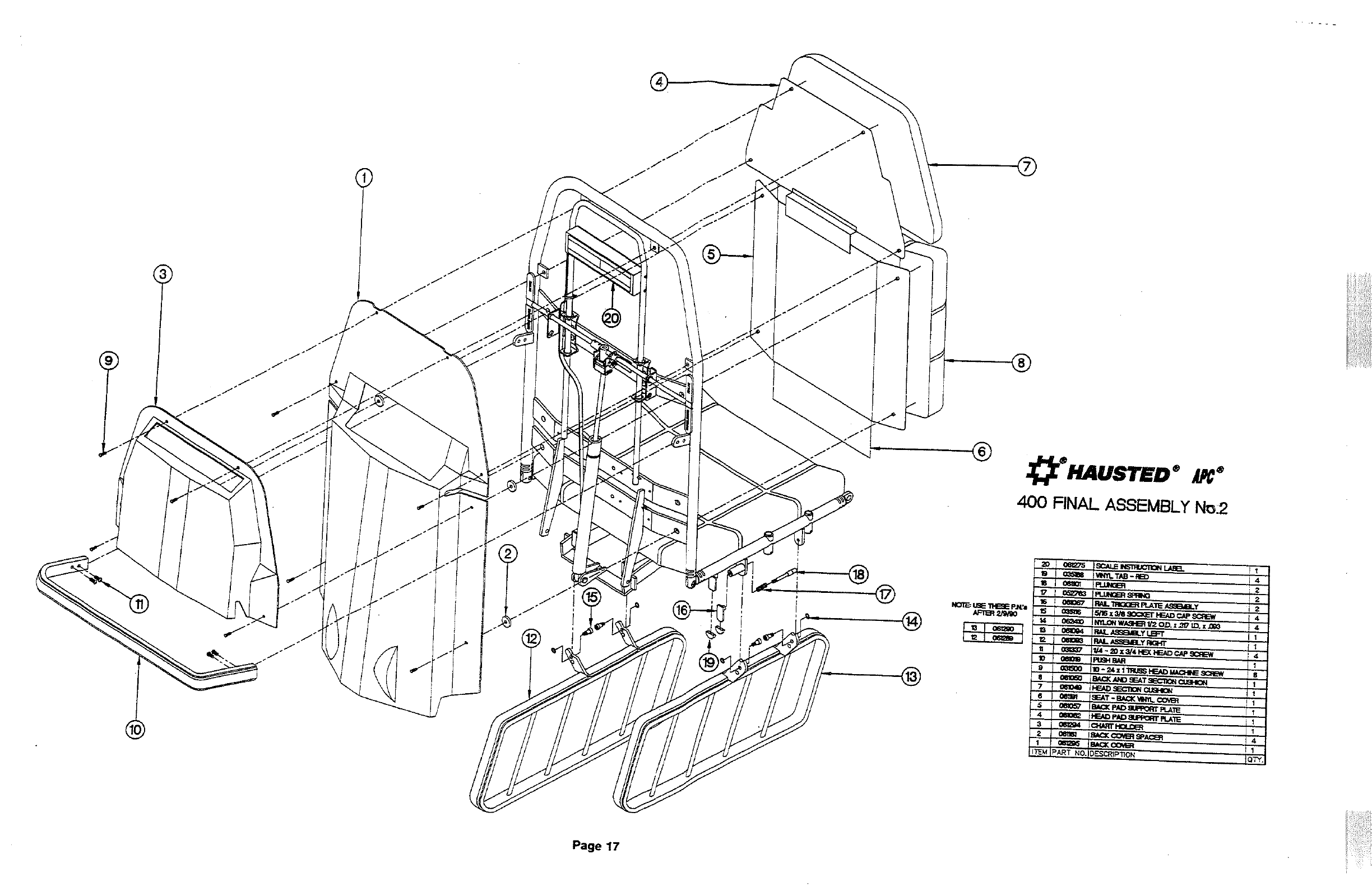

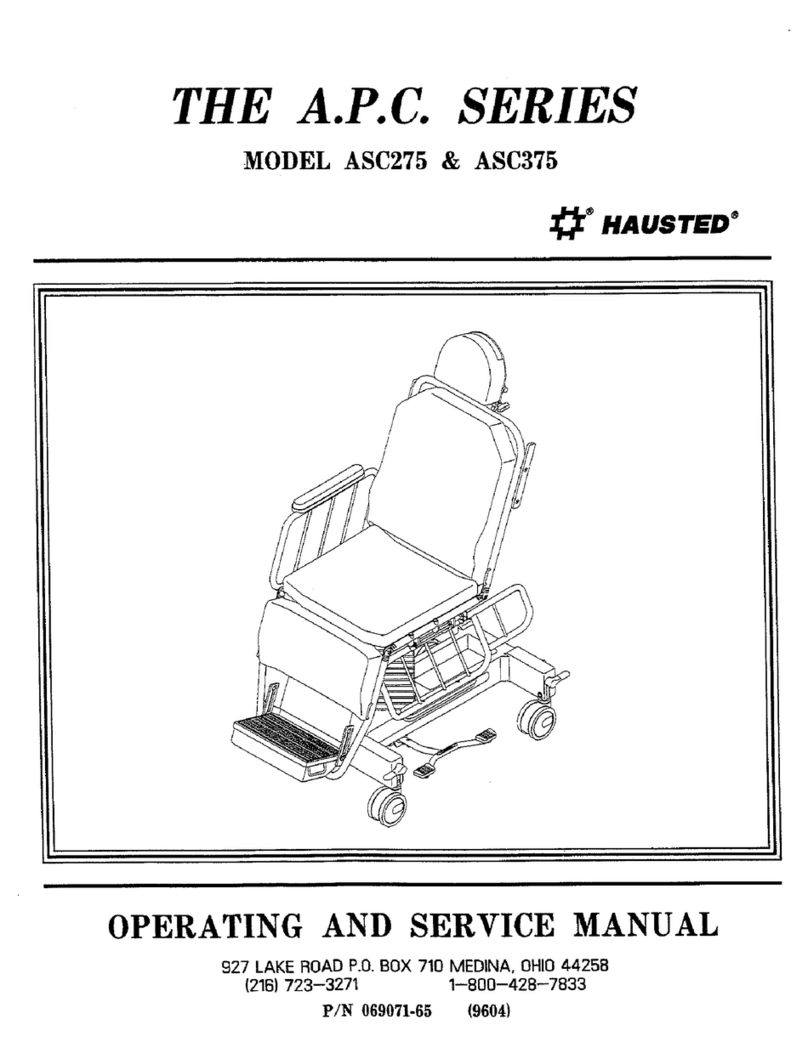

Hausted APC Series User manual

Other manuals for APC Series

1

This manual suits for next models

4

Other Hausted Medical Equipment manuals

Hausted

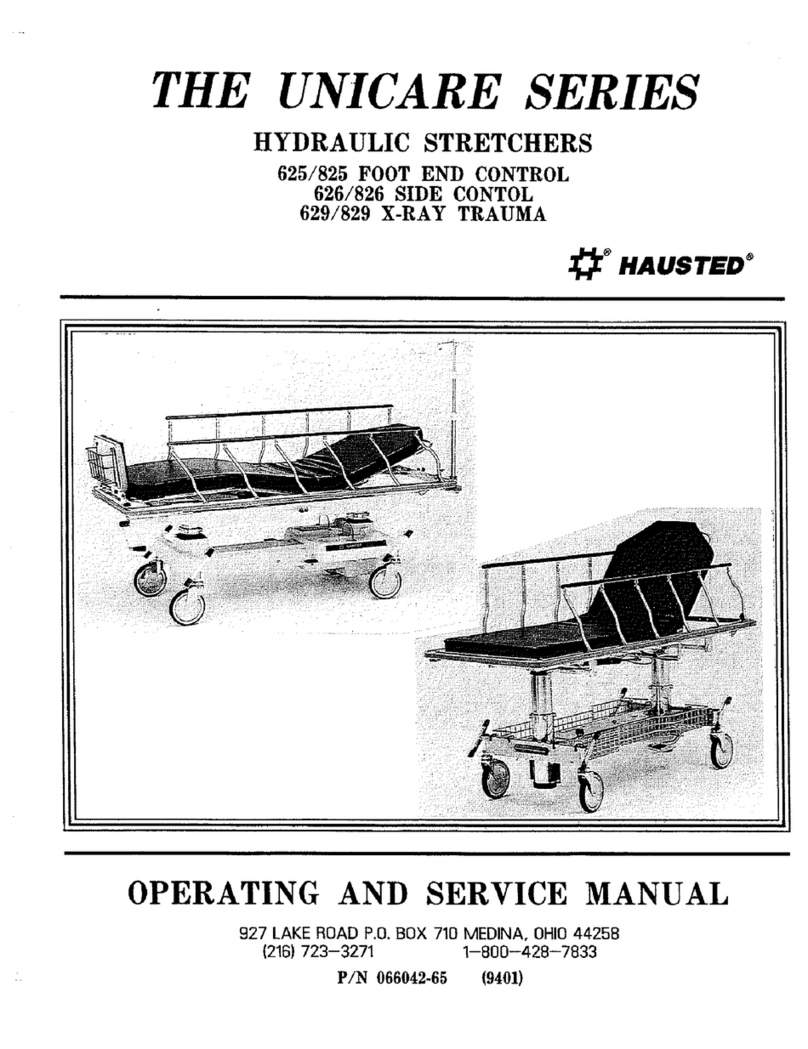

Hausted UNICARE Series Service manual

Hausted

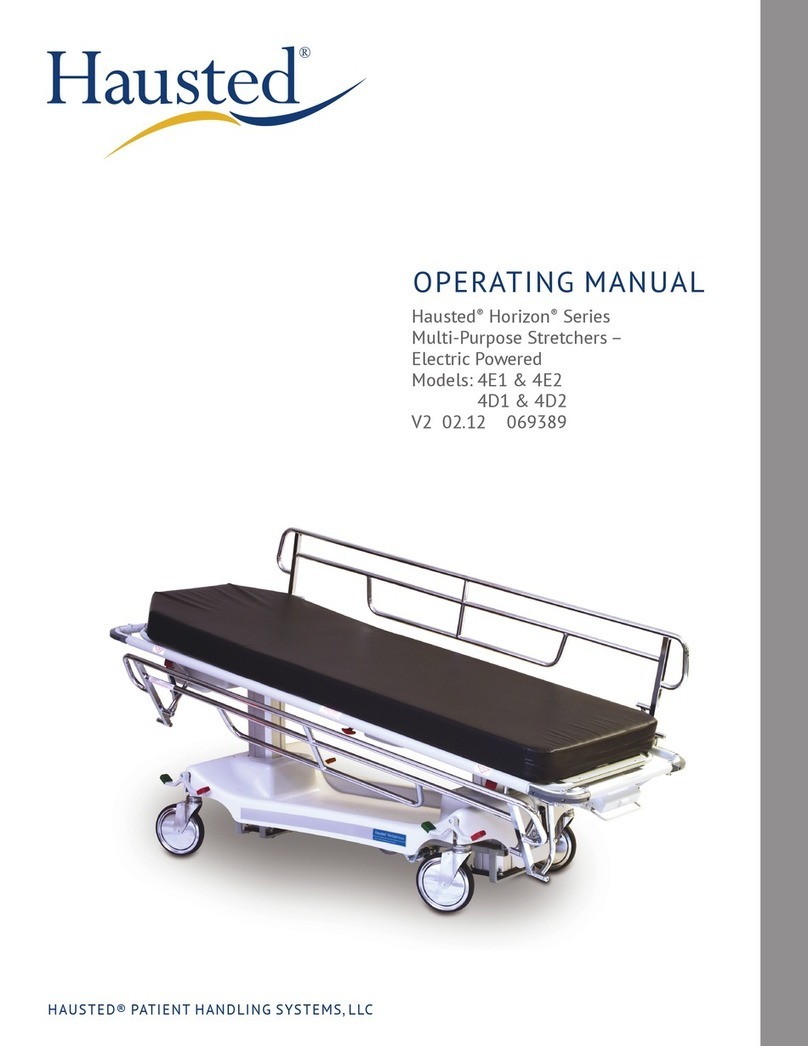

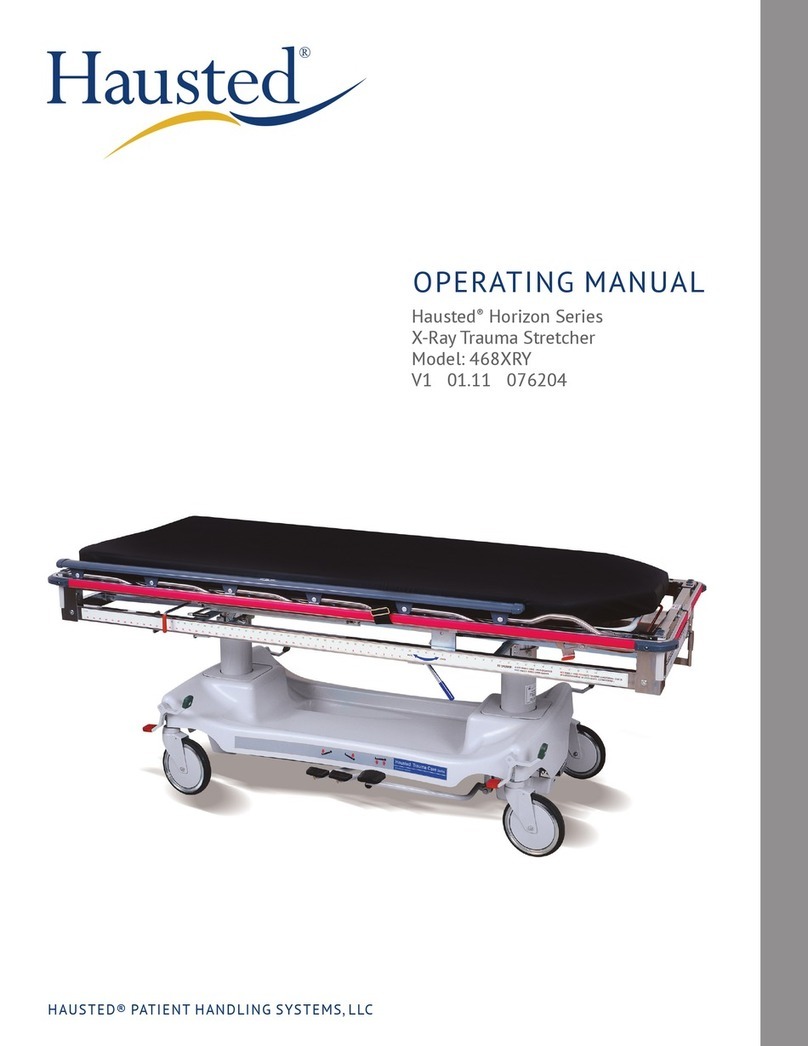

Hausted HORIZON Series User manual

Hausted

Hausted EPC500ST User manual

Hausted

Hausted ESC2 User manual

Hausted

Hausted APC Series User manual

Hausted

Hausted Horizon 462 - A User manual

Hausted

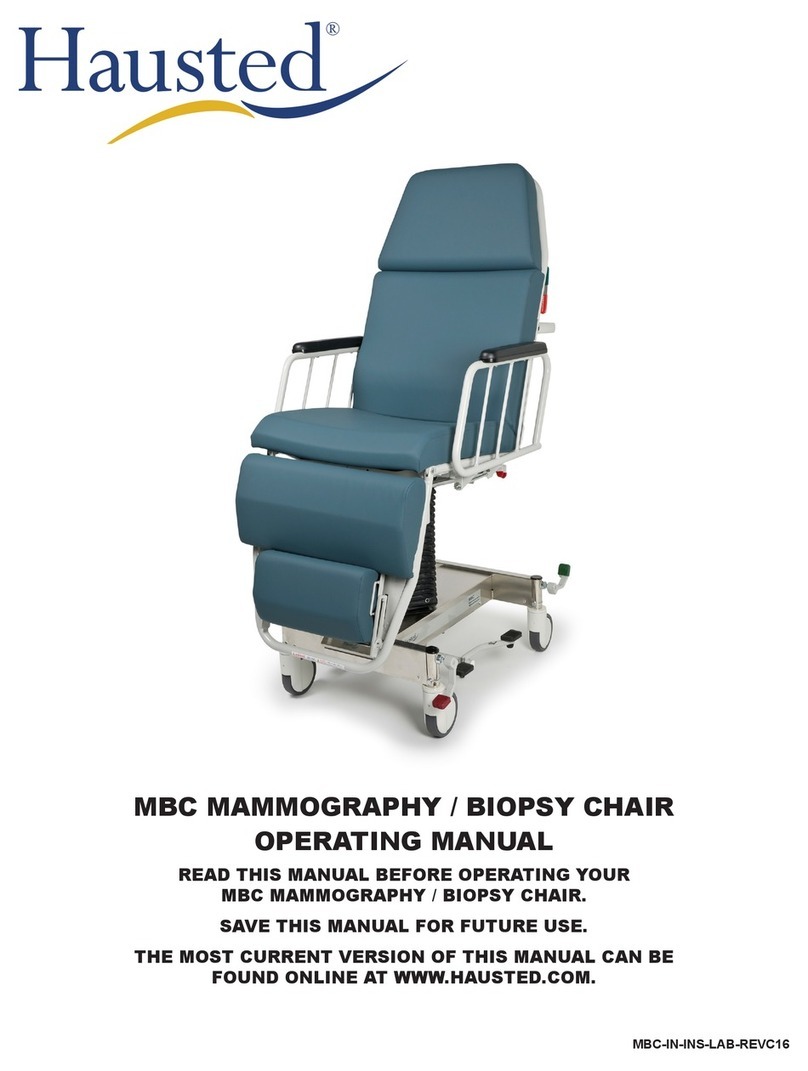

Hausted MBC User manual

Hausted

Hausted ESC2EYEST User manual

Hausted

Hausted HORIZON Series User manual

Hausted

Hausted HORIZON Series User manual

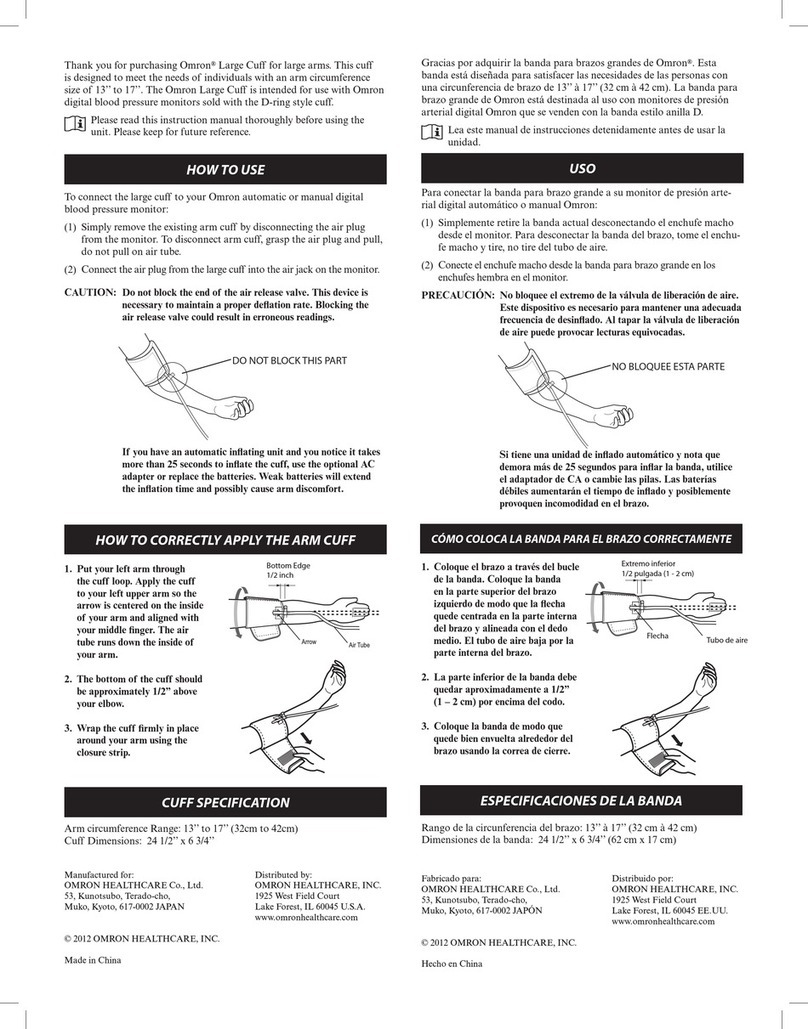

Popular Medical Equipment manuals by other brands

Arthrex

Arthrex Synergy Resection quick start guide

Flaem

Flaem AirMate Instructions for use manual

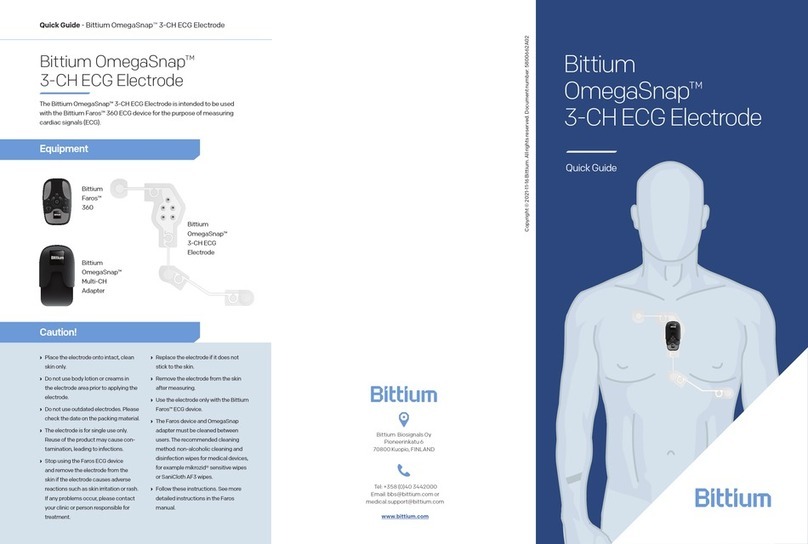

Bittium

Bittium OmegaSnap 3-CH ECG Electrode quick guide

Albrecht

Albrecht CDS KNEE BRACE FLEXION User instructions

Konica Minolta

Konica Minolta REGIUS CS-2 brochure

Ossur

Ossur REBOUND DIABETIC WALKER Instructions for use