6X 1/4-20 X 1/2" BHCS

120 IN-LBS

10%

3X 1/4-20 X 5/8" BHCS

120 IN-LBS

10%

*USE 3 SCREWS TO FASTEN

DOCK DOWN IF POSSIBLE*

MOUNTING BRACKET

LOCK KEY

*RECOMMENDED HOLES

FOR MOUNTING WITH

2 SCREWS*

*RECOMMENDED HOLES

FOR MOUNTING WITH

3 SCREWS*

PLUG INTO "DC INPUT" POWER

CONNECTOR OF DOCKING STATION

CONNECT TO 12 VDC POWER SOURCE

RED (+), BLACK (-)

POWER CORD

(NOT INCLUDED WITH DS-GD-102)

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

PRODUCT I.D.

DATE

WEIGHT: (LBS)

03-27-09

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

PRODUCT I.D.

DATE

WEIGHT: (LBS)

GD-0029-IS-B

SHEET 1 OF 2

PRODUCT DESCRIPTION

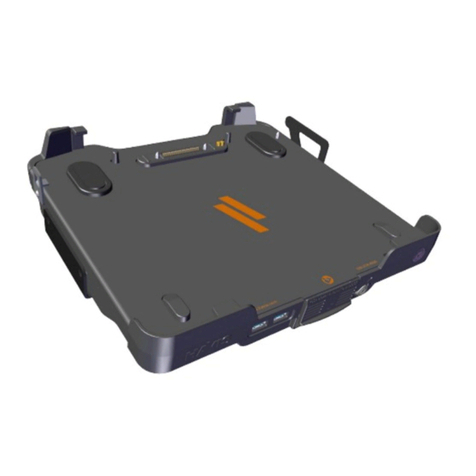

THIS PRODUCT IS USED WITH THE GENERAL DYNAMICS

GO-BOOK XR-1 AND GD8000 SERIES COMPUTERS.

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

PRODUCT I.D.

DATE

WEIGHT: (LBS)

PRODUCT NAME

REV. DATE

DRAWING NUMBER:

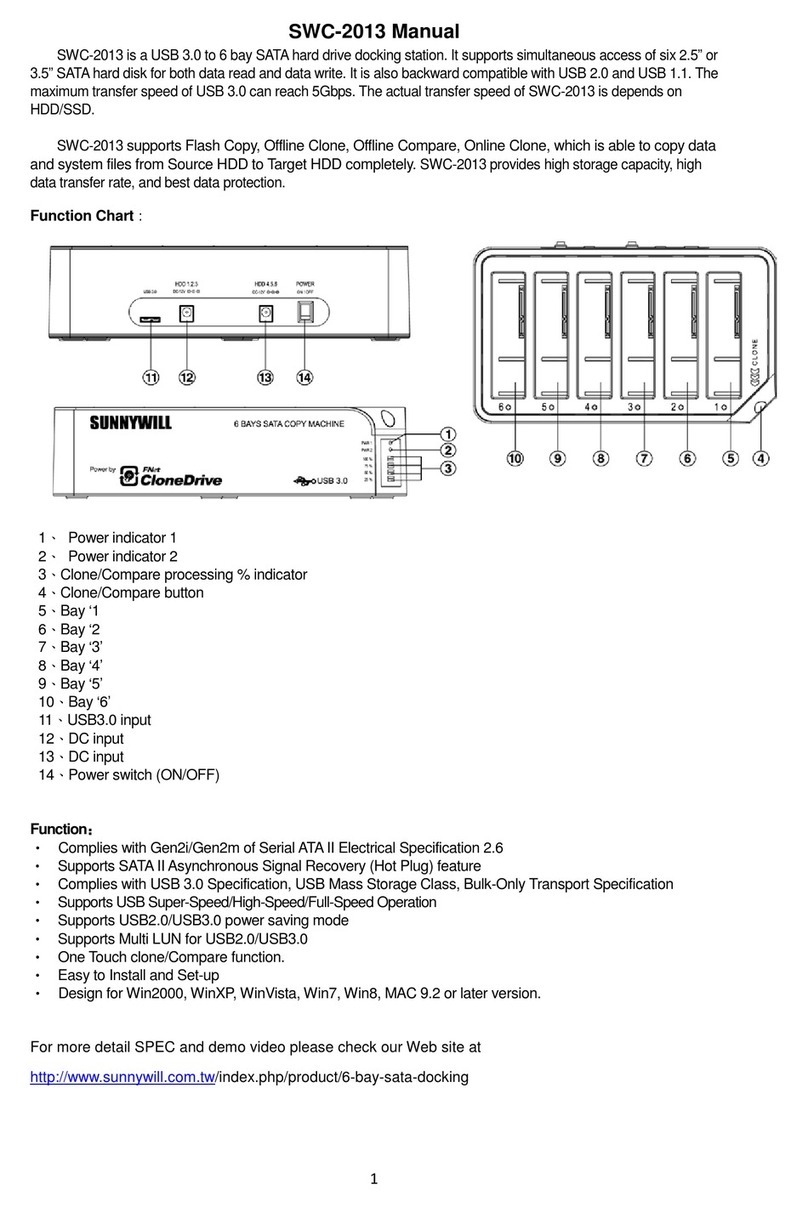

HARDWARE KIT CONTENTS:

INSTALLATION INSTRUCTIONS:

1. REMOVE THE MOUNTING BRACKET FROM THE DOCKING STATION.

2. SET MOUNTING BRACKET ON TOP OF DESIRED SURFACE SO THAT

3 OF THE HOLES ON THE MOUNTING BRACKET LINE UP WITH 3

TAPPED HOLES IN THE MOTION ACCESSORY. IT IS RECOMMENDED

THAT 3 HOLES BE USED TO MOUNT BRACKET TO MOUNTING

ACCESSORY. IF 3 HOLES ARE NOT ACCESSIBLE, 2 MOUNTING HOLES

CAN BE USED. SEE VIEW WITH "RECOMMENDED HOLES" FOR

ATTACHING THE MOUNTING BRACKET.

3. FASTEN THE MOUNTING BRACKET TO THE MOTION ACCESSORY

USING 3X 1/4-20 X 5/8" BHCS (OR 2, DEPENDING ON HOLE

AVAILABILITY).

4. AFTER THE MOUNTING BRACKET IS INSTALLED, ATTACH THE DS-

GD-101 DOCKING STATION, AS SHOWN. LIGHTLY SCREW IN THE

FRONT 3X 1/4-20 X 1/2" BHCS, MAKING SURE NOT TO COMPLETELY

TIGHTEN THE FASTENERS YET.

5. SCREW IN THE 3X 1/4-20 X 1/2" BHCS LOCATED IN THE BACK OF

THE MOUNTING BRACKET. TORQUE THOSE AS SHOWN.

6. RETURN TO THE FRONT THREE BHCS AND TIGHTEN ALL

FASTENERS TO THE INDICATED TORQUE RECOMMENDATIONS. (IF

THE DS-GD-101 DOCKING STATION IS NOT ATTACHED IN THE

SPECIFIED ORDER, PARTS MAY CRACK OR BECOME DAMAGED).

7. ATTACH THE TWO BARE POWER CORD LEADS TO THE 12 VDC

POWER SOURCE (RED TO "+" TERMINAL AND BLACK TO "-"

TERMINAL). NOTE: POWER CORD IS NOT INCLUDED WITH THE

DS.GD8.CDL VERSION OF DOCK.

8. PLUG OTHER END OF POWER CORD INTO DC-INPUT POWER

CONNECTOR ON BACK OF DOCKING STATION. SEE PAGE 2 FOR DC-

INPUT CONNECTOR LOCATION.

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

PRODUCT I.D.

DATE

WEIGHT: (LBS)

DS-GD-101-102

(ALL MODELS)

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

PRODUCT I.D.

DATE

WEIGHT: (LBS)

PRODUCT DESCRIPTION

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

PRODUCT I.D.

DATE

WEIGHT: (LBS)

PRODUCT NAME

REV. DATE

12-02-09

DRAWING NUMBER:

DS-GD-101-102

WARNING: ALL HAVIS INC. PRODUCTS ARE DESIGNED WITH SAFETY OF USE AND INSTALLATION IN MIND. HOWEVER,

IT IS THE SOLE RESPONSIBILITY OF THE OWNER/OPERATOR OF A VEHICLE USING HAVIS INC. MOUNTING AND

DOCKING EQUIPMENT, TO INSURE THAT THE EQUIPMENT IS INSTALLED SO THAT IT WILL NOT INTERFERE WITH VEHICLE

OPERATION, INTERFERE WITH SAFETY DEVICES, OBSTRUCT VIEW OF DRIVING CONDITIONS, OR IN ANY WAY

DEGRADE OCCUPANT SAFETY. IMPROPER INSTALLATION CAN CAUSE SERIOUS INJURY IN THE EVENT OF AN

ACCIDENT. INSTALLATION SHOULD ONLY BE PERFORMED BY QUALIFIED PROFESSIONALS. COMPUTERS AND

MOTION DEVICES MUST BE MOVED TO AND STOWED/SECURED IN THEIR SAFE DRIVING POSITIONS BEFORE

OPERATING VEHICLE.

WWW.HAVIS.COM

1-800-524-9900

F-730-019 REV A