Table of Contents

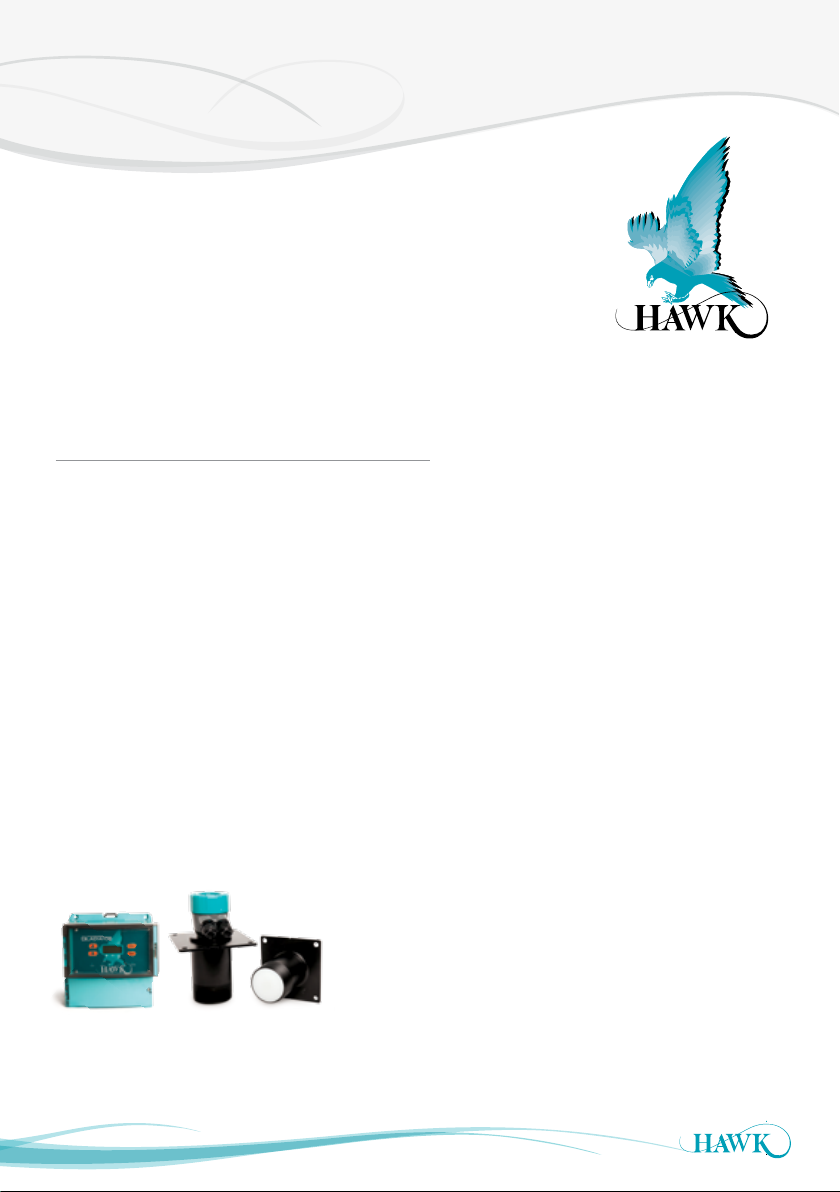

Gladiator Doppler Microwave Series

2

Contents

PROPRIETARY NOTICE

The information contained in this publication is derived in part from proprietary

and patent data. This information has been prepared for the express purpose

of assisting operating and maintenance personnel in the efficient use of the

instrument described herein. Publication of this information does not convey any

rights to use or reproduce it, or to use for any purpose other than in connection

with the installation, operation and maintenance of the equipment described

herein.

WARNING

This instrument contains electronic components that are susceptible to damage

by static electricity. Proper handling procedures must be observed during the

removal, installation, or handling of internal circuit boards or devices:

Handling Procedure:

1. Power to unit must be removed prior to commencement of any work.

2. Personnel must be grounded, via wrist strap or other safe, suitable means,

before any printed circuit board or other internal devices are installed,

removed or adjusted.

3. Printed circuit boards must be transported in a conductive bag or other

conductive container. Boards must not be removed from protective container

until the immediate time of installation. Removed boards must be placed

immediately in a protective container for transport, storage, or return to

factory.

Overview 3

Principle of Operation 3

Typical Uses 3

Function 3

Features 3

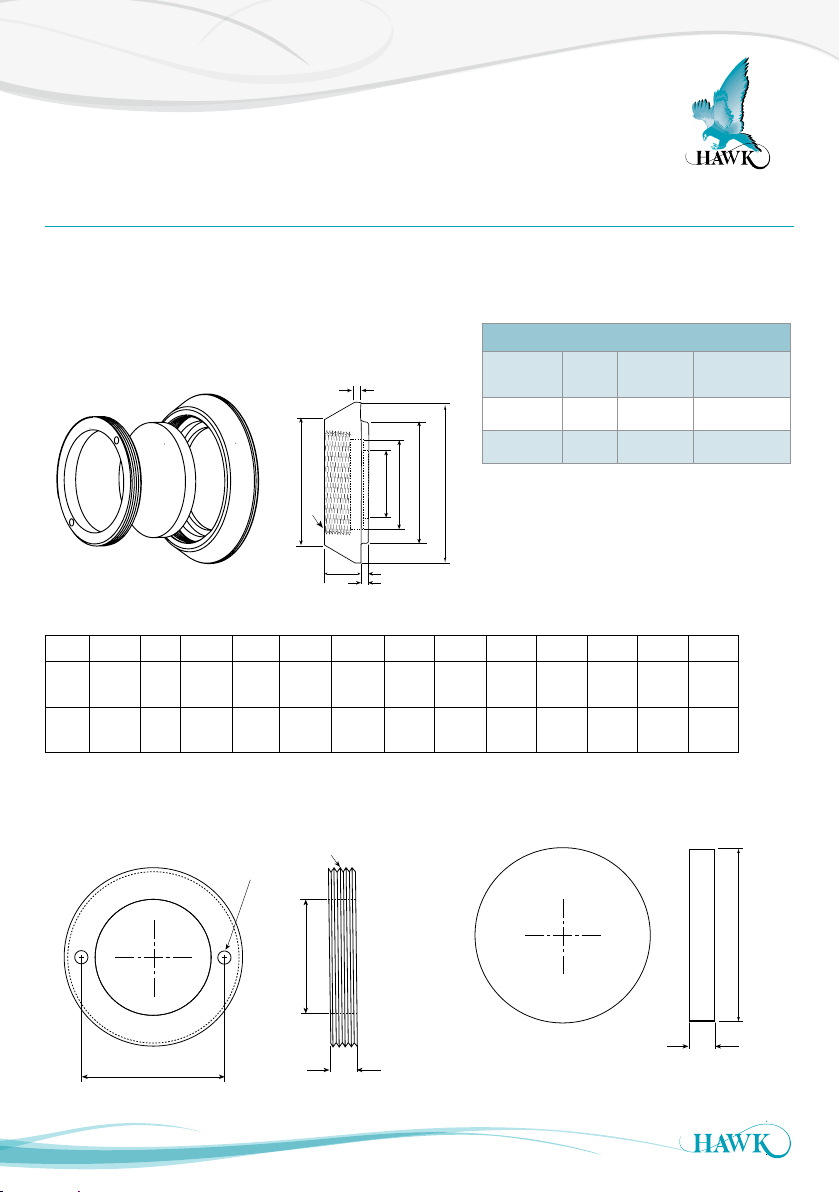

Dimensions 4

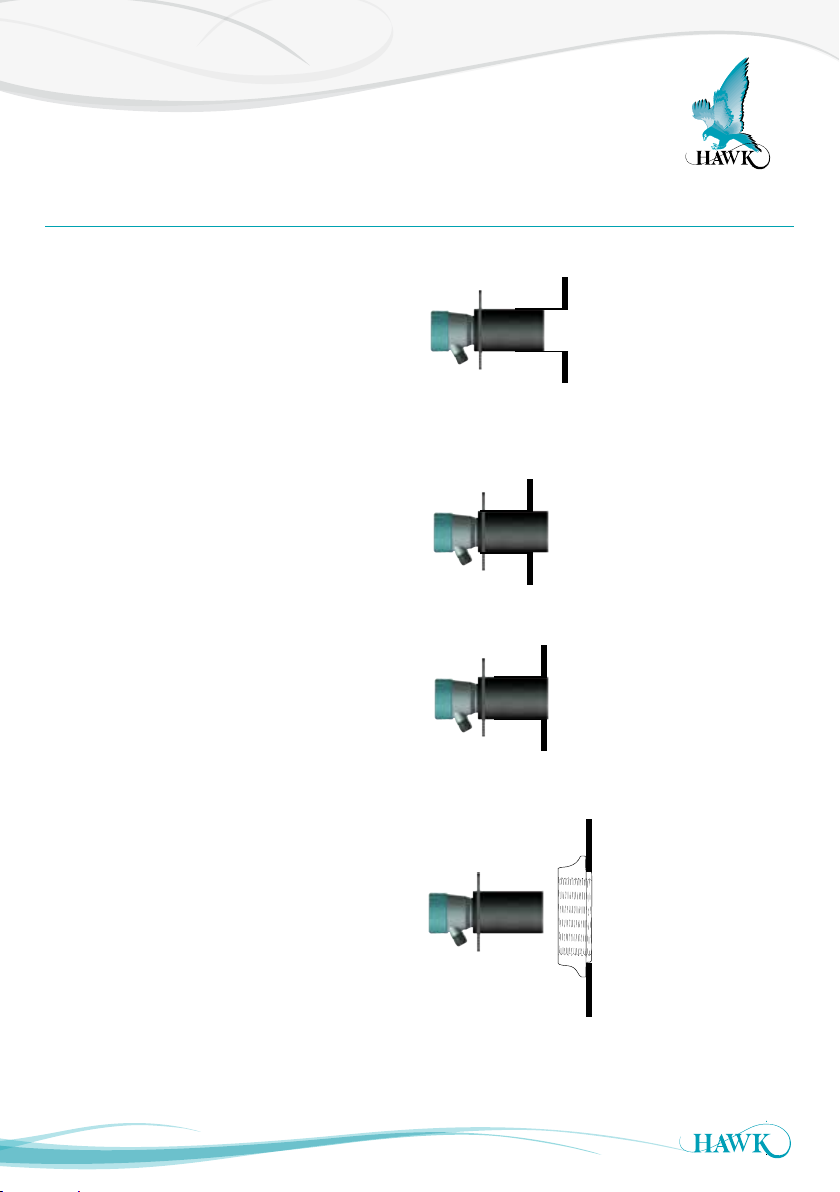

Remote Microwave System 4

MA Series Weldments and Windows (UHMW / PTFE) 5

MA Series Weldments and Windows (Ceramic) 6

MD Series Weldments and Windows 7

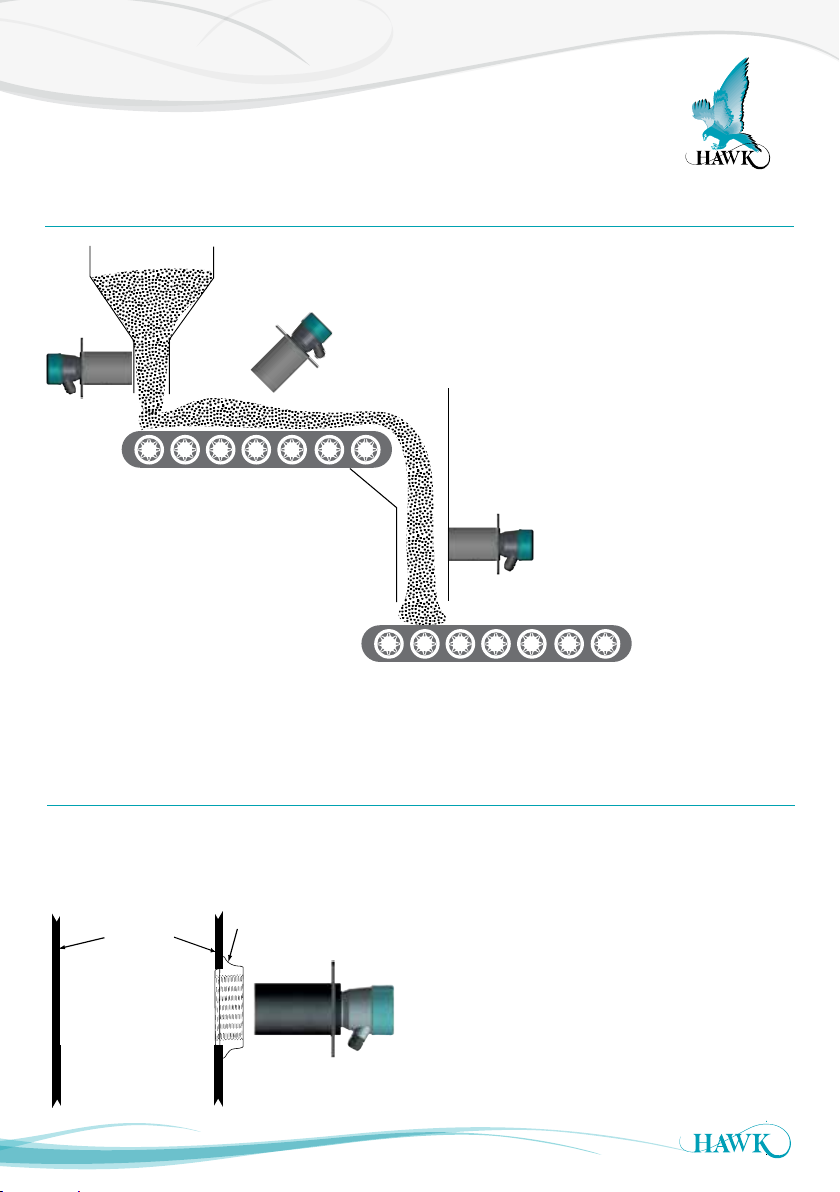

Weldments and Windows (Ceramic Tile & Firebrick

Assemblies) 8

Mounting 9

General Guidelines 9

Mounting 10

Mounting With Windowed Weldments 10

Wiring 11

Remote System Connection - HAWK Supplied Cable 11

Remote System Connection - Customer Supplied Cable

12

Alternate Cable Type Between

Amplifier and Sensors 12

Integral System Connection 13

Wiring - Relay Functions 14

Functionality Layout 15

Integral System 15

Commissioning 16

Remote System 16

Integral System 17

Remote Software 18

Operational Diagnostics 18

Remote Software 19

Main Menus & Interface 19

Quickset Menu - Parameters 20

Advanced Menu - Parameters 21

Integral Test Switch 22

Integral Receiver Test Switch Functions 22

Troubleshooting 23

Troubleshooting 23

Error Codes 24

Safety Information 25

FCC Regulations 25

Part Numbering 26

Remote Version 26

Integral Version 27

Accessories 27

MA Series Mounting Accessories 28

MD Series Mounting Accessories - Kit 28

MD Series Mounting Accessories - Parts 29

Specications 30

A Higher Level of Performance 31