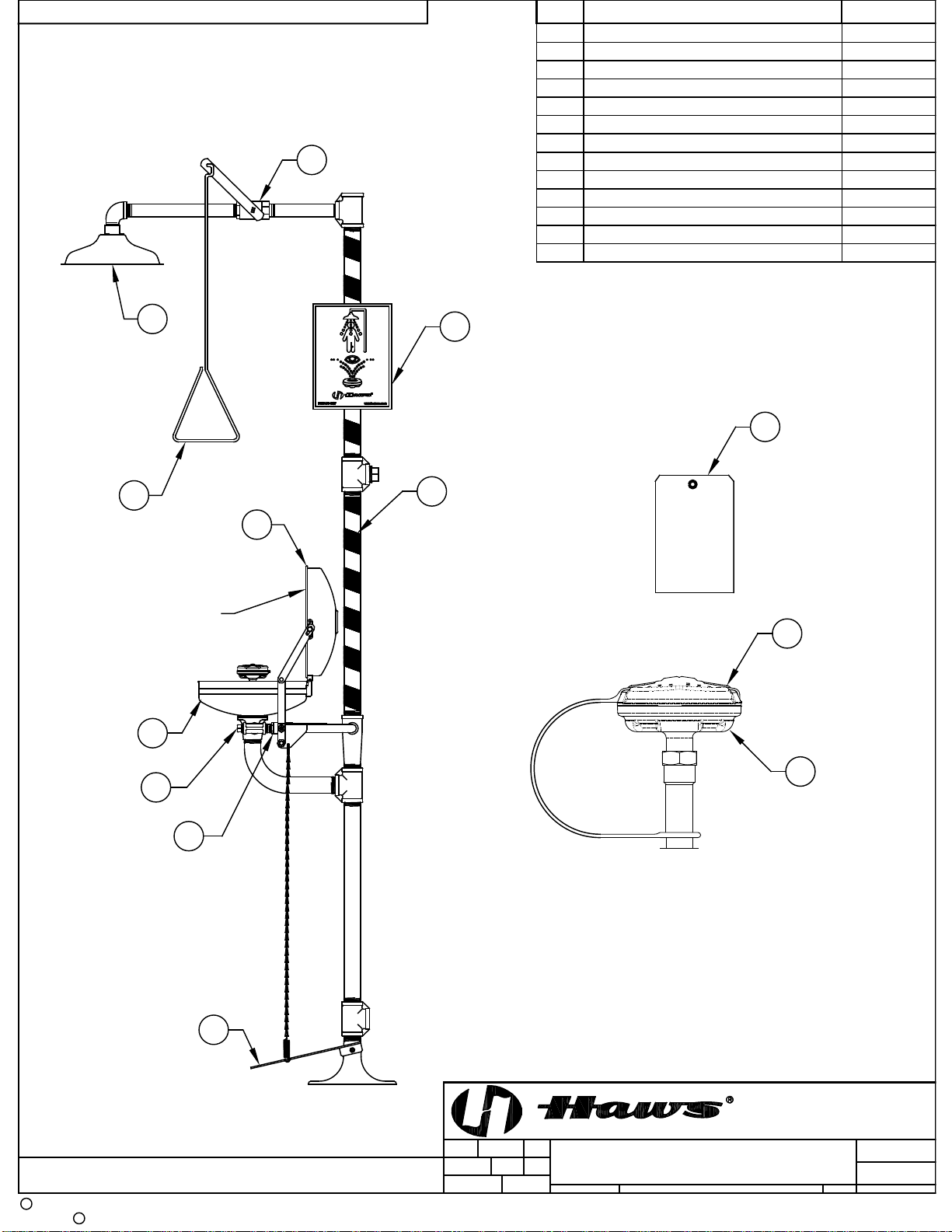

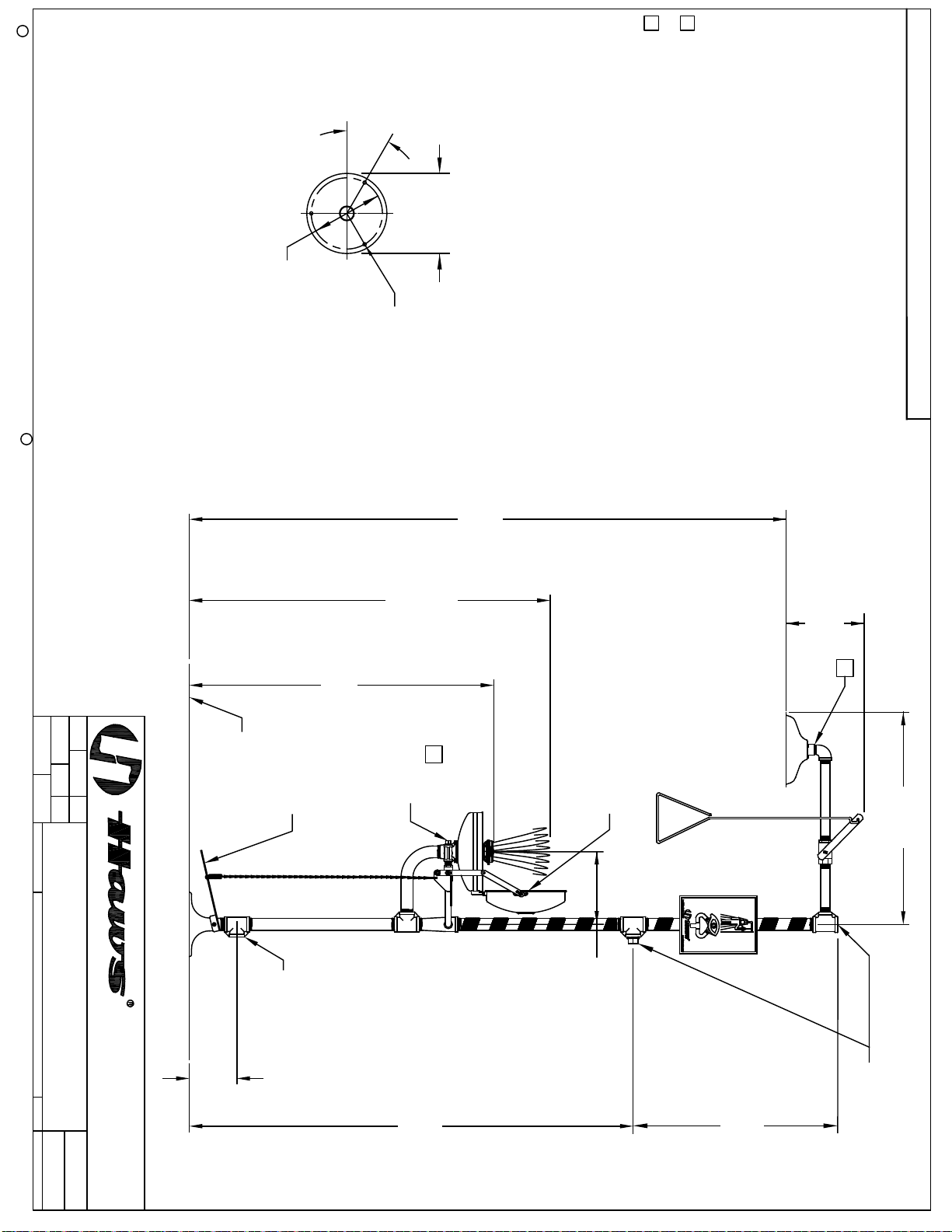

03/20 Model 8330 Page 2 of 5

LOCATION OF UNIT: The Model 8330 Stainless Steel combination Shower

Eye/Face Wash should be installed in close proximity to potential accident areas. It

should be clearly identified, free from obstructions and easy to access.

SUPPLY LINE: The minimum recommended line size is 1-1/4” IPS with 30-90 psi (2-

6 ATM) flowing pressure. Where sediment or mineral content is a problem, an inlet

filter is recommended.

PLUMBING CONNECTIONS: Inlet supply is female 1-1/4” IPS. Waste outlet is

female 1-1/4” IPS.

INSTALLATION PROCEDURE

Refer to Installation Drawing for clarification. Check parts list to insure all required parts

are included. Use pipe joint sealant PST #567 (Loctite) on all connections.

STEP 1: Prepare the emergency shower foundation by using the floor flange as a

template. Locate the three holes for the 3/8-16 UNC x 6” anchor bolts.

(Not supplied). They should extend 1” above the floor level.

STEP 2: Once the concrete foundation is ready (dry), assemble the floor flange to

the anchor bolts; then securely fasten with 3/8-16 UNC Hex nuts and 3/8”

washers (Not supplied). Seal and tighten floor flange and (1-1/4”) tee

making certain the waste tee is facing the proper location and the foot

control holes are facing side to side.

STEP 3: Assemble nipple (1-1/4” x 24”) to the tee and tighten with a pipe wrench.

STEP 4: Assemble the eye/face wash loop assembly to the (24”) nipple from Step

three. Connect the pipe wrench to the nipple between the two tees to

avoid damage.

STEP 5: Assemble in the following order:

Attach nipple (1-1/4” x 24”) onto the loop assembly.

Attach nipple (1-1/4” x 24”) onto the tee.

Attach tee (1-1/4” x 1-1/4” x 1”) onto nipple.

Attach nipple (1” x 8”) and valve assembly onto tee.

Attach street elbow (1”) and nipple (1” x 12-1/2”) onto valve.

STEP 6: Assemble showerhead onto street elbow (1”). If necessary, use Dow

Corning 832 sealant placing 5 small beads on the male threads, just

above the first thread.

STEP 7: Assemble the sign onto the unit. Use the strap, screws, washers and nuts

provided to mount the sign onto the upright. The sign should be positioned

for maximum visibility.

STEP 8: Insert the plug into the optional supply line tee that is not used. Before

connecting the supply water line to the emergency shower; FLUSH THE

LINE THOROUGHLY.