09/20 MODEL 1011HO/1011HO2/1011HPSHO2/1011HPSHO2 PAGE 2 OF 7

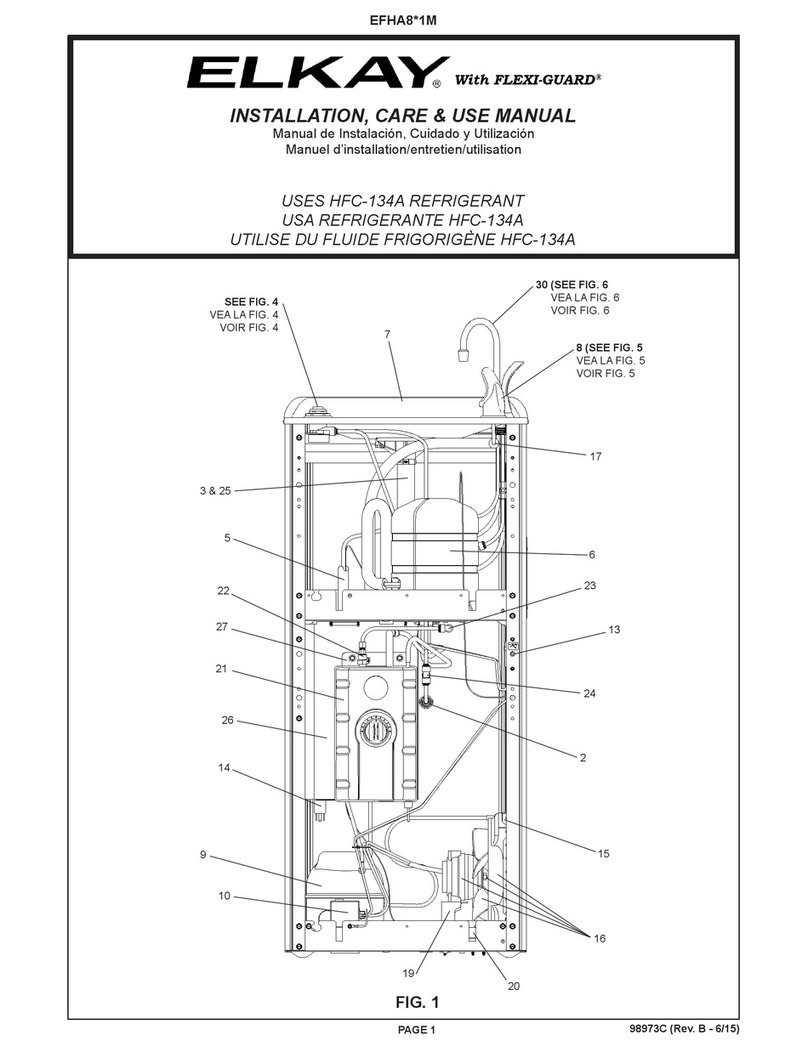

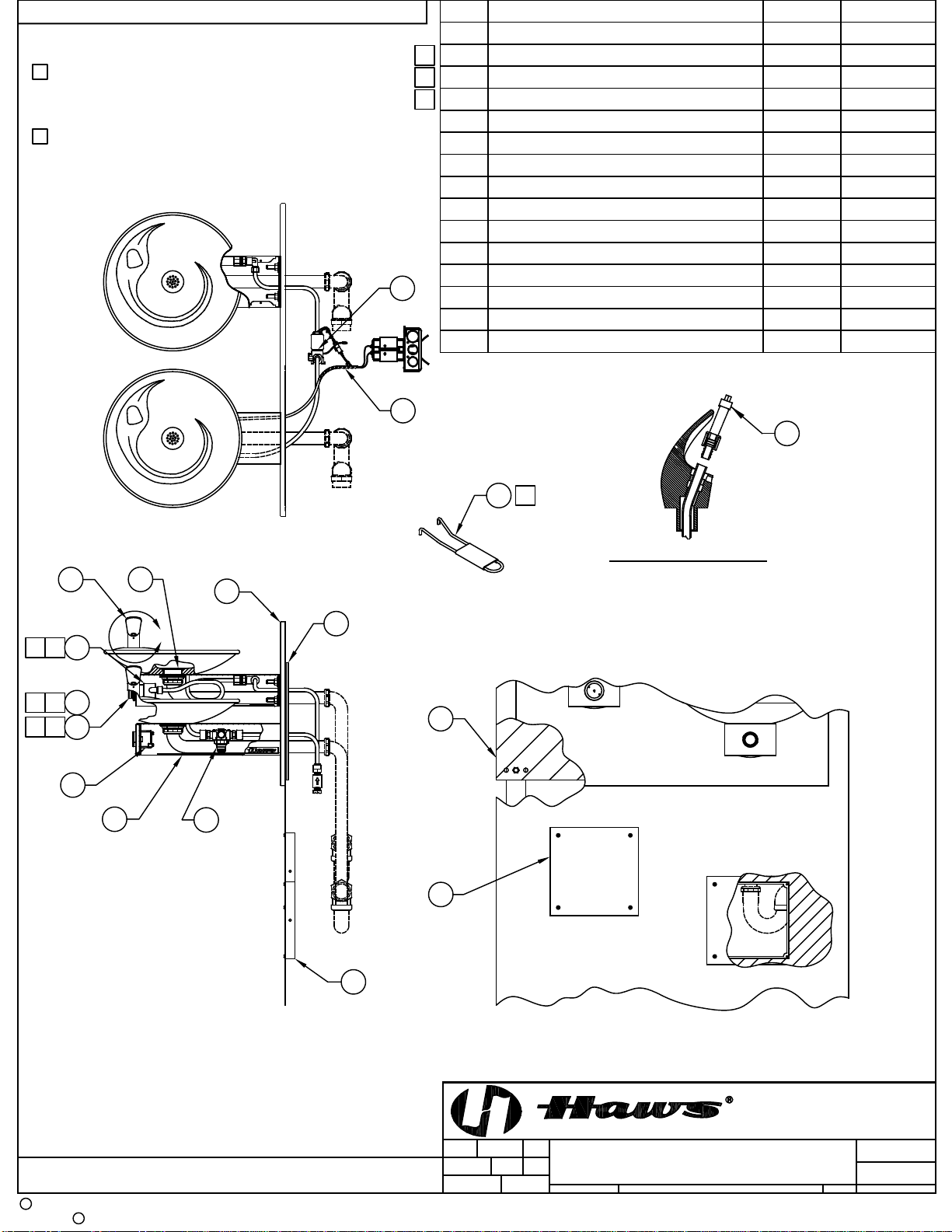

RECOMMENDED TOOLS: Hack saw, pipe joint sealant, screwdriver, level, 12" adjustable

wrench, 10" pipe wrench, 3/32” and 5/32 “ hex key wrench, 9/16”, 1/2", 7/16” socket wrench or

open-end wrench.

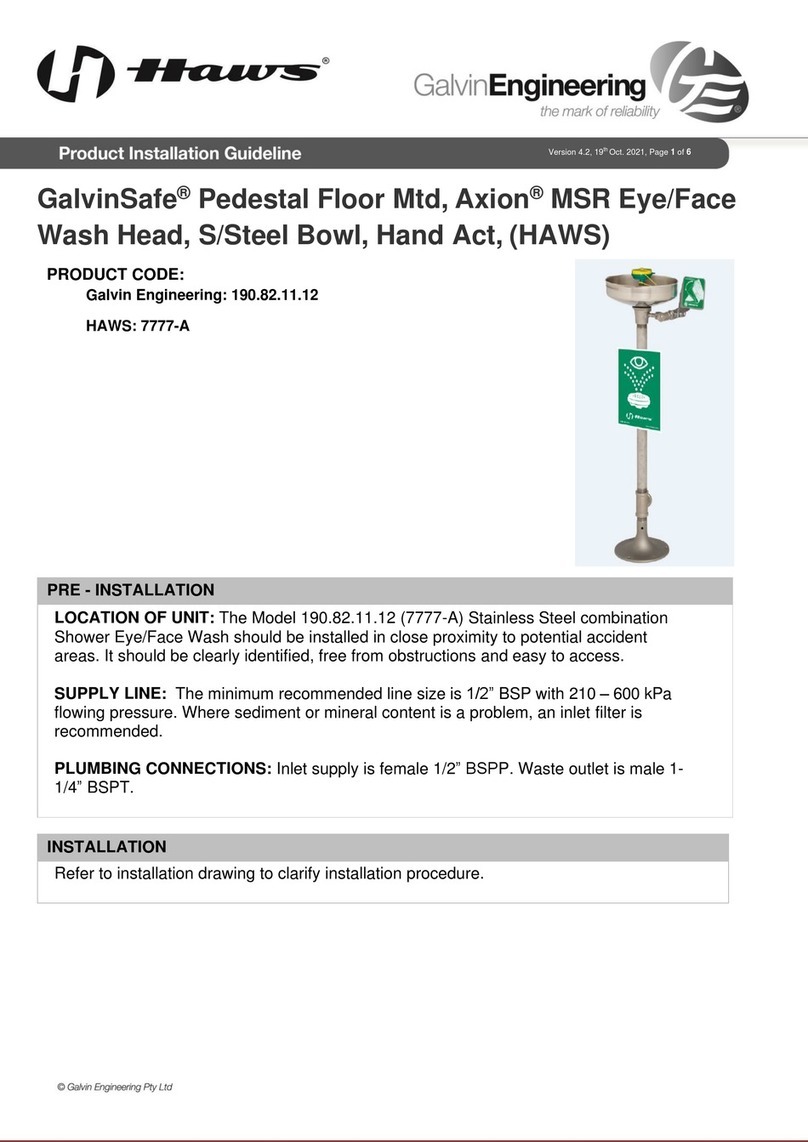

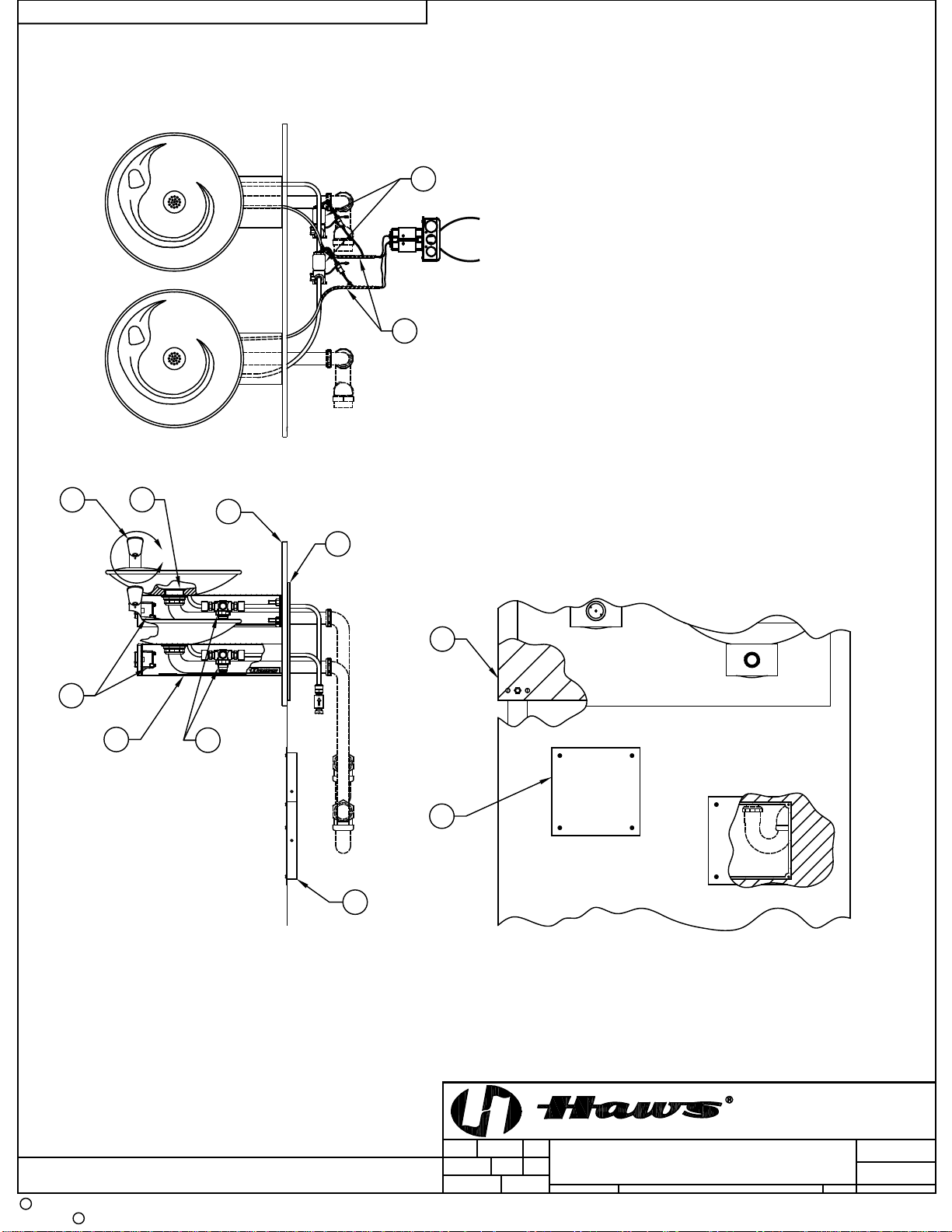

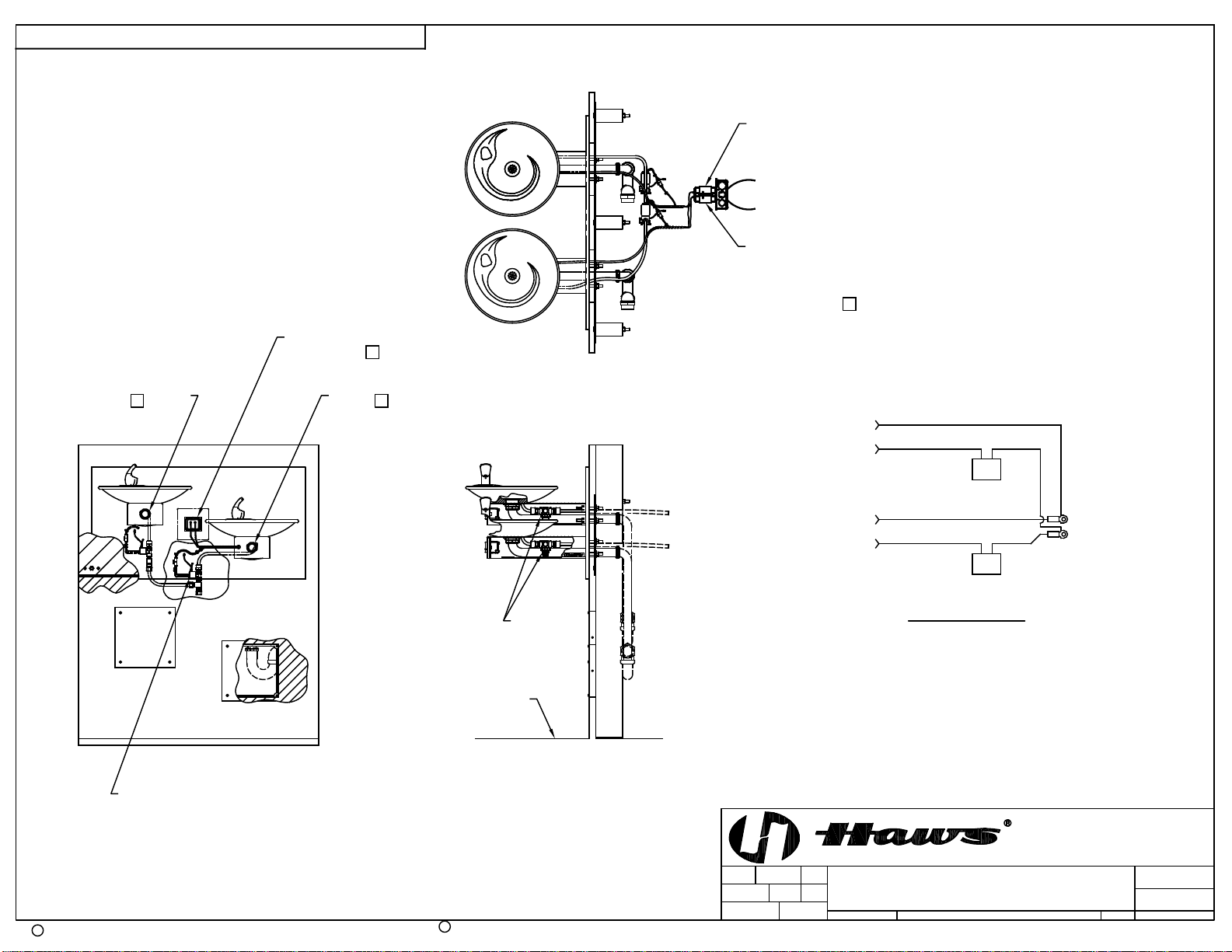

LOCATION OF UNIT: The Model 1011HO/1011HO2/1011HPSHO/1011HPSHO2 Drinking

Fountain is a wheelchair accessible drinking facility. The height dimensions shown, meet

current ADA requirements. When installing this unit, local, state or federal codes should be

adhered to. If height other than shown is required, then dimensions must be adjusted

accordingly.

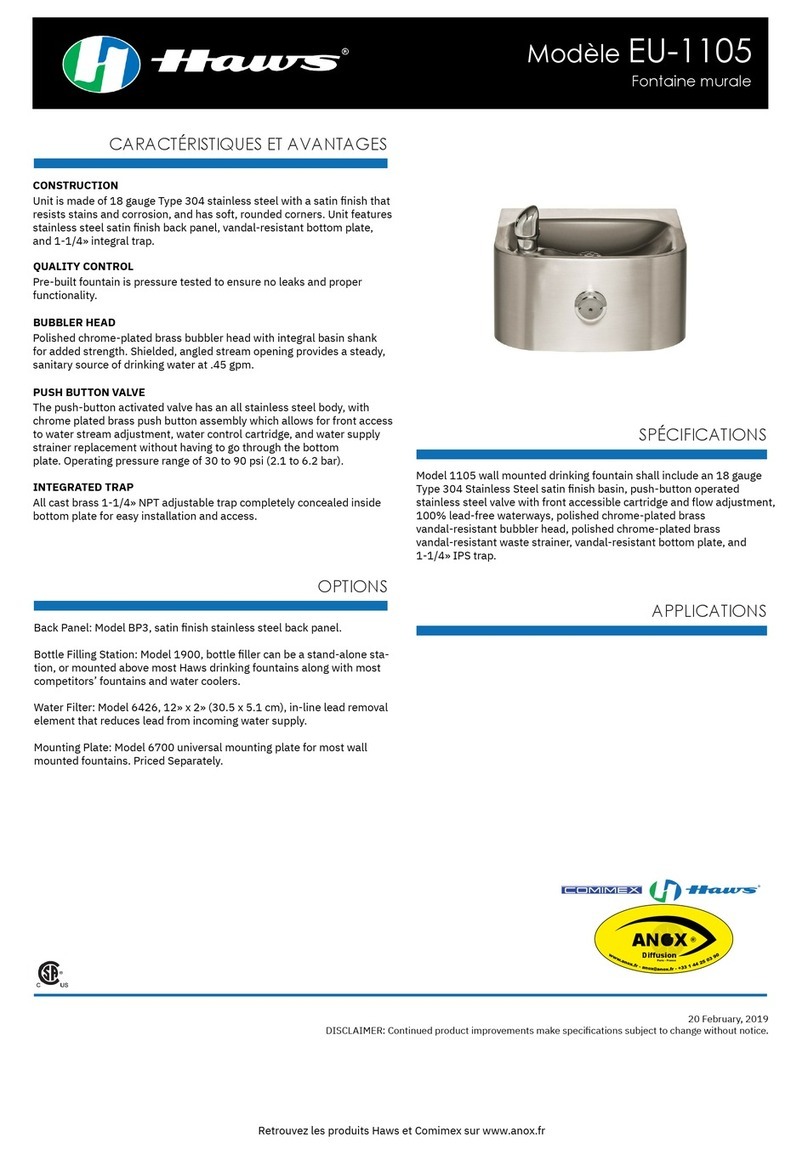

SUPPLY LINE: The minimum recommended line size is 1/2“IPS with 30-90 psi (2-6 ATM)

flowing pressure. Where sediment or mineral content is a problem, an inlet filter is

recommended.

PLUMBING CONNECTIONS: Inlet is 3/8” O.D. tube push-in type fitting. Waste outlet is 1-1/4”

O.D. tube.

ELECTRICAL CONNECTIONS: Drinking Fountain may be mounted on external wall of

building provided transformer shall be mounted inside the wall and protected from

water as shown on RKHO Series O&M details (page 8) per NEC/CEC and local code.

Sensor(s):

1011HO/1011PSHO with RKHO.120/120P:120 x 24 VAC, 60Hz, .68 AMPS.

1011HO/1011HPSHO with RKHO.240:240 x 24 VAC, 60Hz, .68 AMPS.

1011HO2/1011HPSHO2 with RKHO.120/120P:120 x 24 VAC, 60Hz, 1.36 AMPS.

1011HO2/1011HPSHO2 with RKHO.240:240 x 24 VAC, 60Hz, 1.36 AMPS.

MAINTENANCE: Periodically clean the strainer (Located inside push button valve on Models

1011HO/1011HPSHO). Refer to 5874 Series Valve Manual for more information.

INSTALLATION PROCEDURE

GENERAL NOTES:

1. For all plastic push-in type fitting connections, only connect NSF-61 copper or

plastic tubing. Stainless steel or glass tubing is not recommended. The

following assembly instructions must be followed to ensure a watertight

connection:

a. Cut tubing square and clean.

b. Mark from end of tube the length of insertion (See table below).

c. Push tube into the fitting until it bottoms out.

d. To remove, depress collet and pull tubing out.