2.6 Safety instructions

Observe the following notes:

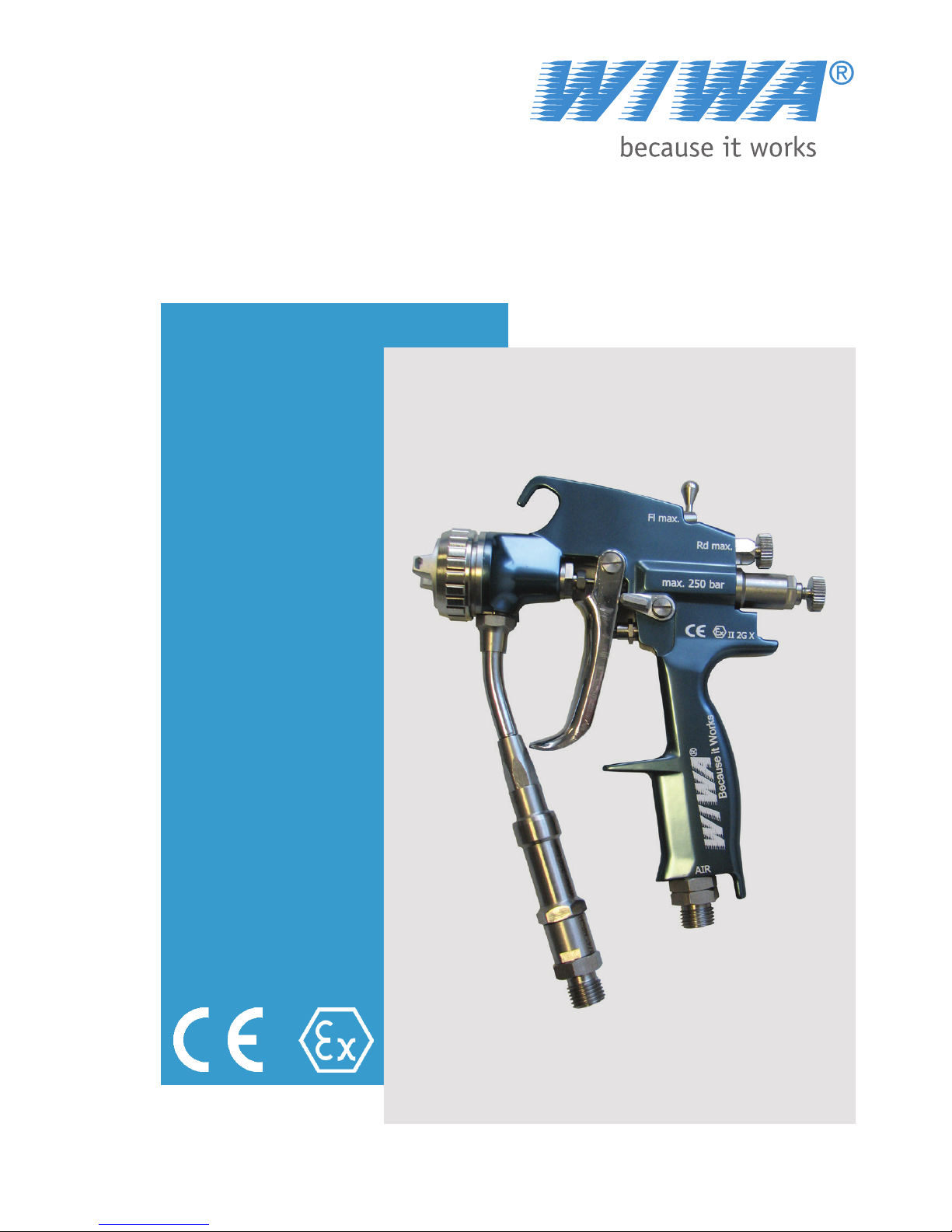

The spray gun must meet or exceed the maximum operational pressure

of the paint spraying equipment being used.

Because of the electrostatic charges produced by spraying, the spray

gun may only be mounted to conductive hoses. All original

hoses are conductive and matched to spray equipment.

It is possible for a static charge to occur due to the high flow speeds

during the airless spraying procedure. Static charges can lead to fire and

explosions.

Therefore, the complete unit (including the spray gun) and the

object to be sprayed must be grounded properly.

Never point the spray gun towards yourself, other people or

other living creatures!

Never hold your finger or hand in front of the gun and never reach into

the spray.

Hold the spray gun securely, as the high operating pressure can result in

severe kickback.

Never try to seal leaks on joints and high pressure hoses with your hand

or by binding the spot. Should a leak occur, the whole system (gun, hose,

pressure filter, pump, etc.) are to be depressurized immediately. Defec-

tive parts are to be replaced.

The spray gun is to be secured and the safety device checked during

every interruption while working, regardless how short.

If working with heated materials, always wear the proper hand

protection. BURN DANGER!

Upon work interruption and decommissioning of the spraying unit the

entire system has to be depressurized. Read and follow the instructions

in the operation manual for the spray equipment. Trigger the spray gun

briefly at the end of work to release any residual pressure.

The entire system is to be depressurized before maintenance and clean-

ing work is carried out. Read and follow the user's handbook for the

10 Translation of the original operation manual

SPAC_Optima2100_1302_en • 0550012 • jw

Safety