10

attempt to complete any part of

the installation or adjustment of

this unit unless technically

qualified to do so.

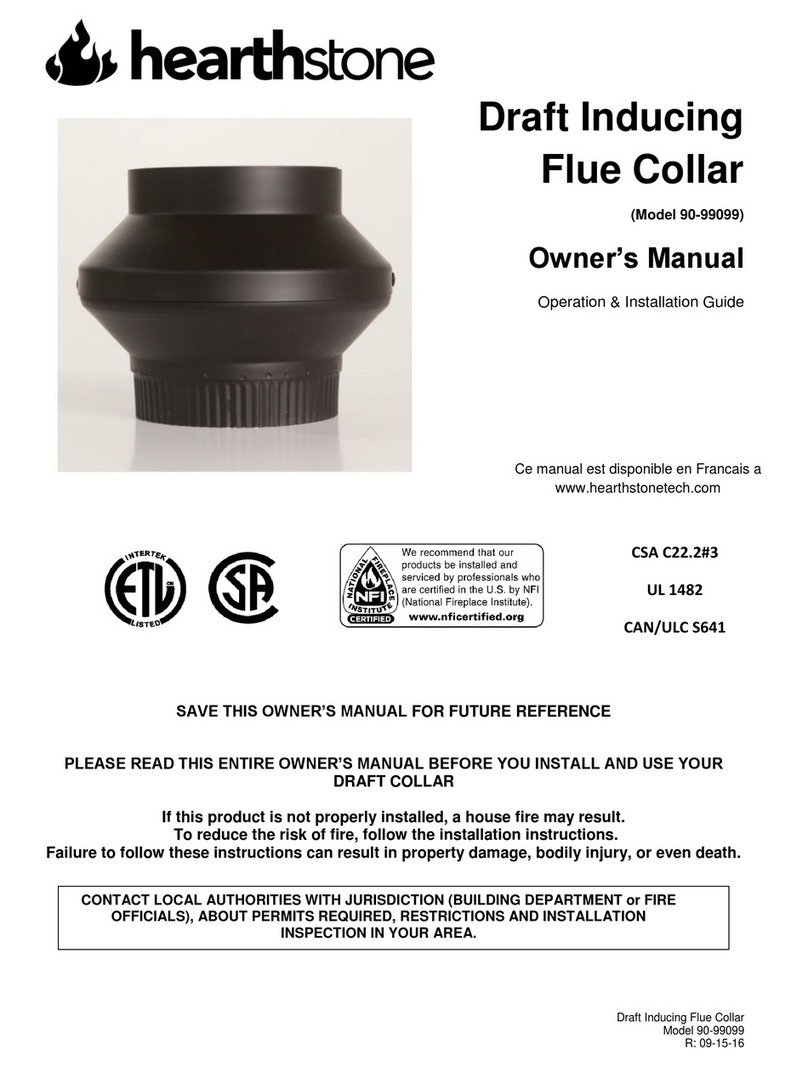

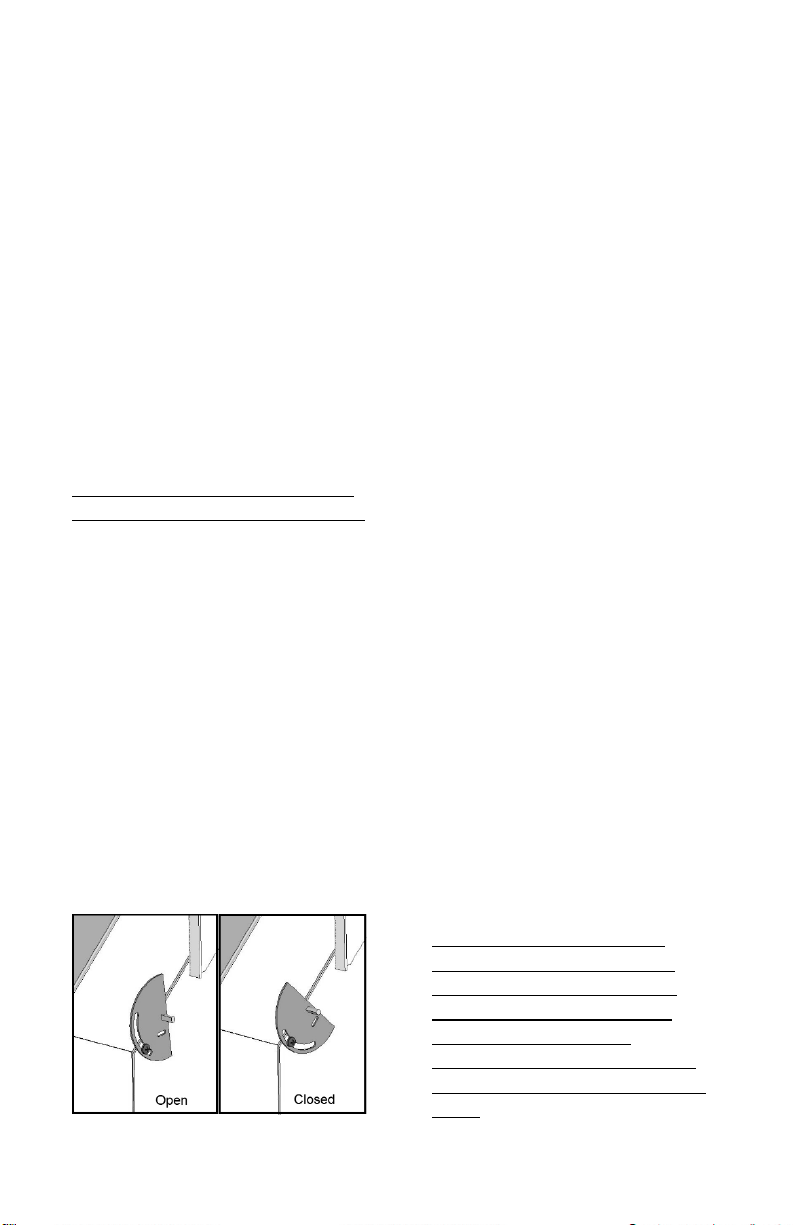

Restrictor Plate

The restrictor plate is used to

control excess draft if necessary.

Controlling the draft also changes

the aesthetics of the flame. The

restrictor plate has a large range of

possible settings (See Figure 19).

The adjustment point is on the left

side of the firebox (from front).

Restrictor Plate Position

The restrictor plate is factory set in

the fully open position for shipping.

This ensures proper flames for a

wide variety of vent configurations

and efficiency. The restrictor plate

consists of a rotating flap in front

of the firebox exhaust port behind

the cast iron baffle plate.

Depending on your vent

configuration, you may need to

adjust the restrictor plate position

to reduce draft.

Restrictor Plate Adjustment

Loosen the screw and position the

restrictor plate in the desired

location. Tighten the screw to lock

in place.

Figure 19 –Restrictor Indicator

To verify input rate:

The approximate input rate of the

converted Stowe may be checked

as follows:

1. Ensure that no other gas

appliances are in operation.

2. Place Stowe in operation on

high, and allow to burn for 15

minutes.

3. Using residential gas meter,

measure the time in seconds

required for the Stowe to

consume 1 cubic foot of gas.

4. The gas consumption of the

Stowe in BTU per hour may be

calculated as (3,600 x heating

value of gas) ÷ seconds to

consume 1 cubic foot. Use

local gas supplier’s heating

value, or use 2,500 for LP or

1,012 for NG.

EXAMPLE: Using LP with a heating

value of 2,500, and a time of 392

seconds (6 minutes 32 seconds):

(3,600 x 2,500) ÷ 392 = 9,000,000 ÷

392 = 22,959 BTU per hour

Note: Stowe may operate safely up

to 105% of its rated input, or

23,520 BTU per hour. If Stowe

input is incorrect, it is necessary to

adjust the gas supply pressure.

Supply line/manifold gas line

pressure adjustments must be

performed by qualified service

personnel. Do not attempt to

complete any part of the

installation or adjustment of this

unit unless technically qualified to

do so.