8

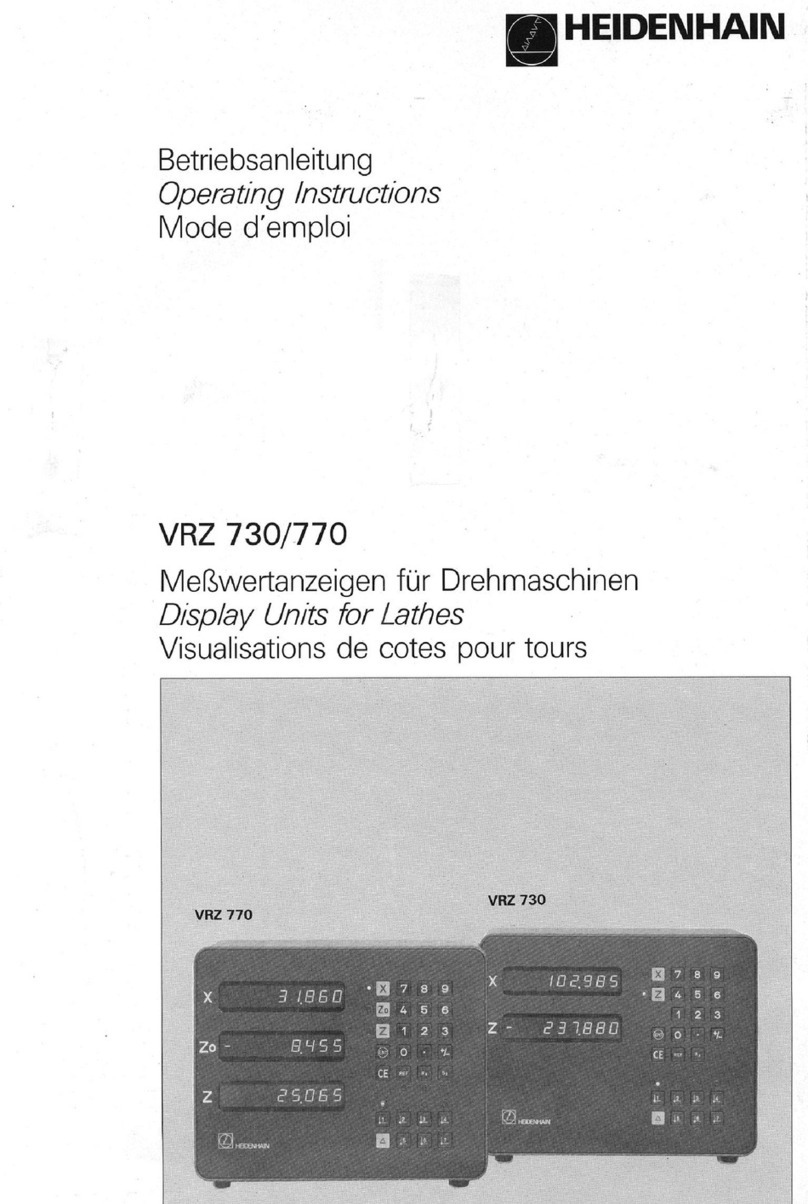

Positionencoders

The position encoders on the machine convert the movements of the

machine axes into electrical signals. The ND display unit evaluates

these signals, determines the actual position of the machine axes and

displays the position as a numerical value.

If the power is interrupted, the relationship between the machine axis

positions and the calculated actual positions is lost. The reference

marks on the position encoders and the REF reference mark

evaluation feature enable the ND to quickly re-establish this

relationship again when the power is restored.

Reference marks

The scales of the position encoders contain one or more reference

marks. When a reference mark is crossed over, a signal is generated

which identifies that position as a reference point (scale datum =

machine datum).

When this reference mark is crossed over, the ND's reference mark

evaluation feature (REF) restores the relationship between axis slide

positions and display values which you last defined by setting the

datum. If the linear encoders have distance-coded reference marks,

you only need to move the machine axes a maximum of 20 mm to do

this.

Y

X

Z

Workpiece

Positionencoder

Scale in Distance-coded

Linear encoder Reference marks

Reference marks

Fundamentals