10

Datum Setting

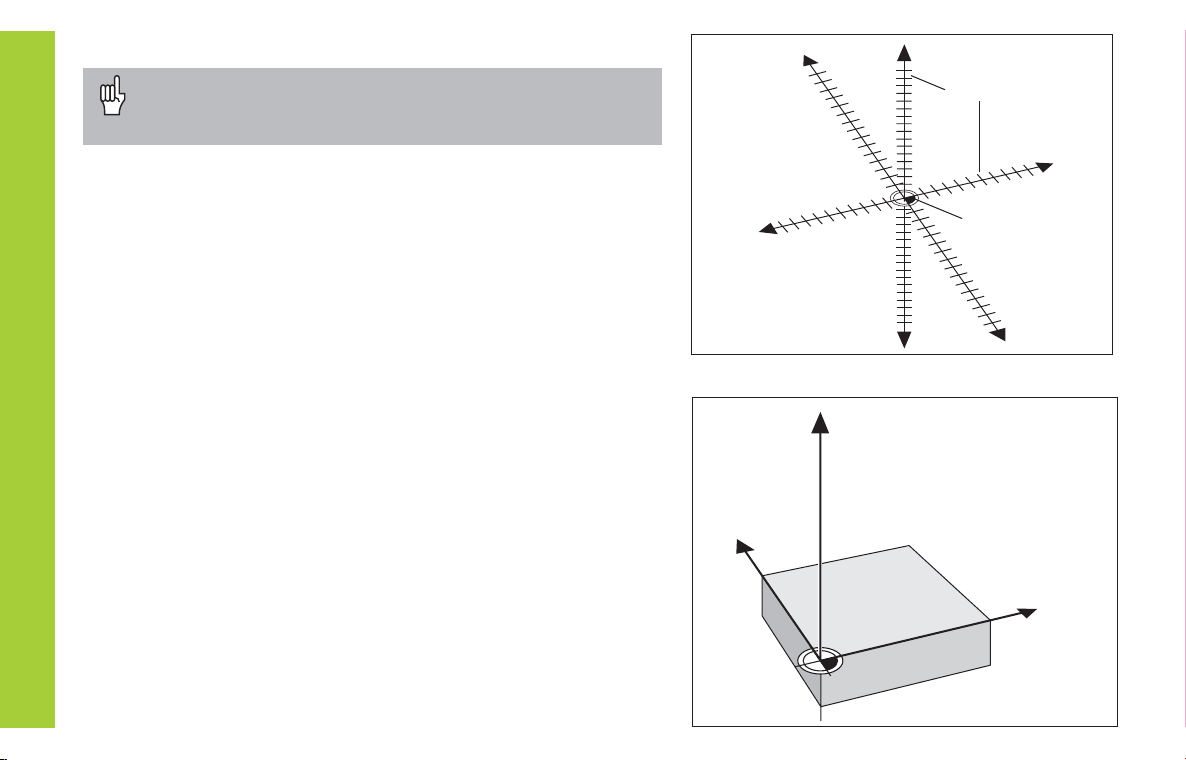

If you want to save the datum points in nonvolatile

memory, you must first cross over the reference

marks.

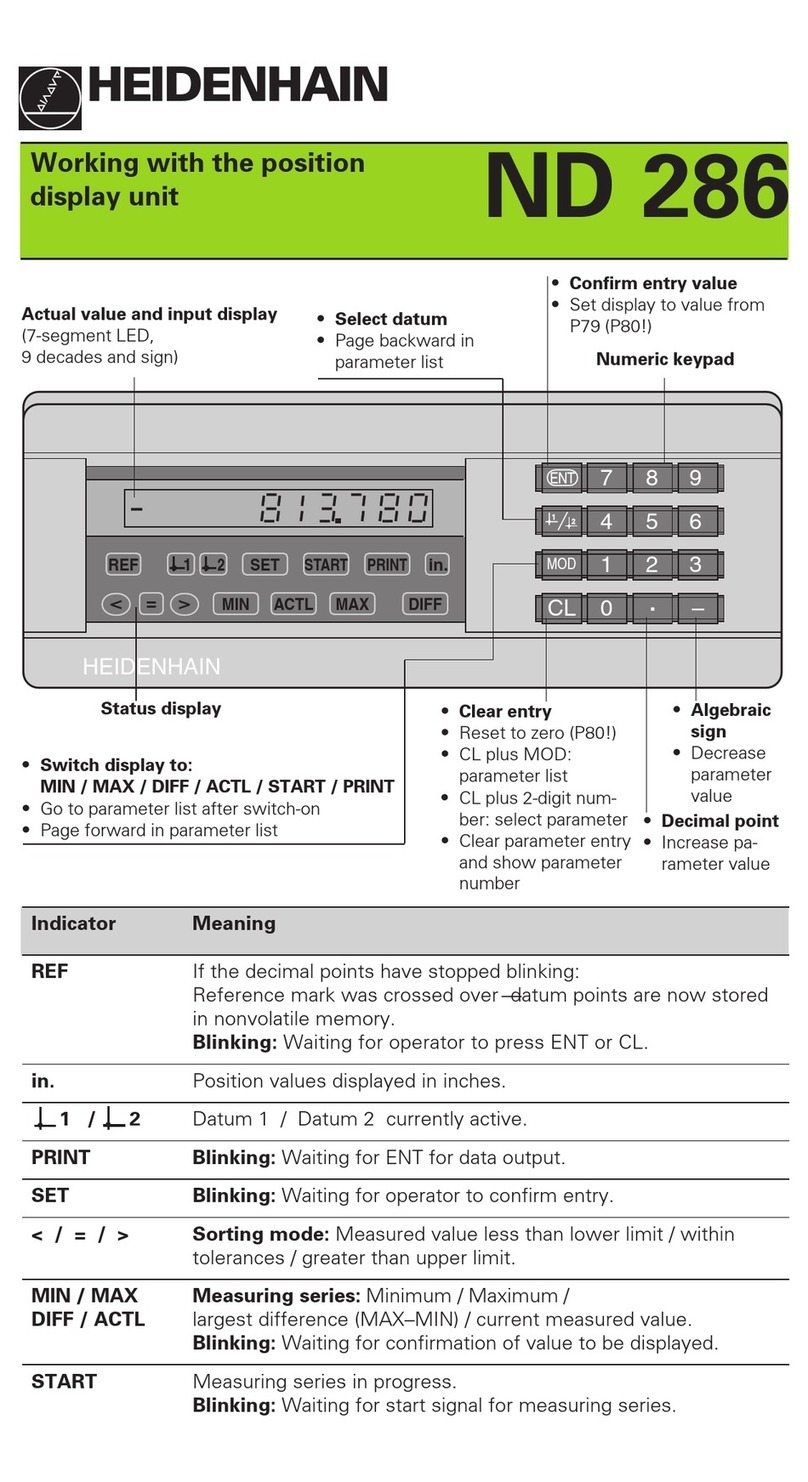

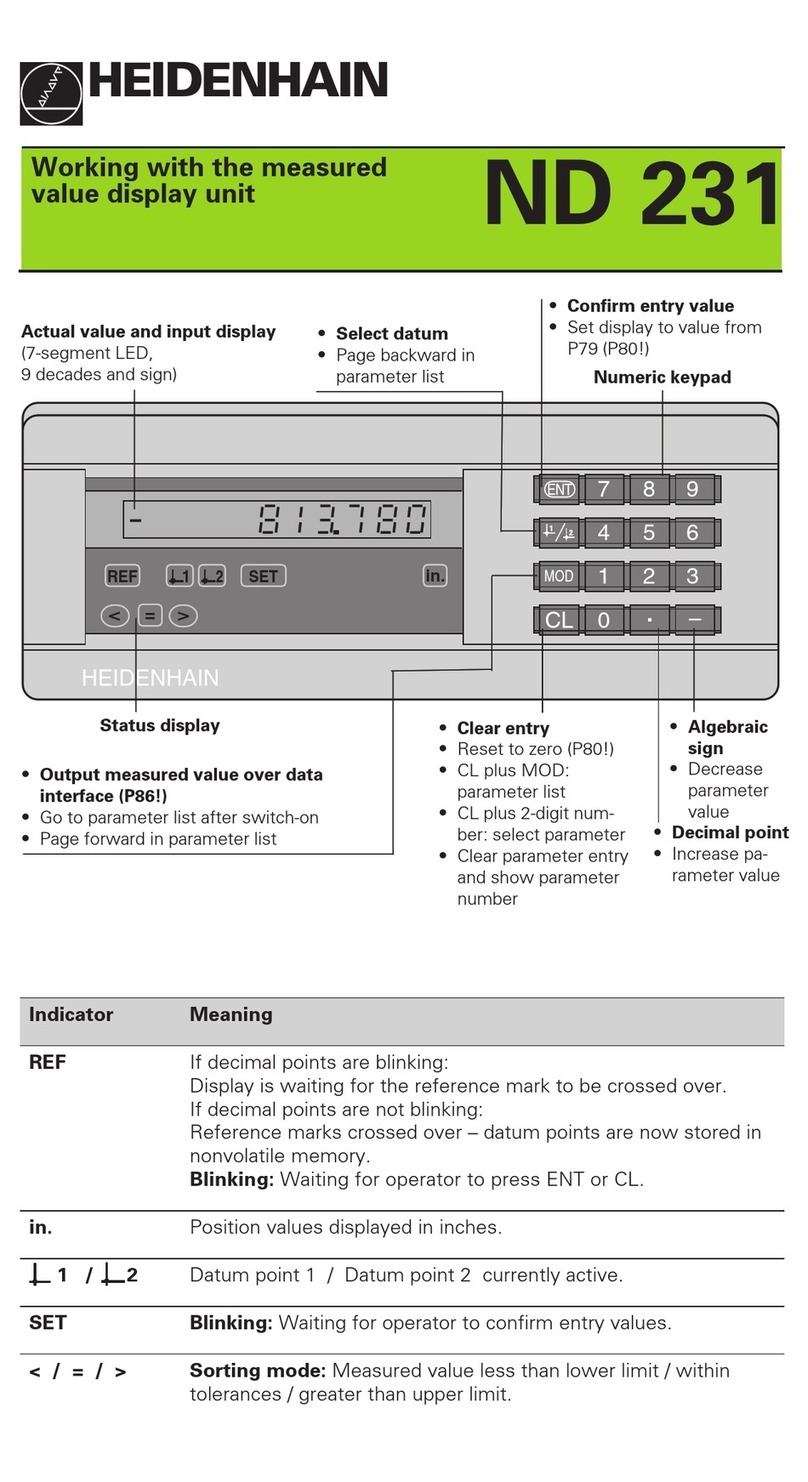

Press the datum key (d starts

blinking).

Datum Setting

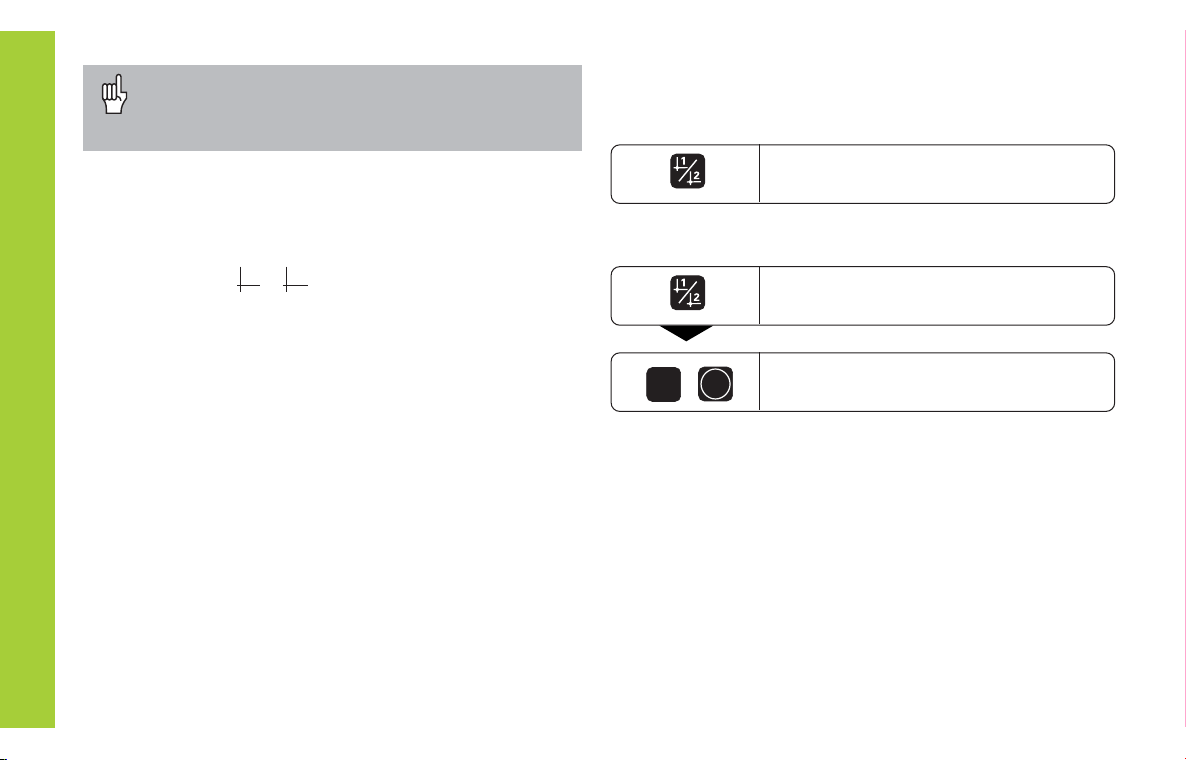

In P70, you can select:

Two datum points: The selected datum point

is displayed via or 2

Nine datum points: The selected datum point

is displayed in the lowest axis via d to d9.

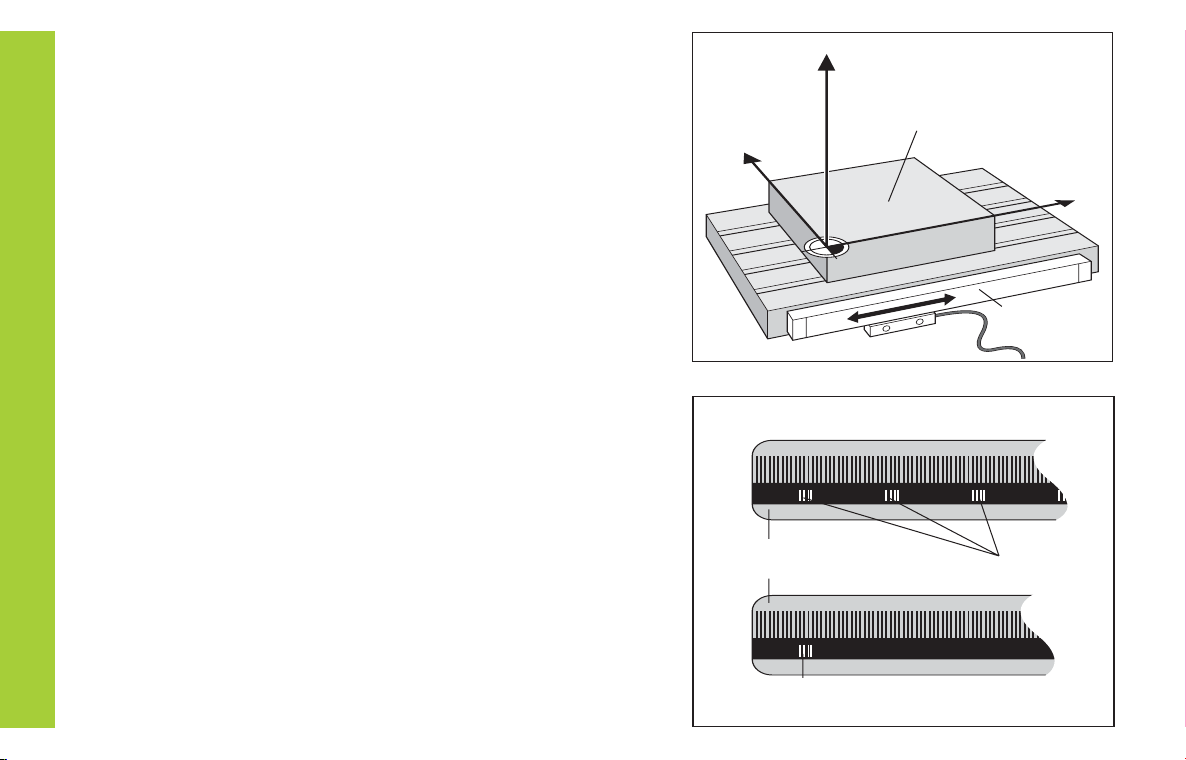

Touch the workpiece with the tool and then set the desired

datum (see example). You can also touch two edges and set

the centerline between them as a datum. The dimensions of

the tool used for this are automatically accounted for (see

Tool Compensation).

Probe the workpiece with the e ge fin er and then set the

desired datum. You can also probe two edges and set the

centerline between them as a datum, or touch the inside of a

circle and set the circle center as a datum (see examples).

The stylus radius and length are automatically accounted for

if they have been entered in parameters P25 and P26,

respectively (see Operating Parameters).

Enter a datum number ( to 9).

1

ENT

Only after crossing over the reference marks can you set

new datums or activate existing ones.

There are two ways to set datums:

To call a datum you have set, proceed as follows:

Select datum or 2.

You have set two datum points in P70:

You have set nine datum points in P70:

Bateil1.pm6 07.11.2001, 10:3610