3

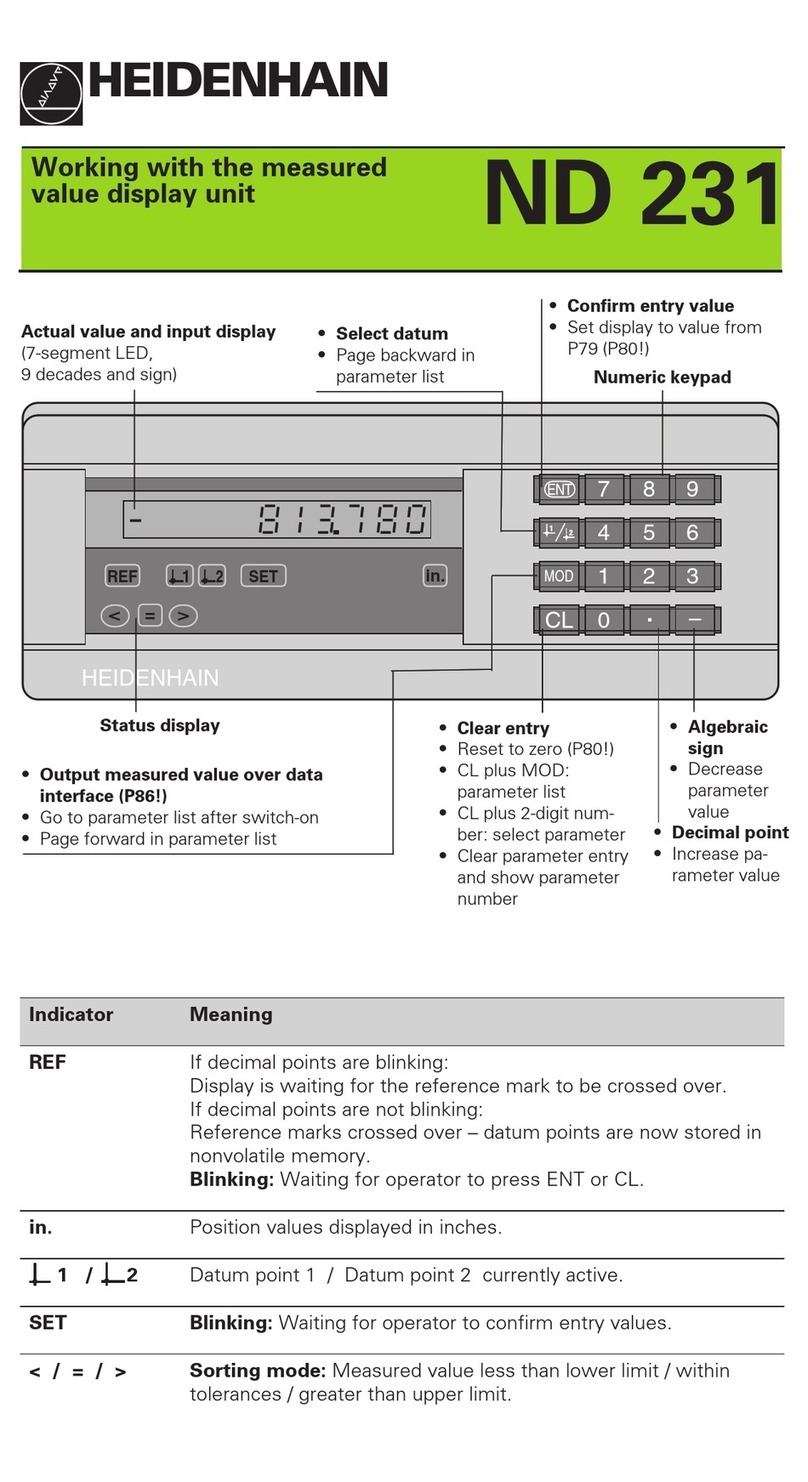

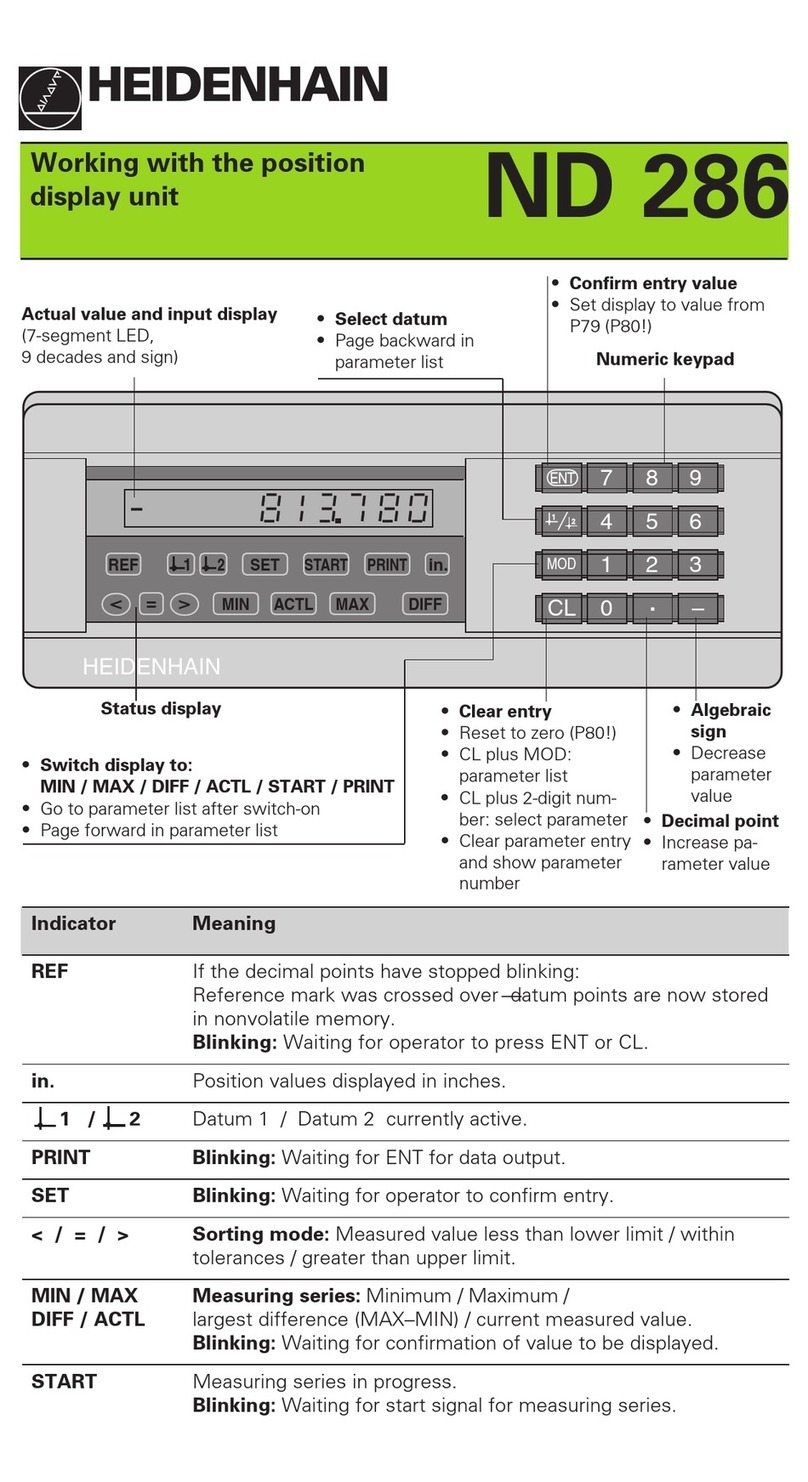

Key Function

• Set datum

• Transfer input value

• Set display to value from P79 (P80!)

• Leave parameter list

• Select datum

• Page backwards in parameter list

• Select parameter after switch-on

• Page forward in parameter list

• Start series of measurements 1)

• Switch display for measurement series 1)

• Start measured value output “PRINT”

• Delete entry

• Set display to zero (P80!)

• CL plus MOD: select parameter list

• CL plus number: select parameter

• Delete parameter input and show

parameter number

• Algebraic sign

• Reduce parameter value

• Decimal point

• Increase parameter value

MOD

1) Only in linear measurement mode.

Indicator Meaning

REF If the decimal point is also blinking:

Display is waiting for reference mark

traversing. If decimal point is not blinking:

Reference mark has been traversed—display

stores datum points in nonvolatile memory

Blinking: display is waiting for ENT or

CL to be depressed

inch Position values in inches

1 / 2 Selected datum point

PRINT "Linear measurement”

Blinking: Display is waiting for ENT to

be pressed for data output

“Angular measurement”

Measured value output with MOD key

SET Blinking: Display is waiting for input values

< / = / > Sorting and tolerance checking:

measured value smaller than lower limit /

within the limits / greater than upper limit

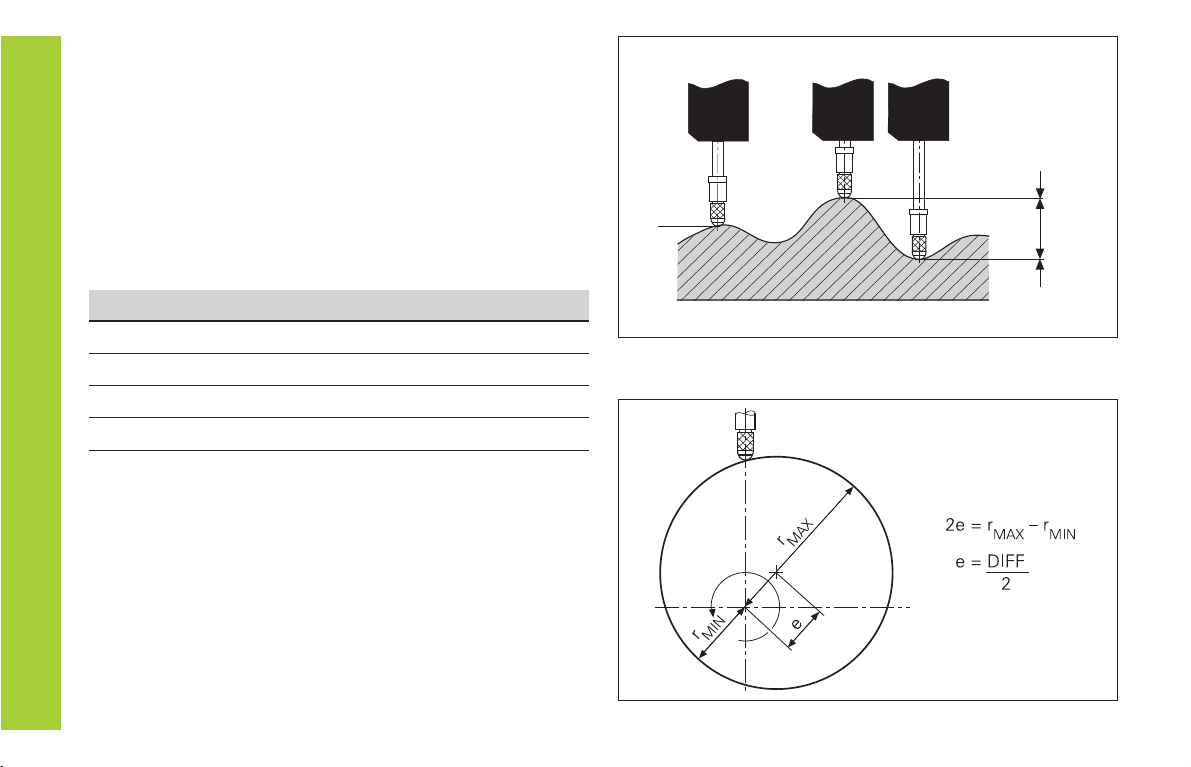

MIN

/

MAX / Series of measurements: Minimum /

maximum / greatest difference (MAX–MIN) /

current measured value

Blinking: Confirm selection or deselect

function

START 1) Series of measurements is running

Blinking: Display is waiting for signal to

start series of measurements

DIFF / ACTL1)