Fundamentals

7

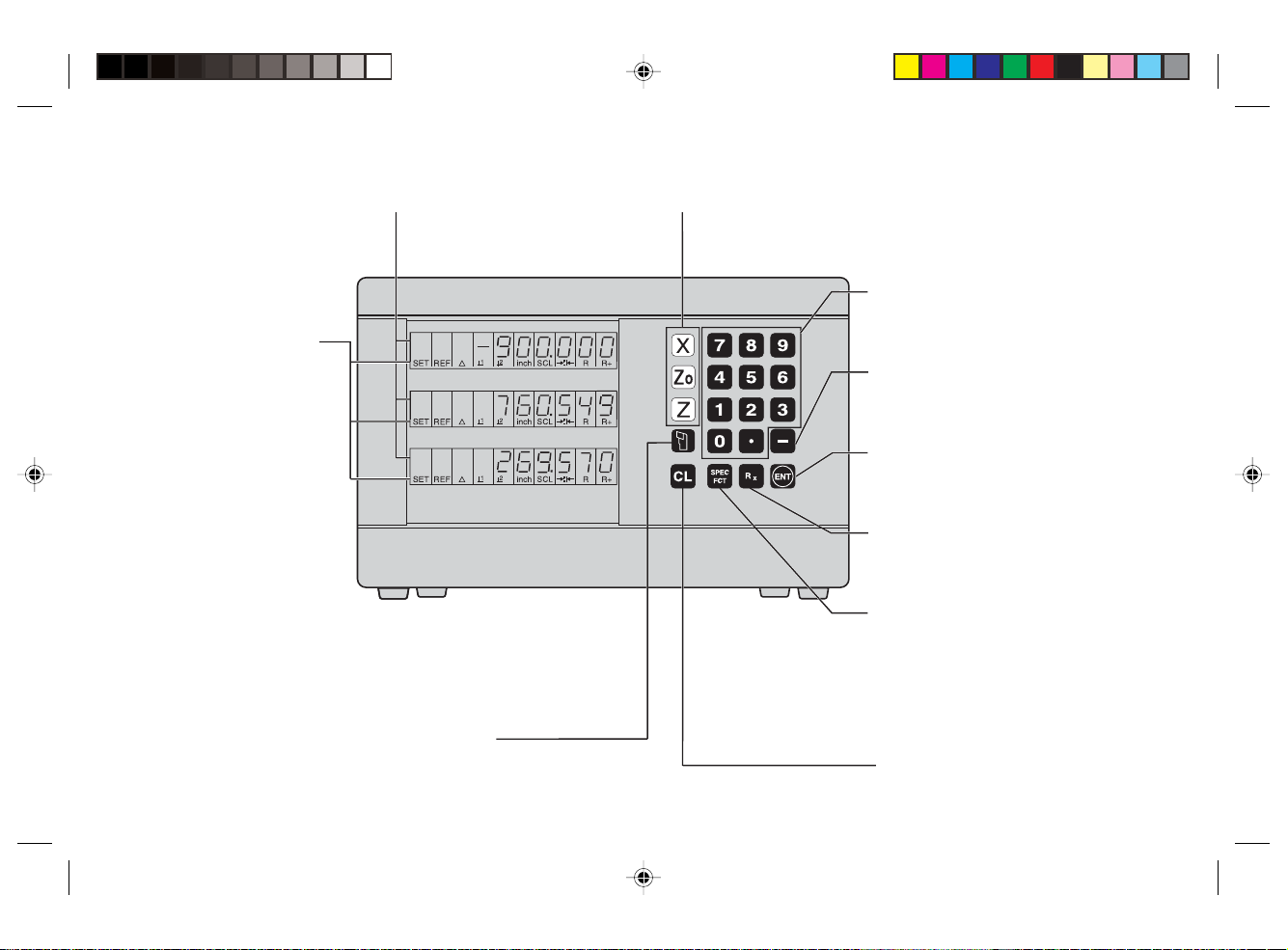

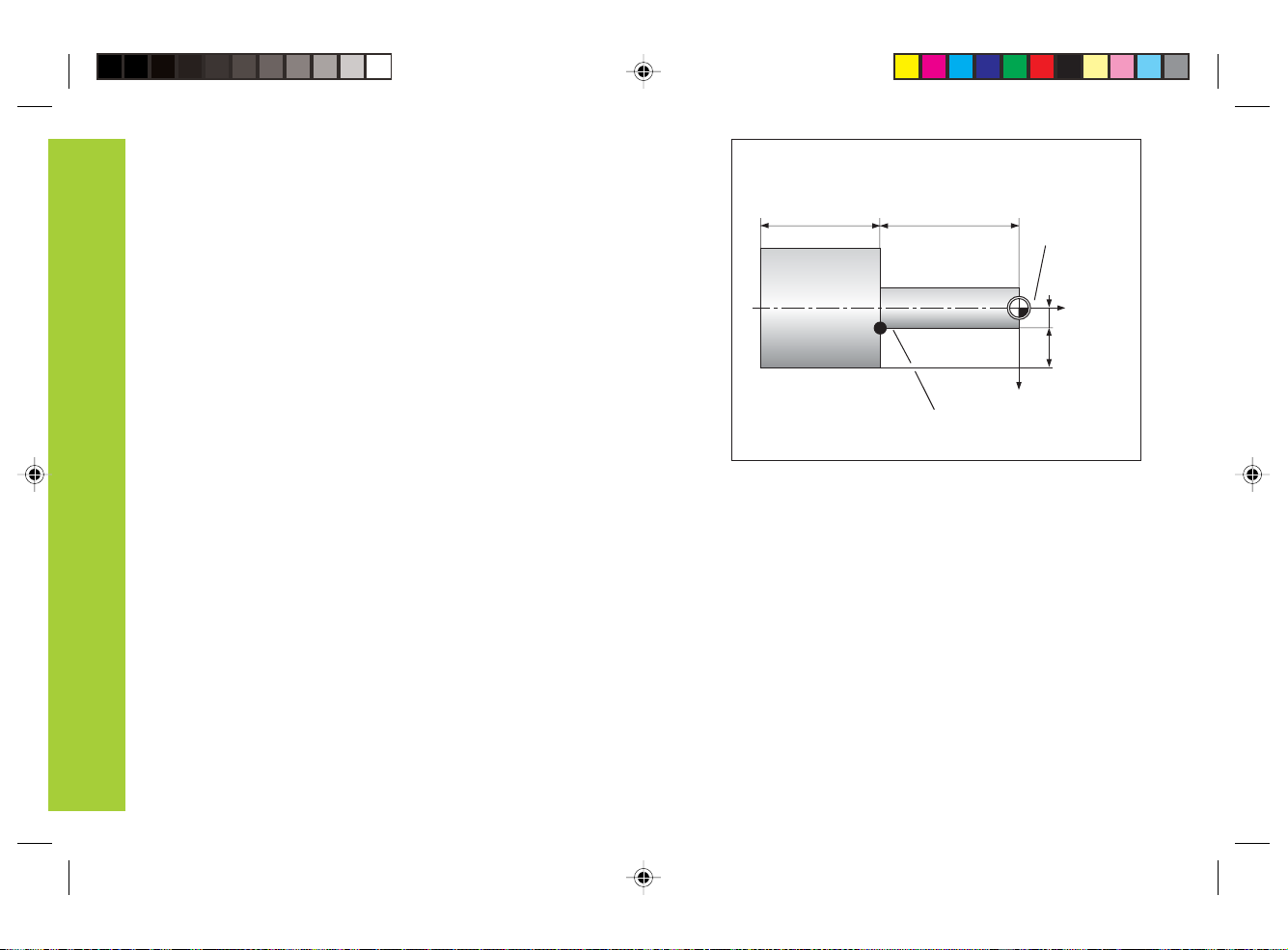

Nominalposition,actualpositionanddistance-to-go

The positions to which the tool is to move are called the nominal

positions (

S

). The position at which the tool is actually located at any

given moment is called the actual position (

I

).

The distance from the nominal position to the actual position is called

the distance-to-go (

R

).

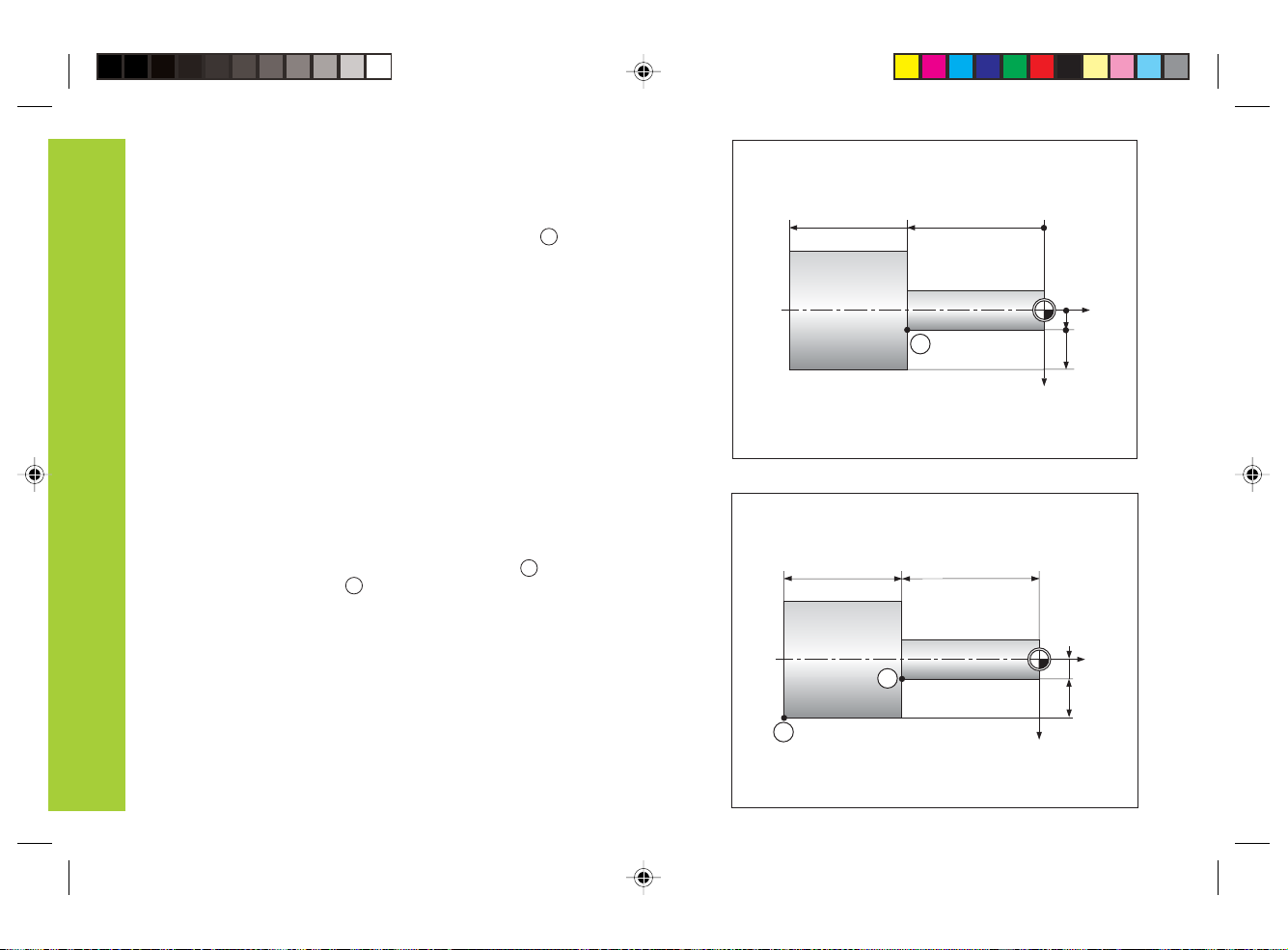

Signfordistance-to-go

When you are using the distance-to-go display, the nominal position

becomes the relative datum (display value 0). The distance-to-go is

therefore negative when you move in the positive axis direction, and

positive when you move in the negative axis direction.

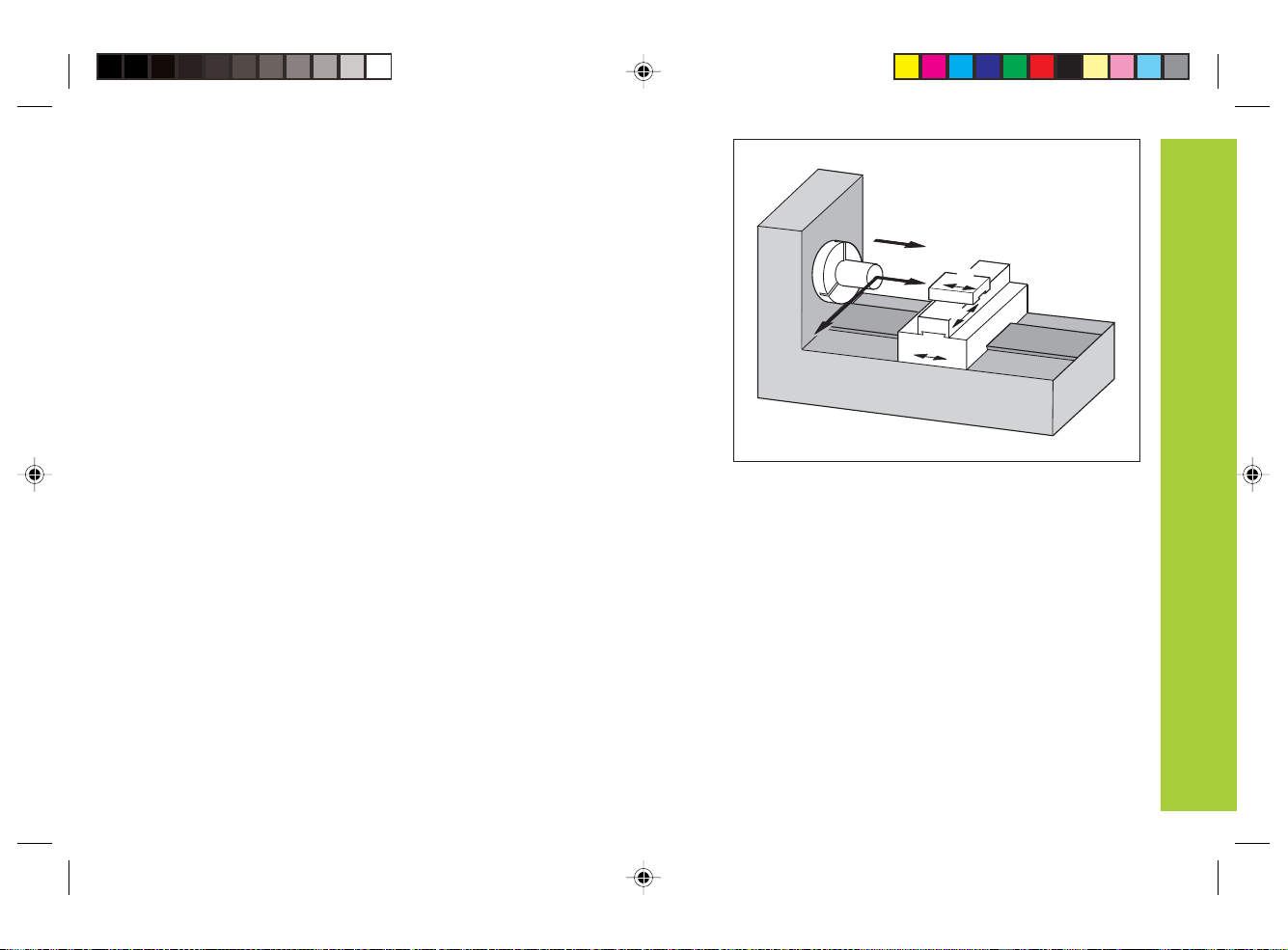

Tooldatums(toolcompensation)

Your display unit should show you the absolute position of the

workpiece, regardless of the length and shape of the particular tool

being used. For this reason you must determine the tool data and

enter it. First touch the workpiece with the cutting edge of the tool

and then enter the associated display value for that position.

You can enter tool data for up to 9 tools. When you have set the

absolute workpiece datum for a new workpiece, all tool data (= relative

datum points) are referenced to the new workpiece datum.

IS

Z

X

R

T1 T2 T3

730_770t1.pm6 21.07.2004, 08:357