heightec Cyclone P20 User manual

heightec.com

USER INSTRUCTIONS

with respect to gravity...

®

TM

Manufactured by;

The heightec Group Ltd, Kendal, Cumbria LA9 6NH, UK

Doc UI-P20- Issue date 25/11/21

Cyclone

Locking Pulley

P20

Not for use as PPE

Do NOT run any pulley against an edge as a severe bending force will be created.

Do NOT use for lifting or supporting persons

Do NOT use as part of a PPE system

Do NOT use with wire cables

Working Load Limit (WLL) 100kg (Factor of Safety 5:1) for the Rope Locking Cam

Working Load Limit (WLL) 300kg (Factor of Safety 5:1) for the Pulley ONLY

Warnings

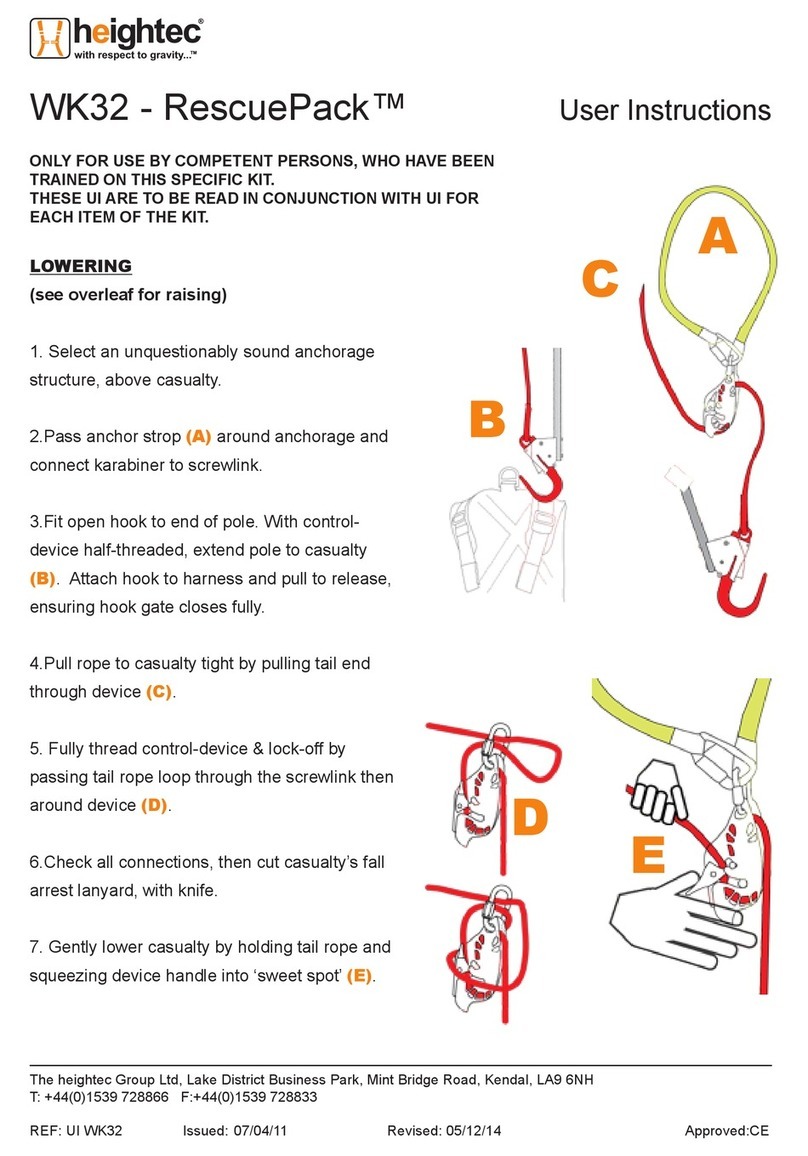

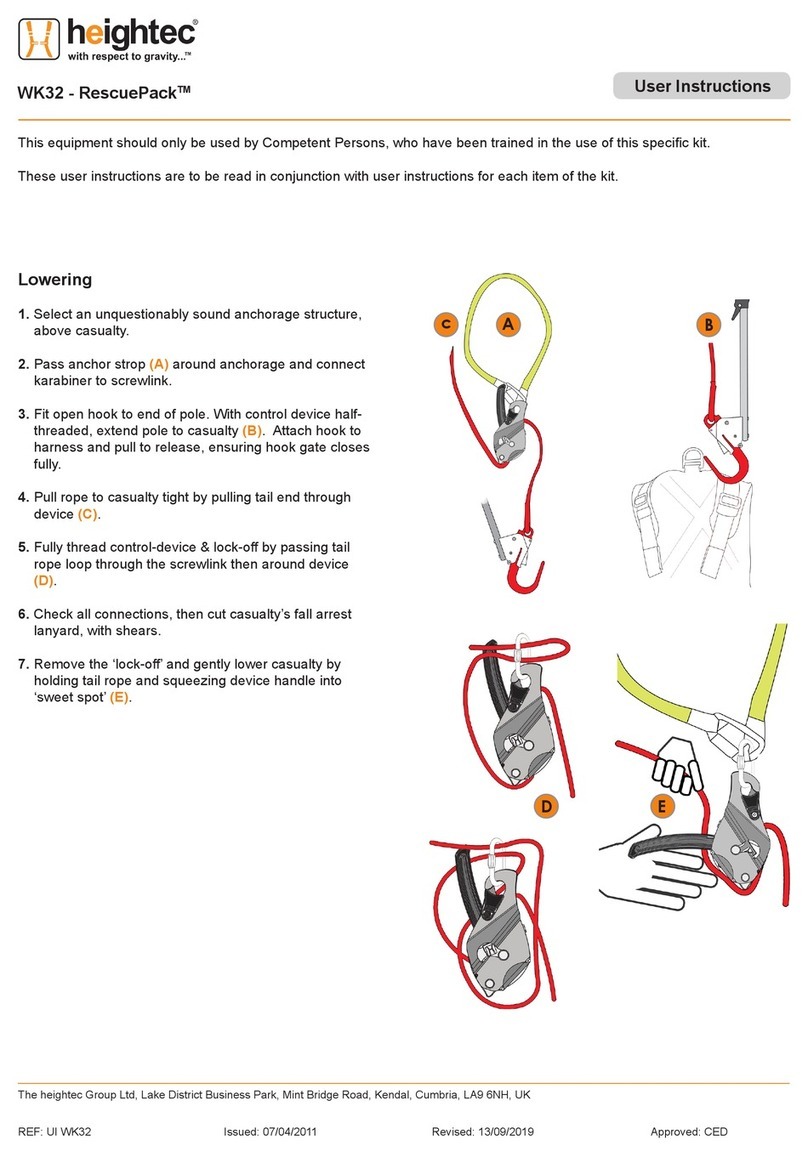

Correct threading of rope

Open the locking cam to insert or remove rope

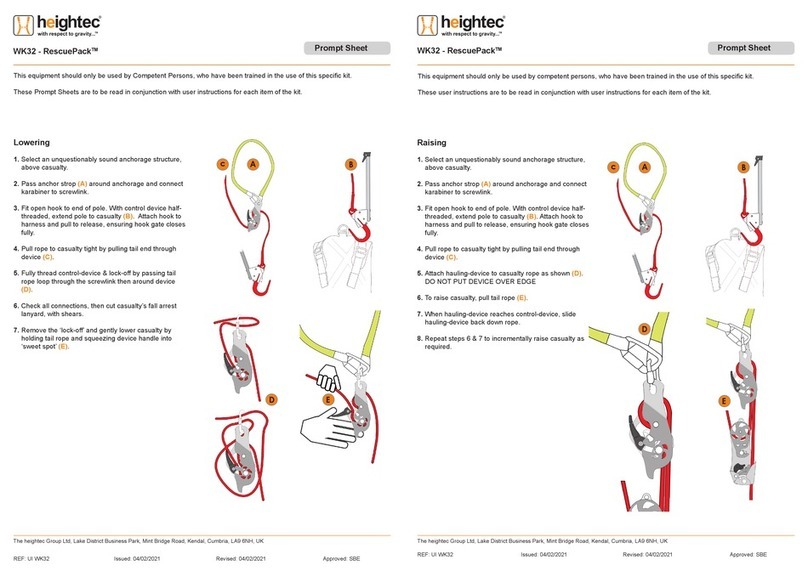

Forces on a pulley

Attachment

All attachments should be made through both cheeks

of the main attachment point, which will accept up to

three 12mm connectors.

Swivel front cheek to insert rope:

For use only with 10.5mm to 11.0mm diameter low-

stretch rope.

P20 - Stainless Steel Body

P201 - Aluminium Body

Pre-Use Checks

• Ensurethereisnosignicantdamageorwear.

• Ensure pulley wheel rotates freely.

• Ensure cheeks are locked closed by connector.

• Ensure locking cam engages and disengages

smoothly.

Ensure that the rope does NOT

rub across the top of the locking

cam which could prevent correct

operation

Remember that the force

experienced by the pulley

and anchor point is twice

that of the load being lifted.

E.g. Load 100kg + force to

lift 100kg = 200kg on pulley

Load

Pull

2 x Load

Approved under the Machinery Directive 2006/42/EC

EN13157:2004 Cranes - Safety - Hand Powered

Cranes

Supply of Machinery (Safety) Regulations 2008

EN13157:2004 + 1A:2009 Cranes - Safety - Hand

Powered Cranes

1 - Personal issue and traceability:

Although this product is not classed as personal protective

equipment, the product should remain traceable to the original

certicate of conformity and a permanent record should be kept

of its use. This user instruction forms part of the permanent

product record. All users must receive and read a copy of these

instructions and should understand what the instructions mean

and be familiar with them, including, but not limited to function,

suitability, compatibility of the product and inspection for defects

arising from damage. A copy of this user instruction should be

kept with the equipment, and referred to before and after each

use. In the event of a rescue, these instructions should be

provided to the rescuer.

2a - Anchor Points:

The anchor device or anchor point used should be of sucient

strength to sustain foreseeable loads in all permitted directions.

Specic standards requirements:

EN: Anchor device should conform to EN795, with minimum

static strength of 12kN. heightec recommend a higher strength

of 15kN as specied in the IRATA ICOP and BS7985.

When more than one system is attached to an anchorage, these

strengths should be multiplied by the number of systems.

Anchorages should be positioned to minimise the potential

for falls, and the distance and consequences of any potential

fall, ideally above the user. Verify there is sucient free space

beneath the user to avoid collision with the ground or other

obstacles and minimise sideways or pendulum falls. The

connecting system instructions should give advice on clearance

required, but a fall arrest energy absorber may extend by up to

1.75m.

2b - Further Requirements for Anchor Points in US (ANSI):

ANSI: (a) where certied, twice the maximum arrest force, or

(b) where not certied 22.2kN (5,000lbf) for fall arrest, 13.3kN

(3,000lbf) for work positioning, or 4.5kN (1,000lbf) for restraint.

When designing, selecting, and certifying a fall arrest anchorage,

the qualied person shall include the limitations on use of the

system in fall protection procedures described in ANSI Z359.2.

Design, selection and installation of certied fall arrest

anchorages shall include determining a safe location where and

how to connect those anchorages by taking into consideration

the forces generated by arresting a fall, total existing and

anticipated loading, load path, structural member strengths,

connection and support strengths, stability, clearance

requirements, swing fall, rescue deection of the system, and

impact on the structural members to which the fall arrest system

is attached.

Anchorages selected for rescue systems shall have a strength

capable of sustaining static loads, applied in the directions

permitted by the rescue system of at least 3,100lbf for

connection of rescue system only, or meet a Factor of Safety

of 5:1 based on the static load placed on the system when the

system is designed, installed and used under the supervision of

a qualied person.

It is essential a rescue plan is in place to deal with emergencies

and in particular to consider treatment and recovery of a fallen

or suspended person. Rescue equipment must be present

and personnel should be competent in its use. Orthostatic

intolerance can occur when a person is suspended motionless

in a harness, and is potentially fatal. Ensure that the rescue of a

suspended person is carried-out promptly.

Contamination with oils, lubricants, water or solvents may alter

the performance of the product. For rope devices behaviour will

vary according to the age, type, diameter and characteristics of

the rope used.

5b - Care of rope during use:

Take any steps necessary to protect the rope from damage

during use, including rope protectors, edge protectors,

intermediate anchor points or deviations to avoid sharp or rough

edges. Consider also the position of the rope below the user.

Ensure rope cannot suer from the eects of wind, or become

trapped around obstacles.

6 - Guarantee:

This product is guaranteed for three years against faults arising

from manufacturing errors or materials defects. This guarantee

does not include normal wear and tear, faults arising from uses

for which the product was not designed and accidental damage.

7 - Notes:

If this product is re-sold outside the original country of

destination the reseller shall provide these instructions in the

language of the country in which the product is to be used.

Persons engaged in rescue operations that are exposed to a fall

hazard, must be provided an anchorage suitable for fall arrest in

accordance with ANSI Z359.1.

Anchorage connectors shall not be attached to anchorages where

such attachment would reduce the anchorage system strength below

the applicable level set forth above or reduce the anchorage strength

below the allowable level set by applicable structural codes. A suitable

anchorage connector shall be used for rigging the connection of

lanyards and lifelines to structural members. A lanyard shall not be

connected back onto itself for use as an anchorage connector unless

specically designed for this purpose.

Anchorage connections shall be stabilised to prevent unwanted

movement or disengagement of the rescue system from the

anchorage. Verify system connections by pre-tensioning the system

before applying the intended load.

Other components used in fall protection or work positioning systems

must conform to the relevant standards, be compatible with each

other and be used in accordance with their user instructions.

3a - Inspection and care:

The strength of this product may be aected by cuts, nicks, deep

scratches, wear, abrasion, deformation, chemical contamination, UV

degradation, exposure to ame, extreme termperatures and other

factors. Keep this equipment away from such sources of damage.

Use this product with caution near moving machinery, electrical

hazards, sharp edges and abrasive surfaces.

This product must be inspected before and after use, and particularly

after being used for rescue, to ensure the product is in a suitable

condition and operates correctly. Written records should be kept of all

inspections.

If there is any doubt about condition of the product, or it has been

subjected to a fall or substantial shock load, withdraw it from use until

conrmed to be safe, in writing, by a person deemed to be competent

by The heightec Group.

No repairs of this product should be undertaken, any attempt to do so

may invalidate it's compliance and/ or certication.

The safety of users depends upon the continued eciency and

durability of this equipment, which must subjected to detailed visual

and tactile examination by a competent person* at intervals of no

greater than 6 months for textiles or 12 months for metals, taking into

account relevant legislation, equipment type, frequency of use and

environmental conditions. These examinations should be carried out

strictly in accordance with the manufacturer’s periodic examination

procedures. Detailed examinations should include conrmation of the

legibility of product markings.

*A competent person may be dened as someone who “...has

appropriate theoretical and practical knowledge and experience...”

The results of examinations should be recorded. Intermittent

inspections of components which may be subject to excessive

wear may also be appropriate. The results of these need not

be recorded. Contact your distributor for information on suitable

inspection procedures.

3b - Inspection criteria:

Textile products or elements: check material and stitching for

damage including cuts, nicks, abrasion, fraying, discolouration,

heat or chemical damage etc. Ensure stoppers are present on

ends of adjustment webbing.

Metal devices or components: check for damage, corrosion,

excessive tightness, sharp edges, excessive play, deformation,

cracking or anything that might aect strength. Check security

and correct operation of any moving parts e.g. side plates, return

action of springs, cams, operating handles, bearings. Check

function of closure mechanisms, where present (e.g. screwlink

thread, connector gates).

3c - Cleaning, maintenance and storage:

Wash textiles by hand with non-detergent soap at approx 25°C

(cool). Rinse and dry naturally, away from direct sources of

heat and sunlight. If necessary use a disinfectant compatible

with polyamide and polyester. Use diluted and rinse thoroughly

in clean water. Dry as previously stated. These cleaning

procedures must be strictly adhered to.

Mechanical metal products with moving parts should be

occasionally oiled, at bearings or pivot points, with excess oil

removed. Store and transport in a dry, clean condition, away

from sources of severe vibration, humidity, direct heat, sunlight

and any physical or chemical contaminants.

4 - Lifespan:

Textile products or elements: maximum 10 year lifespan from

date of manufacture, subject to competent use, maintenance

and examination programme.

Metal products: indenite lifespan, subject to competent

use, care and examination programme. The lifespan of all

products will be reduced by normal wear and tear, particularly

when used in abrasive or corrosive environments. In extreme

circumstances, the life of an item may be reduced to a single

use.

5a - General usage:

Users should be suitably trained and competent to work in

situations where a risk of falling may be present or under the

direct supervision of such a person, fully trained in the use of

this product and free of medical contra-indications for work at

height or rescue. Do not use this product outside of its limitations

or if you are unsure of any aspect of its use. No alterations or

additions may be made to the product. The heightec Group

do not take any responsibility for injury or accident of any kind

arising from the use of this product.

Markings:

The following markings may be present on the product:

CE mark - European Conformity.

Read these instructions before use.

For use with kernmantel ropes conforming to EN1891

type A

XX-YY - Diameter range of rope which this product may

be used, in mm

Direction of use

Date of manufacture is marked on the product in the form:

DAY MONTH YEAR, DDMMYY eg.120510.

The ID no. is unique to this item.

Do not remove or obscure the product labels or markings.

Unique ID should be read in conjunction with product code and

batch number e.g. D01 120510 123

INSPECTION RECORDS ID Number:

Product: PO/ Certicate No.:

Model/Type: Purchase Date:

Manufacture Date: First Use Date:

Date Observations / Comments Actions Inspector Next Due

The heightec Group Ltd, Unit 19, Lake District Business Park, Mint Bridge Road, Kendal, Cumbria LA9 6NH, UK 19/07/2019

2

13

4

This manual suits for next models

1

Other heightec Safety Equipment manuals

Popular Safety Equipment manuals by other brands

Lanex

Lanex PB-20 instruction manual

SKYLOTEC

SKYLOTEC ANCHOR ROPES Instructions for use

Besto

Besto Buoyancy Aid 50N Instructions for use

TEUFELBERGER

TEUFELBERGER NODUS Manufacturer's information and instructions for use

Troy Lee Designs

Troy Lee Designs Tbone Product owners manual

Innova

Innova Xtirpa Instruction and safety manual

bolle SAFETY

bolle SAFETY B810 quick start guide

SHENZHEN FANHAI SANJIANG ELECTRONICS

SHENZHEN FANHAI SANJIANG ELECTRONICS A9060T instruction manual

Hiltron security

Hiltron security POWER8E Installation and use manual

Salewa

Salewa MTN SPIKE user manual

Hatco

Hatco B-950P installation guide

Sitec

Sitec TX MATIC operating manual