Heiniger ICON/I User manual

Exzenterantrieb

Pin-drive

Entraînement à goupille

Accionamiento de pivote

Eksenterdrev

Schneckenantrieb

Worm-drive

Entraînement à vis-sans-fin

Accionamiento por tornillo sinfín

Snekkedrev

swiss made

Ausgabe/Index: ICON/I 10/21

Betriebsanleitung D

Instruction manual GB

Mode d’emploi F

Manual de Instrucciones E

Instruksjonsbok N

2 Instruction manual ICON

Contents

1 Proper Use

1.1 Overall View / Controls

1.2 Intended Use

1.3 Technical Data

1.4 Equipment Items

2 Safety Regulations

2.1 Introduction

2.2 Symbols and Warning Signs

2.3 Proper Use

2.4 Safety Principles

2.4.1 Drive Connections

2.4.2 Servicing and Checking Requirements

2.4.3 Noise Emission / Personal Protective Equipment

2.4.4 Other Dangers

2.5 Essential Operator Skills

3 Putting into Operation

3.1 Controls and Operation Notes

3.2 Shearing Adjustment using theTension Nut

3.3 Lubrication

4 Servicing

4.1 Cleaning

4.2 Fitting the Shearing Blade

4.3 Resharpening the Shearing Blades

4.4 Storing

5 Maintenance & Repairs

5.1 Introduction

5.2 Maintenance

5.3 Repair Kits

5.4 Malfunction List

5.5 How to

6 Environmental Protection and Disposal

6.1 Introduction

6.2 Material Categories

7 Contact Addresses

Illustrations: at the end of the instructions

Instruction manual ICON 3

Pos Description Total

1 Barrel ICON 1x

2 Centre post 1x

3 Locknut 1x

4 Comb screw 2x

5 Crankshaft 1x

6 Ball 1x

7 Safety screw 1x

8 Oil hole cap 1x

9 Tension nut bushing screw 1x

10 Retaining ring 1x

11 Tension pin 1x

12 Tension sleeve upper 1x

13 Tension nut 1x

14 Distance washer 1x

15 Ball bearing 1x

16 Spring washer 1x

17 Gliding bush 1x

18 Retaining ring JV 27 x 1.2 Typ J 1x

19 Seal 1x

20 Back joint cover 1x

1 Proper Use

1.1 Overall View / Controls

Component Names

Illustr. 0

Pos Description Total

21 Back joint cap 2x

22 Back joint spring 1x

23 Inner back joint 1x

24 Outer back joint 1x

25 Ball bearing 2x

26 Cog Z14 2x

27 Drive shaft ICON PIN-Drive (1x)

28 Tapered pin Ø3 x 12 mm 1x

29 Drive shaft ICON WORM-drive 1x

30 Chicken feet retaining spring 1x

31 Pan-head screw M4 x 5 1x

32 Centre post cup 1x

33 Fork body 1x

34 Tension pin retaining spring 1x

35 Tension pin cup 1x

36 Chicken feet L+R (pair) 1x

37 Fork body assembly complete (1x)

38 Ferrule Ø22 x 180 mm solid-drive (1x)

38 Ferrule Ø22 x 160 mm flex-drive (1x)

4 Instruction manual ICON

1.2 Intended Use

The (machine) is intended exclusively for use on sheep and goats, as well as llamas, alpacas

and other members of the camel family.

Other uses, in particular using the machine on people, are expressly prohibited.

1.3Technical Data

Designation:

Model:

RPMmax:

Dimensions (B/H/L):

Mechanical Shearing Handpiece

“ICON“

3500 U/Min.

approx. 65mm x 95mm x 320mm

Max. AmbientTemperature: 0°C - 40°C

Max. Air Humidity: 10% - 90% (relative)

Noise Emission (LpA): >70 dB(A) (EN 50144-1/02.96 & EN ISO 3744/11.95)

Acceleration (ahw): > 2,5 m/sec2(EN 28662-1/01.93)

We reserve the right to adopt technical changes and improvements.

Instruction manual ICON 5

1.4 Equipment Items

1 Shearing Handpiece (machine)

1 Special Screwdriver

1 Operating Instructions

Options:

Various shearing combs and cutters

Special comb cleaning brush

Special lubricating oil

Post Guide

2 Safety Regulations

2.1 Introduction

This Section describes the mandatory safety regulations which must be observed when using

the machine.

All persons undertaking work on or with the machine have an obligation to read the opera-

tion instructions.

The operating instructions must be kept safely and accessible at all times.

2.2 Symbols and Warning Signs

Various symbols are used in the operating instructions.They refer to potential dangers or point

to technical information, the non-observance of which will lead to personal injury, damage to

objects or inefficient operation.

Danger Symbols

Warning

indicates a potentially dangerous situation. If preventive action is not taken, death or very

serious injury could result.

Caution

indicates a potentially dangerous situation. If preventive action is not taken, the consequences

could be slight or minor injuries.

6 Instruction manual ICON

Information Symbols

Note

Note, non-compliance with which can lead to operating malfunctions or damage.

Pictorial Note

This symbol, together with its number, refers to the relevant illustration at the end of the

instructions.

2.3 Proper Use

The use which the machine is intended for, is described in Section 1.2.

The following applies to safe operation:

The details at Section 1.3, “Technical Data“, count as mandatory operating limits and ratings.

Shearing other animals, in particular dangerous animals such as beasts of prey and the like,

counts as misuse.This could lead to circumstances dangerous to life and limb.

2.4 Safety Principles

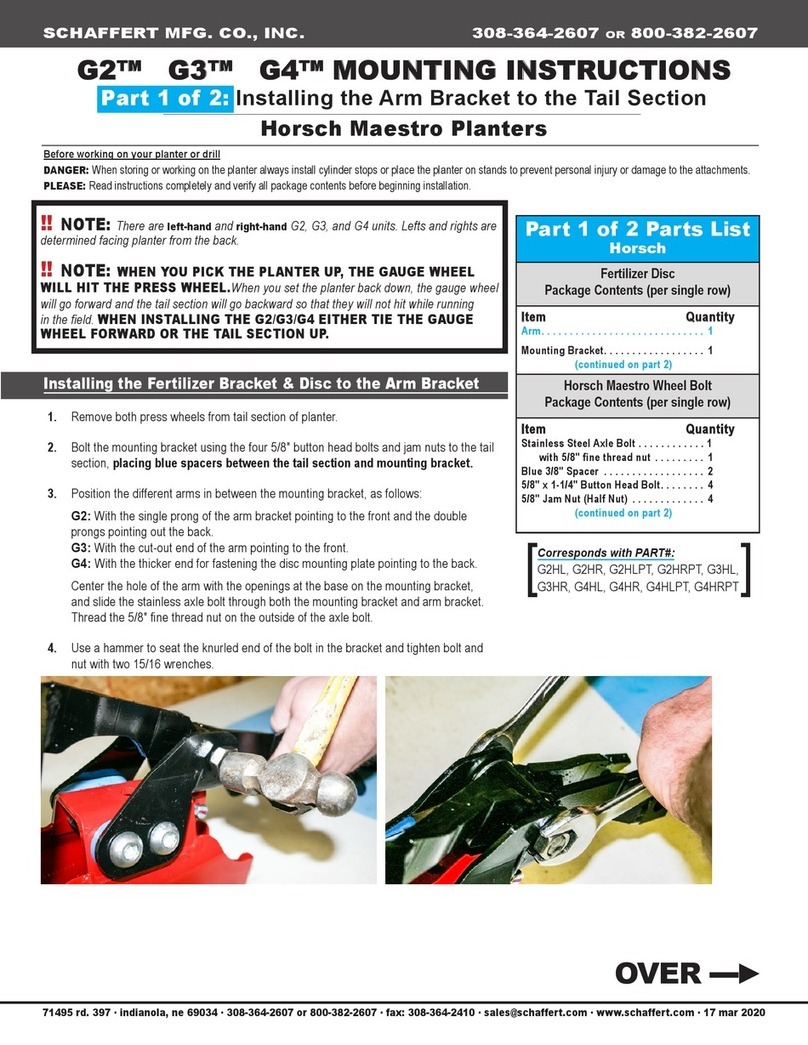

2.4.1 Drive Connections

Only connect the machine up to undamaged, inspected shearing drive shafts & motors

(shearing plants). Damaged shafts or motors can cause lock up which can cause serious injury.

Defective installations can cause an electric shock or a short circuit.

Make sure to use the correct type of drive coupling, i.e. only connect a worm-drive type

handpiece to a worm-drive type shearing drive (Illustration 1, Item 1) and a pin-drive handpiece

to a pin-drive shearing drive (Illustration 1, Item 2). Do not mix the two system as it can cause

malfunction and unexpected behaviour of the whole system.

Servicing and cleaning must only be carried out when the machine is removed from the drive

(shearing plants).

Never leave the machine unsupervised when connected to a shearing drive. Keep children

away from the working area and store the machine out of their reach.

2.4.2 Servicing and Checking Requirements

Only operate the machine if it is undamaged and in a proper condition. Any defects to the

housing (barrel) or the drive shaft connection should be rectified by a repair or service agent.

2.4.3 Noise Emission / Personal Protective Equipment

Wear Ear Protectors !

Typical sound emission when working are >70 dB(A). We recommend that ear protectors

should always be worn when working.

Illustr. 1

Instruction manual ICON 7

Wear Protective Goggles and Gloves !

For your personal protection we recommend that you wear protective goggles and gloves.

Personal protective equipment is to be provided by the operator.

2.4.4 Other Dangers

Should evidence of dangers or potential dangers, not directly related to the shearing of

animals, occur during operation, we would ask you to inform us. This also applies to dange-

rous technical deficiencies.

2.5 Essential Operator Skills

Operating the machine safely makes only small demands of the operator. However, it is essen-

tial that they are observed and carried out.

• Theoperatormustbeexperiencedinhandlingtheanimalstobeshorn.

• Theoperatormusthavereadandunderstoodtheinstructionsorhavebeeninstructedbyan

expert in the machine’s use and have had the potential dangers explained.

Children are not permitted to operate the machine.

3 Putting into Operation

3.1 Controls and Operation Notes

There are dangers inherent in the improper use of mechanical equipment, especially stock-

breeding equipment! Therefore, before using the machine, you should observe the following

accident-prevention measures:

• Observetheadvisorynoteslistedat2.4.1(driveconnections).

• Avoidallcontactwiththemovingshearingblades(comb&cutter).

• Evenwhentheshearingdrive(shearingplant)isswitchedoff,donothandletheareaof

the shearing blades as long as the machine is connected to the shearing drive. Always

disconnect the machine from the shearing drive first when working on the shearing blades/

machine.

• Nevershearwetanimals.Wetwoolmayenterthemachinebody(barrel)andcauselock

up.

• Generally,neverplungetheclipperandclipperheadintoliquidssuchaswater,soapywater,

diesel, petrol, etc.This may cause serious injury to mechanics and motor.

• Neverputyourhandpieceinavice,itwilldisfigurethebarrelandthebackendwillbecome

tight.

• Neverattempttointerchangepartsfromanothermodel/typeorbrandofhandpiece.

• Onlyuseoriginalshearingblades(combs&cutters;Illustration5).Donotusedamaged

shearing blades with blunt, missing or broken off teeth. Only work using sharp shearing

Illustr. 5

8 Instruction manual ICON

blades, ground according to advisory notes listed at 4.3 (Resharpening the Shearing Blades)

• ookingoutforforeignbodies(wire,wood,etc.)inthefleeceandremovethembefore

beginning to shear.

• Wearsuitableworkclothes.Donotwearanyloosefittingclothingoritemsofewellery

which could get caught up in moving machine parts. We would recommend in the strongest

terms that protective goggles and ear protectors are worn.

• Neverinsertanyobectintoanyofthemachinesapertures

• Noisefromthemachinecanworryanimals.onsiderableinurycanbecausedasaresultof

being kicked by an animal or being crushed by its body weight.

• Animalsshouldonlybeshornifunauthorisedpersonshavebeenexcludedfromthe

shearing area.

• Onlyshearinwellventilatedspaces(dust)andnevernearobectsorgaseslikelyto

explode.

• Werecommendyouuseacombfornolongerthananhourandacutterfornolongerthan

15 minutes before you change them for a sharp comb and cutter

These Safety notes must be complied with in all cases.

3.2 Shearing Adjustment using the Tension Nut

Before putting into operation, make adjustments as follows:

Before Shearing:

With the machine disconnected from the shearing drive: ensure that theYoke’s carrier (chicken

feet) cone pins mesh precisely into the positioning holes in the cutter (Illustration 2, Item 2).

Tighten the tension nut until resistance is first noticeable (Illustration 2, Item 1).Then tighten

the tension nut a further 1⁄4 turn.

Connect the handpiece to the shearing drive (observe advisory notes listed at 2.4.1) and start

operating the shearing drive motor. Slacken off the tension nut (Illustration 3) until the shearing

blades exert almost no more contact pressure (noise level rises).

Caution! If the tension is slackened off too much, the cutter can fly off causing injury.

Now tighten the tension nut slowly until the noise level becomes muffled and some resistance

is detectable as you tighten the tension nut. The pressure should now be correctly set. Begin

shearing. If it still does not cut properly, you will have to add a little more tension.

During Shearing

Provided the shearing blades are properly sharpened (ground) the shearing system works with

much less pressure having to be applied than with traditional shearing machines. Care should

be taken, therefore, to ensure that the blade tension is not set too high. Too high tension

causes more friction and reduces the life expectancy of the shearing handpiece as well as the

shearing blades. Slightly adjust the blade tension from time to time during shearing (max. 1⁄4

turn).

Hair may collect between the shearing blades, if the tension nut is insufficiently tightened at

the start of shearing. This will have an adverse effect on further shearing progress or make it

quite impossible. If this happens, the shearing blades must be disassembled, cleaned, oiled

and re-fitted as described at 4.2 (Fitting the Shearing Blades)

Illustr. 2, 3

Instruction manual ICON 9

3.3 Lubrication

Before and During Shearing

A thin layer of oil on the cutter and the comb plate (Illustration 4, Item 4) is essential for good

shearing results and so as to increase the life of the machine and its shearing blades. All other

moving parts must also be well oiled (Illustration 4, Item 3) .

Only use our special clipper oil or a paraffin oil meeting the ISO VG 15 specification. This oil is

non-toxic and produces no irritation on contact with the skin or the mucous membranes. This

paraffin oil degrades to some 20% after 21 days (CEC-L-33-T-82).

You cannot over oil ! The more often you oil, the cooler it will run and the longer it will last.

Especially if you are shearing llamas, alpacas or other camelides, even more frequent oiling of

comb and cutter may be needed.

Always oil the machine before use, and at least at every cutter change.

Oil the following parts

• eforeyouassemblethebladestothehandpieceturnthehandpieceupsidedown

(Illustration 4,Item 1) and run oil into the centre post cup through the hole illustrated.

• Oilthetensionsleeveortopoftensionpin(Illustration4,Item2).

• Turnitbackoverandoiltensionpincup(Illustration4,Item).

• Wetthecogswithoil.

• Oildowntheferruletolubricatetheouterbackhalfointandthepinorwormdrive.

• Oiltheballthroughtheholeinthetopofthebarrel.

• Oilthecutterandcombwhenset(Illustration4,Item4).

Do not put oil or grease between the tension nut and the tension sleeve as this will cause loss

of tension.

Grease

Once a week remove, clean and regrease the following parts:

• okescarrier(chickenfeet)emovethecombandcutter,turntheyokescarrierat

degrees to the fork and pull them out using a pair of pliers. Clean them and the locating

holes in the fork and apply a small amount of grease on the yoke’s carrier shank and replace

it making sure they twist freely in the fork when replaced. If they don’t, remove and clean

more thoroughly.

• ackointapsemovethebackointspring,takeoffthecapsandcleanoutanyold

grease and dirt. Apply a small amount of grease in the cap and reassemble.

• Tensionleeveemovethetensionnut,tensionsleeveandtensionpin.emoveallthe

grease from inside the tension sleeve and from the tension pin. Apply a good amount of

grease to the inside of the tension sleeve and replace it, remember to remove all grease

from the outside of the tension sleeve before replacing the tension nut.

Bearings

The shearing handpiece is fitted with bearings which are sealed and will never need oiling or

greasing.

Illustr. 4

10 Instruction manual ICON

4 Servicing

Before starting any servicing work, disconnect the handpiece from the shearing drive.

4.1 Cleaning

After shearing, remove all oil from the machine by rubbing it down with a dry cloth and

carefully clean the outside of the shearing handpiece and the shearing blades with a dry brush.

Then oil the parts to prevent rusting. Even the smallest rust spots on the blades can adversely

affect shearing or make it completely impossible.

4.2 Fitting the Shearing Blades

A pair of shearing blades consist of a comb plate (Illustration 5, Item 2) and an cutter

(Illustration 5, Item 1). When fitting the blades care should be taken to ensure that the correct

surfaces come to rest against each other.The blades are fitted as follows:

Loosen the tension nut (Illustration 3) and place the machine on a hard surface so that the

comb blade fixing screws lie uppermost. Slacken off the screws (Illustration 6) and remove

both the old shearing blades.

Ensure that the new shearing blades are clean. Particular care should be taken to ensure that

thegroundsurfacearefreeofdirt;ifnot,evennewlygroundshearingbladeswillnotshear

satisfactorily.

Place the new cutter in the yoke’s carrier (chicken feet) cones (Illustration 7 and 2, Item 2) and

push the new comb plate between the loosened screws (Illustration 8). Now tighten the comb

blade fixing screws until you can just move the new comb plate sideways by hand.

Now turn the machine over so that the tension nut is against uppermost.

What is now important is that you rest the blades against each other in such a way that the

ground surface of the comb plate projects approx. 1.5 - 2.0 mm beyond the tips of the cutter

(Illustration 9) at the same time all sharp corners of the cutter indicated at (c) must be within

the indicated area (b)

Once you have adjusted the shearing blades, set the position of the comb plate and tighten up

the comb blade fixing screws.

Check that the shearing blades have been correctly fitted and that the pressure yoke’s carrier

(chicken feet) cones (Illustration 2, Item 2) are situated in the holes provided in the cutter. Now

tighten up the tension nut until the cutter is pressed against the comb plate and you can feel

a slight resistance.

4.3 Resharpening the Shearing Blades

Only work with sharp shearing blades. Replace blunt blades or those with missing teeth.

Proper resharpening can only be done with a special shearing blade grinder and by a trained

technician or experienced Shearer. For correct shearing blade grinding technique, please

follow the instructions which comes with every Heiniger shearing blade grinder.

Illustr. 5, 3, 6

Illustr. 2, 7, 8

Illustr. 9, 2

Instruction manual ICON 11

4.4 Storing

Only store the shearing handpiece in a dry place. Do not connect it to a shearing drive if you

suspect any liquid has got into it.There is then the risk of a corroded and therefore seized drive

mechanism which, if you try to run the handpiece, can cause injury.

Make it a habit to store the machine between use, store it well-cleaned, oiled and with tension

slackened off, in a clean, dry place, out of the reach of children.

5 Maintenance & Repairs

This product has been developed and assembled using the best individual components

available. It is designed to give longevity and high performance. If spare parts are used during

the life of this product, please ensure that they are genuine Heiniger parts. Failure to use

genuine Heiniger spares may reduce the performance of this precision engineered product and

will void any warranty claim.

5.1 Introduction

Always contact an authorised service centre if you are unsure how to rectify the problem and in

the event of malfunctions not contained in these instructions

Details of authorised service centres are to be found at the end in the „7 Contact Addresses“

section.

5.2 Maintenance

It is impossible for us to say how often you should replace parts, as wear factors vary from

country to country and shed to shed, however, the components are manufactured from the

highest quality metals that will enhance the life expectancy of your handpiece.

5.3 Repair Kits

Three repair kits are available. It is advisable to fit complete repair kits and not replace indivi-

dual parts when carrying out a service, this will ensure the smooth and true running of your

shearing handpiece.

Repair kits consists of the following parts:

Illustr. 23

•tensionsleeve

•tensionpin

• tensionpincup

• tensionpinretaining

spring

• centrepost

• centrepostcup

•tensionsleeve

•tensionpin

•tensionpincup

•tensionpinretaining

spring

•centrepost

•centrepostcup

•centrepostlocknut

•2xcogs

•ball

•Frontbearing

•Backhalfjointbearing

•seal

•wavewasher

•circlip

•distancewasher

Short Replacement Kit Bearing Replacement KitLong Replacement Kit

12 Instruction manual ICON

Firstlfindoutwhereexactl

onthehandpiecetheheatis

coingfroetitcooldown

tartagainandatteptto

locatetheoriginalheatsource

andpiecerunshot

stheresandandorgritinside

thefrontofthebarrel

ithcobandcutterin

placeandafirgriponour

handpieceputourthubover

theoilholeandfillthebarrel

withoilfrothefrontwhilethe

handpieceisrunninghilst

stillrunningturnitupsidedown

anddraintheoilout

heckthatourcoband

cutteraresharpandnotover

tensioned.

esharpenhenuseless

tension.

entreposthasdirtbetweenit

andthecentrepostcup

eatonthuborforefinger eovethecutterturnthe

handpieceupsidedownandoil

thecentrepostcupliberall

opoftensionpinandinside

tensionsleeve

Hot tension nut. Firstcleanoutthetension

sleeveandcleanthetension

pinegreaseandtragain

aveouputtheballonthe

wrongwaaroundheflat

sidegoestothecrankhead

otonringfingeroriddleof

handpiece

eoveandturnaround

oolbuildupbetweenball

andcrankheadaroundthe

crankpin

eovewool

opofthetensionpiniswor eplacetensionpinandsleeve

entrepostcuparewell

worm.

Fitshortrepairkit

eatfrofrontregionin

general.

MALFUNCTION RECTIFICATIONCAUSE

5.4 Malfunction List

Actions to be taken to rectify malfunctions are indicated in the „Rectification“ column of the malfunction

list. Those rectification notes printed on a dark background may only be carried out by a trained person or

an authorised service centre.

selesstensionorresharpen

comb and cutter.

Frontbearingsisrunninghot

probablcausedbtoouch

tension or blunt comb and

cutter.

eplacebearingsasthecrankgotalotof

oveentupanddowninside

thebearing

Instruction manual ICON 13

Oilmoreregularly.Cogsmaybedry.Hotonlittlefingeroratthe

backofthehandpiece.

Cogsmaybeworn.

causingthecogstorununtrue.

Resharpencombandcutter.

Backbearingrunninghotdue

totoomuchtension,comband

cutter are blunt.

Replacebearings. Bearingfailure.

Lossoftensionbetweencomb

and cutter.

Cleanthesleeveandinsidethe

tension nut.

Greaseoroilbetweenthe

tensionsleeveandtensionnut.

Replacetensionretaining

spring.Makesuretheend

withoutthe90degreebend

pointsintheclockwisedirec-

tion.

Worn or no tension retaining

spring.

Replaceallthreeparts. Worntensionpin,sleeveand

cup.

Removeit,cleanitandthe

threadinsidethebarrel.

Hasyourtensionnutbushing

screwcomeloose?

Lossofcut. Firstlyaskothershearersin

theshediftheyhavethesame

problem.Iftheydo,maybeit’s

notyourhandpiece.

Checkyourcuttersareground

flatwithaburronthetips.

Ittakes3goodgrindsto

reshapeyourcombstoanew

positiononthediscorwhen

using a new disc.

haveyouchangedgrinder?

Grind down comb screw

thread.

Areyouusingverythincombs

andtheforkishittingthecomb

screws?

Resetwithpostguideorresetto

originalclockmark.

Hasyourpostshifted.

Fitshortrepairkit.Wornparts.

Tension-pin,-cupand-sleeve.

Replacecombscrews.Crackedcombscrews(too

muchhealgrindoncombs).

Sharpenyourgeartwiceto

makesure.

Checkyourcombandcutters

aresharp.

MALFUNCTION RECTIFICATIONCAUSE

Replacecapsandbackjoint

Sidewaysmovementbetween

innerandouterbackhalfjoints spring.

.

Always replace special cogs in pairs.

It is essential to use identical special

cogs.

14 Instruction manual ICON

sethickercuttersorfilea

sallaountoffourpins

reouusingthincutterwith

chickenfeetpinsreaching

throughthecutterandhitting

thecob

eoveandcleanthoroughloolorgreasebuildupunder

thebackjointcover

ightbackend

irtbetweentheinnerback

halfjointandthebush

aveouputourbarrelina

vice

Buanewone

eovethebackjointclean

thebackjointandinsidethe

bushwitharagoistwith

solventeplacethesealreoil

and reassemble.

eplacewithnewcirclip

eplacewithnewcirclip

aveoureassebledthe

handpieceusinganoldcirclip

aveouovercopressed

circlipwhenfitting

esetandtightenasourpostcoeloose

Grind down comb screw

thread

reouusingthincobs

andtheforkishittingthe

cobscrews

fcracksarepresentreplaceit

iediatel

aveouhadacoband

cutterlockupleanand

checkforkthoroughlfor

cracks

eplacecobscrewsrackedcobscrewsfro

toouchhealgrind

eplacechickenfeetheckchickenfeetpinsarenot

overworwherethefitinto

cutter.

Firstllocatewherethe

problesisinourhandpiece

alsotritonanothershearing

drivetoseeiftheprobleis

stillpresent

bnoralvibrationorruns

rough

heckchickenfeetareagood

fitinsideforkbod

eplacechickenfeet

sourcobtightonthecob

bed

ightencobsscrews

ibrationfrofront

hecktheballisagoodfiton

thecrankshaft

ibrationfroiddle eplaceball

MALFUNCTION RECTIFICATIONCAUSE

Instruction manual ICON 15

eplaceforkbod

eplacebearing

hecktheballraceinthefork

issooth

heckthefrontbearingfor

wear.

eplacecapsandbackjoint

spring

heckouhavenooveent

betweenthebackhalfjoints

heckourcogsareingood

condition.

hecktheforkisnothittingthe

crankshaftheadbecausethe

postisnotcorrectlset

esetpost

hecktheferruleisnotslopp

insidetheshorttube

hangetheshorttubeandthe

ferrule

asourhandpiecelockedup

andbentthecrankshaft eplacethecrankshaft

ibrationfrobackend

heckthebearingsintheinner eplaceifwor

andouterbackhalfjoints

eplacethebushfirstifitisstill

sloppreplacetheinnerback

halfjointalwasreplacethe

seal

hecktheinnerbackhalfjoint

isagoodfitinsidethebush

withnosidewasoveent

MALFUNCTION RECTIFICATIONCAUSE

Always replace special cogs in pairs.

It is essential to use identical special

cogs.

16 Instruction manual ICON

5.5 How to

Note: This Section is for experts only. Do not follow this instructions if you are not a trained

technician or experienced Shearer with good knowledge of mechanics. Wrong or unprofessi-

onal repair and maintenance of the handpiece can cause malfunctions which lead to serious

injury, damage and/or reduced life expectancy of your shearing handpiece. Warranty will be

void if unprofessional repair or maintenance has been carried out.

Remove Fork

Unscrew tension nut and remove tension sleeve and tension pin, unscrew fork safety screw.

Fork may now be removed. It is not necessary to remove the centre post when removing the

fork. Reassemble in the opposite order.

Fitting a new ball

Remove fork and ball, place new ball on the crank pin using a piece of wire or a pencil with the

flat side of the ball pointing to the crankhead or rear of the handpiece.

Replacing the tension pin cup

Remove fork, punch out the old tension pin cup. Place the new tension pin retaining spring on

to the tension pin cup before replacing it into the fork, tap the cup into the fork making sure the

slope on the top of the cup faces directly towards the ball race or the back of the fork.

Remove and replace Back Joint

Remove comb and cutter and screw firm tension on tension nut, put a screwdriver down

through the oil hole in the top of your handpiece so it goes between the fork and barrel,

remove the cog from the end of the crankshaft using a cog spanner. The back joint will now

slide out off the barrel.

Fitting Bearing Kit

This is not a difficult job when using a Special Tool Kit (Illustration 11). It’svery important not

to rush, pull everything apart and throw away all the components you will replace. Clean up

all the remaining parts and fit the new ones carefully, taking note of the very important points

listed below, read the following instructions and cross them off once you have completed each

point.

Very Important !

Reassemble Back Joint

•

irstcleanthebackointthoroughly.

•

laceyournewseal(Illustration1,Item1)overtheinnerbackhalfoint(Illustration1,

Item 23) with the two lips facing the cogs. Ensuring that the inner lip on the seal is not

twisted, slide the seal half way up the inner back half joint.

•

Oilthebushinsidethebarrelandtheinnerbackhalfoint.

•

lidethebackointintothebarreluntilthesealisinthebarrel

•

irmlypushthesealintoplacethenpushtheremainderofthebackointhome.

•

Andreplacethespecial cogs.

• Always use pairs of identical special cogs by the same part numbers for replacement.

Illustr. 10

Illustr. 11

Instruction manual ICON 17

• Thebearingsinyourhandpiecearesmallandtheballsinthemaredelicate,eachtimeyou

go to hit the bearing “think first”. The force must never travel through the balls i.e.: if you

are fitting the outer bearing into a casing (Illustration 12, Item 1) hit the outer rim only, not

the seal or the inner rim. And when fitting the bearing onto a shaft (Illustration 12, Item 2)

hit the inner rim only. If you do hit the wrong rim, or the seal, it will distort the balls, do not

use this bearing anymore, throw it away as it will run hot and wear rapidly.

• Donotclampthebarrelinavice.

• se(replace)allthepartscontainedinthebearingkit.

• Neverreuseoldbearings.Thebearingswillhavebeendamagedduringremoval.

• Donotuseasteelhammerasthiswillaranddamagethetoolandthebearing,useanylon

hammer or a piece of wood.

• seapecialToolit(Illustration11)theyarenotexpensiveandwilllastalifetime.

• seasmallpieceofhardwoodtoworkonasabench.

• akesureyouknowthedifferencebetweenthedistancewasherandthewavewasher.The

wave washer is wobbly, the distance washer is flat.

Replace Bearings „Step by Step“

• emovefork.

• emovebothcogs.

• emovebackointspringandcaps.Thebackhalfointwillnowcomeapart.

• emovetheinnerbackhalfointfromthebarrel.

• emovethecirclipusingthecirclippliers.

• leanthecirclipgroovethoroughly(thisisimportant).

• lacethepunch(toolno.;Illustration11)throughthefrontofthebarrel(Illustration1)

and onto the recess in the middle of the crankhead. Holding the barrel and punch in one

hand gently knock the crank shaft free from the barrel. The bush, wave washer and front

bearing will come with it. Don’t allow the bush or the crank shaft to hit the floor as damage

may occur.

• emovethepinorwormdrive.

• lidethepunchdownwherethepinorwormdrivewasremoved,holdingtheouterback

half joint (Illustration 19) in one hand gently knock out the old bearing and clean the back

half joint thoroughly.

•

Place outer back half joint ferrule thread down onto the piece of wood and select

one of the smaller of the three bearings (Illustration 20), tap it gently into position

using tool no. A.

• emoveinnerbackhalfointbearingwiththepunchcomingfromthecrankshaftheadend

(Illustration 19), holding the inner half back joint with one hand gently knock out the old

bearing and clean the inner back half joint thoroughly.

• lacethefrontoftheinnerbackhalfointonthepieceofwoodandgentlytapthesmallest

of the two remaining bearing (Illustration 20) into position using tool no. A.

• emovefrontbearing(Illustration14),putthesmallendoftoolno.Dontothepieceof

wood, place the crank head inside the big end, the distance washer will now rest on the tool.

Screw the thread inside tool no. B onto the crank shaft making the crank shaft twice as long,

hit the tool until the bearing is free of its seating, unscrew the tool and remove the bearing

and the distance washer.

Illustr. 12

Illustr. 11

Illustr. 11+ 13

Illustr. 14

Illustr. 19+20

18 Instruction manual ICON

• Tofitthefrontbearing,placethecrankheadonthepieceofwood(Illustration21)withthe

pin facing down over the edge, place the distance washer (the flat one) over the crankshaft

and then the remaining (biggest) bearing. Using tool no. B with the thread to the top hit the

tool until the bearing is positioned against the seat behind the crank head. Take care that

the distance washer does not get caught between the bearing and the seat behind the crank

head, the distance washer should always be free moving

• leanthebarrelthoroughly(nowisagoodtimetofitarugifrequired).

• Ensuringallbearingsareseatedproperlybeforebeginningtoreassemble.

• lacethemouthofthebarrelonthepieceofwood(Illustration15)andlowerthecrankshaft

with bearing fitted into the barrel, slide small end of tool no. D into the barrel and gently tap

the tool until it rests against the end of the barrel.

• lacethenewwavewasheroverthecrankshaftandloweritontobearing.

• leanthebushandcoatitandtheinsideofthebarrelwithlightoil,slidethebushdownon

top of the wave washer.

• itNEW circlip (do not over compress the circlip when fitting because it will rub on the

inner back half joint and make the back end tight) inside the barrel, then using the small end

of tool no. D against the circlip, tap the circlip into its seat. Make sure the circlip is seated

properly in the groove.

• eassemblethetwobackhalfointswithnewgreaseinthebackointcaps.

• laceaNEW seal over the inner back half joint (see back joint removal and replacement and

Illustration 10) and oil liberally.

• oatinnerbackhalfointandinsideofbarrelwithoilandslideinnerbackhalfointintothe

barrel and screw the cog onto the end of the crankshaft.

• eassemblethewormorpindriveandcog.

• efittheforkmakingsuretheflatsideoftheballisfacingthecrankshaft(Illustration22).

Fitting Pin Drive Pin

The pin drive pin is tapered, identify the small end of the broken pin and tap this small end of

the pin with a punch to remove it. Tap in the new pin gently, don’t hit it hard or you will crack

the end of the shaft. Place the big end of your pin on an anvil or something solid and round

off (or burr over) the small end of the pin ensuring it is a good fit into the shaft, finish this job

by filing the small end flush with the shaft. Make sure the big end does not protrude out past

the outer rim of the drive coupling, if it does this will rub on the tube and run hot, file off the

excess.

Adjust Centrepost using a Post Guide

The post has a notch in the bottom around from the screwdriver slot (Illustration 16). Use this

notch as a setting mark and once you have the handpiece cutting well remember or write

down where this mark is, this will enable you to reset the post to the original position should

the need arise.

• etafreshlygroundcombandcutterthatismmthick.

• Applynormaltensiontocutter.

• ovethecutteruntiltheballisatthebottomoftheforkandthecutterisinthemiddleof

the comb.

• oosenthecentrepostlocknut.

• InserttheostGuide(Illustration1)intheholeandsitthefirstledgeontheforkatthefront

of the ball race.

Illustr. 21

Illustr. 15

Illustr. 10

Illustr. 22

Illustr. 16

Instruction manual ICON 19

• akingsureatalltimesthatyouhaveacuttingtensiononthecutter,adustthecentrepost

up or down until the second ledge sits on the front of the machine surface around the oil

hole.

• ockthecentrepostlocknutandrecheckmakingsurethatbothledgesremainseated.

• WhencorrectlysetitwillbeasperIllustration1.

6 Environmental Protection and Disposal

6.1 Introduction

The owner has a duty to dispose of the shearing blades as well as of the shearing handpiece

properly at the end of its service life. Please observe your relevant national regulations.

6.2 Material Categories

Shearing blades and the whole shearing handpiece consist of high alloy steel and can be

disposed at scrapping facilities.

7 Contact Addresses

Your purchasing point or the company shown on your guarantee certificate are authorised

service centres or refer to the nearest service centre in your area.

Illustr. 17, 18

ICON A1

0

This manual suits for next models

2

Table of contents

Other Heiniger Farm Equipment manuals