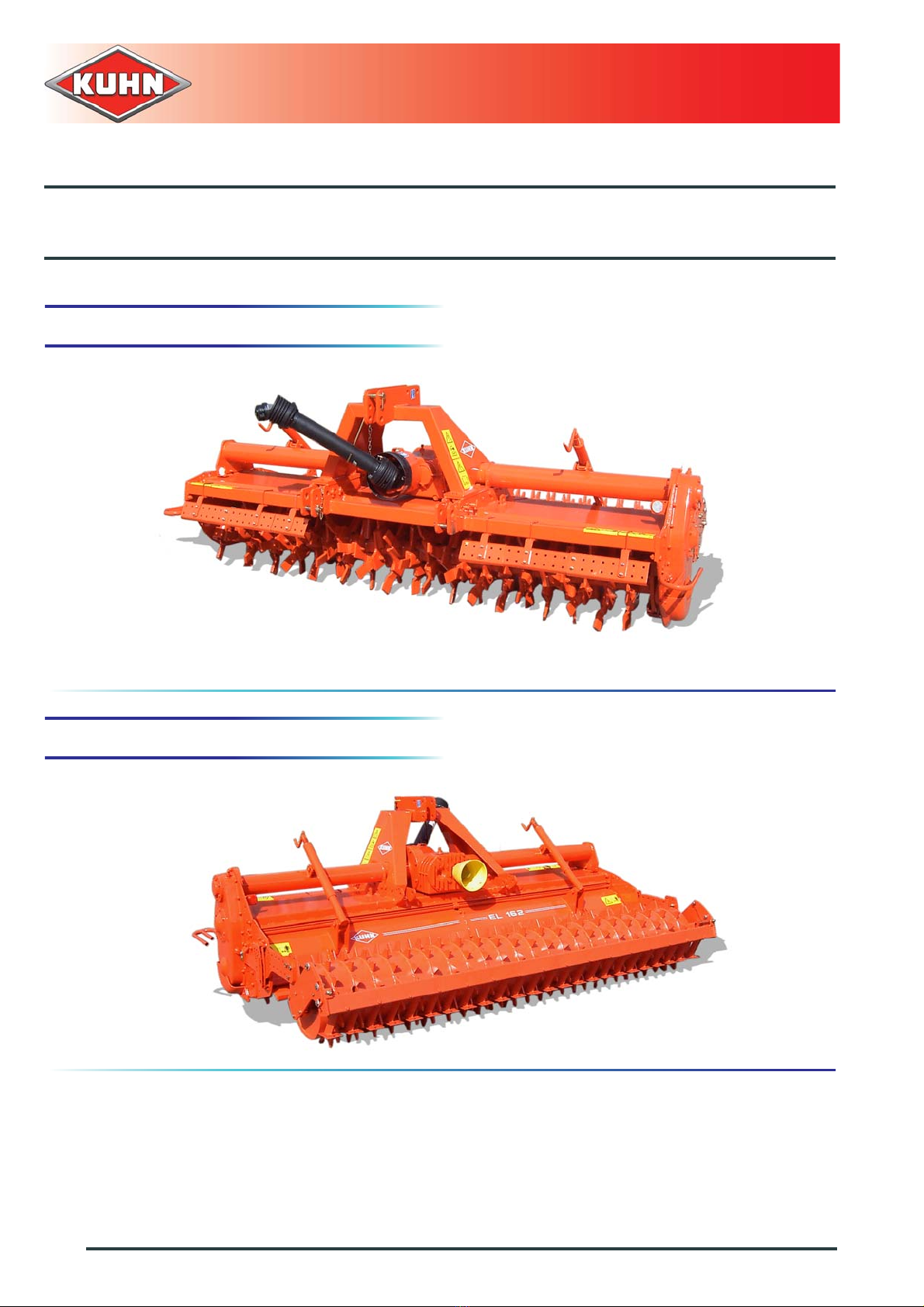

EL162

62. - Contents

KN146AGB_L

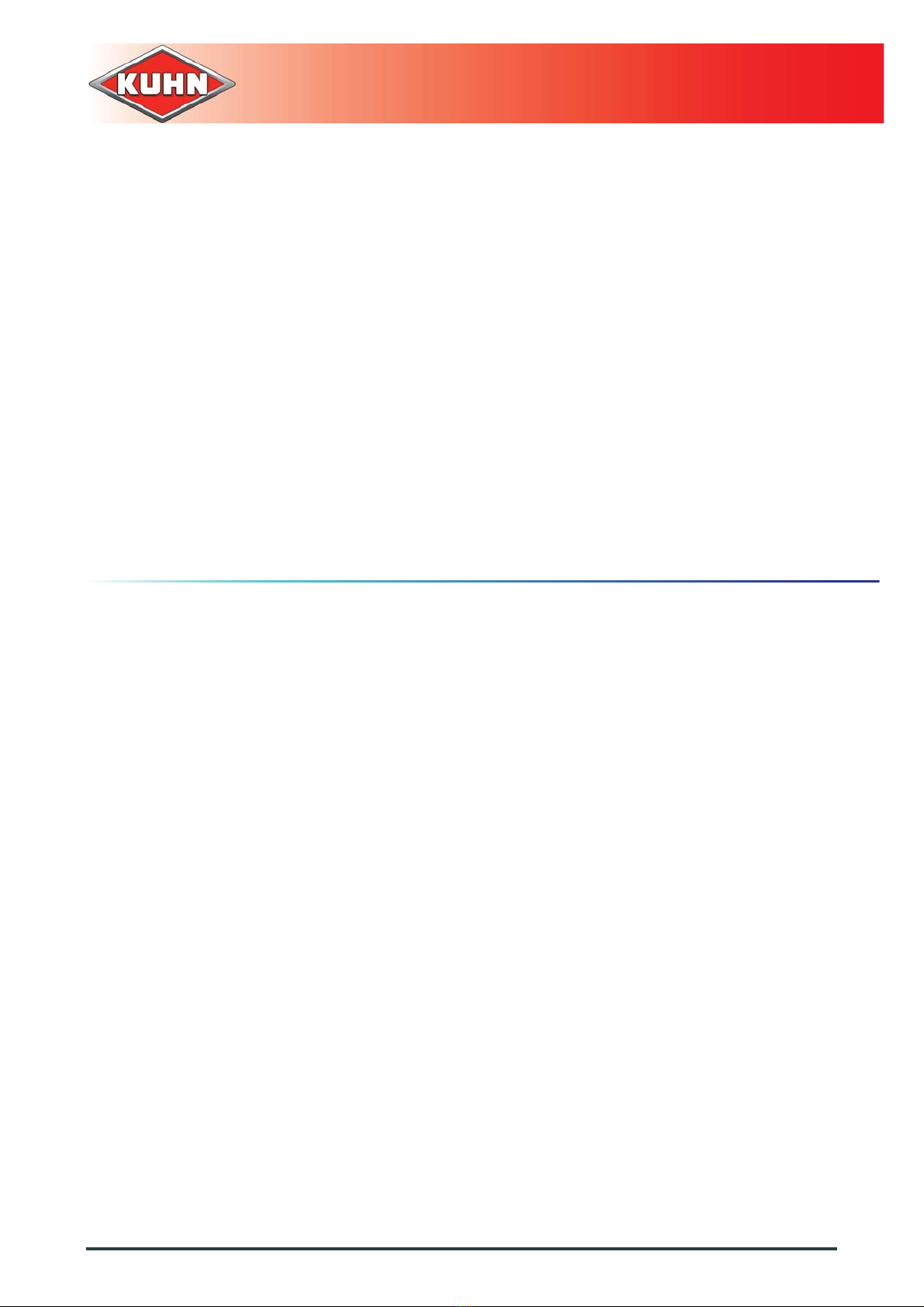

Cultiplow

9.3 Rear wheels...................................................................................................................................81

9.3.1 Signalling.......................................................................................................................... 81

9.3.2 Working depth adjustment................................................................................................ 81

9.3.3 Machine use.....................................................................................................................81

9.4 Skids.............................................................................................................................................. 83

9.4.1 Uncoupling the machine................................................................................................... 83

9.4.2 Working depth adjustment................................................................................................ 83

9.5 Side discs ......................................................................................................................................84

9.5.1 Working depth adjustment................................................................................................ 85

9.5.2 Lateral adjustment............................................................................................................85

9.6 Track eradicators........................................................................................................................... 86

9.6.1 Machine use.....................................................................................................................87

9.7 Offset for track eradicators.............................................................................................................89

9.8 Sets of gearwheels ........................................................................................................................ 89

9.9 Lights and indicators...................................................................................................................... 92

9.9.1 Coupling and uncoupling.................................................................................................. 92

9.10 Lateral signalling equipment.......................................................................................................... 93

9.11 Hydraulic lift linkage....................................................................................................................... 93

9.11.1 Location and description of safety decals on the machine...............................................94

9.11.2 Coupling and uncoupling..................................................................................................95

9.11.3 Putting the machine into transport position ...................................................................... 98

9.11.4 Putting the machine into work position............................................................................. 99

9.11.5 Optional equipment ........................................................................................................100

9.11.6 Maintenance................................................................................................................... 101

9.11.7 Storage........................................................................................................................... 102

9.12 Rear attachment with double acting hydraulic lift......................................................................... 103

9.12.1 Location and description of safety decals on the machine.............................................103

9.12.2 Coupling device.............................................................................................................. 104

9.12.3 Removal ......................................................................................................................... 107

9.12.4 Putting the machine into transport position .................................................................... 107

9.12.5 Putting the machine into work position...........................................................................108

9.12.6 Adjustments in working position..................................................................................... 108

9.12.7 Maintenance................................................................................................................... 109

9.12.8 Storage............................................................................................................................110

9.13 Set of arm + roller multi-hole adjustment plate.............................................................................111

9.14 USA signalling equipment.............................................................................................................111

10. Maintenance and storage ..........................................................................................112

10.1 Frequency chart............................................................................................................................112

10.2 Cleaning the machine...................................................................................................................114

10.2.1 Cleaning the roller scraper bar........................................................................................114