Thank you for placing your trust in our company by purcha-

sing the WTA 50 is a pair of heated tweezers. Production was

based on stringent quality requirements which guarantee the

perfect operation of the device.

1. Important!

Please read these Operating Instructions and the attached

safety information carefully prior to initial operation. Failure to

observe the safety regulations results in a risk to life and

limb.

The manufacturer shall not be liable for damage resulting

from misuse of the machine or unauthorised alterations.

The WTA 50 is a pair of heated tweezers corresponds to the

EC Declaration of Conformity in accordance with the basic

safety requirements of Directives 2004/108/EC and

2006/95/EC.

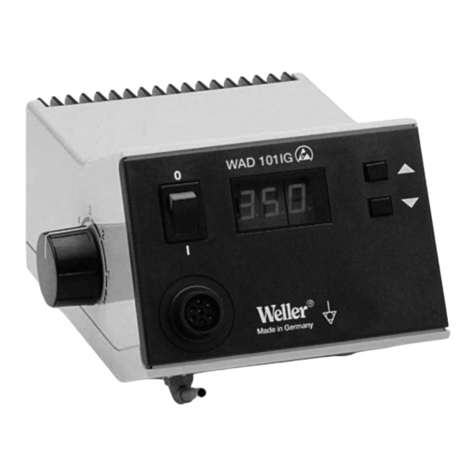

2. Description

The WTA 50 is a pair of heated tweezers for desoldering SMD

components. The desoldering tweezers can be connected to

all Weller soldering and desoldering stations with an electro-

nic control system. In each of the two movable heating ele-

ments there are temperature sensors which ensure precise

temperature balance on both shanks. The heating elements

each have a 25-watt heating output and are operated using

protective low voltage. ESD-compatible design and a tempe-

rature-resistant connection cable supplement the quality

standard.

Technical data

Connection voltage: 24 V protective low voltage

Power consumption: 2 x 25 W

Operating temperature: up to 450°C

Heating-up time: approx. 65 secs.

Inserting and adjusting soldering tips

Insert the soldering tip suited to the soldering application and

align. Fasten the tips using the attachment screws (2). The

soldering tip position can be adjusted precisely by loosening

the attachment screw (4). The complete heating element can

be turned and shifted axially.

3. Commissioning

Place desoldering tweezers in the rest. Insert the connector

plug into the connection socket provided for it and lock.

Remove all flammable objects from the immediate area

around the soldering tool. Switch on the control unit at the

mains switch and set the desired temperature. After the sol-

dering temperature has been reached, moisten the soldering

tip, which can be moistened selectively, with solder.

4. Potential balance

The heating elements are connected to the control unit via a

potential balance lead. The potential balance can be produ-

ced by following the operating instructions for the control

unit.

5. Operating guidelines

Using the soldering tips, melt on both sides of the component

to be connected and lift off the component.While doing so, do

not exert excessive pressure on the structural element. Set

the tip temperature as low as possible in order to protect the

circuit board and the structural elements.

The operating instructions of the control unit being used are

valid alongside these operating instructions.

6. Maintenance instructions

When replacing tips always use new set screws.

Moisten soldering tips regularly with solder containing flux.

7. Scope of supply

WTA 50 desoldering tweezers

Rest with cleaning sponge

Soldering tips

Tool for attachment screws

Operating Instructions

Safety information

Accessories, see page 21

Exploded drawing, see page 22

Subject to technical alterations and amendments!

See the updated operating instructions at

www.weller-tools.com.

English

5