HEKA Favorit-Eco 84 User manual

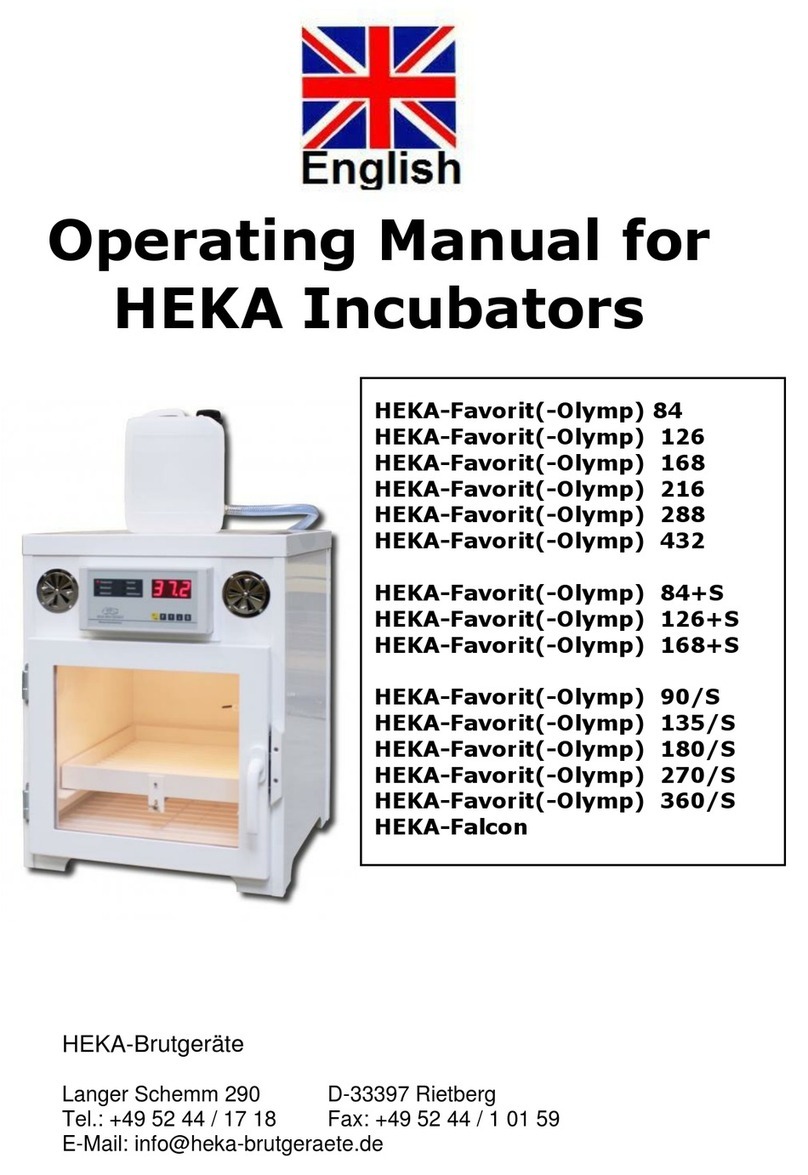

Operating Manual for

HEKA Incubators

HEKA-Brutgeräte

Langer Schemm 290

D-33397 Rietberg

Tel.: +49 52 44 / 17 18

Fax: +49 52 44 / 1 01 59

E-Mail: info@heka-brutgeraete.de

HEKA-Favorit-Eco 84

HEKA-Favorit-Eco 126

HEKA-Favorit-Eco 168

HEKA-Favorit-Eco 84+S

HEKA-Favorit-Eco 126+S

HEKA-Favorit-Eco 168+S

HEKA-Favorit-Eco 90/S

HEKA-Favorit-Eco 135/S

2

Preface

The purpose of this manual is to familiarise the reader with the incubator

and provide instructions on use.

The operating manual contains important information for the safe,

economic, and correct operation of the incubator. Compliance with this

manual helps to avoid dangers, minimise repair costs and downtime, and

increase the reliability and service life of the machine.

The operating manual is suitable for adding environmental protection

regulations to the instructions on the basis of existing national accident

prevention regulations.

The operating manual must always be kept at the place of deployment of

the incubator. All individuals who are authorised to work with the

incubator must read and observe the operating manual. This includes

instructions in the following areas:

●Operation

●Troubleshooting

●Care and maintenance

●Transport

The operator must ensure that only authorised persons work with the

incubator. The operator must check the incubator for externally visible

damage and defects on a daily basis. Moreover, the operator must

promptly report any changes that impair the safety. This also includes

changes in the operating behaviour. The incubator may only be operated

if its condition is flawless.

As a matter of principle, safety equipment must not be removed or

disabled.

Should it be necessary to remove safety equipment during preparation,

repair, or maintenance, the safety equipment must be reinstalled

immediately upon completion of the maintenance or repair work.

The manufacturer does not assume any liability for damages resulting

from unauthorised modification of the incubator.

All safety information and warnings on the incubator must be observed.

In addition to the information in the operating manual, the generally

applicable safety and accident prevention regulations must also be

complied with.

3

Structure of the safety instructions

All safety instructions have a uniform structure:

Pictogram (indicates the type of danger)

Caution! (indicates the severity of the danger)

Information (describes the danger and how it can be avoided)

Pictogram

Signal word

Meaning

Consequences of non-

observance

Danger!

Imminent danger to persons

Very severe to fatal

injury

General

danger

Warning!

Potentially very dangerous

situation for persons

Very severe to fatal

injury

Dangerous

electric

voltage

Caution!

Potentially dangerous situation

for persons

Minor injury

Attention!

Potential damage to property

Damage to the device

Useful information or tip

Other notes in the operating manual

Caution!

Risk of injury due to hot surface!

Warning pointing to a risk of injury to the operator from hot

surfaces.

Please read and observe the operating manual.

Disconnect the power plug before opening the device.

4

General safety instructions!

Caution!

Non-observance of the following safety precautions can result in

bodily injury or damage to the incubator.

Apart from the notes listed below, please also observe the

general safety and accident prevention regulations.

Read the operating manual!

Do not start using the incubator until you have read the

associated operating manual.

●Do not operate the incubator on the ground. Keep a minimum

distance of 50 cm from the ground!

●Do not use the incubator outdoors.

●Do not place the incubator in direct sunlight (counts also for

storage and transport).

●Before connecting the incubator, compare the voltage of the power

supply with the voltage on the type plate.

●In accordance with the intended use, the incubator may only be

used to incubate eggs.

●Never operate the incubator if any part(s) are damaged, if it does

not function properly, or if you suspect damage.

●Defective power cables may only be replaced by the manufacturer,

its customer service, or a similarly qualified person.

●Maintenance work may only be performed by appropriately trained

personnel.

●Repair work and special maintenance work may only be performed

by authorised personnel (manufacturer's personnel) or

appropriately trained personnel.

●Work on the electrical equipment may only be performed by

qualified electricians and persons instructed in electrical

engineering (see DIN VDE 0105).

●Working on live parts and equipment is not permitted.

●Conversion or modification of the incubator is not permitted.

5

Table of contents

Preface.... ................................................................................................2

Structure of the safety instructions ..........................................................3

General safety instructions......................................................................4

1Desciption............................................................................. 6

1.1 Technical data........................................................................6

1.2 Control panel..........................................................................7

1.3 Housing - back .......................................................................7

2Setup and connection........................................................... 8

2.1 Installing the incubation trays.................................................9

3Operating the incubator...................................................... 10

3.1 Switching on/off....................................................................10

3.2 Adjusting the set-values.......................................................10

3.2.1 Temperature set-value...............................................10

3.2.2 Humidity set-value .....................................................11

3.2.3 Double-thermostat and alarm settings.......................12

4Tips for successful incubation............................................. 13

4.1 Incubation temperature ........................................................13

4.2 Humidity ...............................................................................13

4.3 Turning the eggs ..................................................................15

4.4 Cooling-down the eggs ........................................................16

4.5 Inserting the hatching eggs..................................................17

4.6 Putting the eggs into the hatching-trays...............................17

5Shutting-down after incubation ........................................... 18

6Maintenance and care........................................................ 19

6.1 Incubation or hatching chamber of the device.....................19

6.2 Technical compartment (incubation or hatching device) .....19

6.3 Incubators with a separate hatching chamber (Favorit-Eco

84+S, 126+S, 168+S).....................................................................20

6.4 Float valve............................................................................20

6.5 Replacing the power cable...................................................21

7FAQs –Frequent questions................................................ 22

8Disposal ............................................................................. 23

9CE- Declaration of conformity............................................. 24

10 Appendix: Analysis of mistakes at incubation / bad hatching25

11 Appendix: Incubation Periods............................................. 26

This manual suits for next models

7

Table of contents

Other HEKA Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual