Helmer UltraCW II User manual

Automatic Cell Washing System Operation Manual

®

I

I

360386/D

Document Updates

The document is furnished for information use only, is subject to change without notice and should not be construed as a

commitment by Helmer Scientic. Helmer Scientic assumes no responsibility or liability for any errors or inaccuracies that may

appear in the informational content contained in this material. For the purpose of clarity, Helmer Scientic considers only the most

recent revision of this document to be valid.

Notices and Disclaimers

Condential / Proprietary Notices

Use of any portion(s) of this document to copy, translate, disassemble or decompile, or create or attempt to create by reverse

engineering or otherwise the information from Helmer Scientic products is expressly prohibited.

Copyright and Trademark

Copyright © 2018 Helmer, Inc. Helmer®, i.Series®, i.C³®, Horizon Series™, and Rel.i™ are registered trademarks or trademarks

of Helmer, Inc. in the United States of America. All other trademarks and registered trademarks are the property of their respective

owners. Helmer, Inc., doing business as (DBA) Helmer Scientic and Helmer.

Disclaimer

This manual is intended as a guide to provide the operator with necessary instructions on the proper use and maintenance of

certain Helmer Scientic products.

Any failure to follow the instructions as described could result in impaired product function, injury to the operator or others, or void

applicable product warranties. Helmer Scientic accepts no responsibility for liability resulting from improper use or maintenance of

its products.

The screenshots and component images appearing in this guide are provided for illustrative purposes only, and may vary slightly

from the actual software screens and/or product components.

Helmer Scientic

14400 Bergen Boulevard

Noblesville, IN 46060 USA

www.helmerinc.com

ISO 13485 Part No. 360386/ Rev D

Document History

Revision Date CO Supersession Revision Description

A 30 NOV 2017 12878 n/a Initial release.

B 20 DEC 2017 13200 B supersedes A Claried content.

C 15 JAN 2018 13276 C supersedes B Added system error code table

D20 AUG 2018 13855 D supersedes C Updated Indications for Use (formerly Intended Use) statement; Updated Setup

instructions; Included information about the Fill button in Flow Calibration section;

Updated Unit Specications table

* Date submitted for Change Order review. Actual release date may vary.

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 3

Contents

1 About This Manual...................................................................................4

1.1 Safety Precautions and Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 General Recommendations........................................................................5

2 Unpacking..........................................................................................6

2.1 Unpacking Guidelines ............................................................................6

2.2 Emergency Release .............................................................................6

2.3 Transport Bolts .................................................................................6

3 InstallationandConguration .........................................................................7

3.1 Location and Placement ..........................................................................7

3.2 Setup .........................................................................................7

3.3 Initial Start-Up ..................................................................................7

3.4 Rotor Installation and Setup .......................................................................8

3.5 Rotor Type .....................................................................................8

3.6 Balance Rotor ..................................................................................9

3.7 Flow Calibration.................................................................................9

4 Programming ...................................................................................... 10

4.1 Process Descriptions............................................................................10

5 Operation ......................................................................................... 12

5.1 Pre-Installed Programs ..........................................................................12

5.2 Stop/Check Program ............................................................................13

5.3 Custom Program ...............................................................................14

6 ProductSpecications ..............................................................................16

6.1 Operating Standards ............................................................................16

7 Preventive Maintenance .............................................................................17

8 Compliance........................................................................................18

8.1 Regulatory Compliance ..........................................................................18

Appendix A............................................................................................19

Error Codes ........................................................................................19

Appendix B............................................................................................21

Parts ........................................................................................21

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 4

1 About This Manual

This manual provides information on how to use the UltraCW®II in blood banking and other laboratory procedures. This manual is

intended for use by end users of the UltraCW®II automatic cell washing system and authorized service technicians.

1.1 Safety Precautions and Symbols

Symbols found in this document

The following symbols are used in this manual to emphasize certain details for the user:

Task Indicates procedures which need to be followed.

Note Provides useful information regarding a procedure or operating technique when using Helmer

Scientic products.

NOTICE Advises the user against initiating an action or creating a situation which could result in damage to

equipment; personal injury is unlikely.

CAUTION Advises the user against initiating an action or creating a situation which could result in damage

to equipment or impair the quality of the products or cause minor injury.

WARNING Advises the user against initiating an action or creating a situation which could result in damage

to equipment and serious personal injury to a patient or the user.

Manufacturer

Symbols found on the units

The following symbols may be found on the cell washer or cell washer packaging:

CE Mark (European units only) Product falls under the scope of the WEEE

(Waste Electrical and Electronic Equipment)

directive.

Caution: Risk of damage to equipment or

danger to operator

Caution: Biohazard

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 5

Avoiding Injury

Review safety instructions before installing, using, or maintaining the equipment.

♦ Do not move or bump the cell washer during operation.

♦ Before moving unit, disconnect and secure the power cord.

♦ Never physically restrict any moving component.

♦ Avoid removing electrical service panels and access panels unless so instructed.

♦ Use manufacturer supplied power cords only.

♦ Using the equipment in a manner not specied by Helmer may impair the protection provided by the equipment.

CAUTION

Decontaminate parts prior to sending for service or repair. Contact Helmer or your distributor for decontamination

instructions and a Return Authorization Number.

1.2 General Recommendations

Indications for Use

The Helmer UltraCW®II automatic cell washing system is intended to be used for the washing portion of routine blood bank and

laboratory procedures calling for washed red blood cells such as antiglobulin testing, ABO compatibility, Rh, cross matching and

anti-body screening.

The UltraCW®II automatic cell washing system should be operated by a trained individual, such as a clinical laboratory technologist

or similar education, as determining whether desired results have been achieved is subjective and dependent upon user

preparation of blood sample, and parameter selection/adjustment.

General Use

Allow the cell washer to come to room temperature before switching power on.

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 6

2 Unpacking

2.1 Unpacking Guidelines

♦ To avoid damage, unpack the appliance at or near the installation site.

♦ Support the cell washer on both sides when lifting to remove from box (2 people recommended).

♦ Use Emergency Release to open the lid and remove packing around the rotor.

♦ Check the packing slip to ensure delivery is complete.

♦ Inspect unit for damage which may have occurred during shipping. Contact your delivery carrier directly to report

any damage.

2.2 Emergency Release

The emergency release allows the lid to be opened during a power failure or when the cell washer is not powered on.

NOTICE

• Remove plug from emergency release hole, and disconnect power

cord from power outlet prior to using the emergency release.

• Only the plastic release pin provided may be used for emergency release.

1. Ensure power is switched power o “O”, and disconnect power cord from

power outlet.

2. Look through the window on top of the lid to ensure the rotor is at a

complete stop.

3. Insert the release pin into the Emergency Release hole and push in to

release the lid and open.

Note

An error message will appear on the display once unit is powered back on.

Select the Return button to clear.

2.3 Transport Bolts

Transport bolts are located on the bottom of the cell washer and prevent the motor from moving during shipping. Transport bolts

are necessary when moving or shipping the cell washer.

NOTICE

Keep transport bolts and Allen wrench provided for future use.

Remove Transport Bolts

1. With the cell washer powered o, open the lid using the emergency release and remove

the rotor.

2. With the lid closed, place the cell washer in a position allowing access to the bottom of

the unit.

3. On the bottom of the cell washer, locate the 3 transport bolts.

4. Using the Allen wrench included in the packaging, remove the bolts.

5. Return the cell washer to the upright position.

Install Transport Bolts

1. With the cell washer powered o, open the lid using the emergency release and

remove the rotor.

2. With the lid closed, carefully place the cell washer in a position allowing access

to the bottom of the unit.

3. On the bottom of the cell washer, locate the threaded holes for the 3 transport

bolts and hand thread the bolts in each location.

4. Using the Allen wrench included in the packaging, tighten bolts until snug.

5. Carefully return the cell washer to the upright position.

Emergency

Release Hole

Emergency

Release Pin

Transport

Bolts

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 7

3 InstallationandConguration

3.1 Location and Placement

♦ Has a sturdy, level surface

♦ Has a grounded outlet meeting national electric code (NEC) and local electrical requirements

♦ Has access to a supply of saline solution

♦ Has access to a waste container or drain suitable to receive decanted saline and human blood waste product

♦ When the cell washer is running, per EN/IEC 61010-2-020, no individuals or dangerous objects such as ammable or

explosive materials may be within a safety margin of 12” (300mm) around the unit

CAUTIONS

• Use only manufacturer supplied power cord.

• Ensure drain tube is installed at a downward slope for proper drainage.

• Unplug power cord from power receptacle prior to moving.

• Ensure rotor is empty prior to moving.

3.2 Setup

1. Plug saline tube in inlet 1 and place the weighted end of the tube in the Saline box.

2. Connect drain tube in drain outlet ensuring drain tube is installed at a downward slope for proper drainage.

3. Connect power supply to Power-Input.

4. Connect power cord to power supply.

3.3 Initial Start-Up

Notes

• Allow unit to reach room temperature before powering on.

• In the event of an error, an error message will appear at the top of the screen and an audible signal will sound.

1. Plug the power cord into a grounded outlet that meets the electrical requirements on the product specication label.

2. Switch the power switch located on the back of the unit ON. Initialization takes approximately one minute. The Start

screen will appear.

Start screen

Description

APower Input

BInlet 1 Saline

CPower Supply

D Drain Outlet

A B C D

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 8

3.4 Rotor Installation and Setup

Either a 12-place rotor or a 24-place rotor may be installed in the cell washer. Both rotors can hold either 10 mm x 75 mm tubes or

12 mm x 75 mm tubes. Inserts must be used to secure the 10 mm tubes to prevent damage during operation.

Install Rotor

1. Select the open lid button

2. Grasp the rotor on the grip area and place the rotor over the shaft.

3. Align the markings on the top of the rotor with the slots on the rotor shaft.

4. Lower the rotor onto the shaft.

Install Tube Inserts

1. Remove rotor by lifting upward and place on solid surface.

2. Align the key on the insert with the groove in the tube holder.

3. Press the insert into the tube holder all the way down.

Remove Tube Inserts

1. Remove rotor by lifting upward and place on solid surface.

2. While holding the tube holder with one hand, insert a at-head screwdriver into

the slot and slightly twist the screwdriver to raise the top of the insert.

3. Grasp the top of the insert and pull it straight out.

Load Tubes

Gently place tubes in tube holder. If loading fewer tubes than the rotor can hold,

distribute the tubes evenly around the rotor to maintain balance.

3.5 Rotor Type

It is necessary to enter the rotor type prior to running a program. Either a 12-place or 24-place rotor may be used in the cell washer.

Both rotors can hold either 10 mm x 75 mm tubes or 12 mm x 75 mm tubes.

Notes

• This process requires an authorized user.

• If accessing unit for the rst time, use factory created Service User password 46060.

Select Rotor Type

1. From the Start screen, touch the login button .

2. Enter a Service User password and select the green checkmark when nished.

3. Select the settings button . The Settings screen opens.

4. Select the desired rotor type (12-place or 24-place) .

5. Select the green checkmark to save.

6. Select the red return button to return to the previous screen.

Rotor

Shaft

Alignment

Markings

Rotor Grip

Tube

Holder

Tube

Insert

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 9

3.6 Balance Rotor

The rotor must be balanced for the cell washer to operate correctly. If the rotor is not balanced, the process is stopped and the

imbalance error is displayed.

1. From the Start screen, select the Menu button .

2. Select the Spin program. The program screen is displayed.

3. Verify parameter settings are accurate prior to running the program (3500 RPM for 20 seconds).

4. Select the green checkmark to load the program. The Start screen appears with the loaded program name at the

top of the screen.

5. Press the “Start Program” button to begin the process.

6. The “Program successful” dialog box appears once the program is completed.

Note

Refer to the service manual for additional instructions in balancing the rotor.

3.7 Flow Calibration

To calibrate the dispensed saline volume, the amount of dispensed saline must be measured and compared to the value displayed.

The displayed value is the volume per tube multiplied by the number of tubes placed in the rotor.

Service Menu screen Calibration screen

Notes

• The cell washer lid must be open to perform the calibration.

• Ensure air bubbles are purged from saline tubes prior to calibration using the Fill program or ll button .

• This process requires an authorized user.

• If accessing the unit for the rst time, use factory created Service User password 46060.

1. From the Start screen, touch the login button .

2. Enter a Service User password and select the green checkmark to conrm.

3. Select the settings button .

4. On the System Settings screen, select the tools button to open the Service Menu.

5. On the Service Menu screen, select the ruler icon to open the Calibration screen.

6. Touch the target calibration volume.

7. Hold a clean, dry graduated cylinder below the spout on the lid and press the start button . Wait until liquid has

stopped owing from spout.

8. Measure the liquid collected in the graduated cylinder.

9. Use the “+”, “++”, “-”, and “--” on the right side of the screen to adjust the number as needed.

10.Select the green checkmark to nish calibration.

11.Use the red arrow to return to the home screen.

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 10

4 Programming

One or more individual processes make up a program. A program can include up to 20 dierent processes, but only one Loop

process can occur within a program.

4.1 Process Descriptions

Spin Process

During the Spin step, the rotor accelerates to the selected speed, spins for the

specied time, then stops quickly. This step separates unwanted particles and

creates a “button” of red blood cells at the bottom of each tube. The quick stopping

prevents the re-suspension of the red blood cells and dislodging of the red blood

cell button.

The number of revolutions per minute is adjustable from 0 RPM to 3500 RPM.

The time duration is adjustable from one second to two hours (0:00:01 to 2:00:00).

The default values are 3500 RPM and 30 seconds.

Fill Process

During the Fill process, the tubes containing cells are lled with the desired

amount of saline solution. As the rotor spins at 1100 RPM, saline is pumped from

the reservoir through the ow meter to the saline dispensing nozzle. The nozzle

directs the saline solution into the rotor, then the ll ports direct the saline solution

into the tubes. Saline solution enters the tubes in a direct stream to maximize

cell re-suspension

The number of revolutions per minute is adjustable from 0 RPM to 2500 RPM.

The ll volume is adjustable fro 0.1ml to 10ml per tube. The default values are

800 RPM and 3.0ml.

Down Process

During the Down process, the rotor spins at 2000 RPM for the specied time.

The drops clinging to the tube sides are forced to the bottom of the tubes, thereby

increasing the sample yield.

The number of revolutions per minute is adjustable from 0 RPM to 3500 RPM.

The time duration is adjustable from 0 seconds to 20 seconds (0 s - 20 s) .

The default values are 2000 RPM and 5 seconds (5 s).

Agitation Process

During the Agitation process, the rotor accelerates then stops frequently and briey,

disrupting (breaking apart) the cell buttons.

The number of shakings are adjustable from 0 times to 500 times (0x - 500x).

The default value is 15 times (15x).

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 11

Decant Process

During the Decant step, the rotor rapidly accelerates to the specied speed then

decelerates, allowing the tubes to move back to the neutral position so the rotor

lock can engage. The rotor spins in the opposite direction at the specied speed,

while the rotor lock holds the tubes at a slight negative angle. Waste solution is

expelled from the tubes by low centrifugal force, while virtually all the cells are

retained in the tubes in the form of red blood cell buttons. The waste solution is

directed to the drain hole in the bowl by the drainage system. The spent solution

ows out of the cell washer, into the drain tubing, to the waste container or

sanitary drain.

The number of revolutions per minute is adjustable fro 0 RPM to 1500 RPM.

The default value is 370 RPM.

Loop Process

The Loop process allows one or more previous processes to be repeated. Only

one Loop process can be included in a program.

The number of loops is adjustable from 1 to 100 times (1x to 100x). The selected

number of loops includes the initial run of the process(es) included in the loop

(e.g. selecting to loop a process 3 times means that process will run a total

of 3 times).

The default value is 2 times (2x).

Check Process

The Check process allows a program to be paused after one or more processes

in the program have run. Once the previous process(es) has nished, the Check

process will cause the program to be paused and the lid to open. This allows the

user to check the tubes and/or add other uids. The program will continue once the

lid is closed.

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 12

5 Operation

The UltraCW®II provides both pre-installed programs as well as the ability to create custom programs to t user needs. Custom

programming allows multi-cycle wash and basic spin programs to be created.

Program menu screen (showing examples of custom programs)

5.1 Pre-Installed Programs

Select system and user programs have been pre-installed to accommodate common functions of the cell washer.

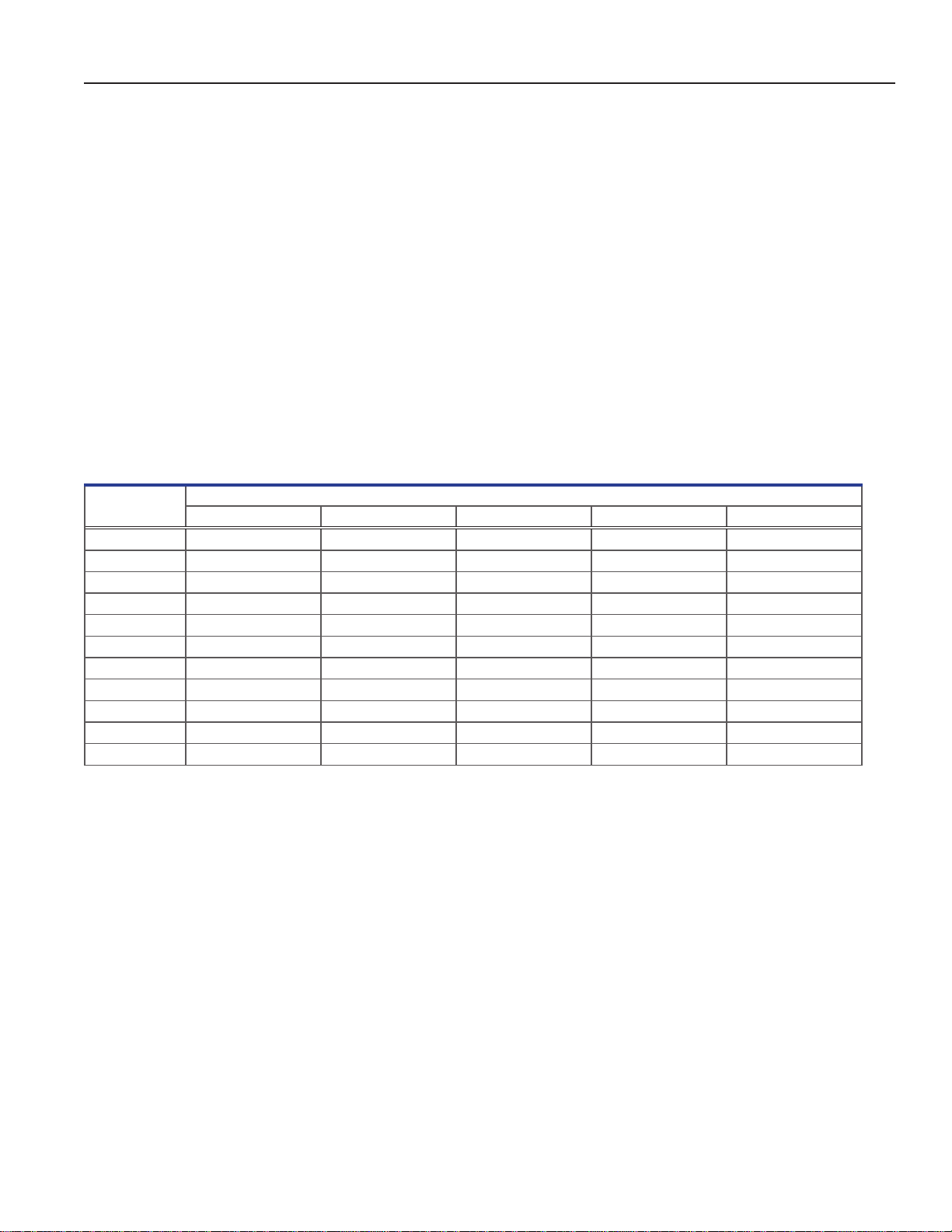

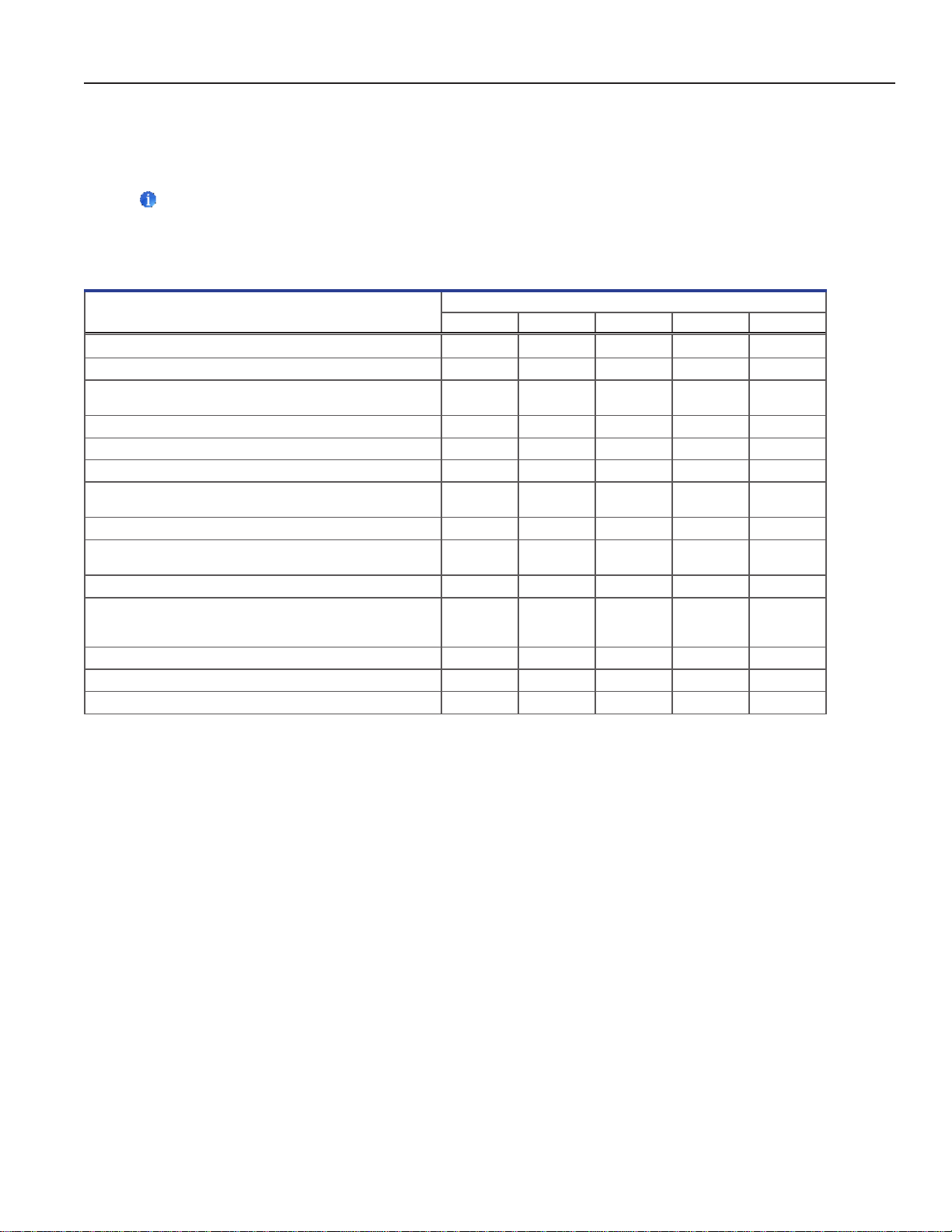

Table 1. Pre-Installed User Programs

Process

Program

10x75 45sec wash 12x75 45sec wash 10x75 35sec wash 12x75 35sec wash 20sec spin 3500

Fill 3.5ml, 1100rpm 4.3ml, 1100rpm 3.5ml, 1100rpm 4.3ml, 1100rpm

Spin 45 seconds, 3500rpm 45 seconds, 3500rpm 35 seconds, 3500rpm 35 seconds, 3500rpm 20 seconds, 3500rpm

Decant 460rpm 460rpm 460rpm 460rpm

Agitate 15x 15x 15x 15x

Loop 3x 3x 3x 3x

Fill 3.5ml, 1100rpm 4.3ml, 1100rpm 3.5ml, 1100rpm 4.3ml, 1100rpm

Spin 45 seconds, 3500rpm 45 seconds, 3500rpm 35 seconds, 3500rpm 35 seconds, 3500rpm

Decant 460rpm 460rpm 460rpm 460rpm

Check

Agitate 15x 15x 15x 15x

Spin 15 second, 3500rpm 15 second, 3500rpm 15 second, 3500rpm 15 second, 3500rpm

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 13

Select Program

1. From the Start screen, select the Menu button .

2. Select the desired program. The program screen is displayed.

Program screens

3. Use the green and yellow directional arrows to scroll through and review each process and verify settings are accurate

prior to running the program.

4. Select the green checkmark to load the program. The Start screen appears with the loaded program name at the top of

the screen.

Start screen Process screen

5. Select Start Program. The Process screen appears with the process being executed highlighted.

6. The “Program successful” dialog box appears once the program is complete.

Notes

• The CHECK button can only be selected when a process is completed.

• Selecting the CHECK button allows the user to pause the program and open the lid to check tubes and/or add uids.

• To interrupt a program in progress, select the STOP button.

5.2 Stop/Check Program

It is sometimes necessary to stop or pause a program in process. Selecting STOP will end the current program while selecting

CHECK will pause the program once the current process is complete. Pausing the program allows the user to check tubes or

add uids.

Stop Program

1. Select the STOP button. Stop Program text box appears.

2. Select the green checkmark to conrm.

3. Select the return arrow to return to the previous screen.

Check Program

1. Select the CHECK button to pause the program. The lid will open once

the process is complete.

2. Close the lid to return to the program.

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 14

5.3 Custom Program

Customized programs can be created to accommodate the user’s needs. A program may contain up to 20 dierent processes. A

loop process may be added to repeat a single process or set of processes multiple times within the program.

Notes

• This process requires an authorized user.

• If accessing unit for the rst time, use factory created Service User password 46060.

Create Program

1. From the Start screen, touch the login button .

2. Enter a Service User password and select the green checkmark to conrm.

3. Select the Menu button .

4. Select the Add New Program button .

New Program screen

5. Select the Edit button at the top of the screen to name the program.

6. Select the Add button to add a process. A menu of available processes is displayed.

Process Menu screen Parameters screen

7. Select the desired process from the options displayed. Programmable parameters appear below the selected process.

8. Touch the + or - to adjust the parameters.

9. Select the green checkmark to save.

10.Repeat steps 4 - 7 as needed to complete the program.

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 15

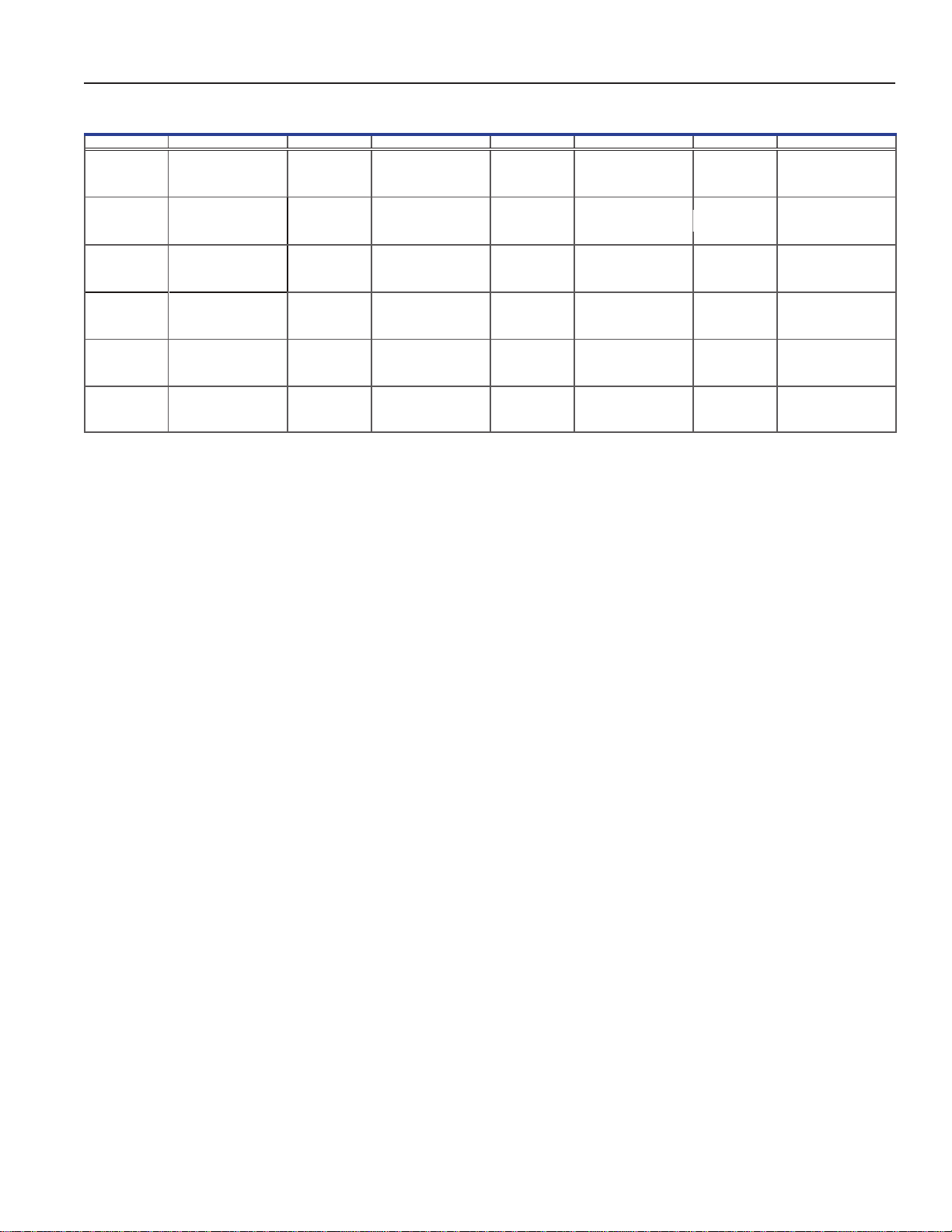

Table 2. Common Buttons Reference Guide

Icon Description Icon Description Icon Description Icon Description

Start Calibration Set/Edit password Conrm/Save

Stand-by Fill Delete user Rotor selection

Settings User settings Add new program Program end

alarm setting

Login Device settings Edit Return to

previous screen

Program menu Service menu Add process Cancel

Open lid History Delete process

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 16

6 ProductSpecications

6.1 Operating Standards

These units are designed to operate under the following environmental conditions:

♦ Indoor use only.

♦ Altitude (maximum): 2000 m.

♦ Ambient temperature range: 5 °C to 40 °C.

♦ Relative humidity (maximum for ambient temperature): 80% for temperatures up to 31 °C, decreasing linearly to 50% at 40 °C.

♦ Transient over-voltages typically present on the MAINS supply.

♦ Do not exceed maximum loaded weight (including tubes and contents). Maximum weight is printed on rotor.

Table3.UnitSpecications

UltraCW®II

Physical

Height 11” (280mm)

Width 13” (330mm)

Depth 18.9” (480mm)

Weight 53.8 lb (24.4 kg)

Rotor Radius 4.1” (105mm)

Maximum RPM / RCF 3500 RPM / 1438 RCF

Speed Tolerance ± 20 RPM

Kinetic Energy 250 Nm

Maximum Density 1.2 kg/dm3

Noise Level ‹ 49db

Electrical

Electrical Power (AC) 100V - 240V, 50/60 Hz

Electrical Power (DC) 6A @ 24 VDC

Fuses 10A / 250V

Maximum Current Consumption 2.2 A

Power Source 150W

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 17

7 Preventive Maintenance

Maintenance tasks should be completed according to the following schedule. Refer to the service manual for more detail on the

various tasks.

Note

These are recommended minimum requirements. Regulations for your organization or physical conditions at your

organization may require maintenance items to be performed more frequently, or only by designated service personnel.

Table 4. Preventive Maintenance Schedule

Task

Frequency

Daily Weekly Monthly Annually 4 years

Inspect tubing and drain and clear obstructions if necessary. ü

Inspect tubing connections and secure if necessary. ü

Clean and dry interior after normal usage to prevent corrosion

and contamination.

ü1)

Flush system with distilled water. ü(1)

Flush system with cleaning solution. ü

Clean ll ports on the rotor. ü

Check the saline volume setting and calibrate it if necessary.

Frequency varies by length of service.

ü

Check rotor speed and ensure within tolerance. ü

Inspect rotor for wear, corrosion, and damage. Replace rotor if

these conditions exist.

ü

Replace rotor ü

Inspect tube holders for wear and damage. Replace tube

holders if worn or damaged, or after they have been in use for

two years.

ü

Clean exterior. ü

Replace supply and drain tubing. ü

Replace tube holder inserts for 10 mm x 75 mm tubes. ü

(1) Perform daily or if unit has been idle for 4 hours or more.

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 18

8 Compliance

8.1 Regulatory Compliance

Pollution degree: 2 (for use in USA and Canada only)

This product is certied to applicable UL and CSA standards by a NRTL.

Sound level (dependent on rotor): ≤ 49 dB(A)

8.2 WEEE Compliance

The WEEE symbol (right) indicates this product falls under the scope of the WEEE (Waste Electrical and

Electronic Equipment) directive.

When disposing of this product in countries aected by this directive:

♦ Do not dispose of this product as unsorted municipal waste.

♦ Collect this product separately.

♦ Use collection and return systems available locally.

For more information on the return, recovery, or recycling of this product, contact your local distributor.

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 19

Appendix A

Error Codes

Error Code Error Name Description Possible Causes

0No Error Program occurred

1Running Program is still running, no error has been

detected (should never be visible in history)

Motor Errors

10 Motor Startup Error Motor could not be started

(no speed could be detected) • Motor is blocked

• Motor cable connection problem

• Motor power supply problem

11 Motor Acceleration Error Motor could not accelerate within tolerance

(motor was too slow) • Wrong rotor type selected

• Too much mechanical friction

12 Motor Acceleration Error Motor could not accelerate within tolerance

(motor was too fast) • Wrong rotor type selected

13 Motor Speed Error Motor could not hold the desired speed

(motor was too slow) • Wrong rotor type selected

• Maximum motor speed limit too high

(not able to maintain 4000 RPM)

• Motor speed control does not work properly

• Motor speed reading failure

14 Motor Speed Error Motor could not hold the desired speed

(motor was too fast) • Motor speed control does not work properly

• Motor speed reading failure

15 Motor Break Error Motor could not slow down within tolerance • Wrong rotor type selected

16 Motor Internal Error Motor has indicated an error • Motor blocked

• Motor overheated

• Motor power supply error

17 Motor Power Supply The 24 V of the motor supply is not available • Lid detected open

Liquid Injection System Errors

20 Pump Error Pump was not able to pump the desired amount

of liquid • Tube blocked

• Pump not working

• Flow sensor not working

21 Liquid Container Empty Not enough liquid available or air is in the tube • Liquid container empty

• Air in the tube

• Flow sensor problem

Lid Errors

30 Lid Blocked Open or check button was pressed, but the lid

could not be opened. • Lid mechanically blocked

31 Unlocking Failed Open or check button was pressed, but the lock

could not be unlocked. • Motor was still rotating when unlocking

command was received

• Problem with the lock

32 Unexpected Unlocking Lid was opened without a request. • Emergency unlocking was used

33 Lid Detection Failure Lid sensor has detected an opening of the lid, but

lock sensor still recognizes lock is closed • Wrong lid detection of the lid sensor

• Wrong lock detection of the lock sensor

System Errors

40 Program Reading Error It was not possible to read the complete program. • Program le is corrupted

• Not enough heap memory was available

42 Eeprom Error Loading data from eeprom failed. (reading not

possible or checksum for data is incorrect) • Eeprom not initialized

(Service User login needed)

• Communication failure

Helmer Scientic Automatic Cell Washing System - UltraCW II Operation Manual

360386/D 20

Error Code Error Name Description Possible Causes

Miscellaneous

50 Unknown An error has occurred, but the kind of the error

could not be identied • Unexpected behavior

51 Program Interrupted A running program was interrupted. • Power interrupted during a running program

52 Program Aborted by User The program was aborted by the user • User has aborted the program

53 Imbalance The program was stopped because of an

imbalance of the rotor • Rotor was not loaded symmetrically

• Positioning of the imbalance sensor not correct

Table of contents

Other Helmer Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Waters

Waters Xevo TQ MS Operator and maintenance manual

palintest

palintest CT12 manual

Hanil

Hanil Smart 15 Plus operating manual

TestEquity

TestEquity 1016H Operation and service manual

Safe Fleet

Safe Fleet FoamPRO AccuMax 3020 Installation and operation manual

Electron Microscopy Sciences

Electron Microscopy Sciences PA 2500 instruction manual