Knauer Azura GPC User manual

Other Knauer Laboratory Equipment manuals

Knauer

Knauer AZURA User manual

Knauer

Knauer Smartline 2800 User manual

Knauer

Knauer BlueShadow 80P Operating instructions

Knauer

Knauer Azura Assistant ASM 2.1L User manual

Knauer

Knauer IF2 User manual

Knauer

Knauer Azura P 6.1L User manual

Knauer

Knauer AZURA User manual

Knauer

Knauer Azura Assistant ASM 2.1L User manual

Knauer

Knauer BlueShadow Detector 10D User manual

Knauer

Knauer BlueShadow Detector 50D User manual

Knauer

Knauer AZURA SMB Lab User manual

Knauer

Knauer AZURA IJM NanoScaler User guide

Knauer

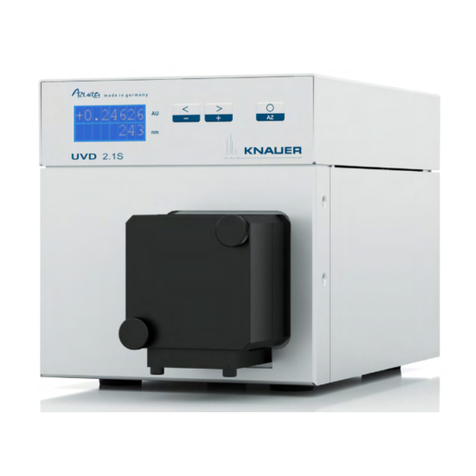

Knauer Azura Detector UVD 2.1S User manual

Knauer

Knauer BlueShadow V6 User manual

Knauer

Knauer Azura Assistant ASM 2.1L Owner's manual

Knauer

Knauer Smartline Pump 1000 User manual

Knauer

Knauer 4000 MiD User manual

Knauer

Knauer Azura DAD 6.1L User manual

Knauer

Knauer BlueShadow Detector 40D User manual

Knauer

Knauer HPLC IFU 2.1 User manual

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual