Helvest DCC100-E User manual

NET Module DCC100-E - User Manual

User manual for the Helvest Flex DCC100-E Module

1. GENERAL PRESENTATION OF THE PRODUCT

1.1 Warnings

The boards are not toys and are not suitable for children under 14 years of age. They

contain small pieces that can be swallowed.

Do not leave the product unattended in a position accessible to children.

Read the instructions for use carefully before using the boards.

Take care to make the electrical connections as described. Incorrect connections can

cause damage to the circuit boards or be dangerous to the user.

Under no circumstances must the products be powered in any mode different from those

specified in the instructions and in particular never exceed a voltage of 16V. Power

supply with inadequate voltages can lead to serious risks for the user and fire hazard.

The product has functional edges and sharp parts.

Do not leave the product powered without supervision.

At the end of the product's life cycle do not throw it in the waste but dispose of it

according to the provisions for WEEE waste.

1.2 Declarati n f c nf rmity

We Helvest Systems GmbH Route des Pervenches 1 CH-1700 Fribourg (Switzerland)

declare under our responsibility that the products:

Description and number: HP100 DCC100 ES400 GAW400 UPW400

comply with the requirements of the Electromagnetic Compatibility Directive

(2004/108/EG).

The product complies with the

standards of the harmonised

standards EN55032:2015 and

EN55024:2010+A1:2015.

1.3 Using the DCC100

m dule

This module is part of the Helvest Flex system and allows you to easily mount an

accessory box and flexibly configure it according to your needs.

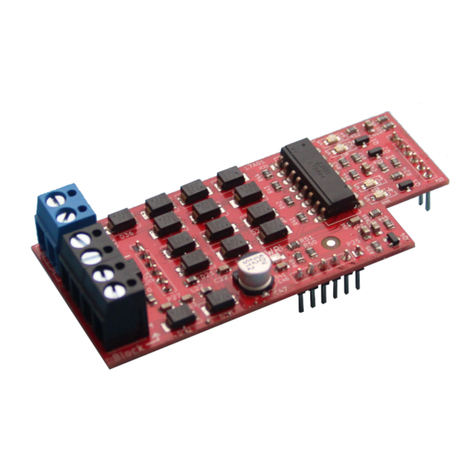

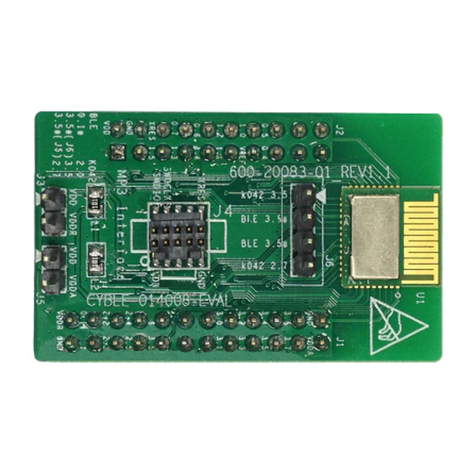

The module works in combination with an HP100 motherboard (figure 1). It must be

connected by inserting it into the "net" type housing. Please take care to insert it with the

correct alignment without forcing the connectors.

This module deals with communication with any DCC control unit i.e. it receives its

commands (any control unit conforming to the DCC standard is required) to control

switches signals or other accessories on the layout of the through the "layout" modules.

1.4 H w t install the m dule

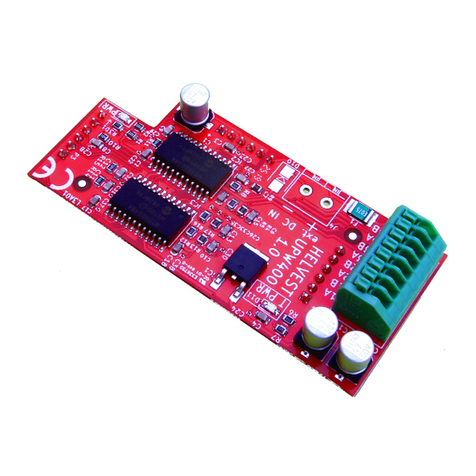

The DCC100-E module

must be connected to

the two wires coming

from the control unit

and carrying the DCC

signal. The wires can be

different for program-

ming and normal

operation. The power

wires on the other

hand should be

connected to the HP100

board. Fig. 2 shows an

example of connections

for the programming

step. For normal

operation instead of the

programming output

connect to the DCC100-

E the same wires that

are connected to the

track. The module is

now ready to receive

signals from the control

unit.

Fig.2

PROGRAM MODE

Programming ouput

Programmierausgang

Your DCC central

Ihre DCC Zentrale

MAX 20

DCC100-E

1.0

Fig. 1

NET Module DCC100-E - User Manual

To connect accessories (turnouts signals or other) please refer to the "layout" module

instructions.

1.5 M unting n the lay ut

The decoder must be not touch anything else during operation. In particular it CANNOT

come into contact with any metallic material.

For temporary installations it can be placed on a non-flammable insulating surface

(plastic glass ceramic floor etc...).

For fixed installation it is recommended to mount it by screwing the HP-100 on a

wooden surface with the screws and spacers provided. This should be done before

inserting the DCC-100 (if additional modules have already been inserted they can be

removed gently without worries).

1.6 N rmal perati n f the DCC dec der

After connecting everything as

described activate the DCC signal

with the controller. Green LEDs 1 and

2 will light up indicating that the

connections are correct and the

decoder is on. (figure 2).

According to DCC-NMRA the

accessories can be addressed in two ways:

a) Decoder address. Each decoder has its own address and drives 4 accessories each of

which has two states (A and B). The accessories are identified by the address of the

decoder and by the position (1-4) relative to that decoder. So for example an accessory

is located in position 2 of the decoder with address 1 and another accessory can be found

in position 2 of the decoder with address 5.

If you use this configuration the default addresses are "1" for Layout Module 1 and "2"

for Layout Module 2.

b) Addressing by accessory: each individual accessory has its own address and

no address is assigned to the decoder. For

example if an accessory on a decoder has

address 2 no other accessory can have that

address even on other decoders.

In this case the default addresses are 1 to 4 for the layout module "1" and 5 to 8 for the

layout module "2".

The choice between the two modes depends on the settings of the digital control unit.

The decoder responds indifferently to both situations.

To change the addresses simply follow the procedure indicated in the chapter 2 of this

manual.

To operate the accessories please use the controls on your digital control unit.

In questo caso gli indirizzi di default sono da 1 a 4 per la scheda layout "1" e da 5 a 8 per

la scheda layout "2".

2. PROGRAMMING OF THE DECODER

2.1 Pr gramming c nnecti ns

The Helvest decoder can be programmed in any of the modes available in the DCC

control units: (by CV by page or by register).

The procedure for programming the decoder is as follows:

- Mount the DCC100-E module on the HP100 board as for normal operation.

- Connect the power wires to the HP100 board.

- Connect the programming wires to the DCC100-E board. In some control units these

come from the same output used for power supply while other control units have a

separated output for a programming track. In this case the HP100 board must be

connected to the programming track output.

- Disconnect any layout modules installed.

This operation is necessary only for some digital control units because of the low power

that they provide in programming mode. Leaving the layout modules connected the

decoder is programmed correctly even if the control unit signals an error. It is advisable

to remove them to confirm that programming has taken place and to read the CVs

correctly.

- Program the decoder according to the procedure provided for any locomotive or

accessory decoder. The programming procedure depends on your central unit.

- The system also allows you to read the CV values and have an acknowledgement of

programming without any additional connection and without the need to connect

anything to the outputs.

- The flashing of LED no. 3 on the DCC100-E module (fig. 2) means that it is responding

to the control unit during programming.

2.2 Addressing m de in the DCC

Fig.3

Decoder

Addresse

1

Access./Zubehör 1

Access./Zubehör 2

Access./Zubehör 3

Access./Zubehör 4

1A

1B

2A

2B

3A

3B

4A

4B

DCC100-E

1.0

41

2

3

Fig.4

NET Module DCC100-E - User Manual

There are two ways for the DCC standard to address boards as already specified above:

decoder address (base address) and accessory address (output address). The fact that the

controller "calls" the entire decoder or the individual accessory depends on the settings of

the control unit

2.3 Addressing the dec der

DCC standards require for each decoder to have 4 outputs (each corresponding to a

turnout signal or other accessories) and each of the outputs has two positions (e.g.

correct track or diverting red/green for a signal on/off for other devices etc...).

Each of the two "layout" modules that can be installed acts as an independent decoder

with its own address. The "layout 1" module has the preset address 1 the "layout 2"

module has the preset address 2: If no changes are made the modules will work with

these addresses.

The basic address is divided between two different CVs according to DCC standards. To

change the address therefore you must write on these two CVs.

The addresses can be found in CV1 and 9 for the "layout1" module and in CV35 and 36

for the "layout" module 2.

In section 3.2 there is a table with the correspondence between the address and the CVs

for the smaller addresses. You can find the complete table on our website www.helvest.ch

2.4 Addressing the individual access ry utputs

If the control unit is set to address the individual accessories an address can be

automatically programmed for each single output of the "layout" modules.

By assigning a value to CV1 and 9 (for the "layout 1" module) and CV35 and 36 (for the

"layout 2" module) the outputs will automatically acquire an address according to table

in section 5.1.

If you prefer assigning an address to each accessory output write it in CV 120 130 140

150 for Layout 1 and 160 170 180 190 for Layout 2.

The correspondence between the address of the outputs and the address of the board can

be found in the table in section 3.2 for the smaller addresses. You can download a

complete table on our website www.helvest.ch

2.5 Switching time

It is possible to adjust the motor drive time for decoders that drive motors (switches or

similar). Signal and lighting decoders provide a constant power supply over time so they

do not need this type of control.

The LED no. 4 in fig. 2 stays on as long as the decoder is switching an accessory. To

make a precise adjustment of the times it is advisable to operate the accessory and check

that the switching is complete. For example in the case of a switch check that the needle

has reached the end of the stroke when the motor stops and LED no. 4 turns off. In order

to keep a reasonable safety margin it is advisable to check that LED n.4 goes off a few

tenths of a second after switching. If the switching is not complete increase the

switching time.

If you notice that LED 4 lights up significantly longer than the switching time (more than

half a second) it is advisable to reduce the switching time not to force the motor.

2.6 H w t pr gram a single switching time f r all utputs

You can either set a single time for all eight outputs (global time) or set different times

for each of them. The time is calculated by multiplying the value of these CVs by 0.02

seconds (1 second = 50 the maximum value 255 corresponds to about 5 seconds).

The CV37 sets the time valid for all outputs of the Layout1 module and the CV38 sets

the switching time for all outputs of the Layout2 module.

2.7 H w t pr gram a different switching time f r each individual utput

If you want to program a different or specific switching time for each output you must

act on the CV 122 132 142 ...192 . These control the switching time of the individual

output.

The switching time of the individual outputs must be programmed after the global

switching time. If a different global time is programmed (see section 2.5) all specific

programming times are overwritten.

The calculation of the switching time is exactly the same as for the gobal time: It is

obtained by multiplying the value of these CVs by 0.02 seconds (1 second = 50

maximum value 255 i.e. about 5 seconds).

NET Module DCC100-E - User Manual

3. CV AND ADDRESSES TABLES

3.1 List f supp rted CVs

CV Description Range Preset value

1 Layout 1 address LSB ("short") 1-63 1

7 SW version (read-only) --

8 Manufacturer ID (read only) 167

To completely reset the decoder write 255

in this CV.

9 Layout 1 address 1 MSB 0-7 0

29 Configuration (read only) 128

35 Layout 2 address LSB ("short") 1-63 2

36 Layout 2 address 1 MSB 0-7 0

37 Layout 1Overall time for accessories 0-255 100

38 Layout 2 Overall time accessories 0-255 100

120 Output 1 address LSB 0-2044 0-252 1

121 Output 1 address 1 MSB 0-2044 0-7 0

122 Output 1 Switching time 0-255 100

130 Output 2 address LSB 0-2044 0-252 2

131 Output 2 address 1 MSB 0-2044 0-7 0

132 Output 2 Switching time 0-255 100

140 Output 3 address LSB 0-2044 0-252 3

141 Output 3 address 1 MSB 0-2044 0-7 0

142 Output 3 Switching time 0-255 100

150 Output 4 address LSB 0-2044 0-252 4

151 Output 4 address 1 MSB 0-2044 0-7 0

152 Output 4 Switching time 0-255 100

160 Output 5 address LSB 0-2044 0-252 5

161 Output 5 address 1 MSB 0-2044 0-7 0

162 Output 5 Switching time 0-255 100

170 Output 6 address LSB 0-2044 0-252 6

171 Output 6 address 1 MSB 0-2044 0-7 0

172 Output 6 Switching time 0-255 100

180 Output 7 address LSB 0-2044 0-252 7

181 Output 7 address 1 MSB 0-2044 0-7 0

182 Output 7 Switching time 0-255 100

190 Output 8 address LSB 0-2044 0-252 8

For both modules

Decoder address

CV 1 CV 9 CV 35 CV 36 Output address

n. 1 n. 2 n. 3 n. 4

11 0 1 0 1 2 3 4

22 0 2 0 5 6 7

33 0 3 0 9 10 11 12

44 0 4 0 13 14 15 16

55 0 5 0 17 1 19 20

66 0 6 0 21 22 23 24

77 0 7 0 25 26 27 2

80 0 29 30 31 32

99 0 9 0 33 34 35 36

10 10 0 10 0 37 3 39 40

11 11 0 11 0 41 42 43 44

12 12 0 12 0 45 46 47 4

13 13 0 13 0 49 50 51 52

14 14 0 14 0 53 54 55 56

15 15 0 15 0 57 5 59 60

16 16 0 16 0 61 62 63 64

17 17 0 17 0 65 66 67 6

18 1 0 1 0 69 70 71 72

19 19 0 19 0 73 74 75 76

20 20 0 20 0 77 7 79 0

21 21 0 21 0 1 2 3 4

22 22 0 22 0 5 6 7

23 23 0 23 0 9 90 91 92

24 24 0 24 0 93 94 95 96

25 25 0 25 0 97 9 99 100

26 26 0 26 0 101 102 103 104

27 27 0 27 0 105 106 107 10

28 2 0 2 0 109 110 111 112

29 29 0 29 0 113 114 115 116

30 30 0 30 0 117 11 119 120

Values for Layout

1 module

Values for Layout

2 module

NET Module DCC100-E - User Manual

191 Output 8 address 1 MSB 0-2044 0-7 0

192 Output 1 Switching time 0-255 100

3.2 Ass ciati n f b ard address/access ries address and related CVs

This table shows the correspondence between the address given to the layout

module the relative CVs to be programmed and the address of each of its four

outputs for the individual accessories according to the DCC standards. For a more

detailed example see paragraph 3.3.

The complete table can be downloaded from www.helvest.ch

The choice of having two possible ways to activate the accessories depends on the

control unit used. it is also possible to assign individual addresses but in this case

please refer to the instructions in paragraph 5.

3.3 H w t use the table and pr gramming example

- Choose the address to assign to the module "layout 1" and according to that

program the CV1 and CV9.

For example if you want to assign address 10 program CV1 with 10 and CV9

with 0.

- To know the addresses of the four corresponding outputs refer to the last four cells

of the same line.

In the example for address 10 of the module you have outputs n. 37 38 39

40.

- Choose the address to assign to the module "layout 2" and according to that

program the CV35 and CV36.

For example if you want to assign address 5 program CV35 with 5 and CV36

with 0.

- To know the addresses of the four corresponding outputs refer to the last four cells

of the same row.

In the example for address 5 of the module you have outputs n. 17 18 19 20.

4 . Tr ublesh ting

To troubleshoot powering/connection issues etc. related to the "layout" modules,

please see troubleshooting of the layout module or HP100 manual.

To completely reset the decoder write the value 255 in the CV8. This restores the

factory settings as in list 3.1.

Problem Possibili cause e soluzioni

DCC signal arrives (DCC

LED is on) but the module

does not respond to

commands.

The signal from the controller does not correspond to the

DCC standards. Check controller instructions

The card is incorrectly inserted. Check for correct insertion.

An incorrect address was set by mistake. Program CV1 and

CV9 with a new address (see chapter 2).

Some parameters have been set incorrectly due to an error.

You can reset the decoder to the factory settings.

The single accessory

does not switch.

The connection to the control unit is incorrect (e.g. the

control unit has a programming track and the running

track has been connected). Check the connections and

correct them if necessary.

Layout modules remained connected on the board.

Disconnect the modules and repeat the procedure.

You have set a specific address for the individual output

that differs from the global address (CV 120 121 etc.).

Reprogram the decoder as desired.

The mechanical accessory to be controlled (e.g. a

switch) is not free to move. Try disconnecting the motor

from the decoder remove it from the accessory and

operate it with a suitable power source e.g. a battery.

(NEVER operate accessories with other power sources

when they are connected to the layout board!) This can

happen if the motor travel is larger than the turnout

needle movement and the motor does not reach the end

of its travel. Adjust the motor accordingly.

The accessory draws too much current and the decoder

goes into protection: The accessory can be controlled by

means of a relay and an ES400 GAW400 or UPW400

module (see relevant instructions).

NET Module DCC100-E - User Manual

Warning: NEVER perate access ries with ther p wer s urces when

c nnected t the lay ut b ard!

5. ADVANCED SETTINGS (f r experienced users)

5.1 Addressing individual utputs

Setting a base address automatically assigns an address to the outputs as shown in

Table 3.2 but you can assign a specific address to each individual output.

The address of the single outputs is recorded in the CVs as shown in the following

table.

The value can range from 1 to 2044. For programming divide the desired value by

256 the result of the division must be written in the MSB while the rest must be

written in the LSB.

Example: you want to assign the value 1136 to the output 2 of the layout 1 module.

1136 : 256 = 4 with rest 112. So the value 112 must be written in CV 130 and the

value 4 in CV 131.

The default values of the ouptut addresses depend on the base address of the two

modules. If "n" is the base address the values automatically assigned to the outputs

are (n-1)x4+1 (n-1)x4+2 (n-1)x4+3 (n-1)x4+4.

All these calculations can be simplified with the calculation tool on the website.

5.2 Pr gramming f a large lay ut

In the case of large systems it is possible to reprogram the CVs of the individual

Helvest Flex decoders with a very simple procedure that allows to minimize the

electrical connections.

1) Prepare an additional DCC100-E module dedicated to programming.

2) Connect the DCC terminal of this module to the programming output of a control

unit. This control unit must NOT be connected in any way to the other decoders.

3) Move closer to the decoder to be programmed disconnect all the layout modules

and the DCC module. Connect the DCC100-E programming module.

4) Power the decoder normally (also with a DCC signal provided that it comes from

a different control unit than the one used for programming). Program the decoder

with the control unit following the normal procedure.

5) Disconnect all power supplies reconnect the layout modules and the original

DCC module. The decoder is ready go on to program the next one.

6. TECHNICAL SPECIFICATIONS

Board Type: HP-100 Motherboard DCC Decoding Module

Power supply: provided by the motherboard

Decoding: NMRA-compliant DCC signal from the motherboard or

supplied as input.

Programming: According to NMRA standards with ACK built into the

board.

Signalling LED: main power DCC signal programming ACK DCC

status.

Firmware HP100 >1.2

User manual rev. 1.0 (2021).

All rights reserved. Copying even in part of the contents of this manual is only

permitted with the express written consent of the manufacturer.

Modulo Output 1 Output 2 Output 3 Output 4

LSB MSB LSB MSB LSB MSB LSB MSB

Layout 1 CV 120 CV 121 CV 130 CV 131 CV 140 CV 141 CV 150 CV 151

Layout 2 CV 160 CV 161 CV 170 CV 171 CV 180 CV 181 CV 190 CV 191

La centrale digitale

segnala errore o "no

locomotiva" durante

la programmazione

Il collegamento alla centrale non è corretto (ad esempio la centrale

prevede un binario di programmazione ed è stato collegato il

binario di corsa). Controllare i collegamenti ed eventualmente

correggerli.

Sulla scheda sono rimasti connessi i moduli di tipo "layout".

Disconnettere i moduli e ripetere la procedura.

Table of contents

Other Helvest Control Unit manuals

Popular Control Unit manuals by other brands

Rockwell Automation

Rockwell Automation Allen-Bradley POINT I/O B Series installation instructions

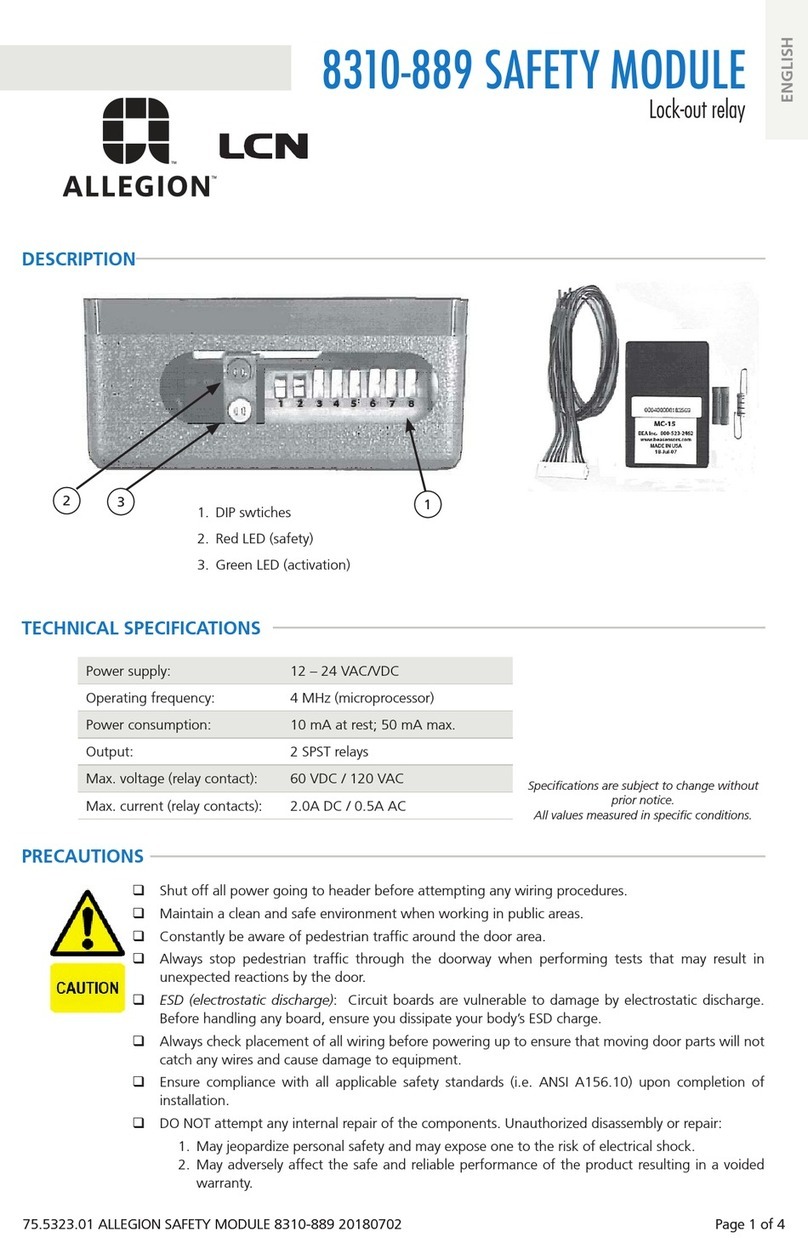

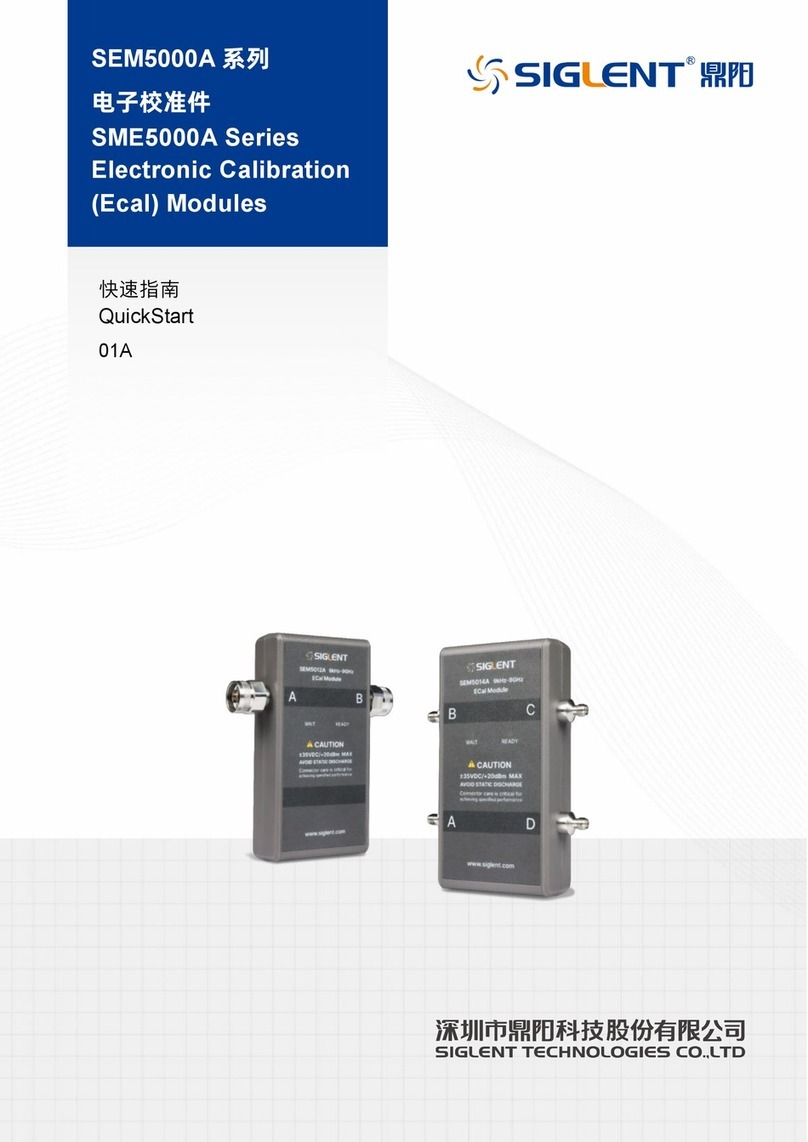

SIGLENT

SIGLENT SEM5000A Series quick start

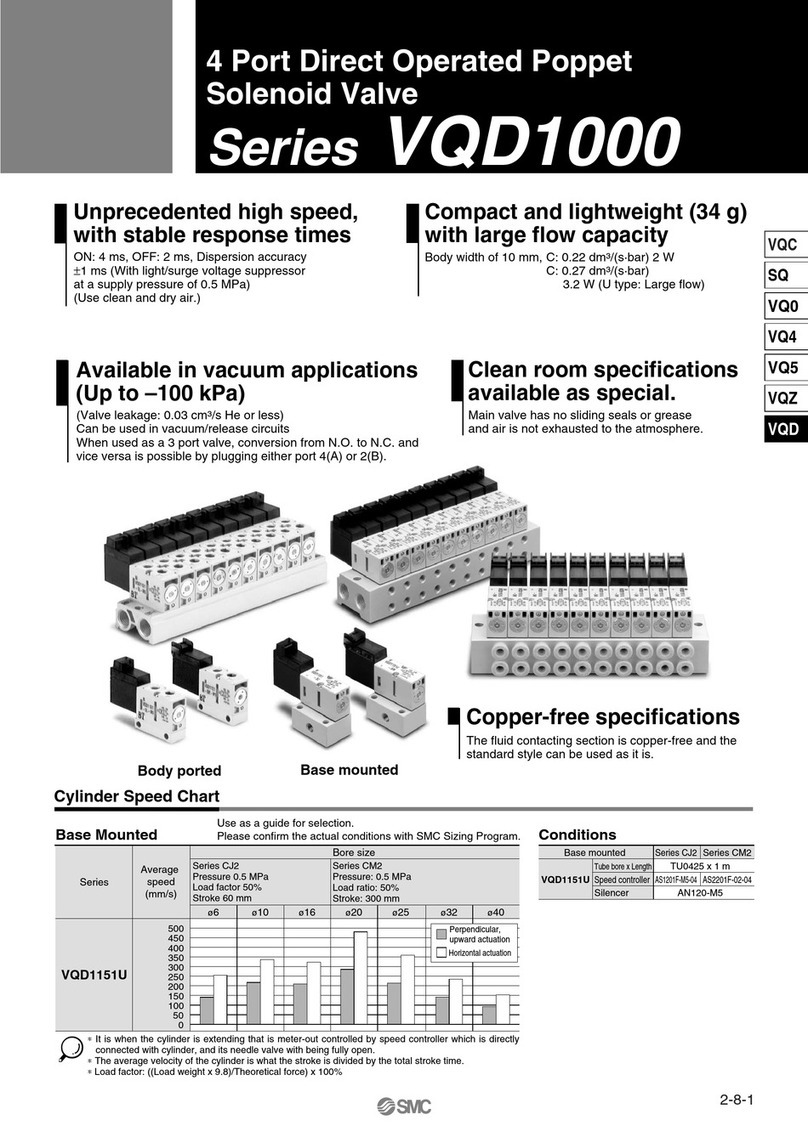

SMC Networks

SMC Networks VQD1000 Series manual

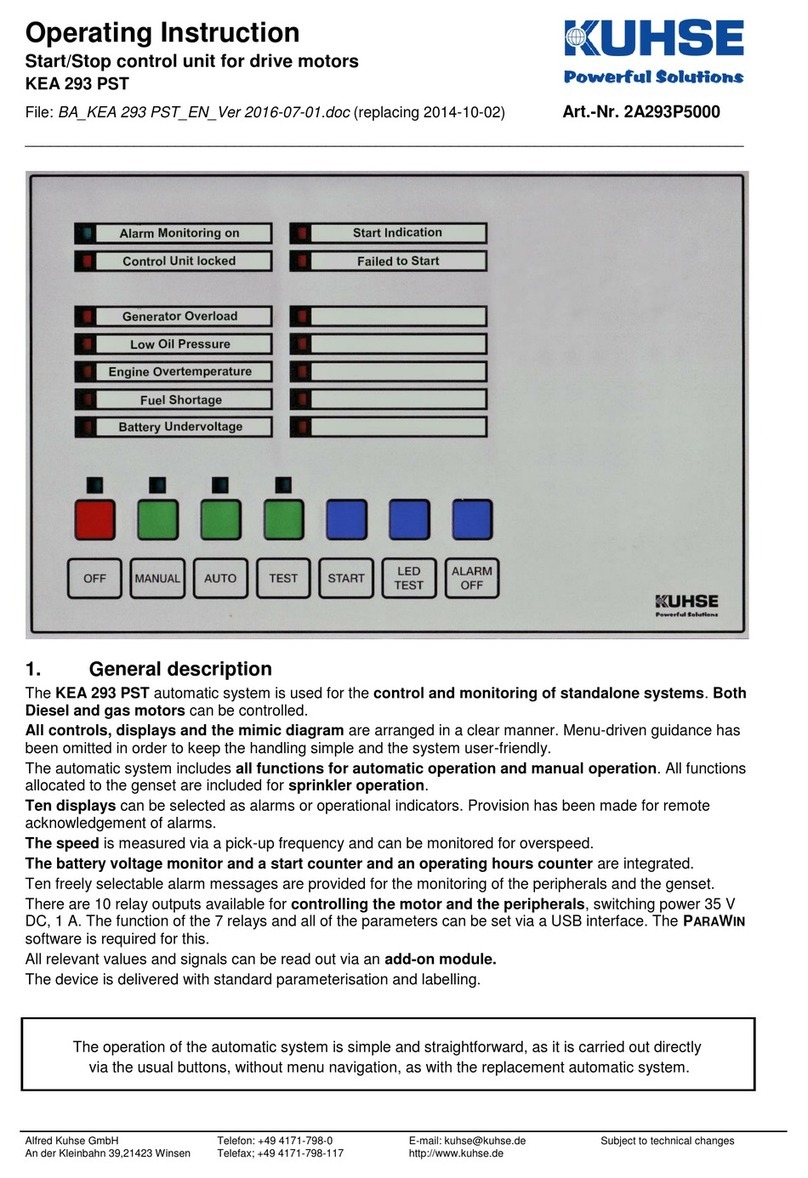

Kuhse

Kuhse KEA 293 PST Operating instruction

COMEPI

COMEPI MS1A31-024 manual

Flowserve

Flowserve R6 Installation, operation and maintenance instructions

HORNER APG

HORNER APG HE-XPBS Specifications & installation

ProSoft Technology

ProSoft Technology MVI56E-61850S user manual

Tema Telecomunicazioni

Tema Telecomunicazioni AA-600/SM5 Series Technical Manual And Integration Guide

Rittal

Rittal SV9343.070 Assembly instructions

Motorola

Motorola MVME410 user manual

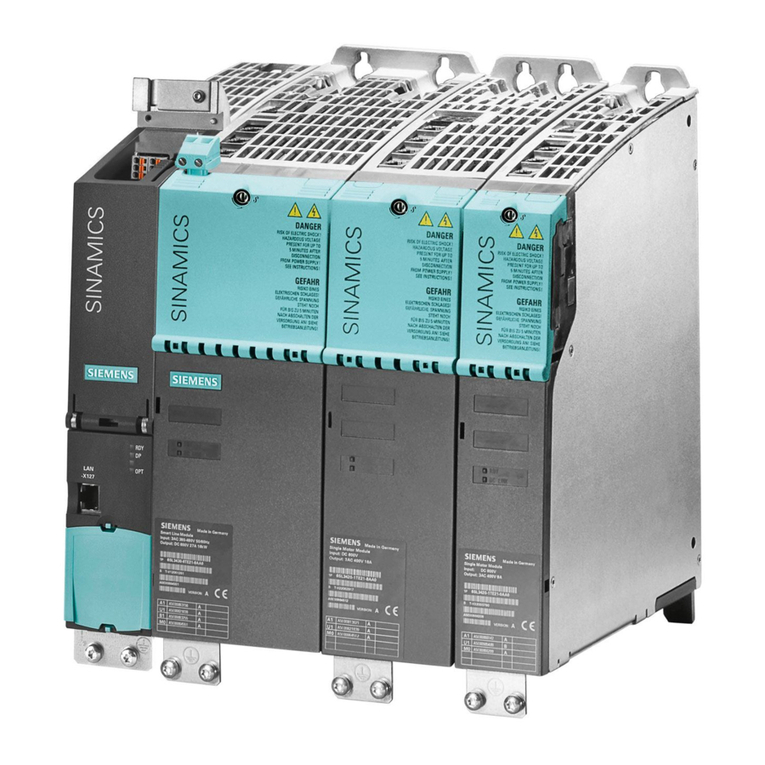

Siemens

Siemens SINAMICS S120 Commissioning manual